Patents

Literature

176results about How to "Shorten the resting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

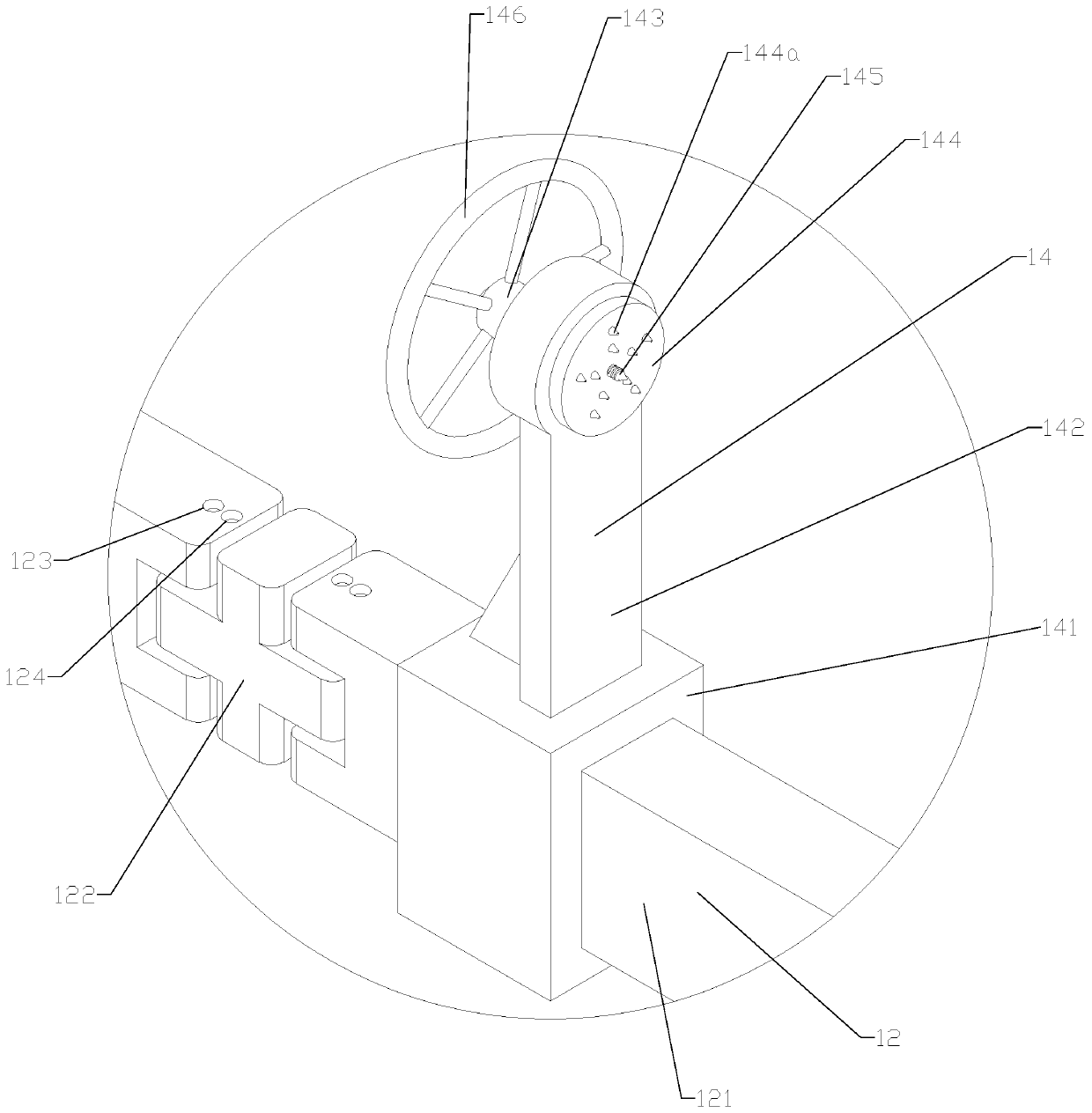

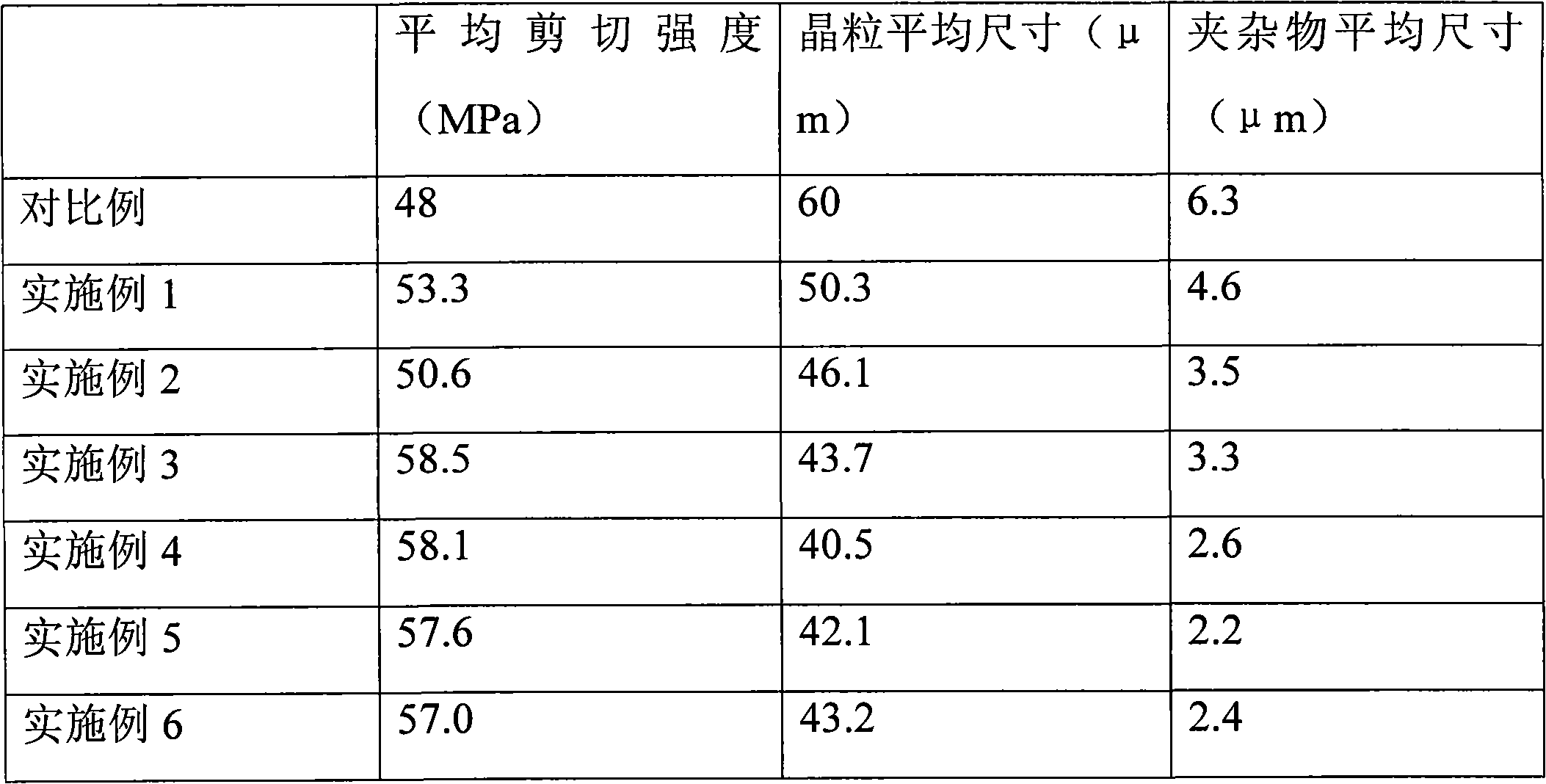

A kind of magnesium alloy solder containing rare earth element Er and preparation method thereof

InactiveCN102294553ASolve severe segregationSolve the coarse grainWelding/cutting media/materialsSoldering mediaRare-earth elementSlag

The invention relates to a magnesium alloy brazing filler metal containing a rare-earth element Er and a preparation method thereof, and belongs to the technical field of magnesium alloy connection. The magnesium alloy brazing filler metal comprises the following components in percentage by weight: 40-55% of Mg, 39-55% of Zn, 1-5% of Al and 0.1-1.5% of Er, wherein the Er is uniformly distributed.The preparation method comprises the steps of arranging alloy ingots in a preheat crucible, heating under protective atmosphere and mechanical stirring, fishing slag after the alloy ingots are completely fused, stopping heating brazing filler metal, stirring the brazing filler metal, applying ultrasonic waves on the fused brazing filler metal after the brazing filler metal is cooled to 380-600 DEG C, inserting an ultrasonic rod preheated to 300-700 DEG C into a brazing filler metal liquid level with the ultrasonic frequency of 18-22kHz, ultrasonic intensity of 0.5-5W / cm2 and the time of 10-150s, standing still after moving out the ultrasonic rod after ending, pouring the brazing filler metal liquid into a mould and air cooling to room temperature. The number of dendritic crystals of the obtained product is obviously reduced, crystal grains are refined, and the strength and the toughness are improved.

Owner:BEIJING UNIV OF TECH

New technology for refining Fischer-Tropsch synthesis light fraction oil

InactiveCN106753546AReduce volatile lossEasy extractionTreatment with plural serial refining stagesSolid phase adsorptionImpurity

The invention relates to a new technology for refining Fischer-Tropsch synthesis light fraction oil. The new technology comprises solid-phase adsorption, extraction refining, separation and extraction agent refining and a recycling unit. In the new technology for refining Fischer-Tropsch synthesis light fraction oil provided by the invention, Fischer-Tropsch synthesis light fraction oil is used as a raw material; metal ion impurities and oxygenated compounds in the Fischer-Tropsch synthesis light fraction oil are removed by the technology unit while the recycled refined extraction agent is circularly utilized. The new technology for refining Fischer-Tropsch synthesis light fraction oil provided by the invention has the advantages of simple process, high recycling efficiency, recycling and cyclic utilization of extraction agent, low cost of extraction agent, small investment, and the like.

Owner:LUOYANG HEMENG TECH CO LTD

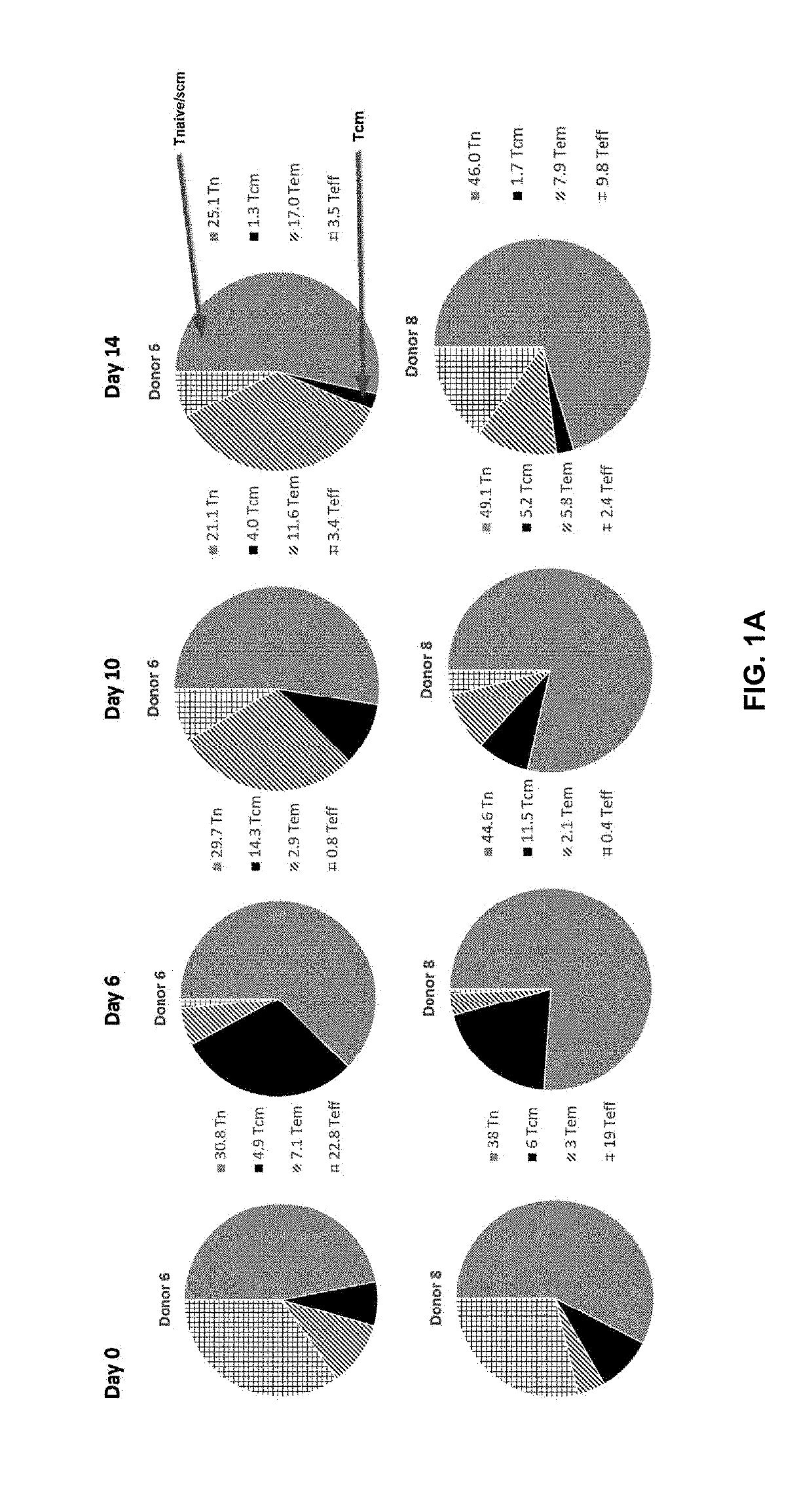

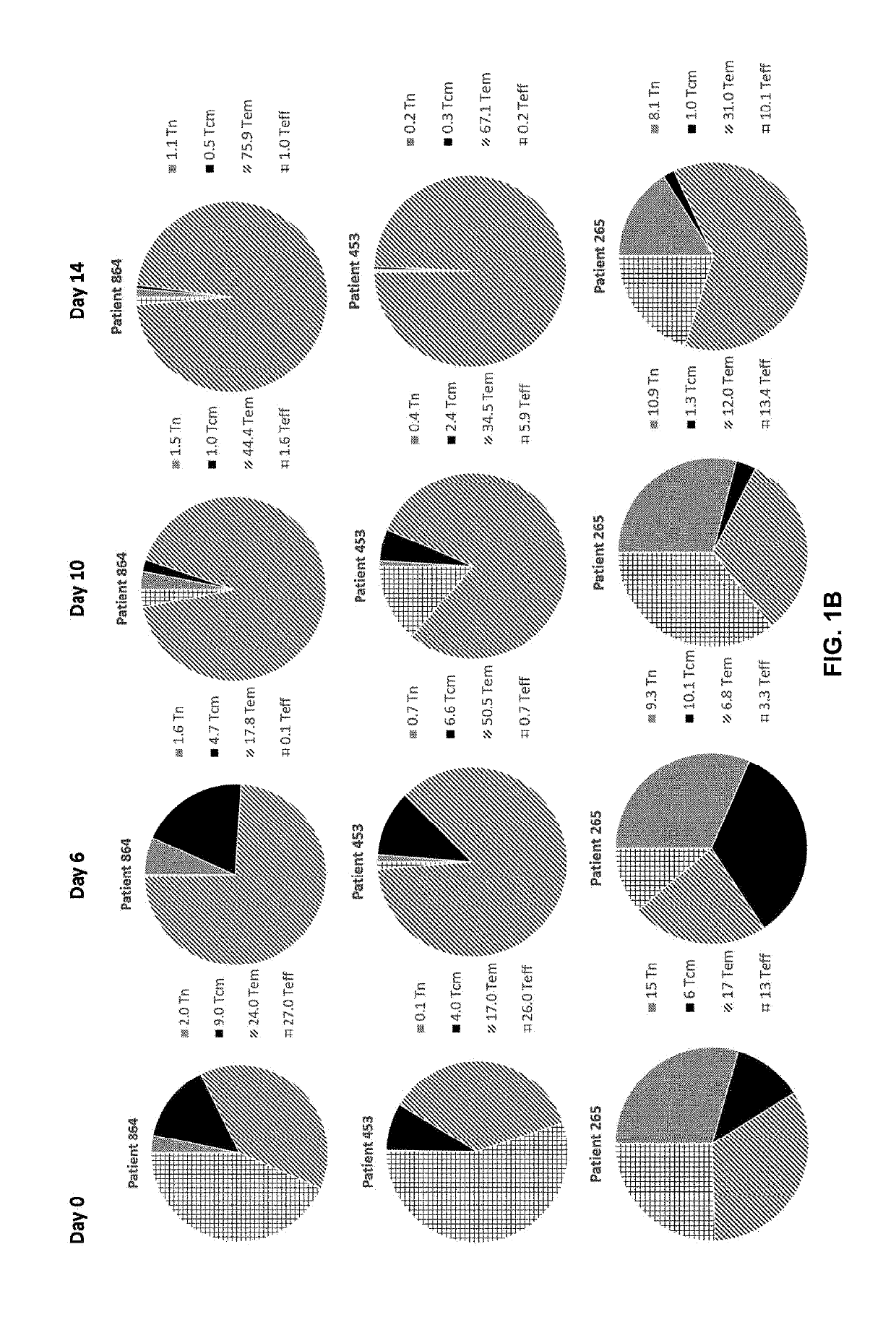

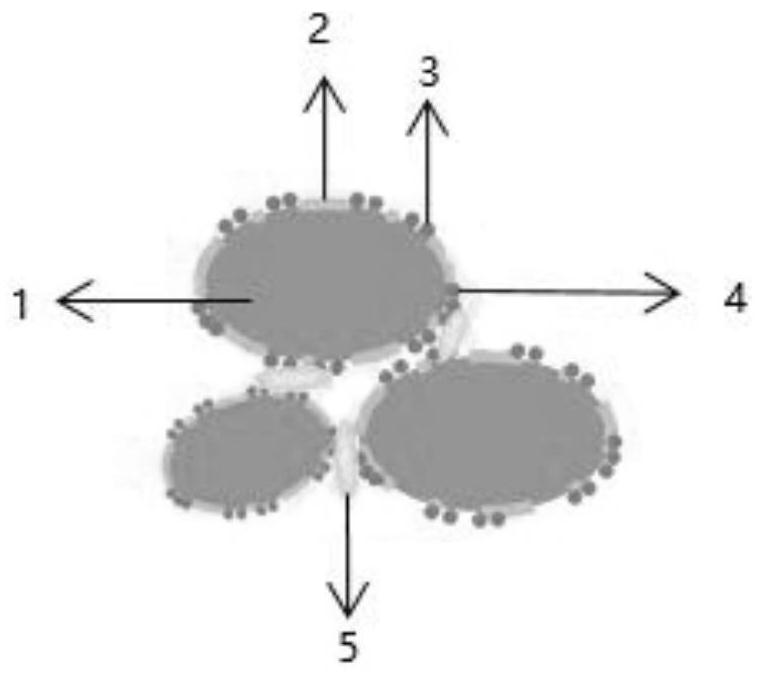

Methods for manufacturing t cells

ActiveUS20190247433A1Shorten the resting timeGenetically modified cellsGenetic material ingredientsVirus typeCD28

The disclosure relates to methods of manufacturing T cells for adoptive immunotherapy. The disclosure further provides for methods of genetically transducing T cells, methods of using T cells, and T cell populations thereof. In an aspect, the disclosure provides for methods of thawing frozen peripheral blood mononuclear cells (PBMC), resting the thawed PBMC, activating the T cell in the cultured PBMC with an anti-CD3 antibody and an anti-CD28 antibody immobilized on a solid phase, transducing the activated T cell with a viral vector, expanding the transduced T cell, and obtaining expanded T cells.

