Preparation method, production system and application of foamed ceramic and foamed ceramic

A foamed ceramics and production system technology, applied in the field of foamed ceramics, can solve problems such as accelerated kiln speed, long exhaust time, and large loss on ignition, so as to improve production efficiency and output, ensure product quality, and accelerate firing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

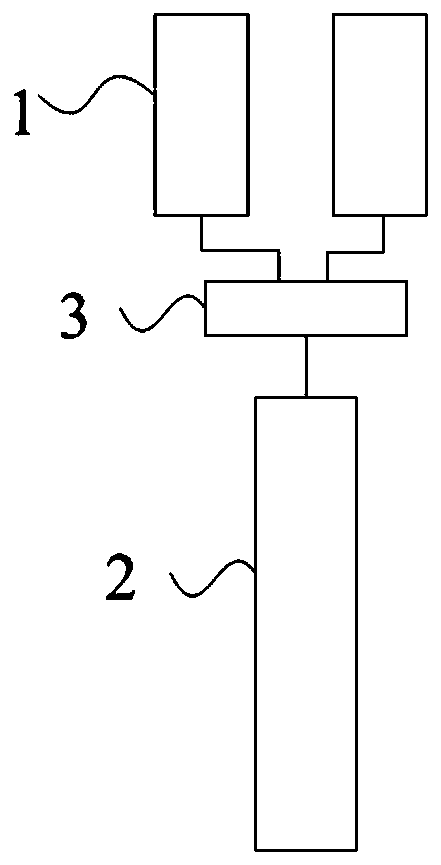

[0030] According to one aspect of the present invention, a method for preparing foamed ceramics is provided, comprising: first bisque firing the foamed ceramic powder, and then firing to obtain the foamed ceramics.

[0031] In the above method, the foamed ceramic powder is bisque-fired first, and then fired. In the bisque-fired stage, the structural water, bound water, organic matter, carbonate, sulfate and other substances in the powder can be decomposed and fully discharged. The gas that is beneficial to the production of foamed ceramics, bisque firing before firing can not be affected by the temperature and airflow in the middle and late stages of firing, and the gas that is not conducive to the product can be discharged as much as possible, without decomposing and exhausting during the firing stage, and The thickness of the powder can be increased; then the sintering and foaming process is completed in the firing stage, the powder is directly fired without preheating, and t...

Embodiment 1

[0073] A method for preparing foamed ceramics, comprising: first bisque-firing foamed ceramic powder, and then firing to obtain foamed ceramics;

[0074] Bisque firing includes: raising the temperature of the foamed ceramic powder to the biscuit firing temperature, keeping it warm, and then cooling down to 100°C to obtain the bisque fired powder;

[0075] The bisque firing temperature is 480°C, and the holding time is 100min;

[0076] Firing includes: raising the temperature of the bisque-fired powder to 1200° C. for 90 minutes, and then cooling down to room temperature to obtain foamed ceramics.

Embodiment 2-4

[0078] A method for preparing foamed ceramics. The difference from Example 1 is that in Examples 2-4, after biscuit firing and heat preservation, the temperature is respectively lowered to 150°C, 300°C and 450°C.

[0079] The temperature of cooling in biscuit firing in embodiment 2-4 is within the preferred range of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com