Energy-saving device capable of preheating coal gas on ceramic kiln

A ceramic kiln and gas technology, applied in the field of ceramic kiln, can solve the problems of unfavorable energy saving and consumption reduction, affecting the firing quality of ceramic products, and large axial flow of cold gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

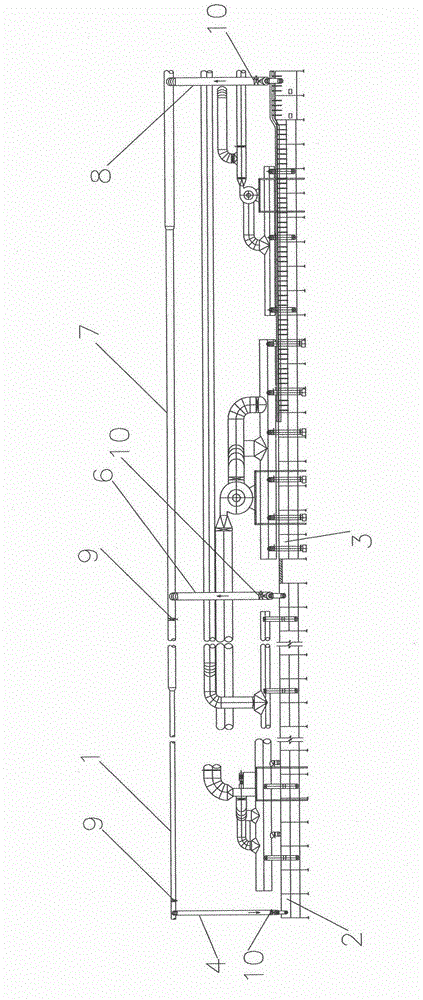

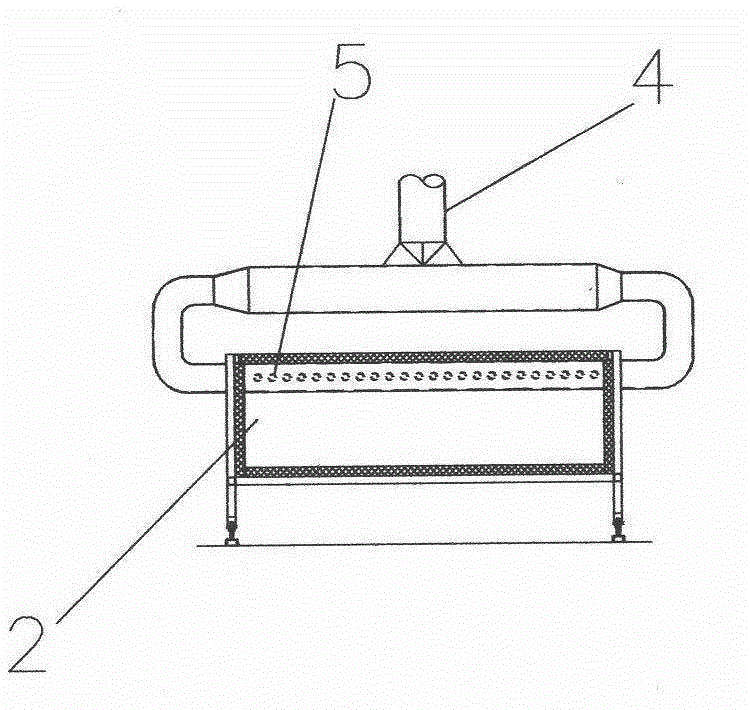

[0015] see Figure 1-Figure 4 , providing an energy-saving device capable of preheating gas on a ceramic kiln. The ceramic kiln includes a single-layer drying area and a single-layer preheating area in sequence. A cold gas pipe 1 extending transversely is arranged above the two, and the drying area and the preheating zone respectively include several drying boxes 2 and preheating boxes 3 extending transversely, above the drying box 2 at the beginning of the drying zone, there is a cold gas inlet main pipe 4, which is vertically connected with the cold gas pipe 1, The lower part traverses into the top position of the drying box 2 at the beginning of the drying area, and the intake manifold 4 is located on a section of each starting drying box 2, and is vertically connected with 24 gas preheating pipes 5, and all preheating pipes 5 are all along the direction from the drying area to the preheating area, passing through several drying boxes 2 and preheating boxes 3 in sequence; a...

Embodiment 2

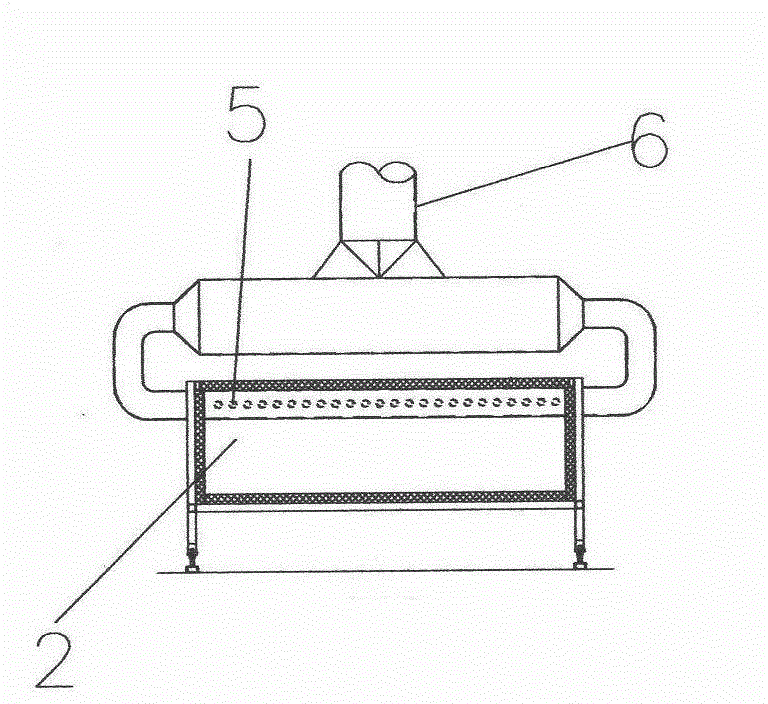

[0018] see Figure 5-Figure 6 , the main difference with Embodiment 1 is only that the drying area of the ceramic kiln is a two-layer drying area, and the air intake main pipe 4 of the cold gas is laterally branched into the top position of the drying box 2 at the beginning of each layer of the two-layer drying area. , the lower part of the primary output pipe 6 is connected to several preheating pipes 5 passing through the drying oven 2 at the end of each layer of the two-layer drying zone. The structure and realized functions of other aspects are completely consistent with the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com