Owner:IMMATICS US INC

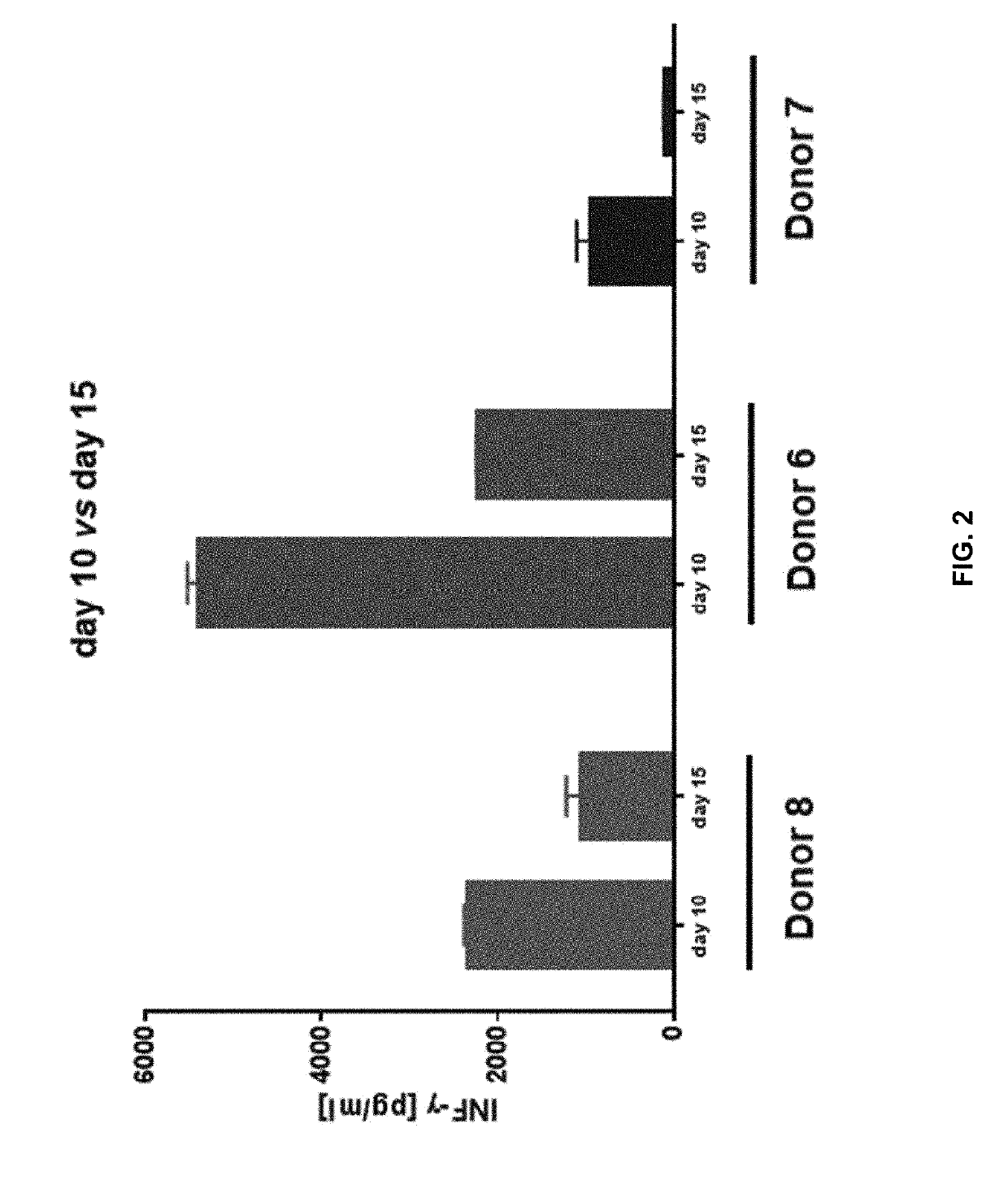

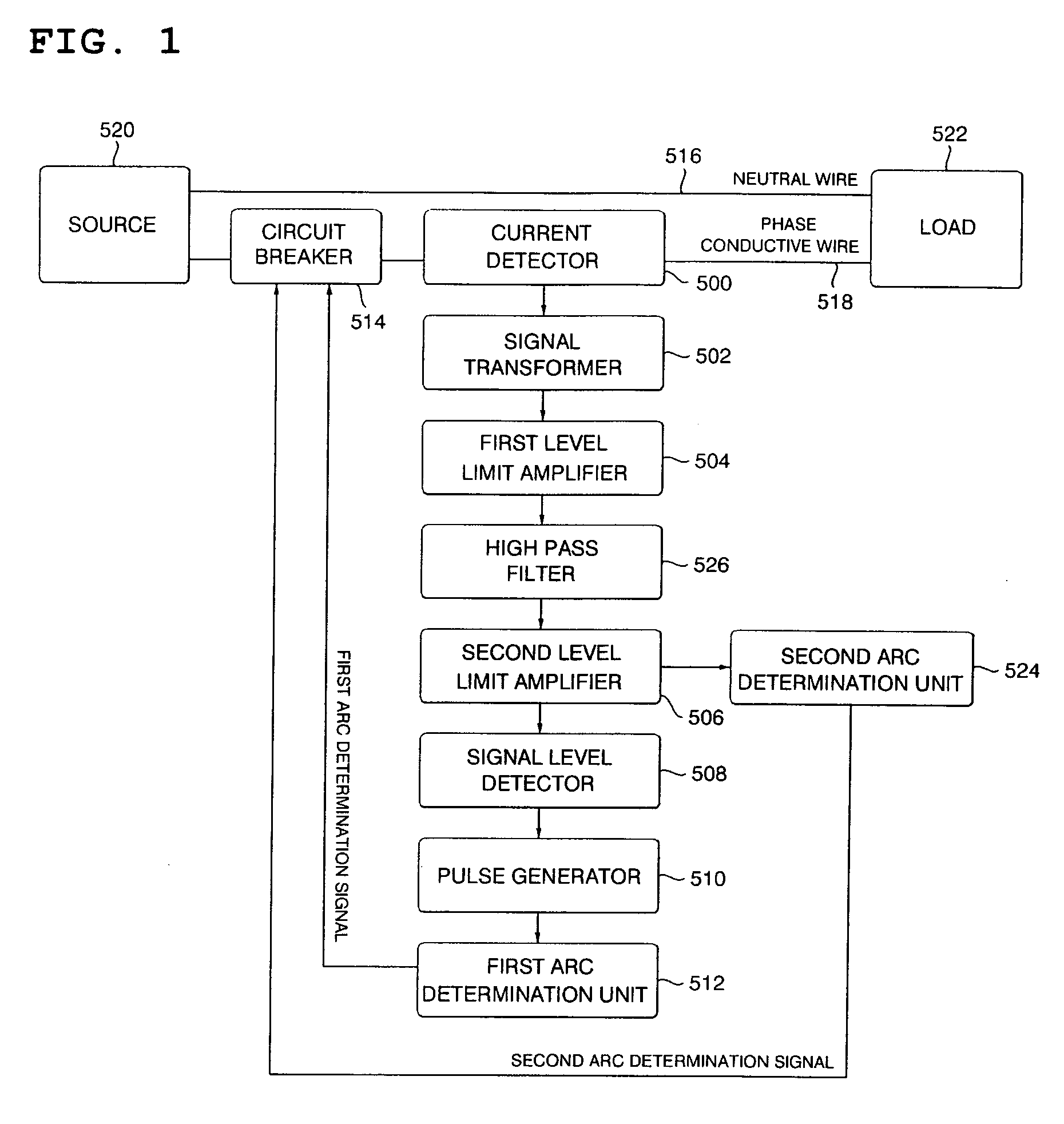

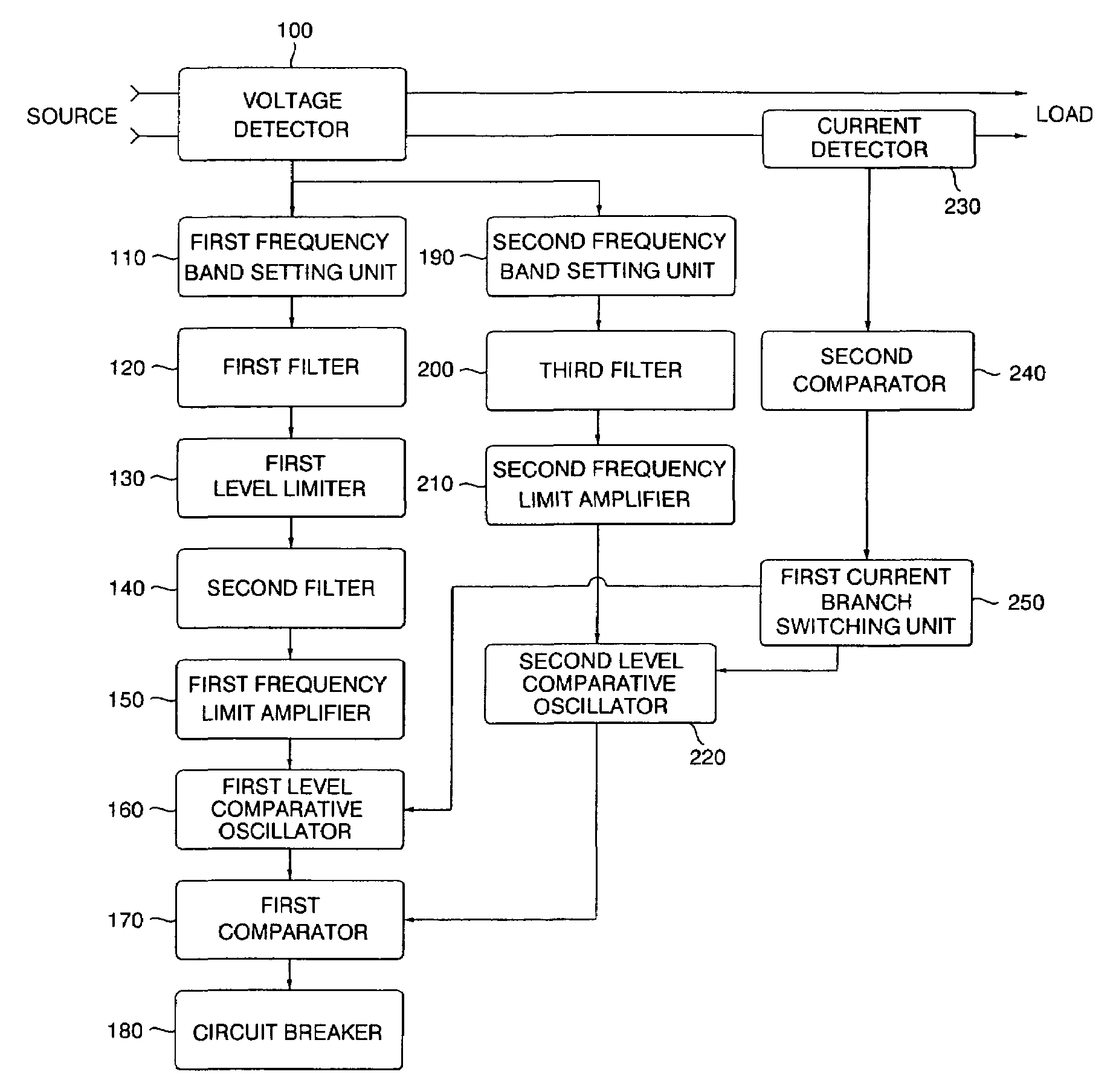

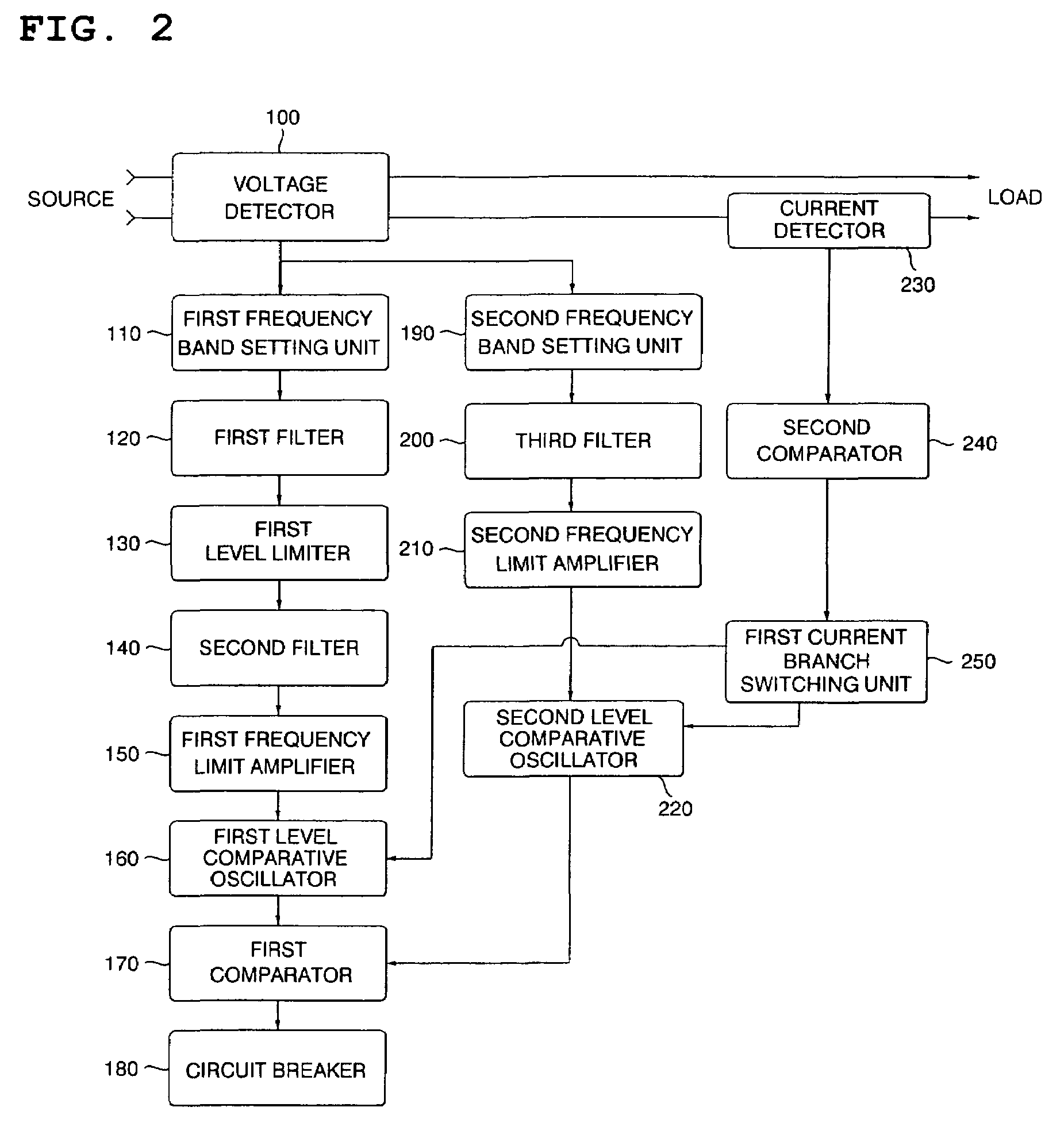

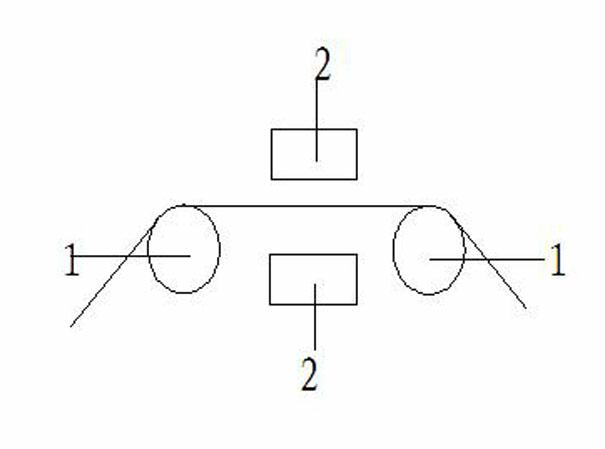

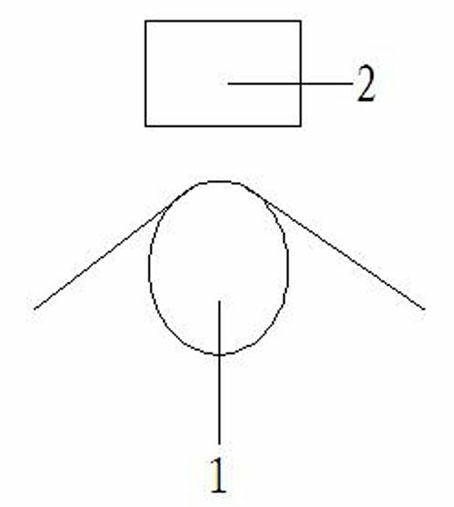

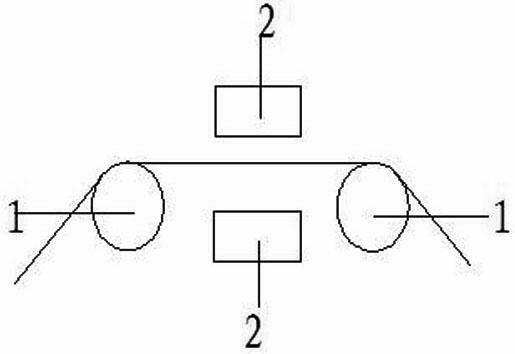

Apparatus for detecting arc fault

InactiveUS20070121261A1Avoid failureReduce the risk of fireTesting dielectric strengthEmergency protective arrangement detailsEngineeringComparator

Disclosed herein is an apparatus for detecting an arc fault, which prevents a malfunction caused by a conventional current detecting method by detecting a source voltage applied onto a conductive wire to determine whether there is an arc fault, prevents a malfunction with respect to a pseudo arc signal by dividing a current detecting route into two according to the magnitude of a load current occurring onto the conductive wire to determine whether there is the arc fault by voltage detection, and lessens the danger of a fire by reducing a circuit break time according to the magnitude of the load current. A voltage detector detects the arc fault by use of two detecting routes. Each route differs in a filtering value of a filter, presence / absence of level limit, an amplification factor of an amplifier, an accumulation value of a comparator, etc. according to the magnitude of a load current occurring on a conductive wire, thereby reducing a circuit break time.

