Integrated treatment method and device for flue gas wet-type phase-change ultraclean dust removal and rime fog removal

A processing method and processing device technology, applied in the direction of chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of severe haze, environmental pollution, white plume of smoke, water mist and rain without obvious improvement, etc. Achieve the effect of saving water resources, significant technical advantages, and solving the effect of smearing visual perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

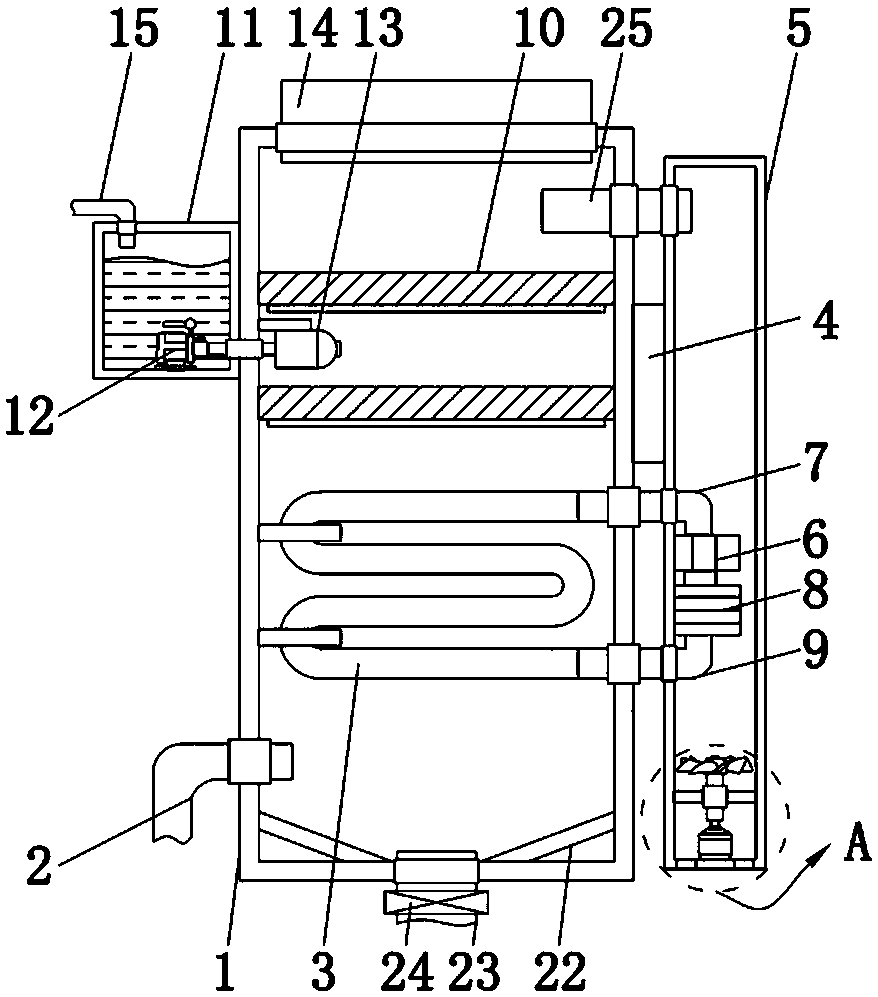

[0038] An integrated treatment method for flue gas wet phase change ultra-clean dedusting and demisting and whitening, comprising the following steps:

[0039] 1) Cooling and cooling: first cool the flue gas to be treated at a temperature of 0°C, so that the saturated wet flue gas phase changes and liquefies into liquid droplets; the cooling and cooling is carried out using a condenser tube, and the condensation The material of the tube is 205 stainless steel, and the wall thickness of the tube is 0.2mm;

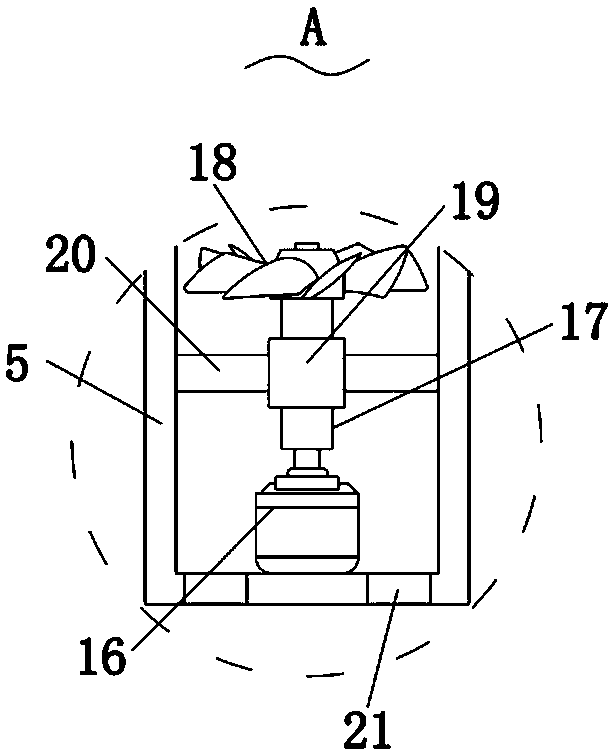

[0040] 2) Droplet reunion and dust removal: continue to collide and reunite the flue gas treated in step (1) under the action of the swirl plate, and the formed water droplets will absorb the dust during the falling process;

[0041] 3) Defogging and whitening: fully mix the flue gas treated in step (2) with air before exhausting to form unsaturated flue gas, and then discharge the treated flue gas directly.

[0042] The flue gas dust content rate 8mg / m treated by this embo...

Embodiment 2

[0044] An integrated treatment method for flue gas wet phase change ultra-clean dedusting and demisting and whitening, comprising the following steps:

[0045] 1) Cooling and cooling: first cool the flue gas to be treated at a temperature of 10°C, so that the saturated wet flue gas phase changes and liquefies into liquid droplets; the cooling and cooling is carried out using a condenser tube, and the condensation The material of the tube is 205 stainless steel, and the wall thickness of the tube is 2mm;

[0046] 2) Droplet reunion and dust removal: continue to collide and reunite the flue gas treated in step (1) under the action of the swirl plate, and the formed water droplets will absorb the dust during the falling process;

[0047] 3) Defogging and whitening: fully mix the flue gas treated in step (2) with air before exhausting to form unsaturated flue gas, and then discharge the treated flue gas directly.

[0048] The dust content rate of flue gas treated in this embodime...

Embodiment 3

[0050] An integrated treatment method for flue gas wet phase change ultra-clean dedusting and demisting and whitening, comprising the following steps:

[0051] 1) Cooling and cooling: first cool the flue gas to be treated at a temperature of 5°C, so that the saturated wet flue gas phase changes and liquefies into liquid droplets; the cooling and cooling is carried out using a condenser tube, and the condensation The material of the tube is 205 stainless steel, and the wall thickness of the tube is 1mm;

[0052] 2) Droplet reunion and dust removal: continue to collide and reunite the flue gas treated in step (1) under the action of the swirl plate, and the formed water droplets will absorb the dust during the falling process;

[0053] 3) Defogging and whitening: fully mix the flue gas treated in step (2) with air before exhausting to form unsaturated flue gas, and then discharge the treated flue gas directly.

[0054] The dust content rate of flue gas treated in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com