Ultrasonic-assisted low-temperature glass brazing method

A technology of low-temperature glass and brazing method, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as high viscosity of molten glass, insufficient wetting and spreading, residual pores, etc., achieve good wettability, overcome Insufficient fluidity, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

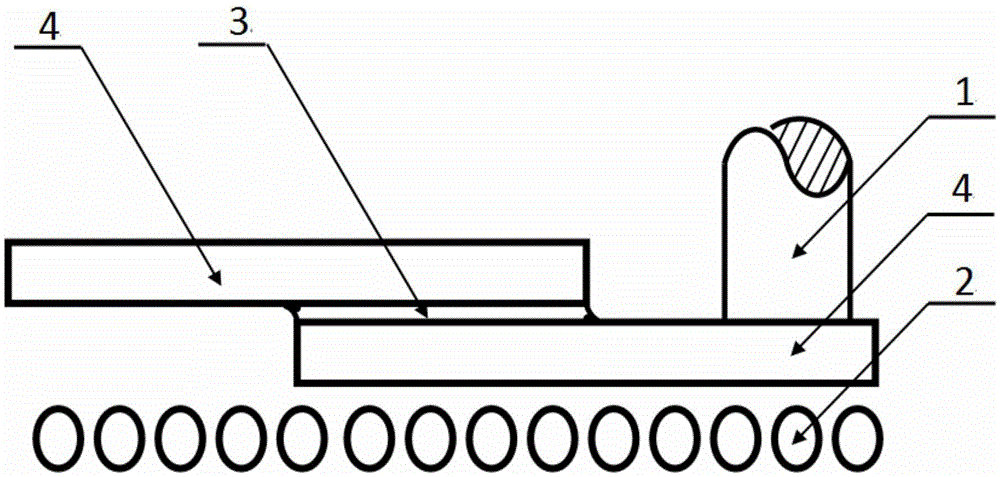

[0019] Specific implementation mode one: the ultrasonic-assisted low-temperature glass brazing method of this implementation mode is carried out according to the following steps:

[0020] 1. Mix the low-temperature sealing glass powder and the adhesive, put it in a solder paste mixer, and stir at a speed of 100-150r / min for 1-2 hours to obtain a low-temperature glass solder paste;

[0021] 2. Use cutting equipment to cut the raw materials to be welded into shapes to obtain weldments;

[0022] 3. Place the weldment obtained in step 2 in acetone, perform ultrasonic cleaning at room temperature, use water sandpaper to mechanically polish the weldment after ultrasonic cleaning, then place it in acetone for ultrasonic cleaning, and finally transfer it to a drying box drying in medium to obtain dry weldments;

[0023] 4. Use the screen printing method to evenly coat the low-temperature glass solder paste on the pre-connection position on the surface of the dry weldment to obtain th...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the low-temperature sealing glass solder described in step one consists of 50 parts by mass of P 2 o 5 , 12 parts of SnO, 18 parts of ZnO, 6 parts of B 2 o 3 , 1 copy of A1 2 o 3 , 1 part of SiO 2 and 0.5 parts of Li 2 O composition. Other steps and parameters are the same as those in Embodiment 1.

[0027] In this embodiment, the sealing temperature of the low-temperature sealing glass solder is 480-600°C, and the coefficient of thermal expansion is between 75-125×10 -7 / °C, the viscosity at sealing temperature is 10 3 ~10 5 Pa·s.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the particle size of the low-temperature sealing glass frit described in step 1 is 25-75 μm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sealing temperature | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com