Owner:SUNG SAM KYOUNG

Lithium ion battery assembly method and lithium ion battery

InactiveCN110690506AImprove securityImprove cycle performanceFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryBattery cell

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery assembly method which comprises the following steps: baking a positive plate, anegative plate and a diaphragm to obtain a baked positive plate, a baked negative plate and a baked diaphragm; laminating and / or winding the baked positive plate, the baked negative plate and the baked diaphragm; welding a tab to obtain a bare battery cell; soaking the bare battery cell in an electrolyte to obtain a battery cell soaked in the electrolyte; putting the battery cell soaked in the electrolyte into a shell, and performing packaging; and forming and re-packaging the packaged battery cell to obtain the lithium ion battery. According to the method, the bare battery cell is directly soaked in the electrolyte, so that the battery pole piece and the diaphragm are fully soaked by the electrolyte; then the liquid supplementing procedure is added according to the designed weight, so that the electrical consistency among battery batches can be ensured; and the standing time of a battery after liquid injection can be shortened, and the production efficiency is improved. The lithium ion battery prepared by the method disclosed by the invention is high in safety performance and good in cycle performance.

Owner:汇洋世纪新能源科技有限公司

A high-size special-shape carbon-based composite material member and a preparing method thereof

The invention relates to a high-size special-shape carbon-based composite material member and a preparing method thereof. The member includes, by mass, 20-35% of carbon fibers, 35-75% of pyrolytic carbon and 5-15% of SiC. The preparing method includes needling the continuous carbon fibers into a prefabricated blank the density of which is 0.4-0.55 g / cm<3> according to a required shape of the member; then fixing the inner and outer surfaces of the prefabricated blank by adopting a graphite mold; and then performing high-temperature thermal treatment, a first time of carbon deposition, demolding, coarse machining, a second time of carbon deposition, graphite processing, silicon vapor bathing and finish machining in order to obtain a finished product. According to the member and the method, a problem that high-size special-shape carbon-based composite material members are liable to deform in long-time standing processes and preparing processes is overcome, and the obtained product has advantages of good mechanical performance, a low thermal expansion coefficient, high thermal conductivity, good chemical stability, and the like, is suitable for industrial production, and can be applied in the field of aviation and aerospace, the field of communication and transportation, the field of biomedicine, and the like.

Owner:CENT SOUTH UNIV

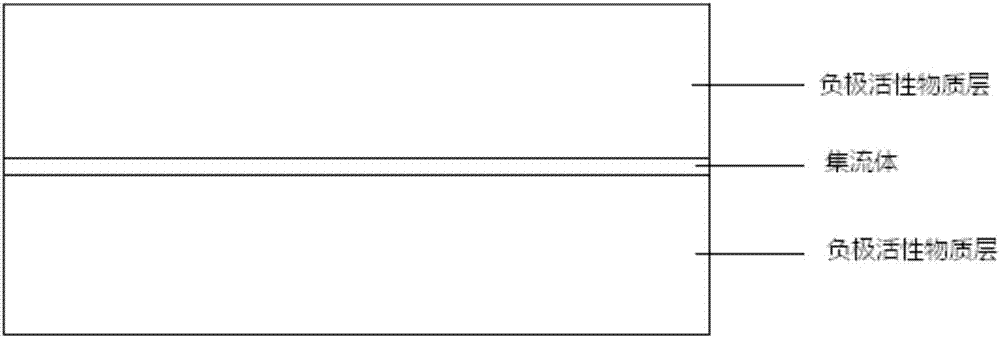

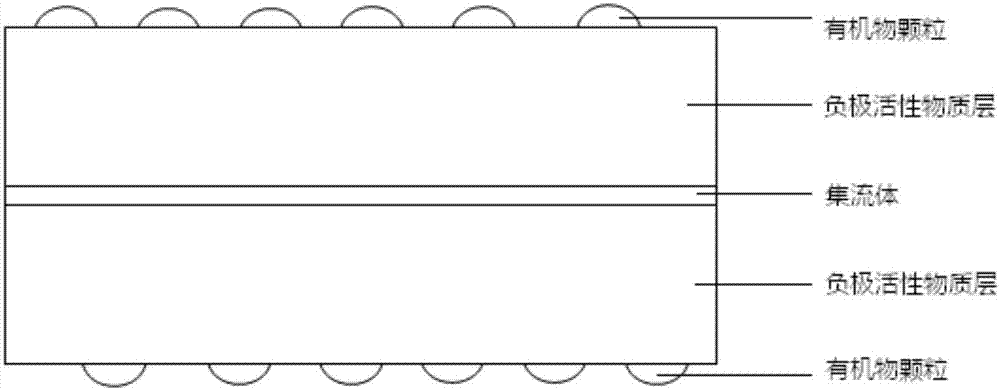

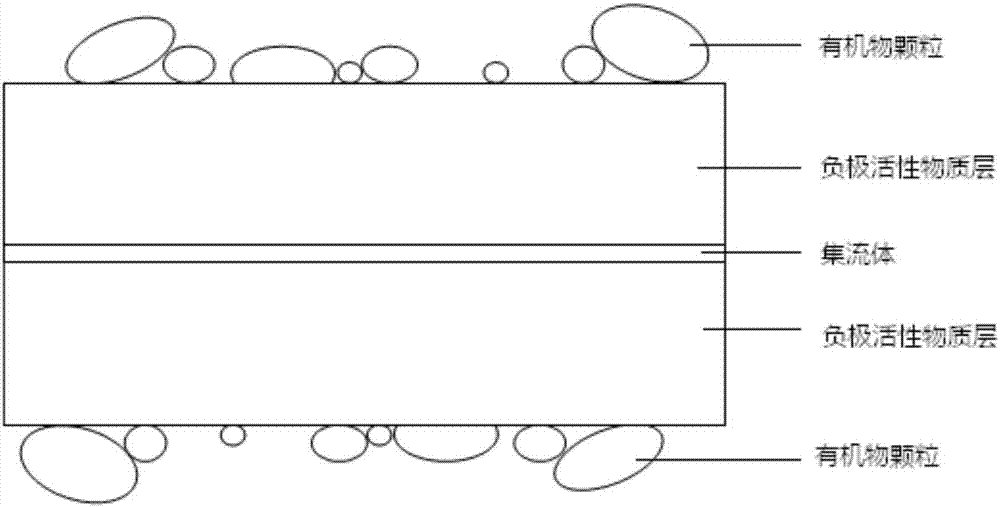

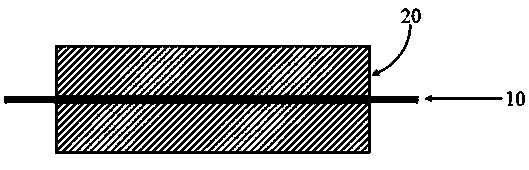

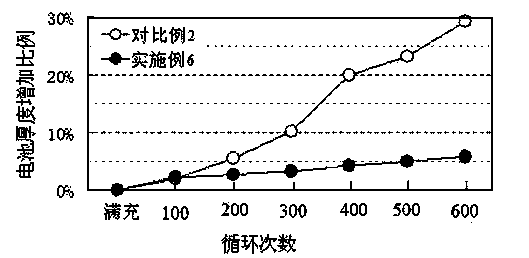

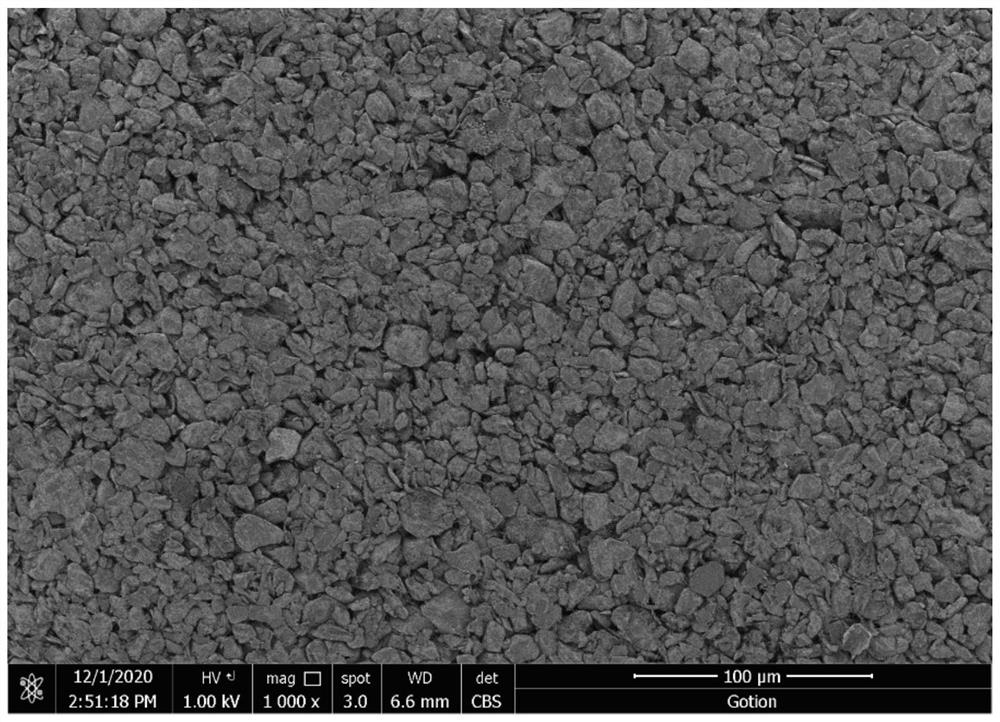

Lithium ion battery and negative plate thereof

ActiveCN107403904AAvoid breakingImprove cycle lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesMembrane tensionCyclic process

The invention discloses a lithium ion battery negative plate. The lithium ion battery negative plate comprises a negative current collector and negative active substance layers distributed on two surfaces of the negative current collector, wherein at least one surface of each negative active substance layer is provided with a hot-press molten protruded point structure, and the distribution density of the protruded point structure is 0.1-10mg / 1540.25mm<2>. By utilizing the protruded point structures arranged on the lithium ion battery negative plate, a buffer gap is provided between the negative plate and a diaphragm layer so as to relieve an expansion force generated during continuous expansion of the negative plate in a cycle process and an insulation membrane tension force generated during winding, so that the cycle life of a lithium ion battery can be prolonged, and the safety performance of the lithium ion battery can be improved; and by utilizing the buffer gap, a high-speed channel is provided for the infiltration of electrolyte into the negative plate, so that the standing time after liquid injection of the lithium ion battery can be shortened. Besides, the invention further discloses the lithium ion battery adopting the lithium ion battery negative plate.

Owner:CONTEMPORARY AMPEREX TECH CO

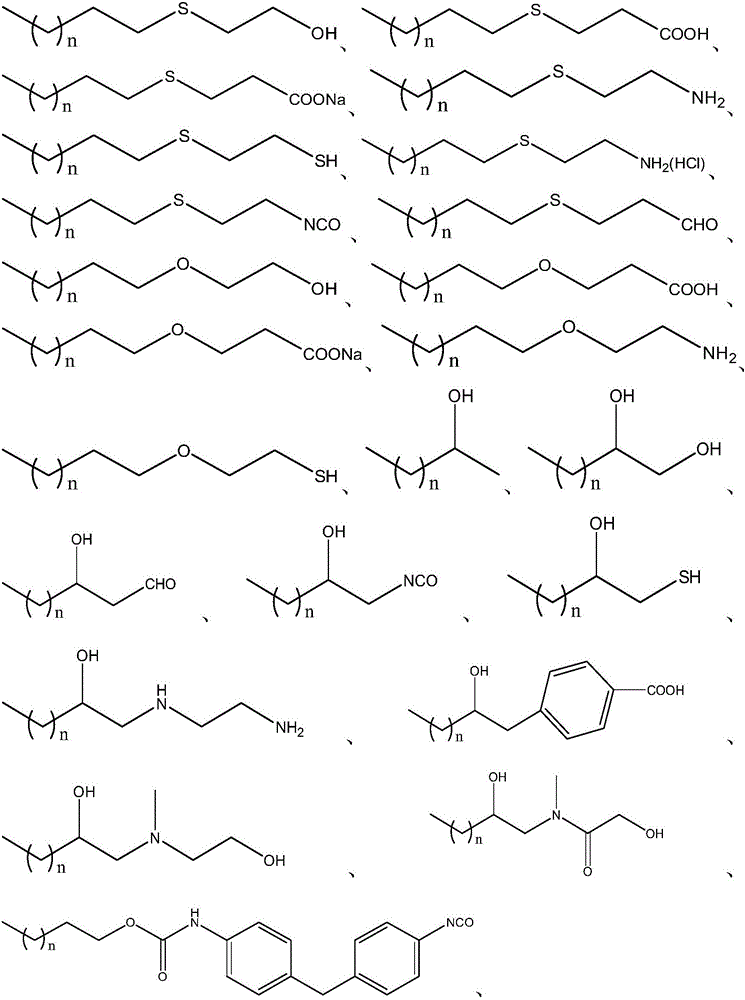

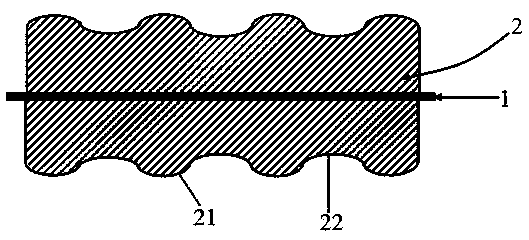

Diaphragm, method for preparing diaphragm and secondary battery comprising diaphragm

InactiveCN105789538AGood electrophilic performanceImprove hydrophilicityCell component detailsPolyvinyl butyralPolyolefin

The invention relates to the field of secondary batteries, in particular to a diaphragm, a method for preparing the diaphragm and a secondary battery comprising the diaphragm. The diaphragm comprises a base material and a modification layer arranged on the surface of the base material, wherein the modification layer contains amphiphilic polymers which are at least one of polyvinyl butyral, amphiphilic segmented copolymer and polyolefin with a functional end group, and the functional end group at least contains a hydrophilic group. The diaphragm has high electrolyte loving property and water loving property, so that the diffusion rate of electrolyte in a prepared lithium ion battery is high, infiltration time is shortened, and the charge-discharge rate of the battery is increased; besides, the standing time of a naked battery cell after injection can be shortened, and then efficiency is improved and cost is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

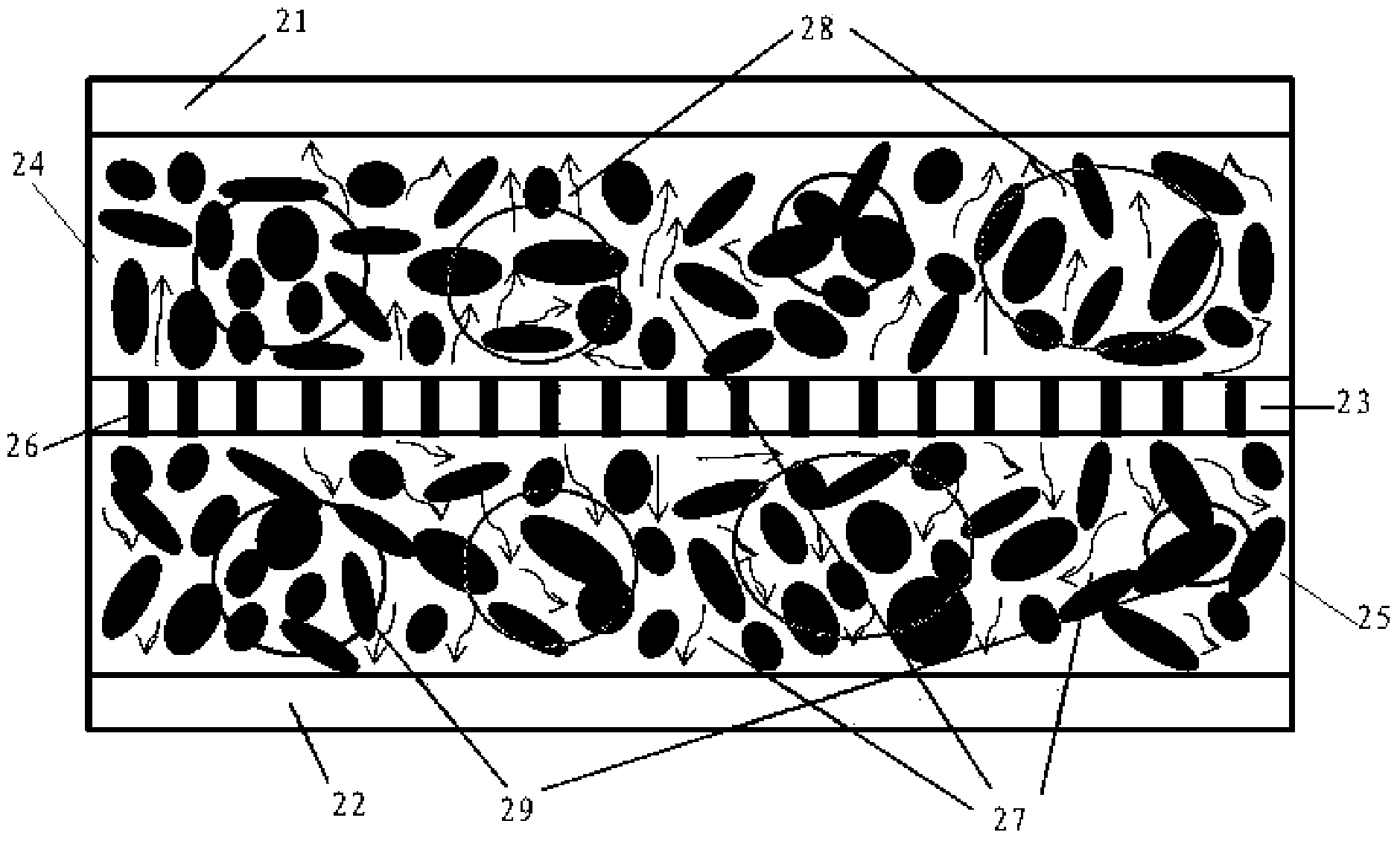

Method for wetting polymer lithium ion batteries

InactiveCN103721972AShorten the resting timeReduce production energy consumptionFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryLithium-ion battery

The invention belongs to the field of technologies for wetting batteries, and relates to a method for wetting polymer lithium ion batteries. The method is used for wetting the polymer lithium ion batteries by the aid of an ultrasonic cleaning device. The method particularly includes steps of enabling battery air bags filled with liquid to upwardly and vertically stand in a water tank of the ultrasonic cleaning device; filling pure water into the water tank and submerging pole groups of the batteries in the surface of the pure water under the control; heating the pure water under the control to enable the temperature of the pure water to range from 23 DEG C to 27 DEG C, enabling the frequencies of ultrasonic waves to range from 50KHz to 70KHz under the control, and ultrasonically wetting the polymer lithium ion batteries for 1.0-2.0 hours; taking the wetted batteries out of the water tank and drying the batteries by a hot air device. The method for ultrasonically wetting the polymer lithium ion batteries has the advantages that diffusion of organic electrolyte inside the batteries, particularly in gaps among pole pieces and diaphragms of the batteries, can be promoted by the aid of ultrasonic oscillation, wetting the insides, particularly the gaps among the pole pieces and the diaphragms, of the batteries by the organic electrolyte can be promoted by the aid of ultrasonic oscillation, accordingly, the standing time can be greatly shortened, and production energy consumption can be reduced; an effect which is identical to an effect realized by a conventional method for wetting polymer lithium ion batteries at high temperatures can be realized, the production cost can be reduced, and the production efficiency can be improved; the method is high in practicality and is applicable to wetting various models of batteries.

