Cement clinker production admixture

A technology of cement clinker and admixture, which is applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problems of reducing the firing temperature, firing speed, single function, poor comprehensive efficiency, etc., to speed up the firing speed. , the effect of improving combustion efficiency, inhibiting diffusion and slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

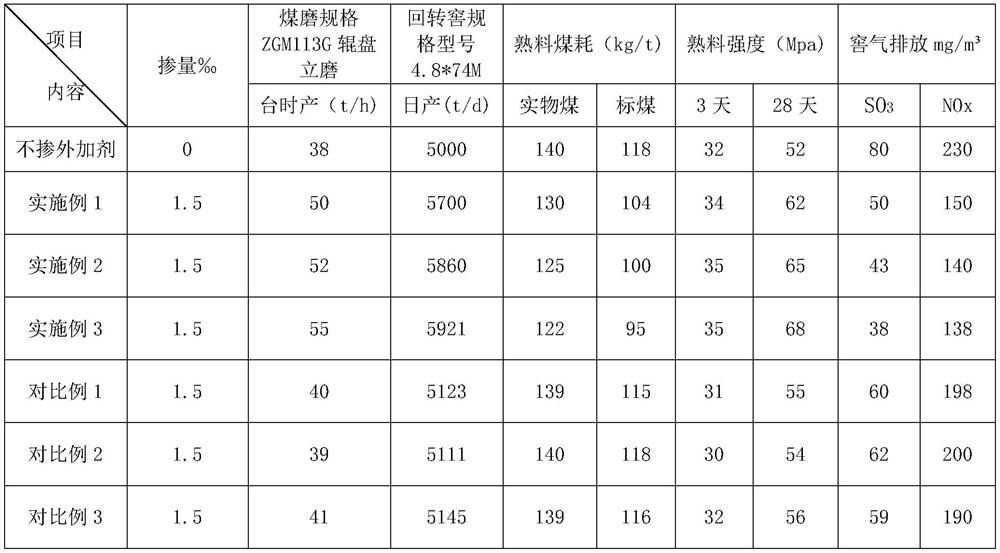

Examples

Embodiment 1

[0023] An admixture for cement clinker production is composed of the following raw materials in percentage by weight: 1% ferric chloride, 2% ferric sulfate, 5% urea, 3% glycerin, 8% compound sodium sulfate, 6% ammonium nitrate, and The amount is water.

[0024] The composite sodium sulfate is obtained by mixing sodium carbonate and nano-boron nitride according to a mass ratio of 1:1; the preparation method of the nano-boron nitride is: dispersing 6g of hexagonal nano-boron nitride in 200mL of N-formaldehyde Add 5-10ml of N,N-dimethylethanolamine, 50ml of 5M NaOH solution to pyrrolidone, stir at 80°C for 12h, sonicate for 4h, centrifuge at 6000rpm for 20min, wash the lower precipitate with absolute ethanol, and dry in vacuum for 8h to obtain nano boron nitride.

[0025] The nano-boron nitride of the present invention adopts commercially available finished hexagonal boron nitride, which is purchased from Liaoning Boda Technology Co., Ltd.

[0026] The purity of N,N-dimethyleth...

Embodiment 2

[0032] An admixture for cement clinker production, which is composed of the following raw materials in weight percentage: 2% ferric chloride, 1% ferric sulfate, 6% urea, 4% glycerin, 6% compound sodium sulfate, 8% ammonium nitrate, and the balance for water.

[0033] The composite sodium sulfate is obtained by mixing sodium carbonate and nano-boron nitride according to a mass ratio of 1:1; the preparation method of the nano-boron nitride is: dispersing 6g of hexagonal nano-boron nitride in 200mL of N-formaldehyde Add 6ml of N,N-dimethylethanolamine, 50ml of 5M NaOH solution to pyrrolidone, stir at 80°C for 12h, sonicate for 4h, centrifuge at 6000rpm for 20min, wash the lower precipitate with absolute ethanol, and dry it in vacuum for 8h to obtain nano-nitrogen Boron.

[0034] The nano-boron nitride of the present invention adopts commercially available finished hexagonal boron nitride, which is purchased from Liaoning Boda Technology Co., Ltd.

[0035] The purity of N,N-dime...

Embodiment 3

[0041] An admixture for cement clinker production is composed of the following raw materials in percentage by weight: 3% ferric chloride, 5% ferric sulfate, 8% urea, 5% glycerin, 5% compound sodium sulfate, 7% ammonium nitrate, and the remaining The amount is water.

[0042] The composite sodium sulfate is obtained by mixing sodium carbonate and nano-boron nitride according to a mass ratio of 1:1; the preparation method of the nano-boron nitride is: dispersing 6g of hexagonal nano-boron nitride in 200mL of N-formaldehyde Add 8ml of N,N-dimethylethanolamine, 50ml of 5M NaOH solution to the base pyrrolidone, stir at 80°C for 12h, sonicate for 4h, centrifuge at 6000rpm for 20min, wash the lower precipitate with absolute ethanol, and dry it in vacuum for 8h to obtain nano-nitrogen Boron.

[0043] The nano-boron nitride of the present invention adopts commercially available finished hexagonal boron nitride, which is purchased from Liaoning Boda Technology Co., Ltd.

[0044] The pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com