Sagger brick and masonry fire clay for firing sliding bricks by buried carbon

A sliding brick and saggar technology is applied in the field of refractory materials, which can solve the problems of complex components and high production costs, and achieve the effects of improving service life, speeding up heat transfer and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

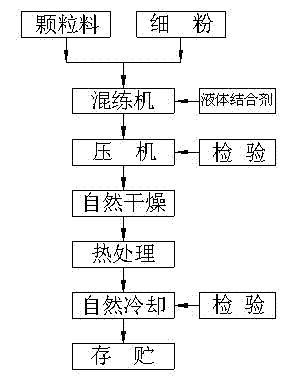

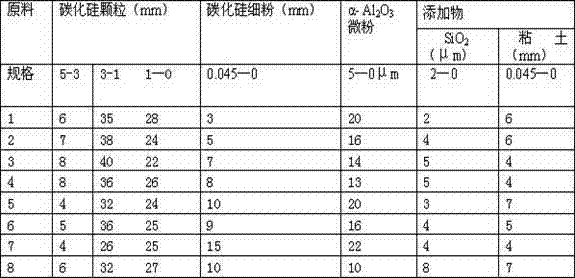

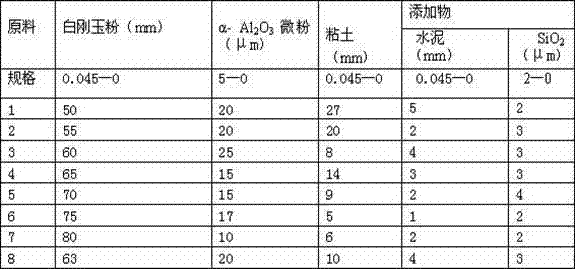

[0038] In order to further describe the present invention, a kind of sagger brick and fire clay for masonry of the present invention will be described in more detail in conjunction with the accompanying drawings and examples.

[0039] In order to ensure that the carbon-containing slides are fired in a reducing atmosphere, the method of embedding carbon in the sagger is used, which requires the sagger itself to have good sealing performance and fast heat conduction; at the same time, it should have high strength and structural stability under high temperature conditions. Good characteristics, after a lot of research, mainly choose two kinds of material combination: one is silicon carbide, which has the characteristics of good thermal conductivity, low thermal expansion coefficient, good high temperature strength, etc., but it is not stable enough in oxidizing atmosphere; the other is corundum (α -Al 2 o 3 ), corundum has excellent performance at room temperature and high tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com