Owner:TIANJIN LISHEN BATTERY

Lithium ion battery pole piece and lithium ion battery comprising pole piece

ActiveCN103367702AImprove qualityExtended service lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryEngineering

The invention belongs to the technical field of lithium ion battery, and especially relates to a lithium ion battery pole piece. The pole piece comprises a current collector and an active substance layer arranged on the surface of the current collector. A plurality of protrusions and recesses are arranged on the active substance layer. Compared with prior art, According to the invention, the protrusions and recesses are arranged on the active substance layer, such that a pole piece with a unique convex-concave structure is formed. During the battery application process, when anode pole piece volume expansion occurs, the shape of a corresponding cathode pole piece is basically maintained, such that anode pole piece expansion can be limited and induced, such that anode pole piece expansion degree and irregularity can be reduced. Therefore, battery appearance deformation and subsequent battery performance deterioration caused by anode expansion can be effectively inhibited. Therefore, the pole piece has an important significance upon lithium ion battery quality and service life. Also, the invention discloses a lithium ion battery comprising the pole piece.

Owner:DONGGUAN AMPEREX TECH

Method for printing printed circuit board double sided characters

InactiveCN101670718AShort production processReduce consumptionOther printing apparatusScreen printingRoom temperature

The invention relates to a method for printing printed circuit board double sided characters. The technical points include that a printed circuit board printed with characters on one side is turned over to the other side and placed into another screen printer, a location pin is used for location and alignment of a screen printing plate and the printed circuit board, ink is poured onto the screen printing plate, a 70-80 degrees angle is kept between a scraper and the screen printing plate, the pressure of the scraper is 6-7.5kg / cm<2> for printing, thus characters on the other side are printed,the printed circuit board is taken out, standing is carried out for 15-30 minute, the printed circuit board is placed into an oven, heated to 145-160 DEG C and baked for 20-40 minutes, and the printedcircuit board is taken out, thus obtaining the printed circuit board printed with characters on double sides. The invention saves time of standing, baking and cooling to room temperature in first side of the printed circuit board, effectively improves labour productivity, reduces energy consumption and labor intensity of workers and has the characteristics of simple printing process and high production efficiency.

Owner:BOMIN ELECTRONICS CO LTD

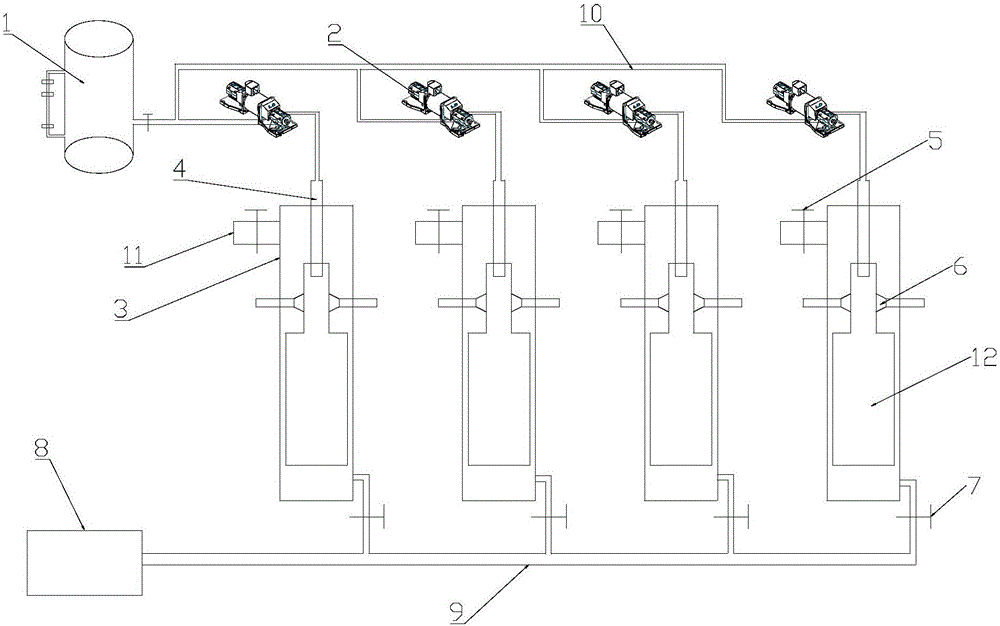

Liquid injection device and liquid injection method of polymer lithium battery electrolyte

The invention provides a liquid injection device and a liquid injection method of polymer lithium battery electrolyte. The liquid injection device comprises a plurality of vacuum liquid injection chambers; the bottom of each vacuum liquid injection chamber is connected with a vacuum pipeline, and the other end of the vacuum pipeline is connected with a vacuum pump; the top of each vacuum liquid injection chamber is connected with a liquid injection pipeline; each branch end, inserted into a corresponding vacuum liquid injection chamber, of the liquid injection pipeline is fixedly provided with a liquid injection needle, and the other main end of the liquid injection pipeline is connected with a liquid storage chamber; a liquid injection pump is arranged on each branch pipeline used for connecting the liquid storage chamber with the corresponding vacuum liquid injection chamber; a plurality of vacuum chucks are arranged in each vacuum liquid injection chamber; combination of the vacuum chucks is capable of opening gas bags of batteries, and the liquid injection needles are inserted into the gas bags for injection; and the chamber wall of each vacuum liquid injection chamber is connected with a pressure releasing channel. The liquid injection device and the liquid injection method are capable of accelerating wetting velocity of positive and negative plates and diaphragm by electrolyte in liquid injection process, and increasing production capacity.

Owner:捷威动力工业江苏有限公司

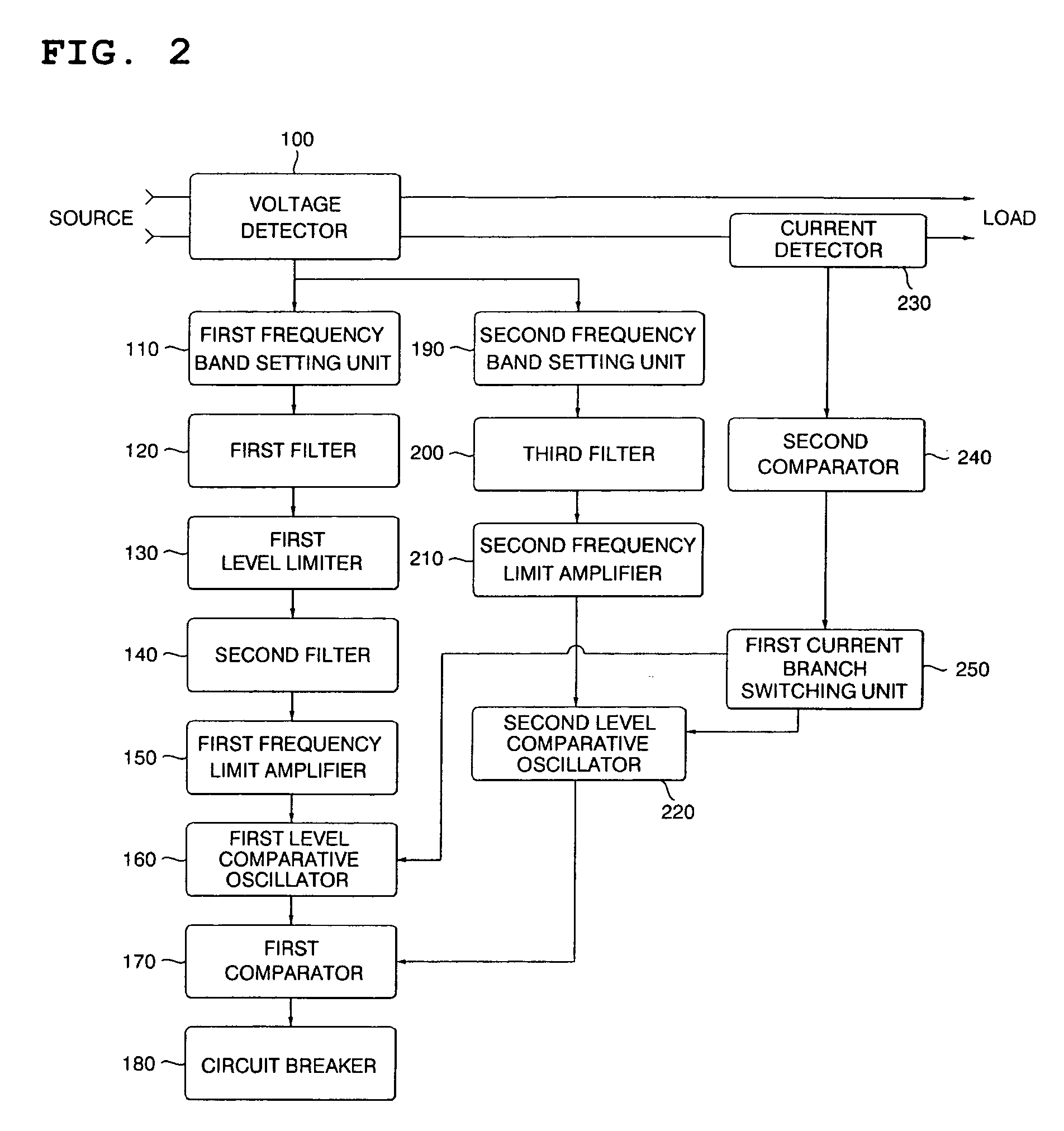

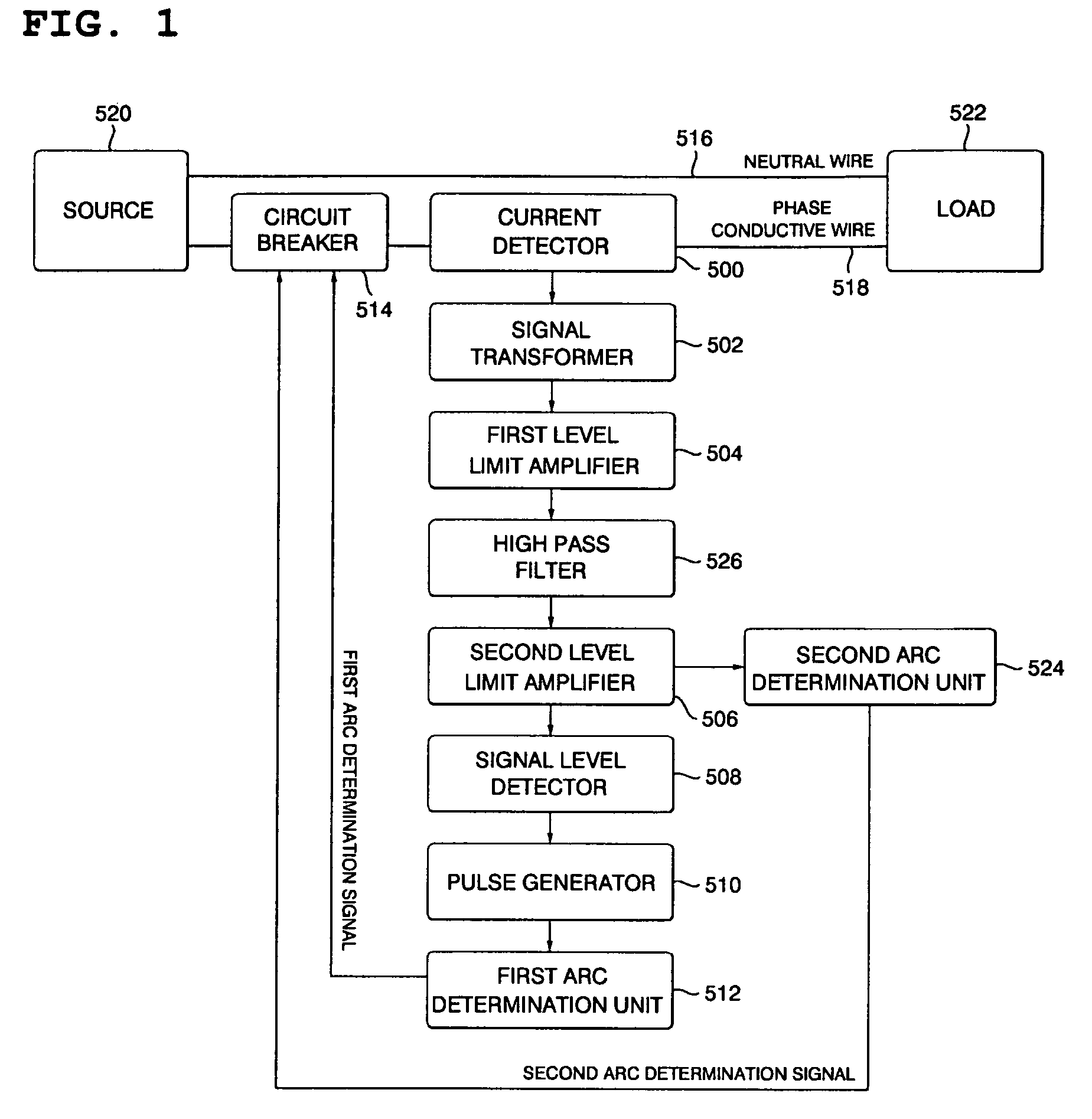

Apparatus for detecting arc fault

InactiveUS7443640B2Reduce the risk of fireShorten the resting timeTesting dielectric strengthEmergency protective arrangement detailsEngineeringComparator

Disclosed herein is an apparatus for detecting an arc fault, which prevents a malfunction caused by a conventional current detecting method by detecting a source voltage applied onto a conductive wire to determine whether there is an arc fault, prevents a malfunction with respect to a pseudo arc signal by dividing a current detecting route into two according to the magnitude of a load current occurring onto the conductive wire to determine whether there is the arc fault by voltage detection, and lessens the danger of a fire by reducing a circuit break time according to the magnitude of the load current. A voltage detector detects the arc fault by use of two detecting routes. Each route differs in a filtering value of a filter, presence / absence of level limit, an amplification factor of an amplifier, an accumulation value of a comparator, etc. according to the magnitude of a load current occurring on a conductive wire, thereby reducing a circuit break time.

