Equipment capable of punching ceiling and mounting expansion bolt conveniently

A technology for expansion bolts and ceilings, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as unfavorable construction personnel's personal health, access to construction personnel, frequent lifting, movement and alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

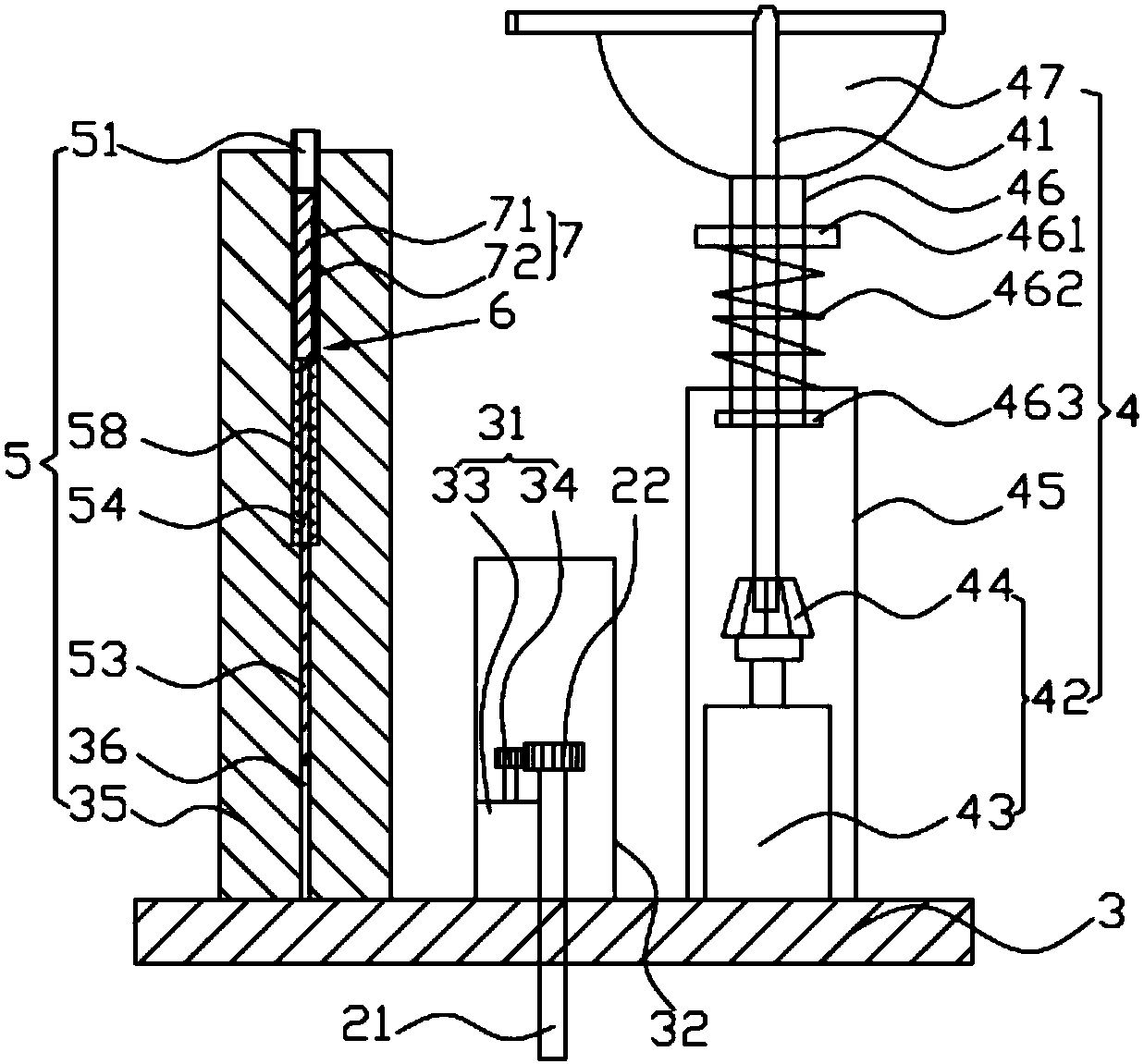

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

