Disc type ceramic membrane and one-step forming method thereof

A molding method and ceramic membrane technology, which is applied in the field of ceramic membranes, can solve the problems of reducing the service life of ceramic membranes, reducing the filtering effect of ceramic membranes, and easy separation of support structures, so as to achieve the effects of increasing service life, low cost, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

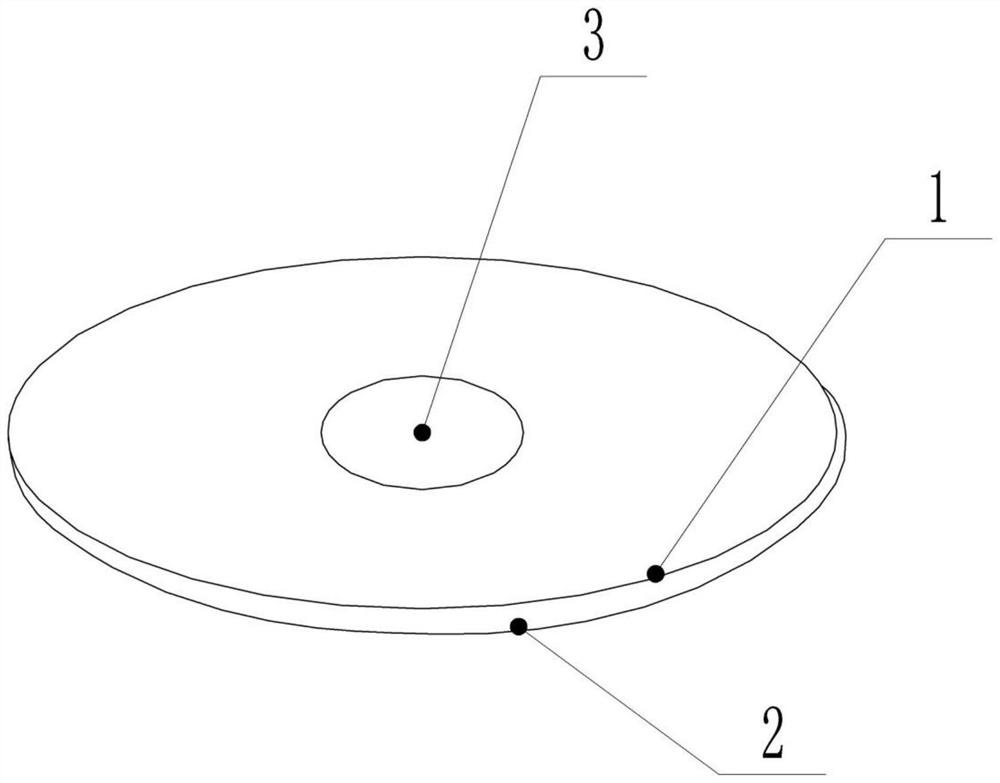

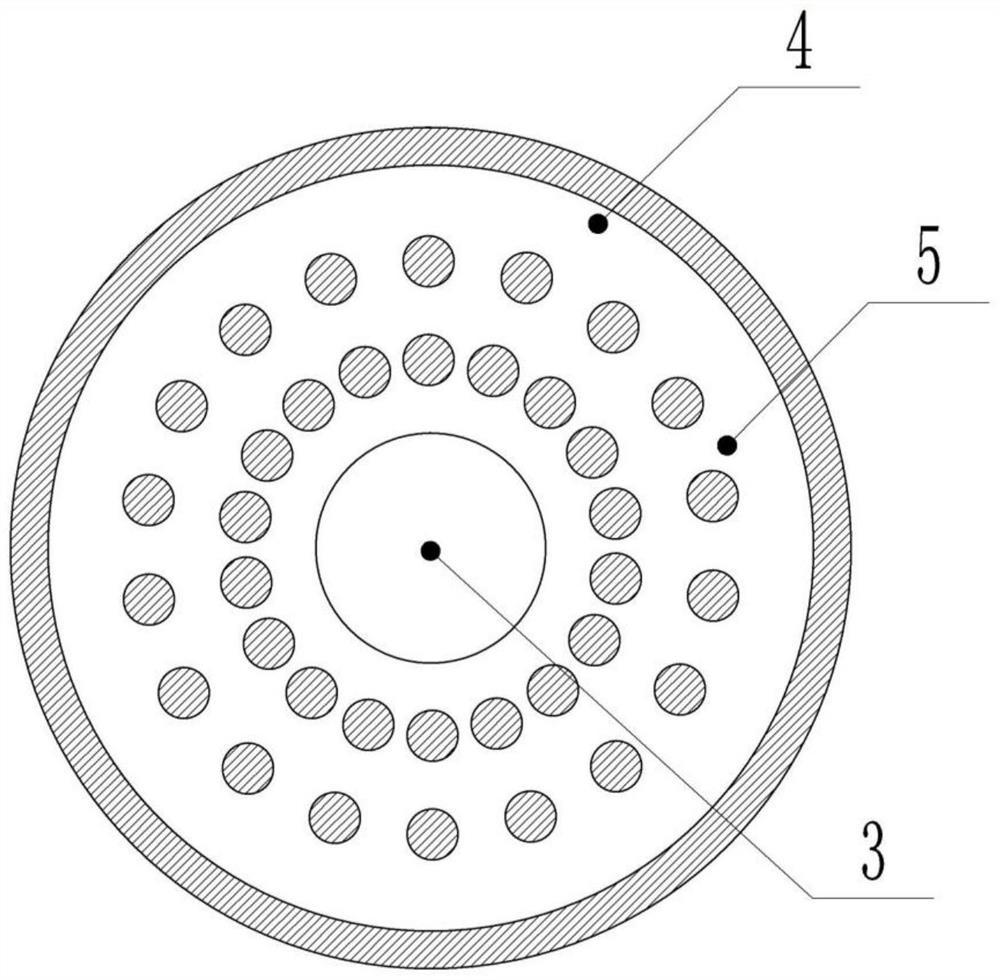

[0027] Disc ceramic membrane, if attached figure 1 , attached figure 2 And attached image 3 As shown, it specifically includes: a support body 4 and a separation filter layer. The separation filter layer includes a top membrane 1 and a bottom membrane 2 , and the top membrane 1 and the bottom membrane 2 are respectively located on the upper and lower sides of the support body 4 . The supporting body 4 , the top membrane 1 and the bottom membrane 2 are integrated; the supporting body 4 is in the shape of a flying saucer, and the center of the supporting body 4 is provided with a water-collecting through hole 3 . The outer peripheral end of the support body 4 is closed; the support body 4 is provided with a water collection channel 5 for discharging the filtered solution, and the water collection channel 5 communicates with the water collection through hole 3 .

[0028] The solution is infiltrated from the top membrane 1 of the separation filter layer, under the action of th...

Embodiment 2

[0040] The difference between this example and Example 1 is that in Step 5, the ceramic film semi-finished product is first calcined at 1250°C~1300°C for 1~2h, and ultrasonic dispersion is carried out at the same time; and then heated for 30min to increase the calcining temperature To 1300 ~ 1750 ℃ for calcination molding.

[0041] Under the condition of 1250~1300℃, the combustibles will burn and consume the oxygen in the space formed by the first support layer and the second support layer, and the space formed by the first support layer and the second support layer is relatively close to the air circulation channel of the outside world. Small, the oxygen inside the space formed by the first support layer and the second support layer will be relatively small. Under the condition of 1250~1300℃, the combustion of combustibles will mainly generate CO gas, and the generated CO gas will pass through the first support layer and the second support layer. The second support layer es...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com