Owner:SUNG SAM KYOUNG

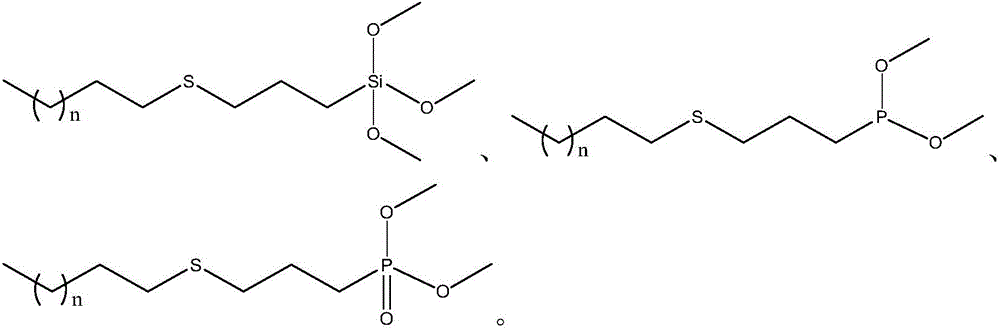

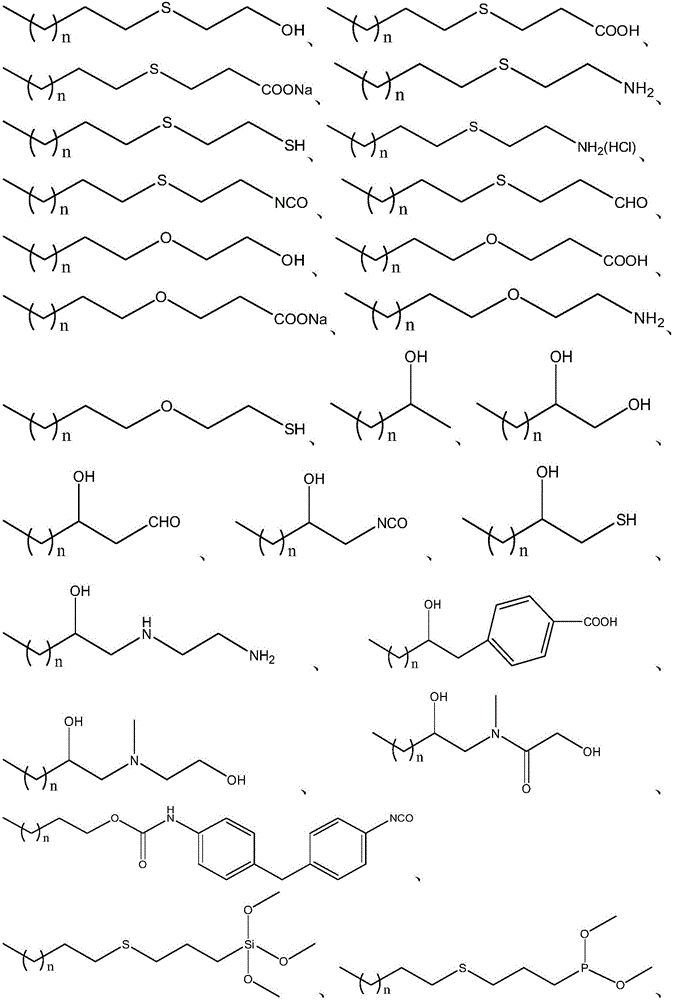

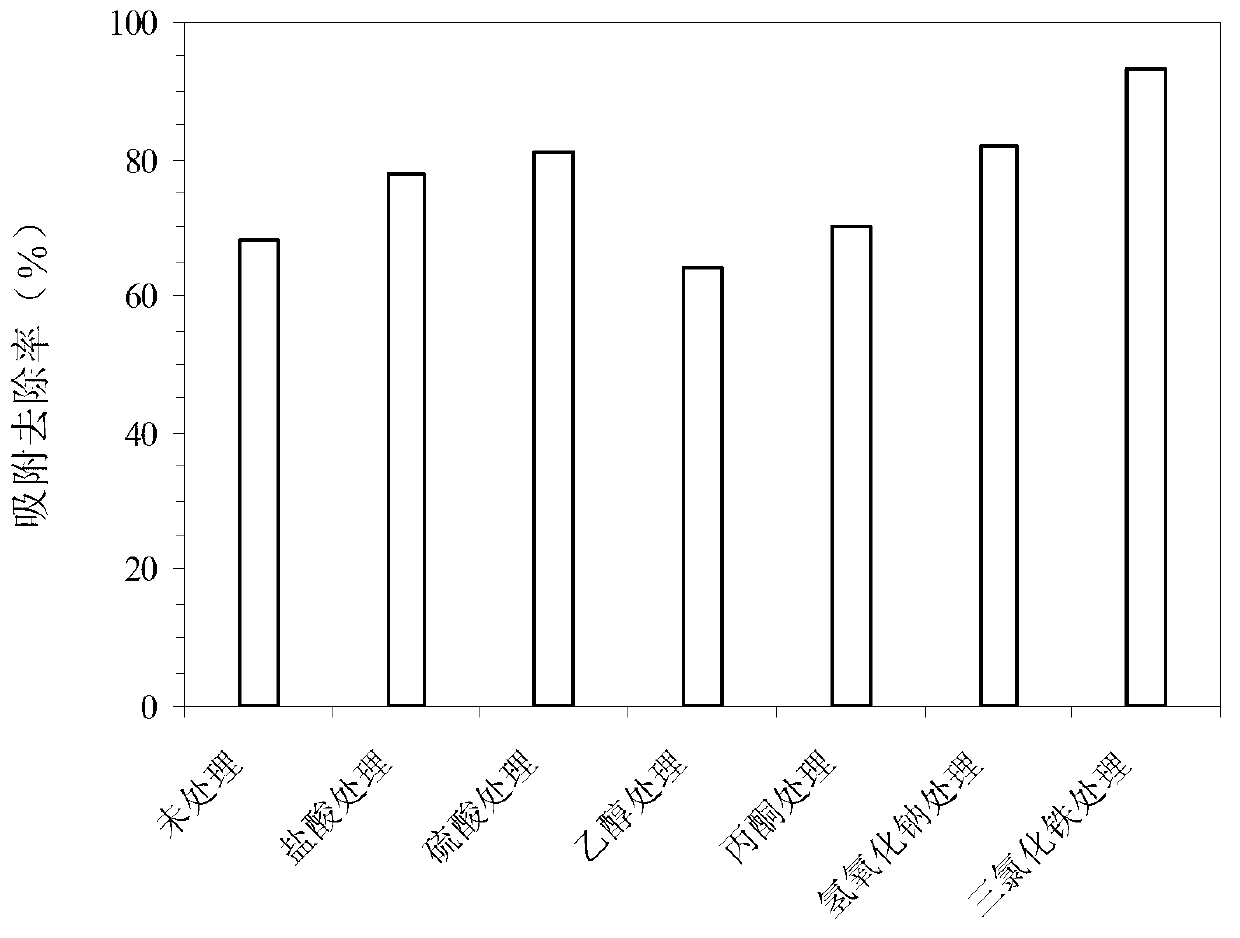

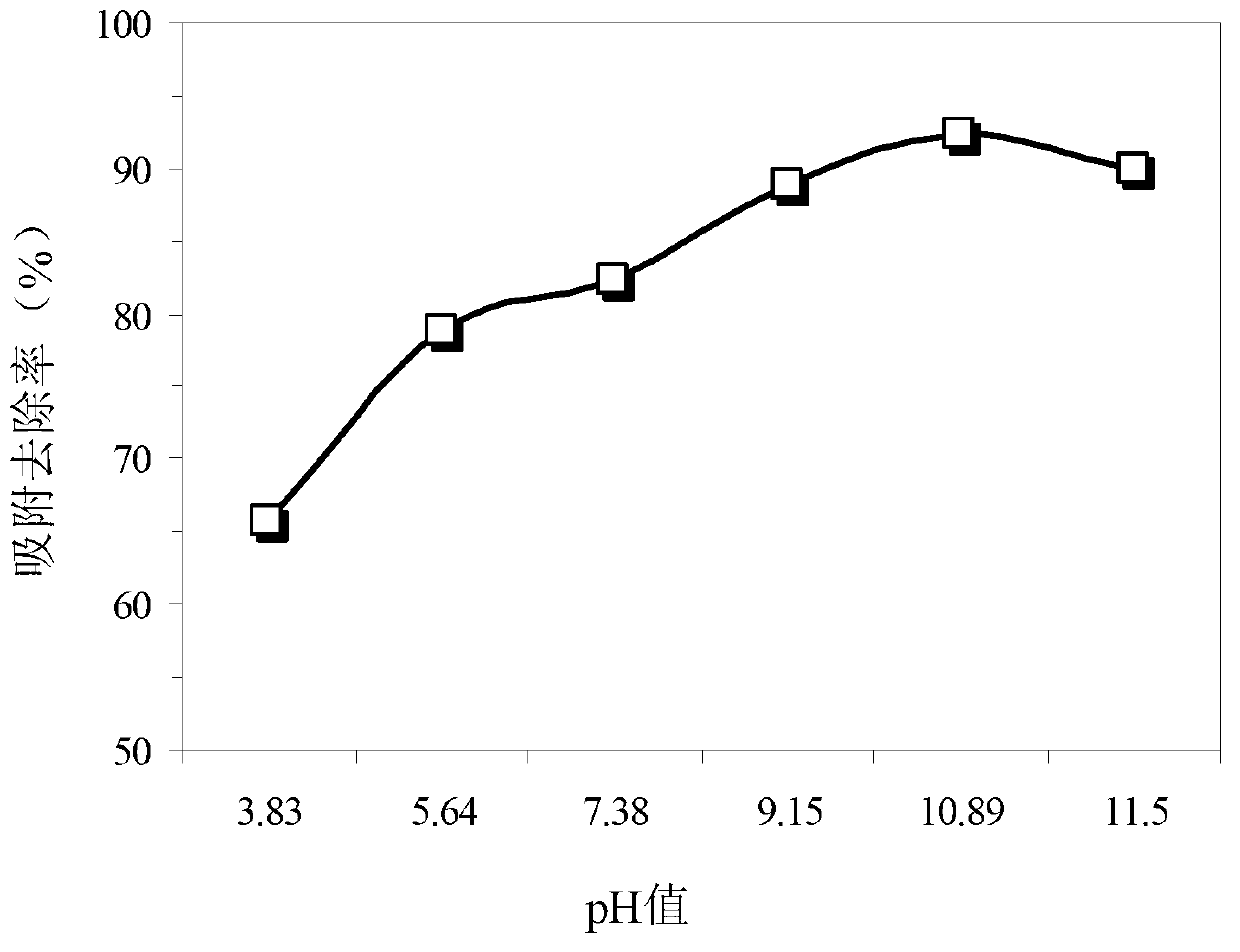

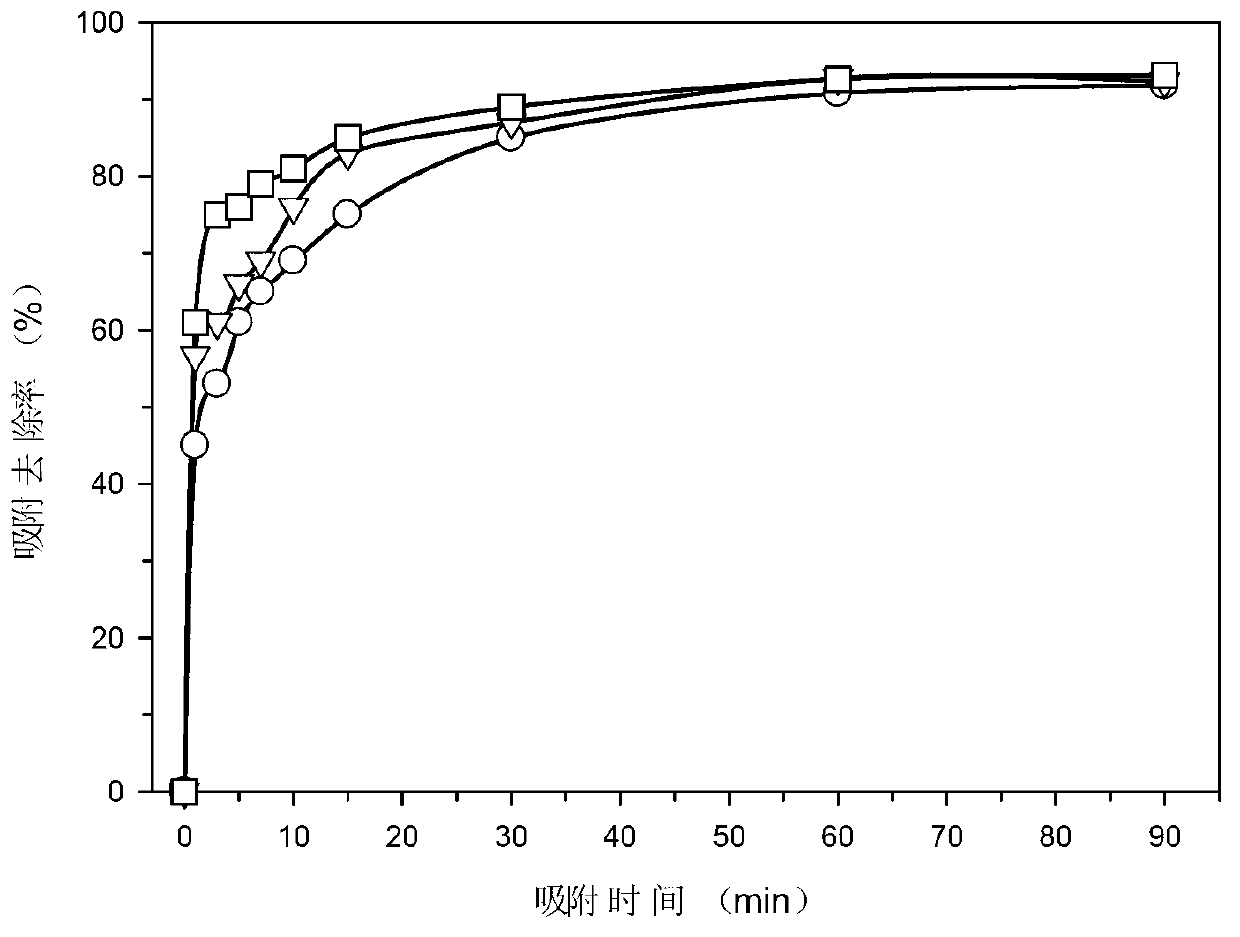

Method for treatment of low-concentration mercury containing wastewater by utilizing modified pelelith

InactiveCN103121730ASmall particle sizeCost advantageOther chemical processesSilicon compoundsSorbentWastewater

The invention discloses a method for the treatment of low-concentration mercury containing wastewater by utilizing modified pelelith. The method comprises the following steps: (1) crushing the pelelith, putting the pelelith into a prepared traditional adsorbent solution for modification and filtering and drying, thereby obtaining a pelelith adsorbent; (2) treating the mercury containing wastewater by utilizing the pelelith adsorbent; and (3) detecting the wastewater and discharging the detection-qualified wastewater. As the method for the treatment of the mercury containing wastewater by utilizing the modified pelelith adsorbent is used, on the basis of controlling the cost, the problem that the mercury content in the low-concentration mercury containing wastewater exceeds the specified standard is solved. The method is low in cost, simple in equipment, simple and convenient to operate, short in treatment period, time-saving, labor-saving, environment-friendly and free of pollution in treatment process and good in treatment effect. In addition, the pelelith adsorbent can be repeatedly recycled for multiple times.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Lithium ion battery pole piece processing method

InactiveCN102694144AHigh surface energyImprove wettabilityElectrode manufacturing processesSurface energyCurrent collector

The invention belongs to the technical field of lithium ion batteries and particularly relates to a lithium ion battery pole piece processing method. A pole piece comprises a current collector and a membrane arranged on the surface of the current collector, and the pole piece is subjected to corona treatment after cold-pressing process of the pole piece and before reeling or laminating process of a battery cell. Compared with the prior art, as the single sides or both sides of both a cathodal pole piece and an anodal pole piece are subjected to corona treatment, the surface energy of the pole pieces can be increased, generation of a hydrophilic atom set or functional group on the surfaces of the pole pieces is promoted, and accordingly, the purposes of improving the wettability of an electrolyte to the pole pieces and improving the imbibition performance of the battery cell are achieved. Therefore, the stewing time after liquid charging and before formation is shortened, the production period of a battery is shortened, and the manufacturing cost is lowered eventually; a stable solid electrolyte interphase (SEI) interface can be formed in the formation procedure, so that the performance of the battery cell is ensured; and the liquid rise of the battery cell is reduced, products with damaged appearance are reduced and the product acceptance rate is improved.

