Method for drying and burning alkali-containing aluminosilicate slurry

A technology of silicate and slurry, which is applied in the fields of alumina/hydroxide, sustainable manufacturing/processing, and climate sustainability. It can solve problems such as bulky equipment, high equipment maintenance costs, and condensation, and achieve material The effect of sufficient chemical reaction, high capacity per unit volume, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

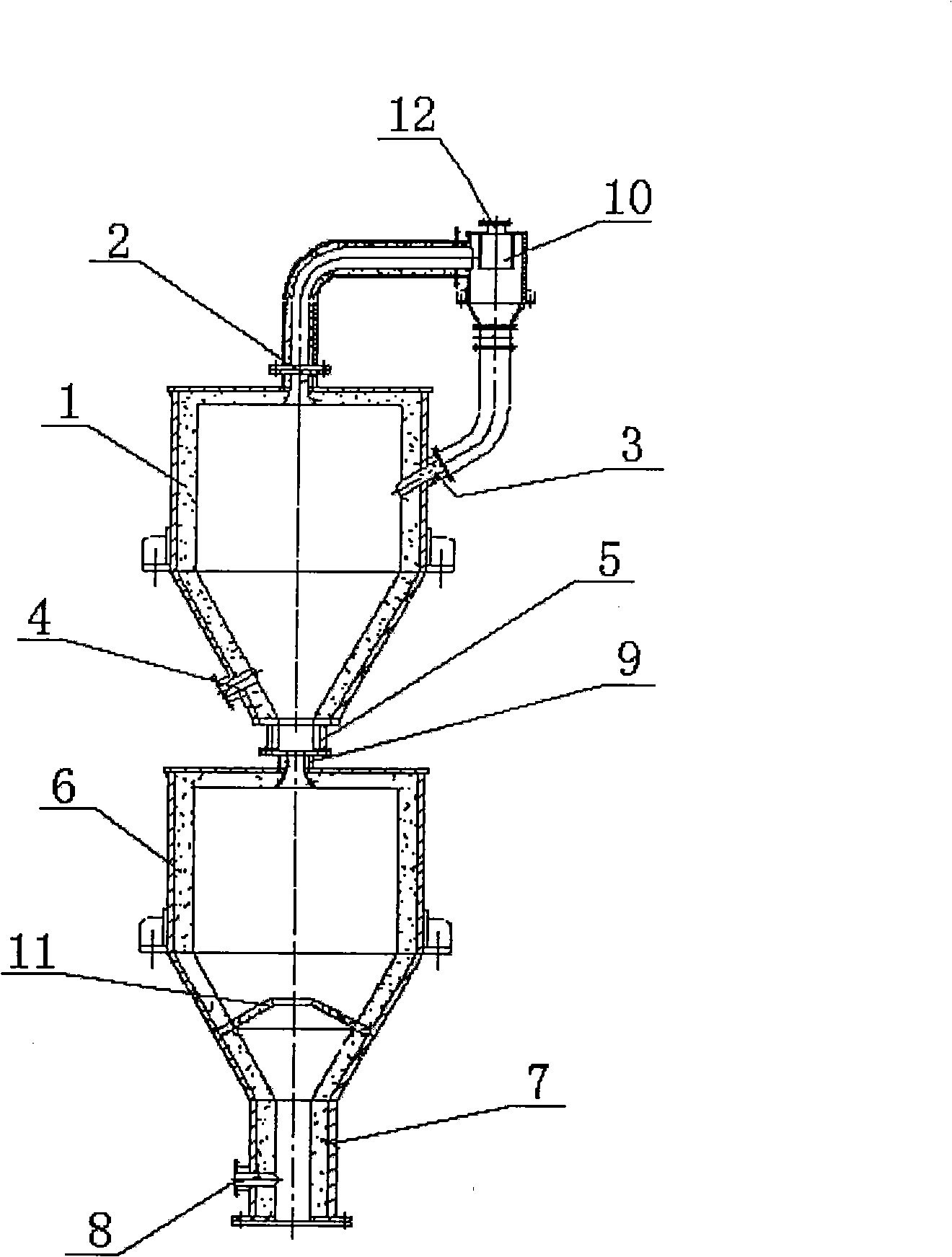

Embodiment 1

[0065] 1. Slurry material: raw bauxite slurry, moisture content 36%-43%, sodium oxide 15%-20%, alumina 22%-30%, particle size composition 100# sieve (English sieve number) 20%, 9% under 325# sieve.

[0066] 2. Test condition 1: Firing temperature 500-800℃, high-temperature flue gas flow rate 3-8m / s, negative pressure in the furnace 500-800Pa. After the bauxite dry raw meal is sintered, the particle size distribution of the material is as follows:

[0067] Sieve No. 100# sieve 100-200# sieve 200-325# sieve 325# sieve bottom (English sieve size)

[0068] Percentage 29.2 58.4 8.6 3.8

[0069] 3. Test condition 2: Firing temperature 800-1000℃, high-temperature flue gas flow rate 10-20m / s, negative pressure in the furnace 600-1000Pa. After the bauxite dry raw meal is sintered, the particle size distribution of the material is as follows:

[0070] Sieve No. 100# sieve 100-200# sieve 200-325# sieve 325# sieve bottom (English sieve size)

[0071] Percentage 32.5 52.1 14.2 0.8

...

Embodiment 2

[0077] 1. Slurry material: silicon slag produced in the alumina production process, with a moisture content of 35%-45%, a sodium oxide content of 17%-21%, and a particle size composition of 100# sieve (imperial sieve number) 21%, 325# sieve Down 9%.

[0078] 2. Test condition 1: Firing temperature 500-800℃, high-temperature flue gas flow rate 3-8m / s, negative pressure in the furnace 500-800Pa. After the silicon slag is fired in a suspension fluid state, the particle size distribution of the material is as follows:

[0079] Sieve No. 100# sieve 100-200# sieve 200-325# sieve 325# sieve bottom (English sieve size)

[0080] Percentage 35.0 37.8 18.2 9.0

[0081] 3. Test condition 2: Firing temperature 600-1000℃, high-temperature flue gas flow rate 10-20m / s, furnace negative pressure 600-1000Pa. After the silicon slag is fired in a suspension fluid state, the particle size distribution of the material is as follows:

[0082] Sieve No. 100# sieve 100-200# sieve 200-325# sieve 32...

Embodiment 3

[0089] 1. Slurry material: tailings slurry of tailings after bauxite flotation, containing 44%-50% of alumina.

[0090] 2. Test conditions: drying temperature 600-800°C, high-temperature flue gas flow rate 10-20m / s, negative pressure in the furnace 500-800Pa. The particle size distribution of the dried material is as follows:

[0091] Sieve No. 100# sieve 100-200# sieve 200-325# sieve 325# sieve bottom (English sieve size)

[0092] Percentage 80.4 10.6 5.6 4.4

[0093] 3. Conclusion: The suspension fluid firing system device established by this technical invention is used to carry out the industrial test of drying and activating tailings powdery materials after bauxite flotation. Since the technical device has sufficient gas-solid heat exchange, the furnace The thermal intensity is uniform, the drying and activation time is short, the activation performance of flotation tailings is more than 60% higher than other high-temperature drying equipment, and the particle size distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com