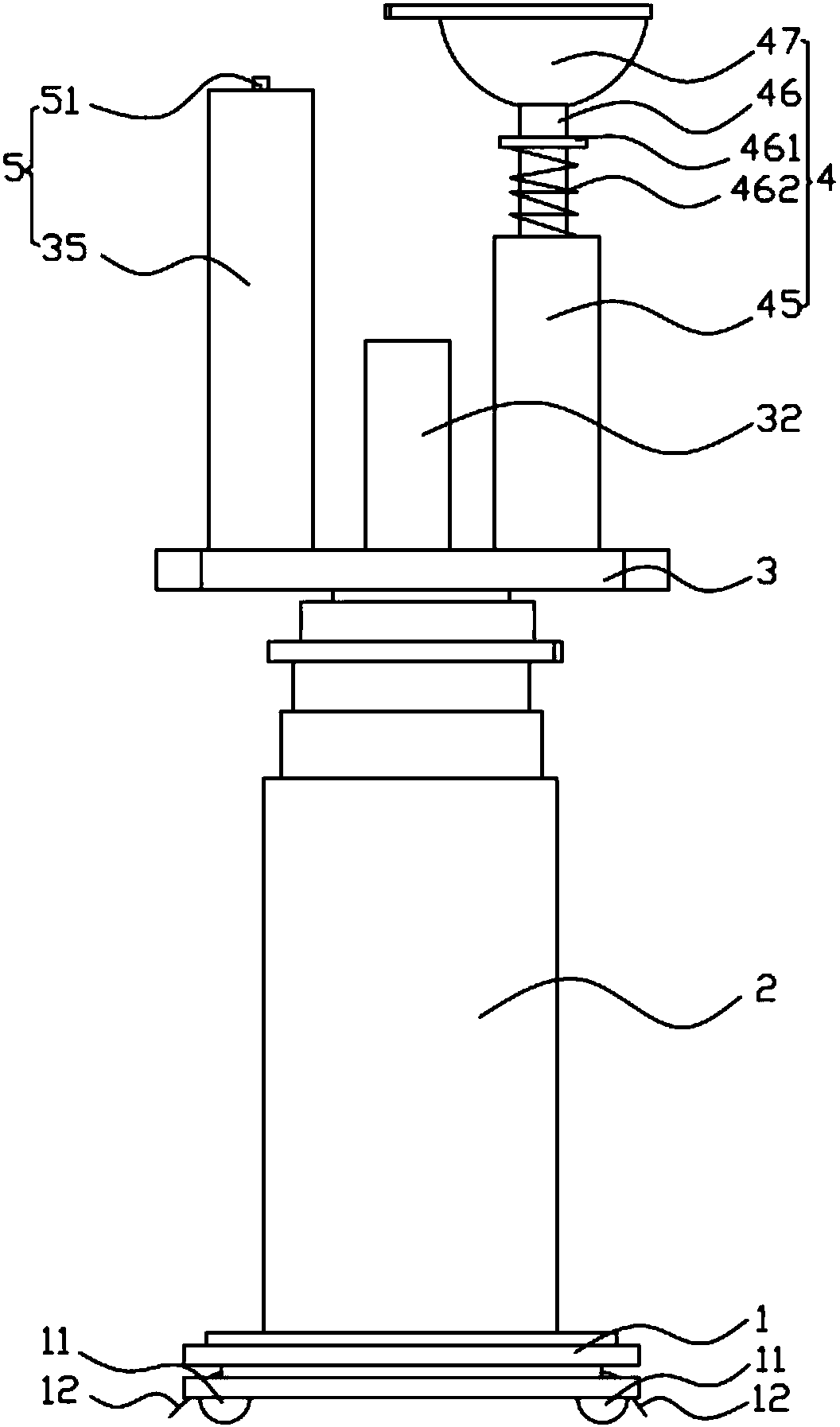

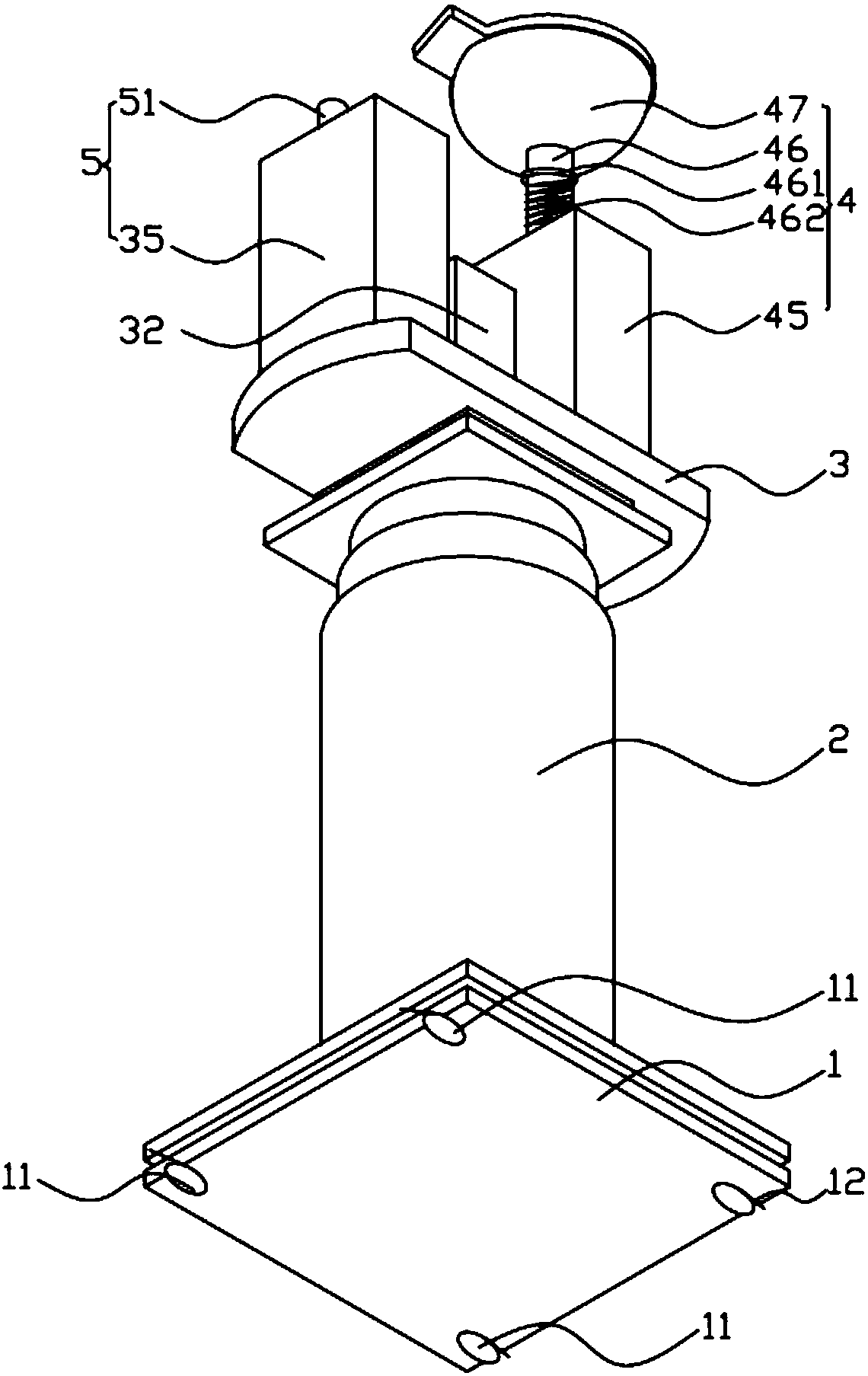

[0037] Such as Figure 1~4 As shown, the device provided by the embodiment of the present invention is convenient for punching holes in the ceiling and installing expansion bolts. It includes a base 1 on which a vertical lifting device 2 is fixed. The rotating platform 3 is provided, and the two sides of the upper part of the rotating platform 3 are respectively fixed with a drilling device 4 and an expansion bolt installation device 5, and the expansion bolt installation device 5 is inserted with a clip-type feeding device 6;

[0038] The base 1 is placed on the ground;

[0039] The lifting device 2 is used to drive the rotating platform 3 to move up and down, thereby driving the drilling device 4 and the expansion bolt installation device 5 to move up and down;

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com