Owner:DONGGUAN AMPEREX TECH +1

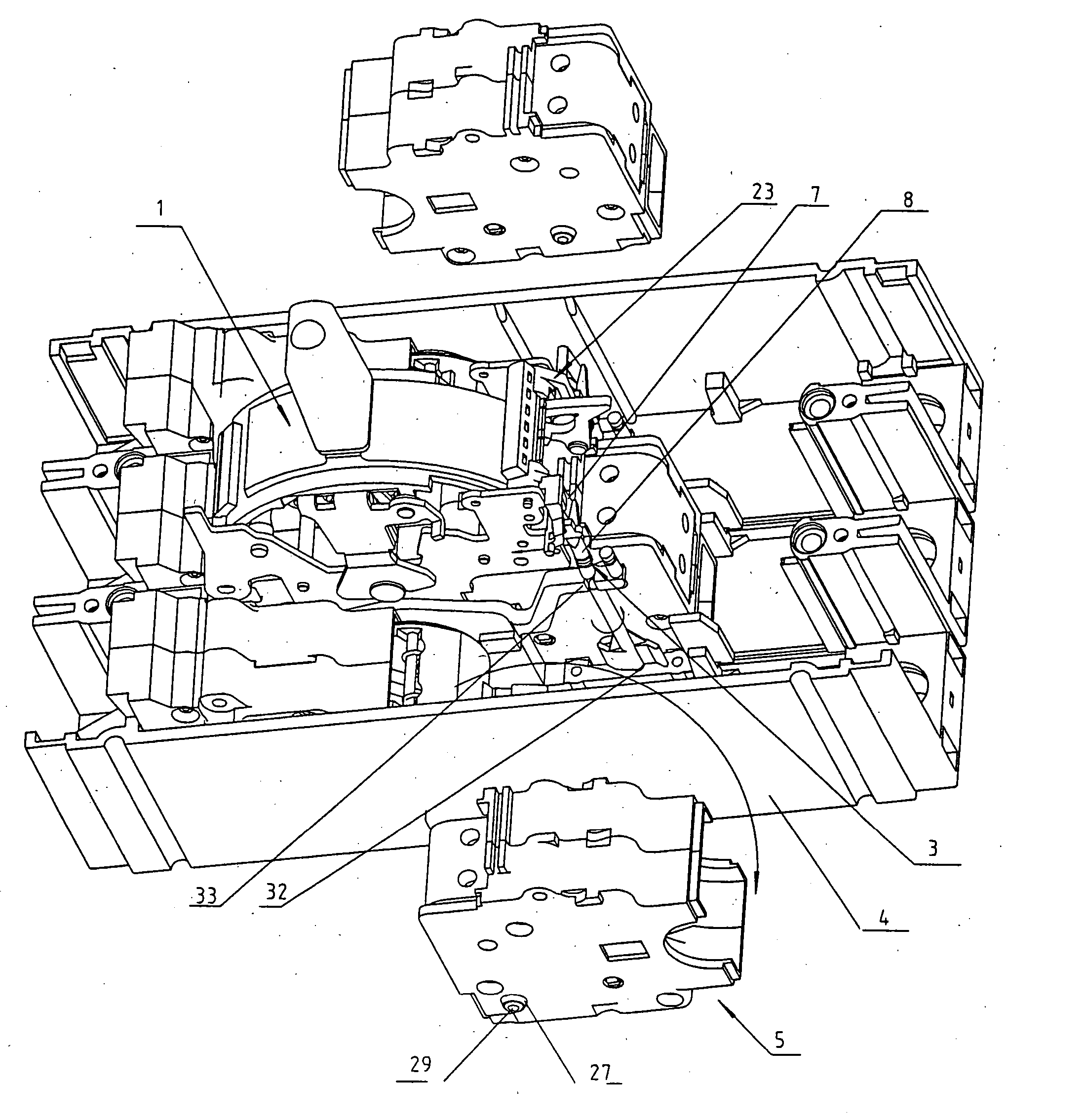

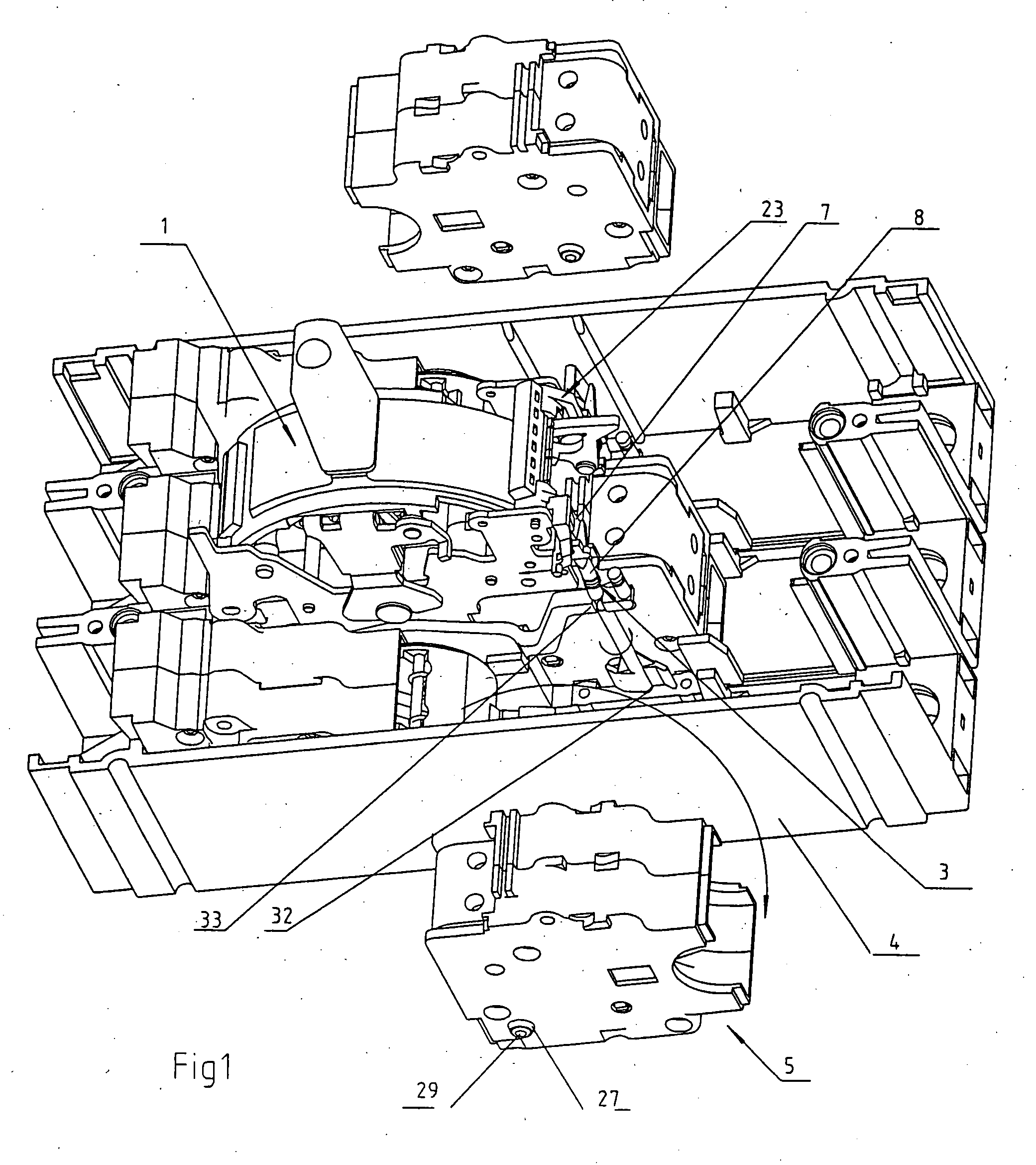

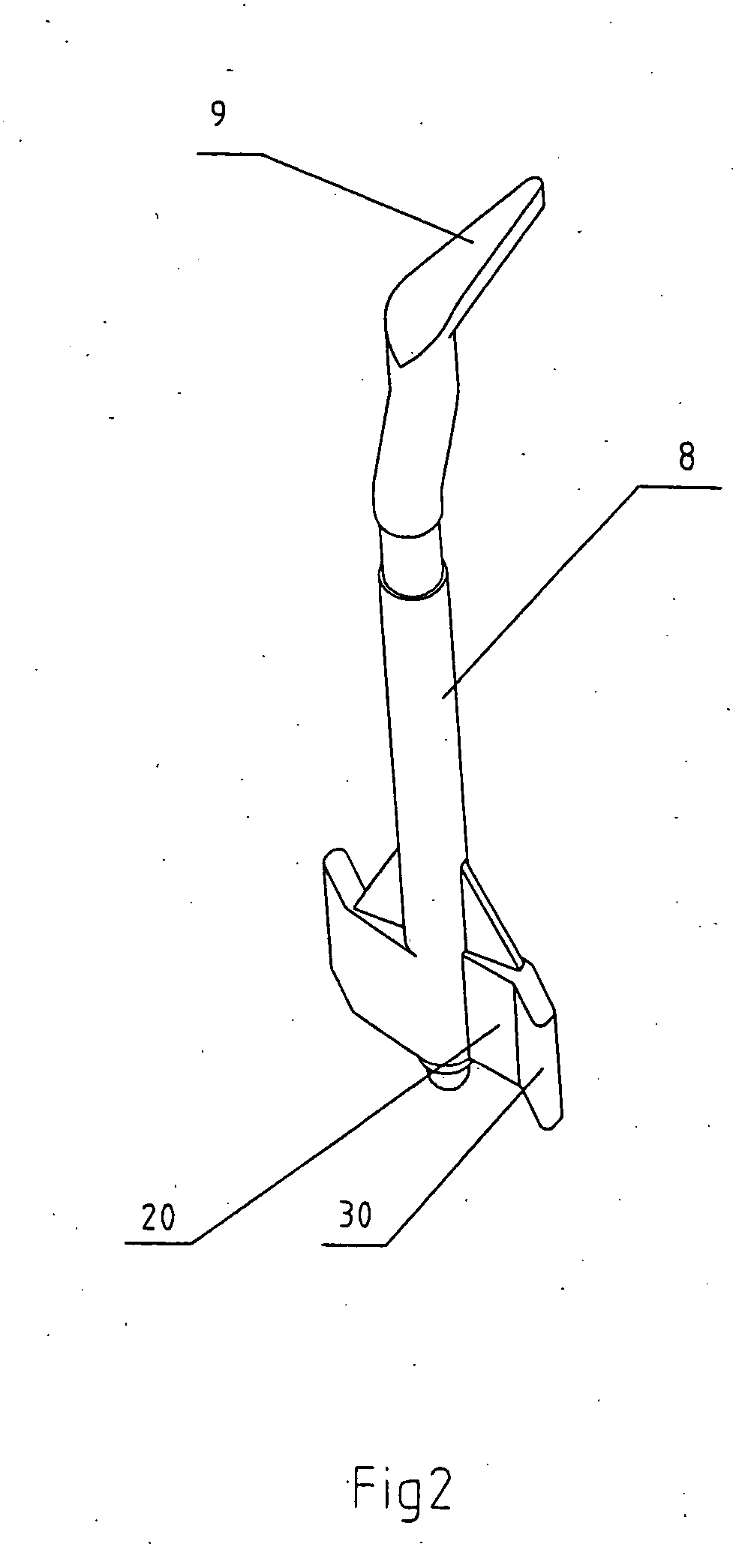

Low-voltage circuit breaker with a capability of tripping quickly

InactiveUS20050151607A1Current is limitedImprove abilitiesGearingCircuit-breaking switch detailsLow voltage circuitsEngineering

This invention discloses a low-voltage circuit breaker with a capability of tripping quickly. Its main feature is that at least one of the side faces of the contact device provides an open flange which has an internal through hole, and the bottom of a rotating shaft disposed on the bottom part provides a stressed member. The stressed member receives the over-pressure airflow escaping from the open flange of the contact device to generate a force. The force is passed to the activating member by the rotating shaft and is magnified, then hits the latch quickly and makes a trip. An intermediate step is bypassed due to the force produced earlier, the force which is produced by the electromagnetism part in the heat energy and electromagnetic system, so that the low-voltage breaker can open quickly and reduces opening time greatly and improve the breaking capability.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

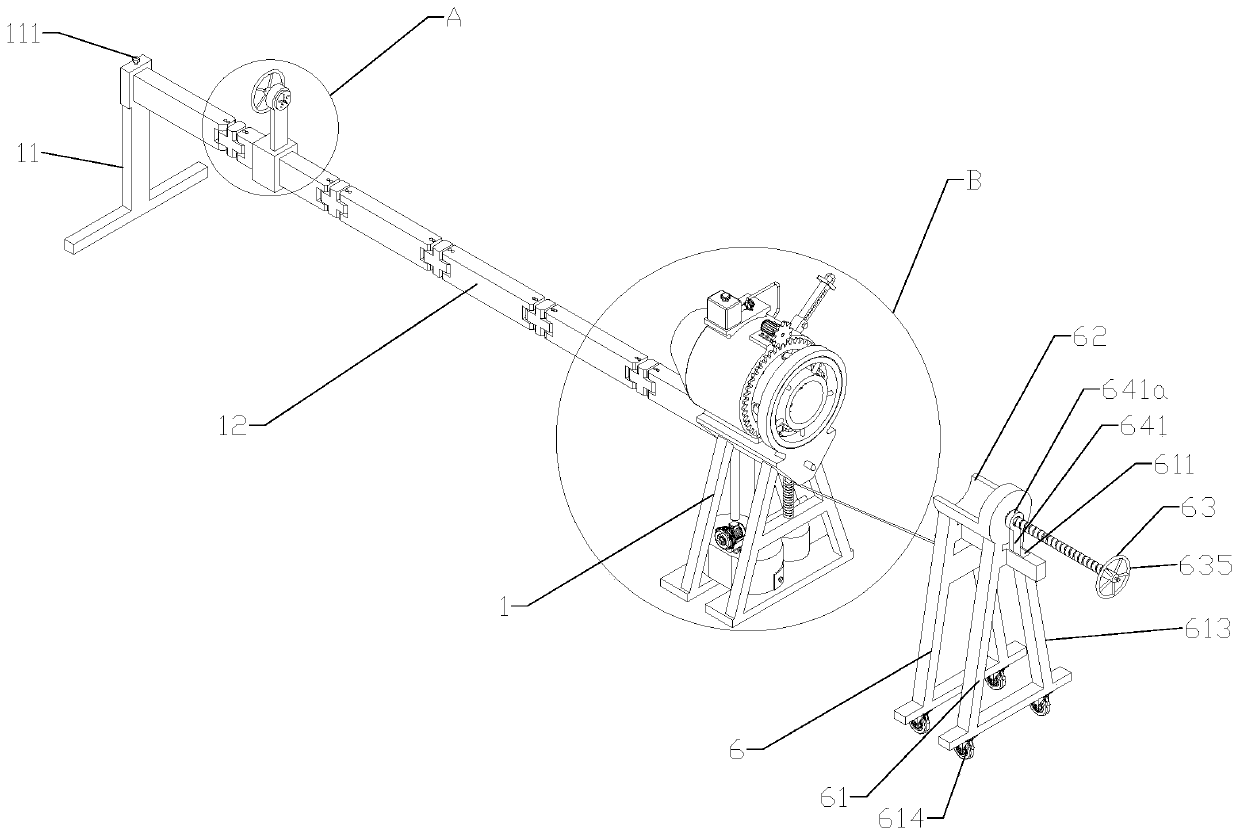

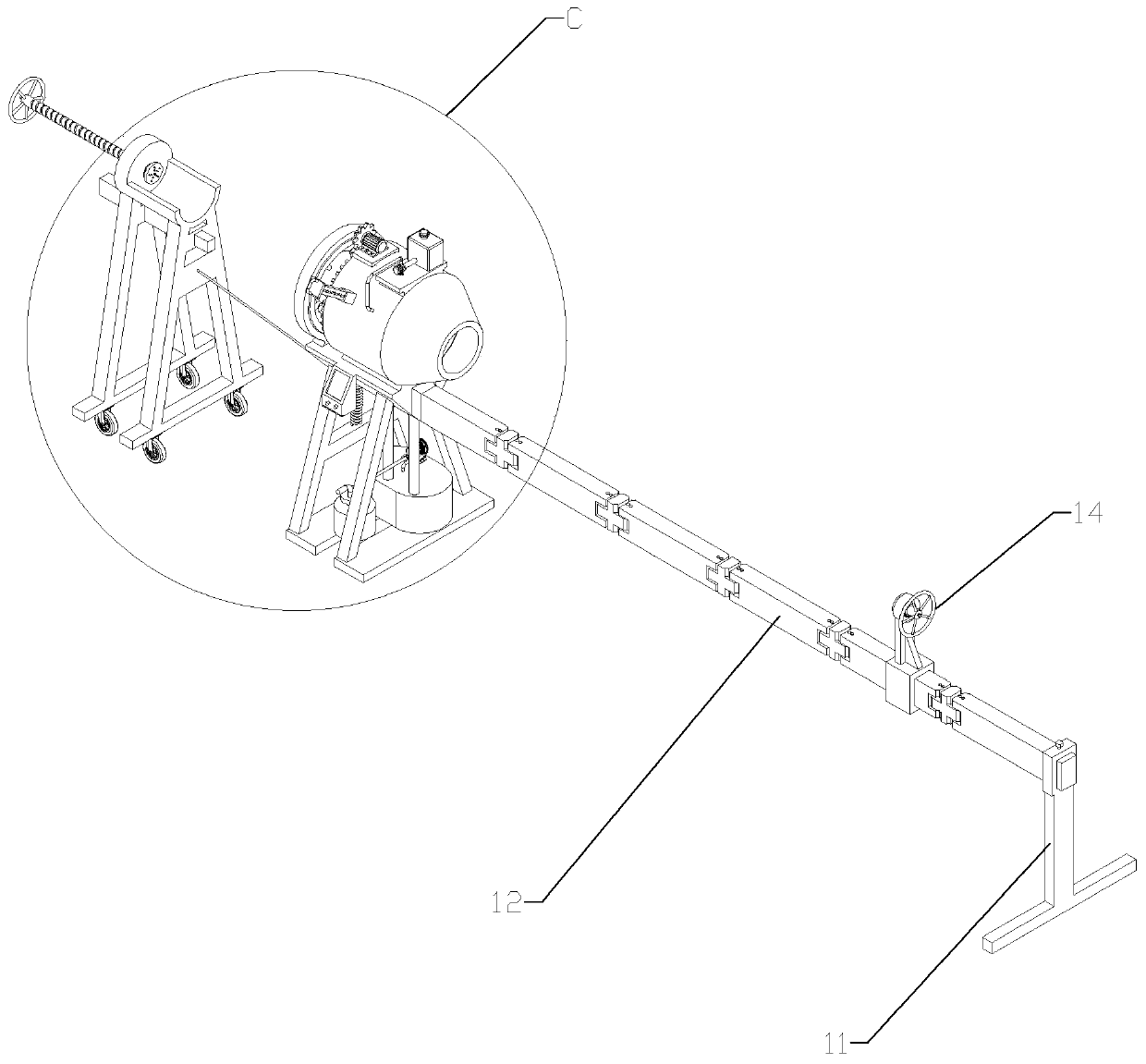

Paint spraying equipment

ActiveCN111250325AEasy to drySave drying spaceGrinding drivesBelt grinding machinesBattenSupport plane

The invention discloses paint spraying equipment. The paint spraying equipment comprises a first supporting frame and a second supporting frame, wherein the first supporting frame sequentially comprises a front supporting leg, a folding rod and a rear supporting leg from front to back; a batten front end clamping device is slidably arranged on the folding rod; and the upper end of the rear supporting leg is connected with a fixing seat, a barrel with opens at front and rear is fixed to the fixing seat, and a clamping mechanism, a grinding device, a paint spraying device and a drying device aresequentially arranged in the barrel from back to front. The paint spraying equipment has the characteristics of preventing paint from accumulating to the bottom end, automatically grinding and preventing pollution.

