Bearing puller

A puller, axial technology, applied in the field of bearing puller devices, capable of tackling surfaces, either pulling outwards on rolling elements, cages or even outer rings of bearings, sliding, or scratching inwards for assembly Axis, unstable moving state and other problems, to achieve the effect of reliable positioning, fast location finding, and convenient disassembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

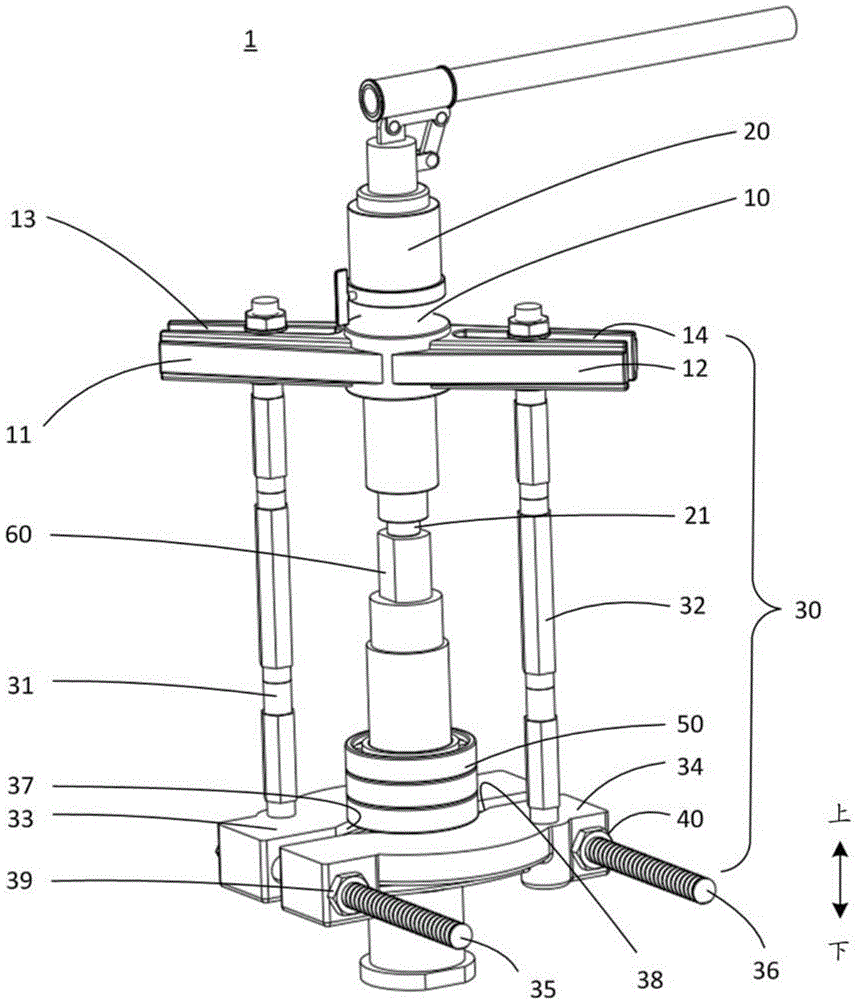

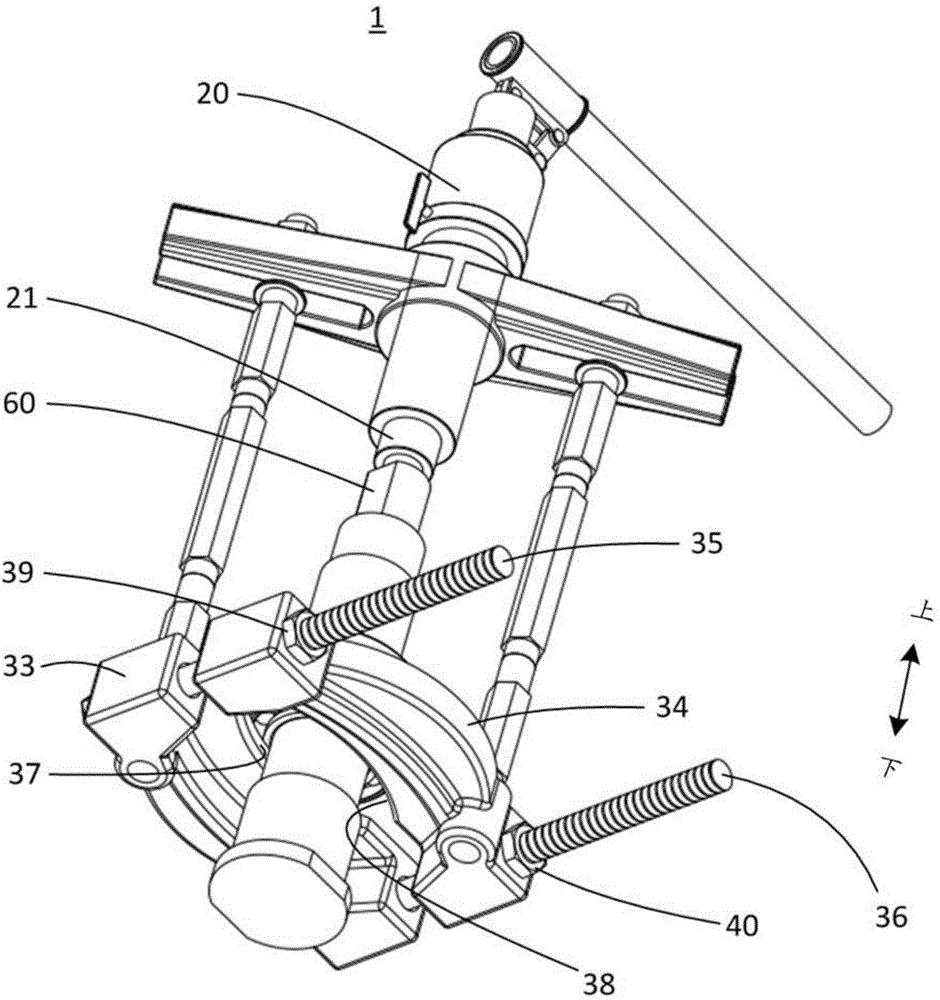

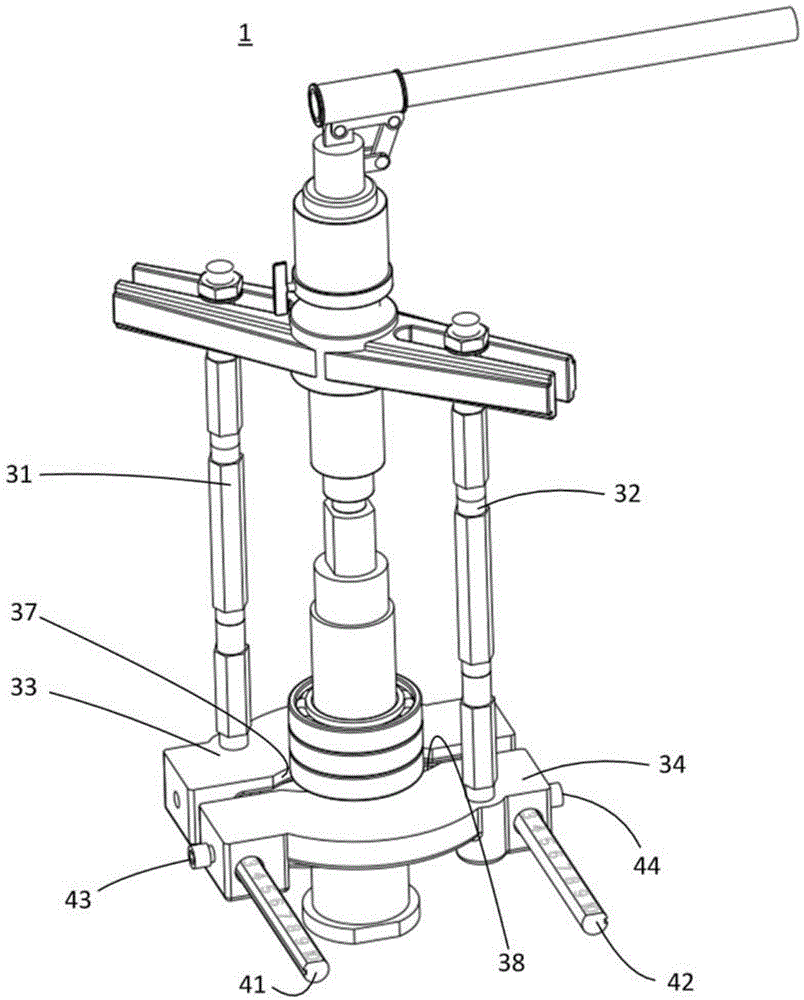

[0016] The puller provided by the present invention is generally consistent with the traditional puller in terms of overall structure, the only difference is that the pair of pulling blocks use the positioning mode of "slider + positioning member" to replace the "thread" described in the background technology. Rod + Locating Nut" positioning mode.

[0017] Specifically, as image 3 and 4 As shown, the pulling blocks 33 and 34 positioned at the longitudinal ends of the gripping arms 31 and 32 are arranged side by side on a pair of parallel sliding bars 41 and 42, and are arranged on a pair of sliding bars in a series connection similar to train carriages. 41 and 42 on the guide rail. By adjusting the relative distance between the drawing blocks 33 and 34 on the slide bars 41 and 42 , the size of the opening between the opposing lips 37 and 38 of a pair of drawing blocks can be smoothly adjusted.

[0018] exist image 3 and 4 In the specific embodiment shown, the drawing bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com