Owner:TAICANG CITY LVDIAN INFORMATION TECH CO LTD

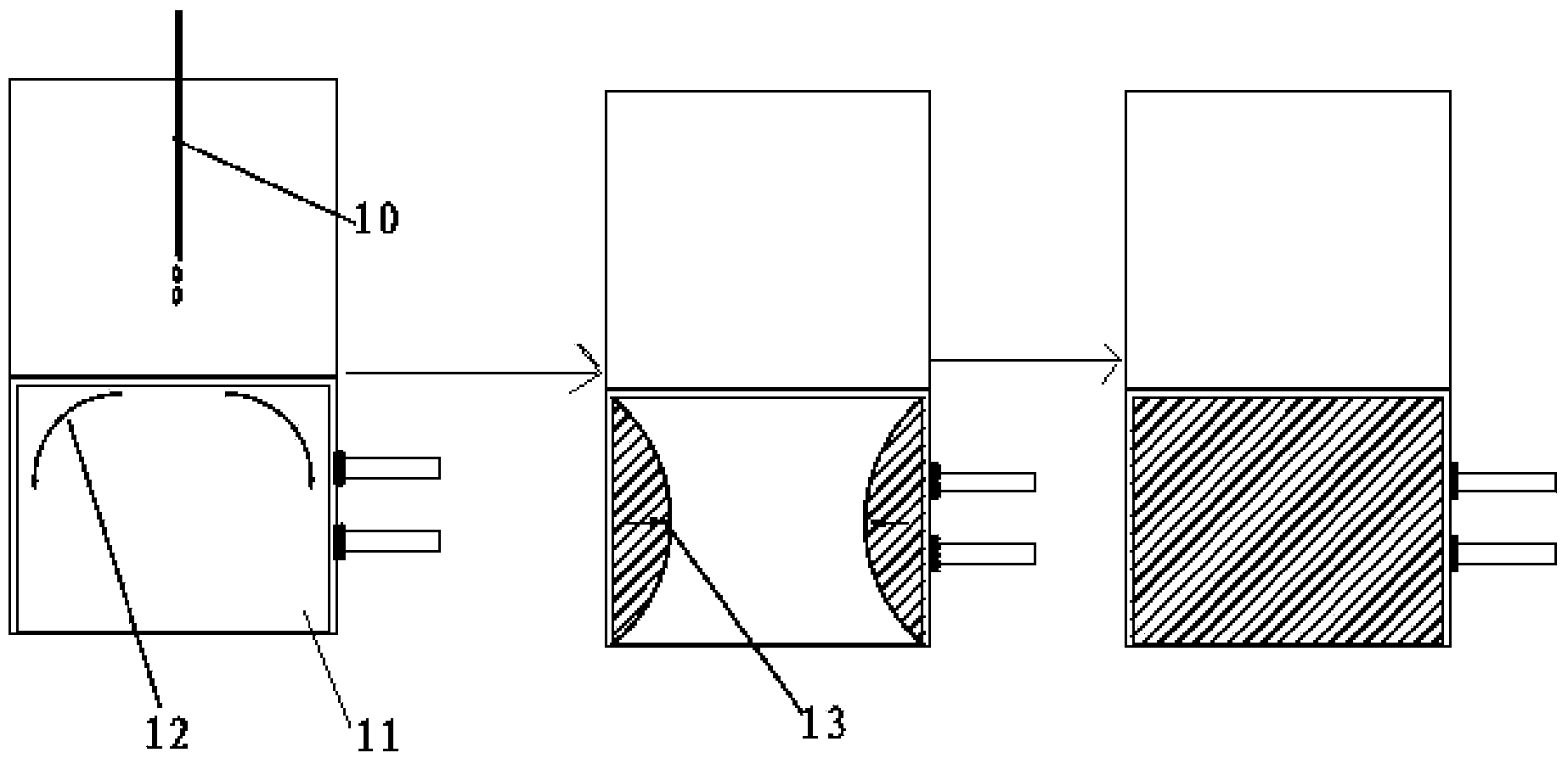

Method for preparing magnesium alloy solder

InactiveCN102071337AEvenly distributedReduce in quantityWelding/cutting media/materialsSoldering mediaSlagLiquid surfaces

The invention discloses a method for preparing a magnesium alloy solder, which comprises the following steps of: preheating a crucible or a smelting furnace, spreading a covering agent, and heating an alloy ingot in protective atmosphere to the temperature which is 50 to 150 DEG C higher than the prepared solder liquid phase line; melting the alloy ingot, collecting slag, and stirring; applying ultrasonic waves to the melted magnesium alloy solder by adopting an ultrasonic generator, namely inserting a preheated ultrasonic rod to a position 5 to 50mm lower than the liquid surface of the melted magnesium alloy solder, wherein the difference between the preheating temperature of the ultrasonic rod and the melting temperature of the solder does not exceed 20 DEG C, the frequency of the ultrasonic waves is 18 to 22kHz, the intensity of the ultrasonic waves is 0.5 to 5W / cm<2> and the time is 0 to 150 seconds; moving the ultrasonic rod out, and standing alloy melt; and injecting the melted solder into a stainless steel mold, and cooling to room temperature to obtain the solder. Alloy elements, particularly microalloy elements are uniformly distributed, the crystals are fine, the toughness is improved, and the shearing strength of brazing lap joints is improved by 5 to 20 percent.

Owner:BEIJING UNIV OF TECH

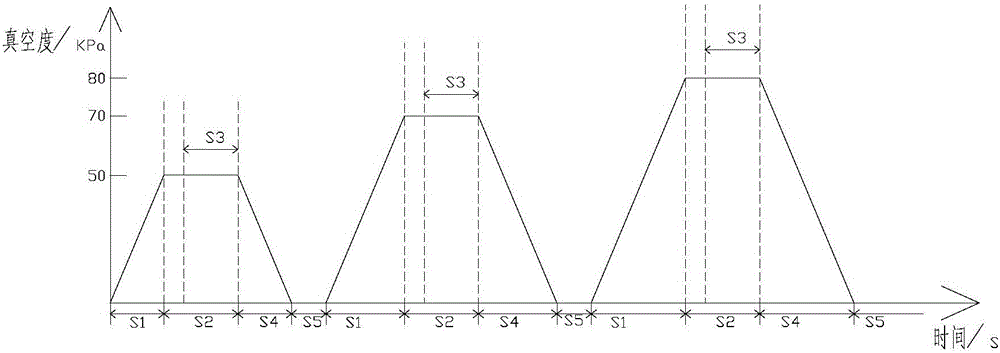

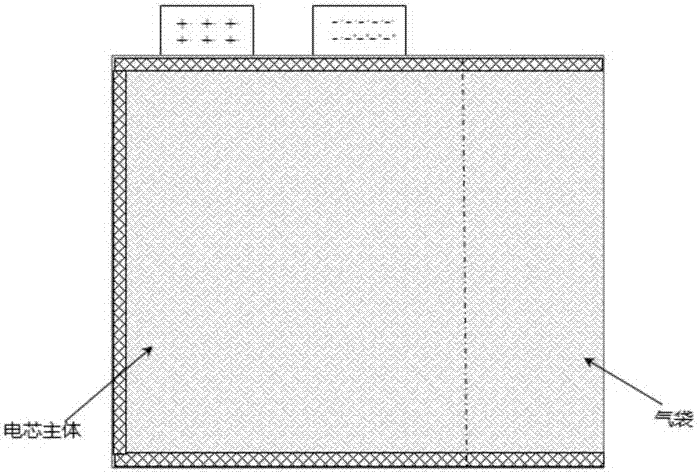

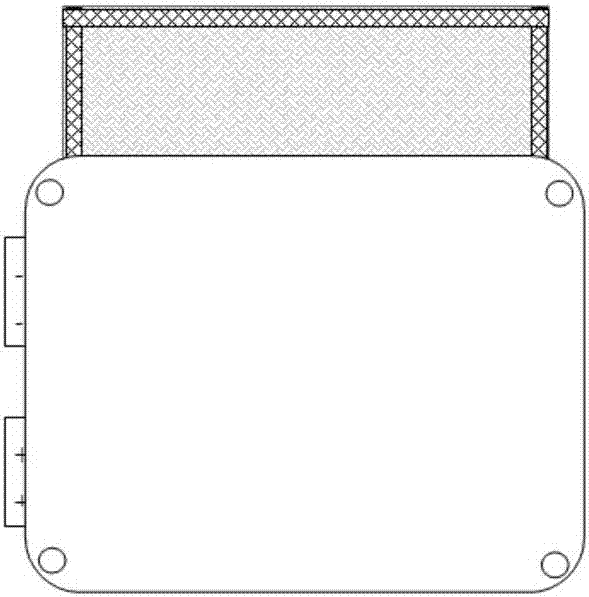

Standing method for soft package lamination lithium ion power battery after liquid injection

InactiveCN107546419ARealize mass productionEvenly distributedFinal product manufactureCell component detailsPower batteryLithium

The invention provides a standing method for a soft package lamination lithium ion power battery after liquid injection. The standing method comprises the following steps of S1, allowing a battery cell after being liquid-injected and pre-sealed to vertically stand for a certain time; S2, vertically fixing the battery cell between two clamping plates, making the battery cell stand for a certain time, and processing the battery cell with intermittent ultrasonic waves during the period, wherein pressure applied to the battery cell by the clamping plates is (0.06-0.09) MPa; S3, adjusting the pressure of a surface of the battery cell to (0.15-0.18) MPa after the standing of the step S2 is ended, and performing high-temperature pre-charging; and S4, reducing the pressure of the surface of the battery cell to (0.05-0.08) MPa after pre-charging is completed, and allowing the battery to stand under a high temperature for a certain time. According to the standing method for the soft package lamination lithium ion power battery after liquid injection, an electrolyte can be uniformly distributed in the battery cell when the clamping plates act on a cell pack main body, and the electrolyte canenter the core pack from different parts; and with the adoption of vertical standing, the standing method is efficient and convenient, and the mass production of the battery cell can be achieved.

Owner:TIANJIN ENERGIES

Positive plate, positive plate and solid-state battery

ActiveCN112670483AIncrease the number of transfersIncreased diffusion rateElectrode manufacturing processesFinal product manufactureMetallic lithiumElectrical battery

The invention provides a positive plate, a positive plate and a solid-state battery. Raw material components for preparing the positive plate comprise 60%-98% of an active electrode material, 1%-15% of an electronic conductive agent, 0.2%-10% of an auxiliary agent and 0.8%-15% of an ionic conductive agent. And the positive plate is formed by compounding a positive plate and a current collector layer by adopting hot rolling. The solid-state battery is formed by assembling a positive electrode plate layer formed by positive electrode plates, a solid-state electrolyte layer and a negative electrode plate laminated sheet formed by a metal lithium negative electrode in sequence. The positive plate has low porosity; by adopting the active electrode material, the ion conductive agent, the auxiliary agent and the like, the migration number and diffusion rate of lithium ions can be improved, and the conductivity and battery rate are improved; according to the preparation process, a solvent-free dry process is adopted, so the interface contact impedance in the solid-state battery is effectively reduced, an integrated electrode with an electron and ion conductive network is constructed, integrated forming of the solid-state electrolyte of the electrode is realized, and industrialization of the solid-state battery is promoted to be realized as early as possible.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

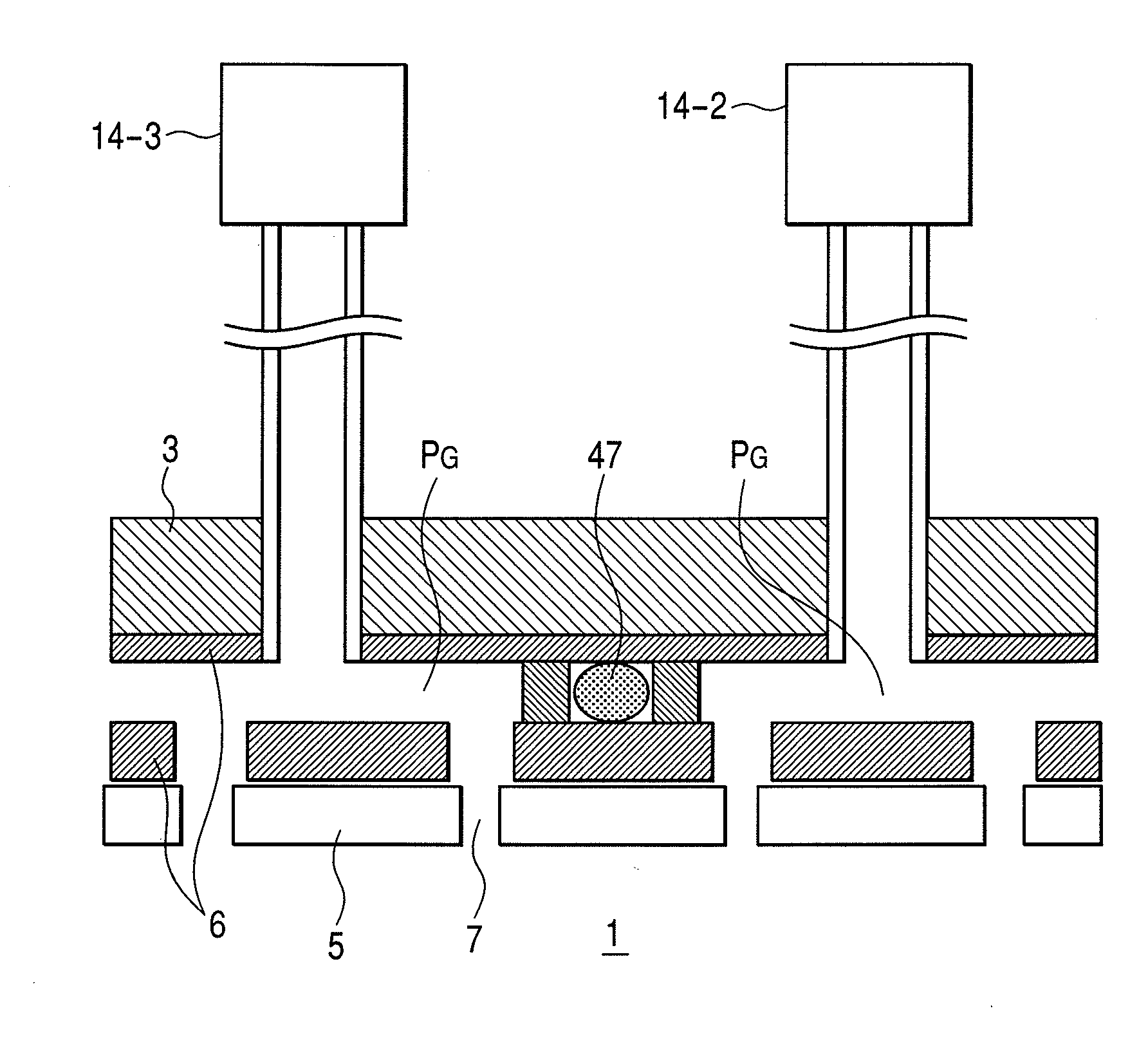

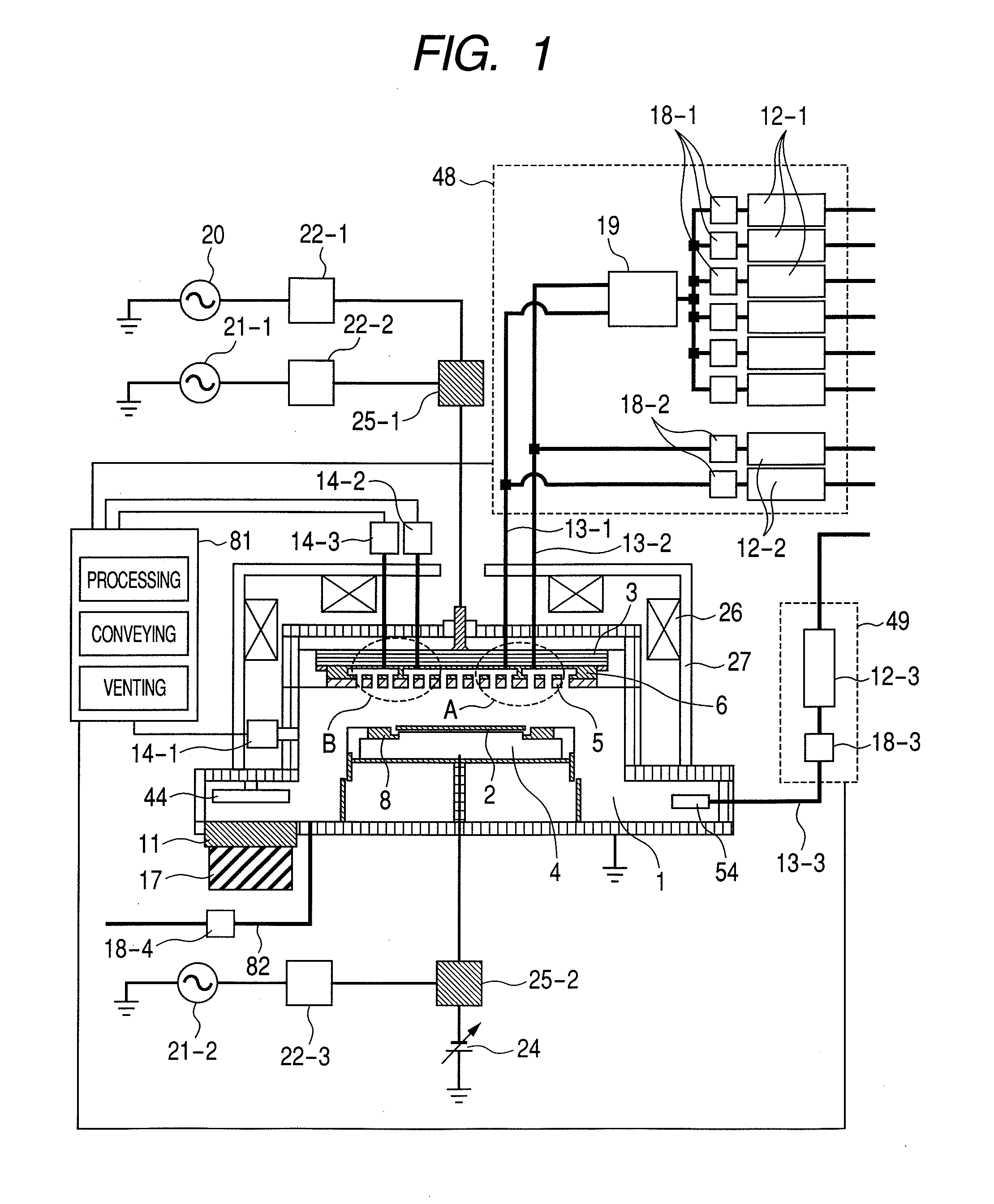

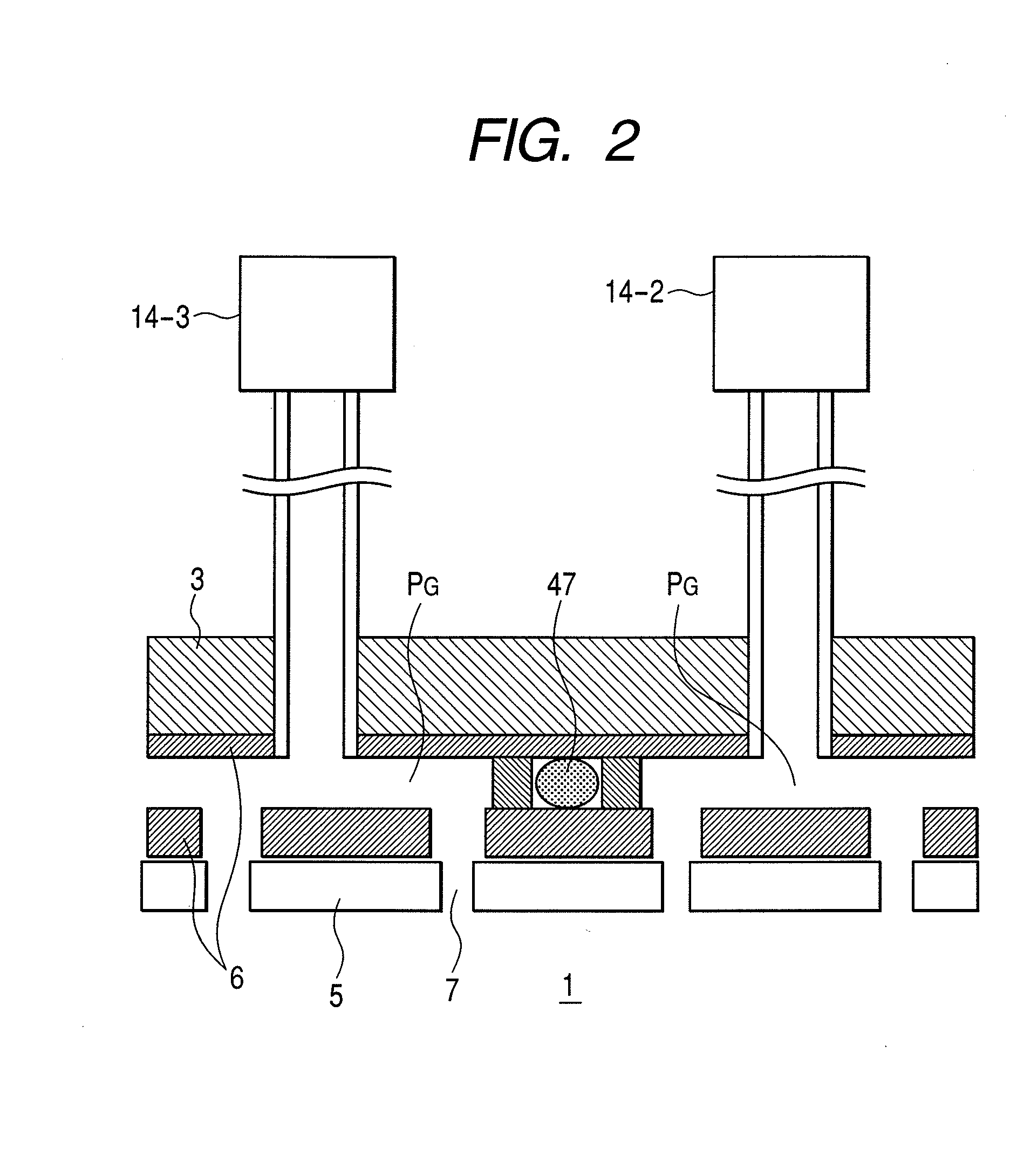

Plasma Processing Apparatus and Method for Venting the Same to Atmosphere

ActiveUS20090183683A1Shorten the resting timeImprove productivityLiquid surface applicatorsSemiconductor/solid-state device manufacturingPositive pressureEngineering

In a plasma processing apparatus provided with control means, gas supply means includes a first gas supply path for supplying a vent gas into a processing chamber by way of a shower plate and a second gas supply path for supplying a vent gas into the processing chamber without via the shower plate, and the control means is capable of adjusting a flow rate of the vent gas of at least one of the first and second gas supply paths in such a manner that a pressure on a back side of the shower plate becomes a pressure that is a positive pressure relative to a pressure in the processing chamber and less than a withstand pressure of the shower plate.

Owner:HITACHI HIGH-TECH CORP

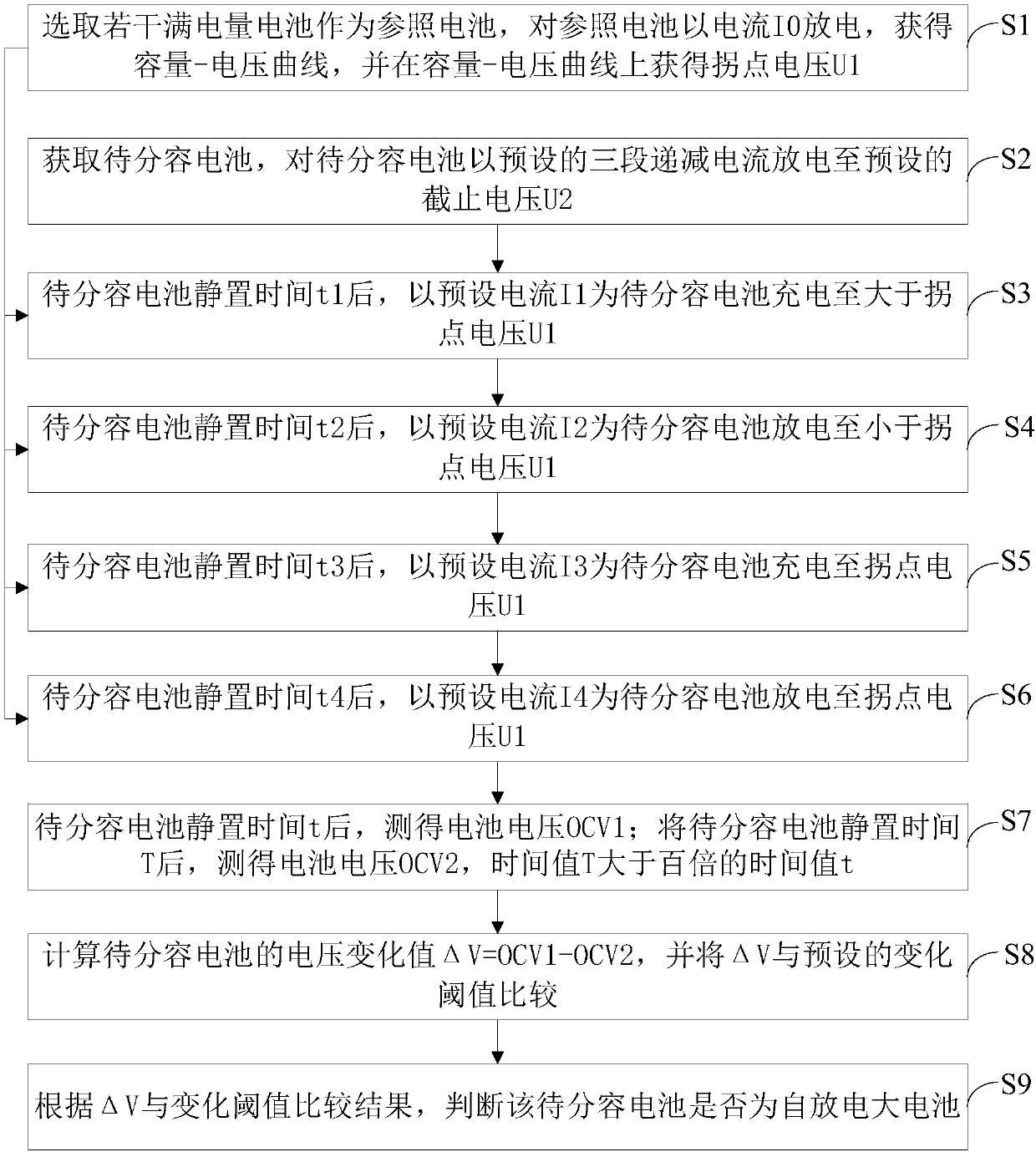

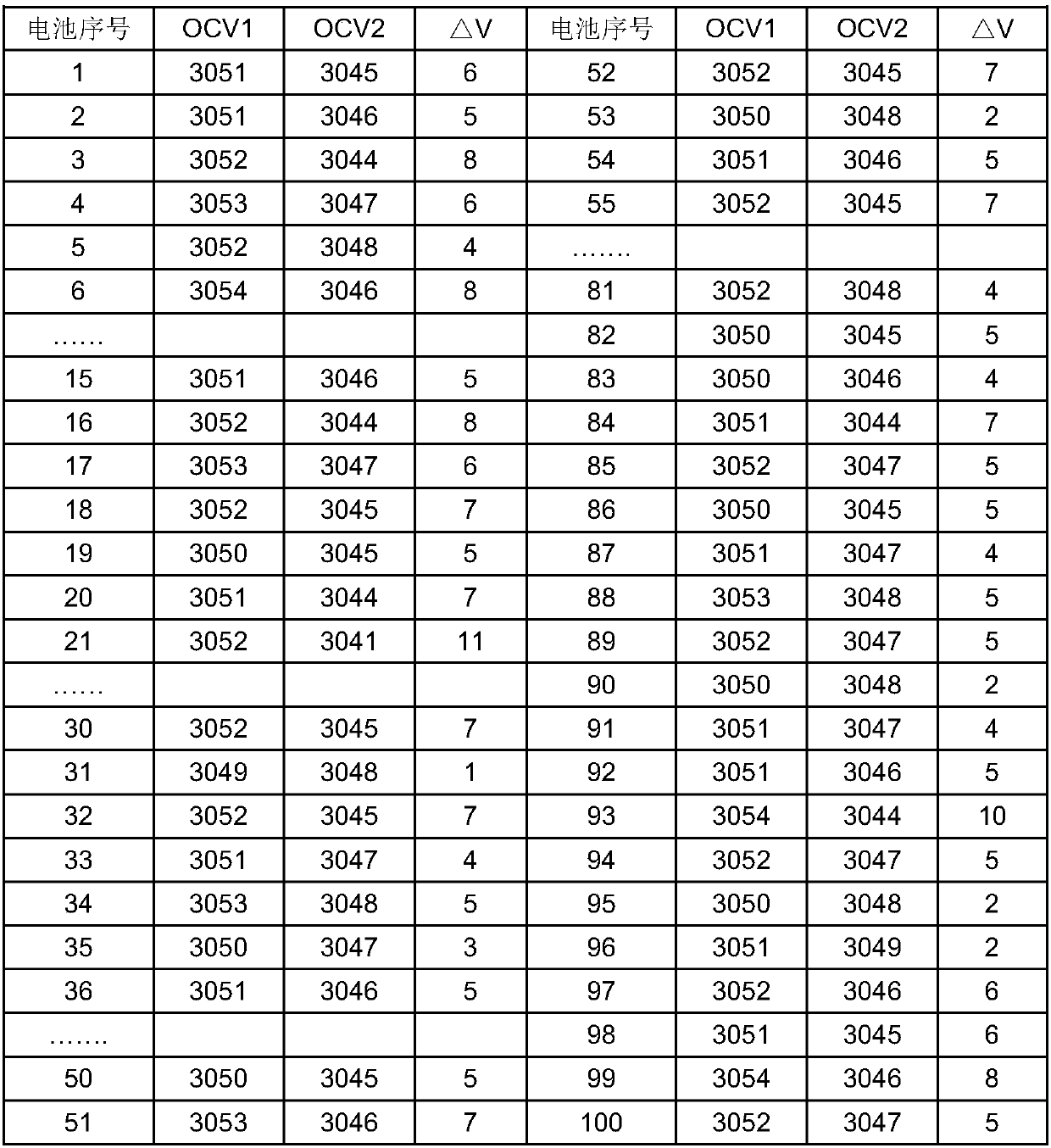

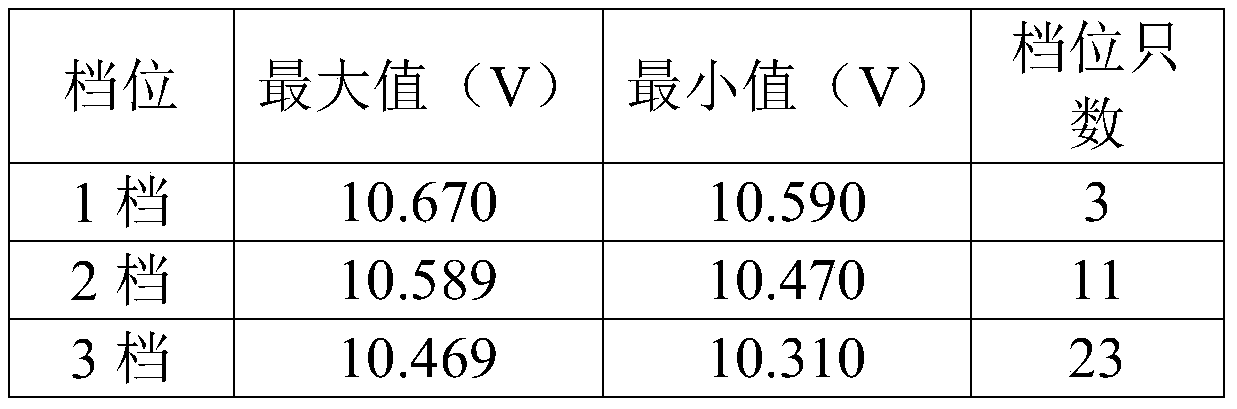

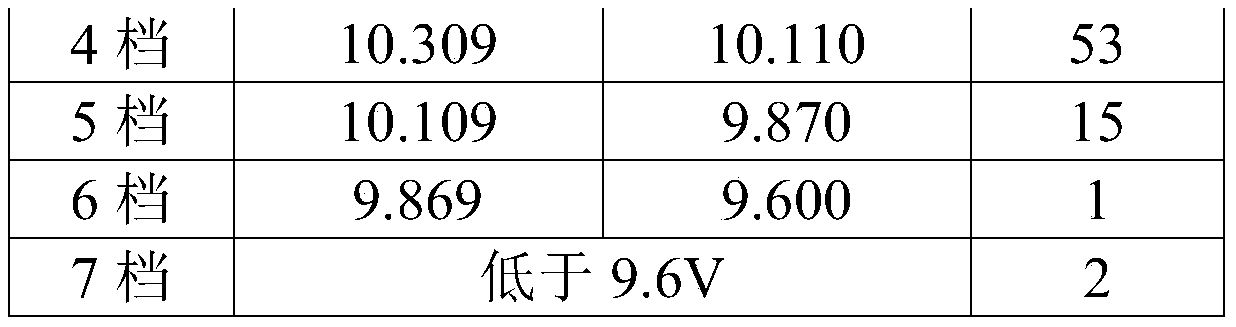

Lithium iron phosphate battery auto-discharge screening method

ActiveCN107561449AShorten the production cycleShorten the resting timeElectrical testingLow voltageElectrical battery

The invention discloses a lithium iron phosphate battery auto-discharge screening method. First, batteries are selected, and the voltage sudden change points of the batteries in the low-voltage stateare determined through low-current discharge. A produced battery is discharged at three currents decreasing gradually to a preset cutoff voltage, and is then charged and discharged at a low current within a narrow voltage range, in order to eliminate battery polarization to the greatest extent, make the final real voltage a sudden change voltage, and increase the accuracy of auto-discharge screening based on voltage drop. Through the method, whether a lithium iron phosphate battery meets the requirements can be determined in a short time, the production cycle of lithium batteries can be shortened, judgment is accurate, zero error can be basically guaranteed, the standing time of batteries can be shortened, and the supply rate can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for injecting liquid into a battery

InactiveCN109273663AIncrease chance of contactIncrease the rate of wetting the pole pieceCell component detailsElectrolytic agentElectrical battery

A method for injecting liquid into a battery is provided. The method comprises the following steps: (1) injecting an electrolyte into a battery to be treated to obtain an inject battery, performing negative pressure static pretreatment on that injected battery, performing positive pressure static pretreatment after exhaust to normal pressure, and obtaining a pretreated battery after exhaust to normal pressure; (2) enabling the pretreated battery under negative pressure, then exhausting the battery to atmospheric pressure and then stationary under positive pressure, and completing a differential pressure treatment cycle after exhausted to atmospheric pressure; (3) repeating the differential pressure treatment cycle of the step (2) for at least one time to obtain a cyclically treated battery; (4) carrying out negative pressure static post-treatment on the cycled battery, and exhausting to atmospheric pressure to obtain the battery for completing liquid injection. The method of the invention realizes the reduction of the area of the electrode dry area after the liquid injection, the increase of the electrolyte infiltration rate and the shortening of the standing time required for waiting for the electrolyte to be completely infiltrated after the liquid injection process is completed.

Owner:EVE ENERGY CO LTD

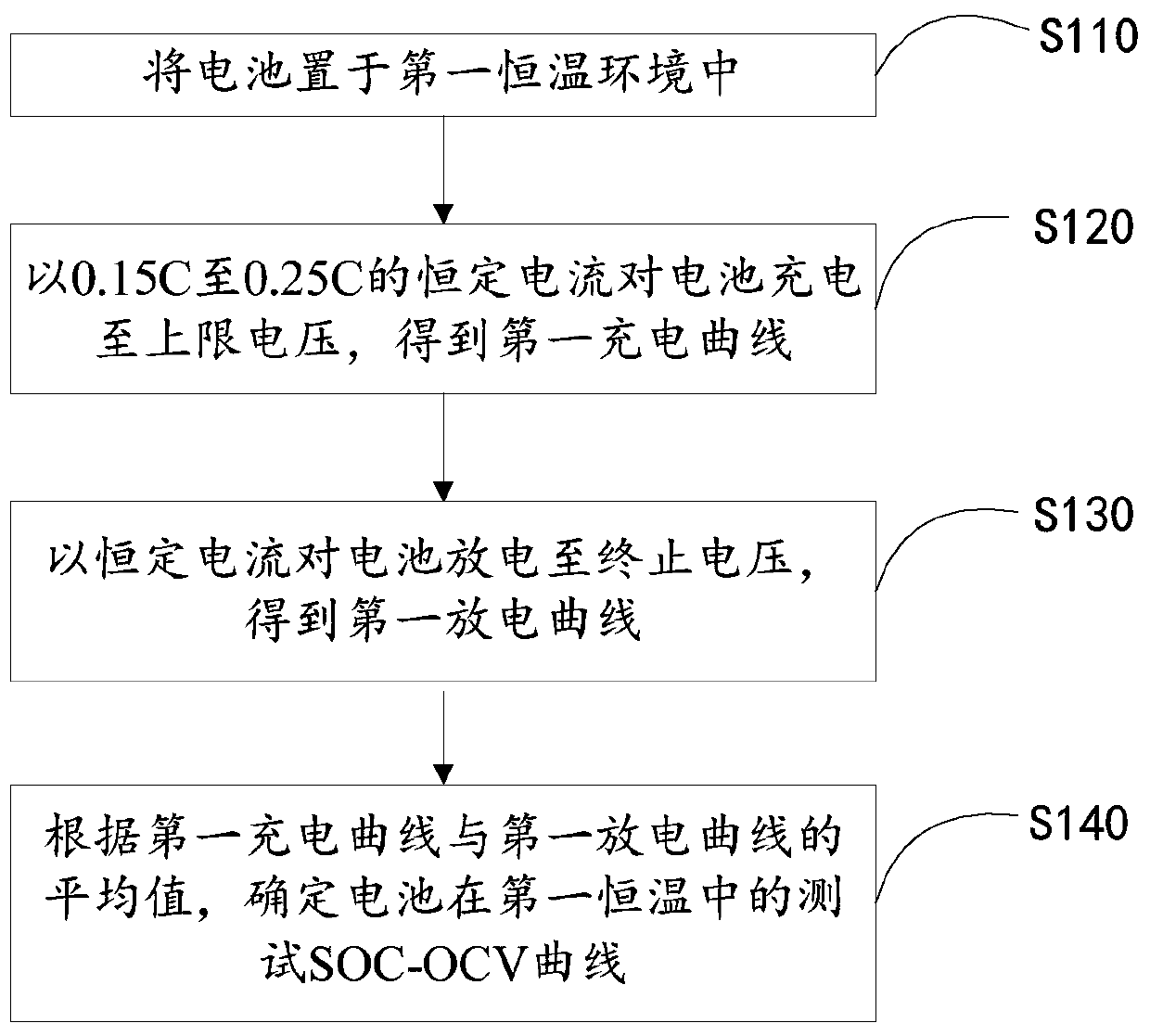

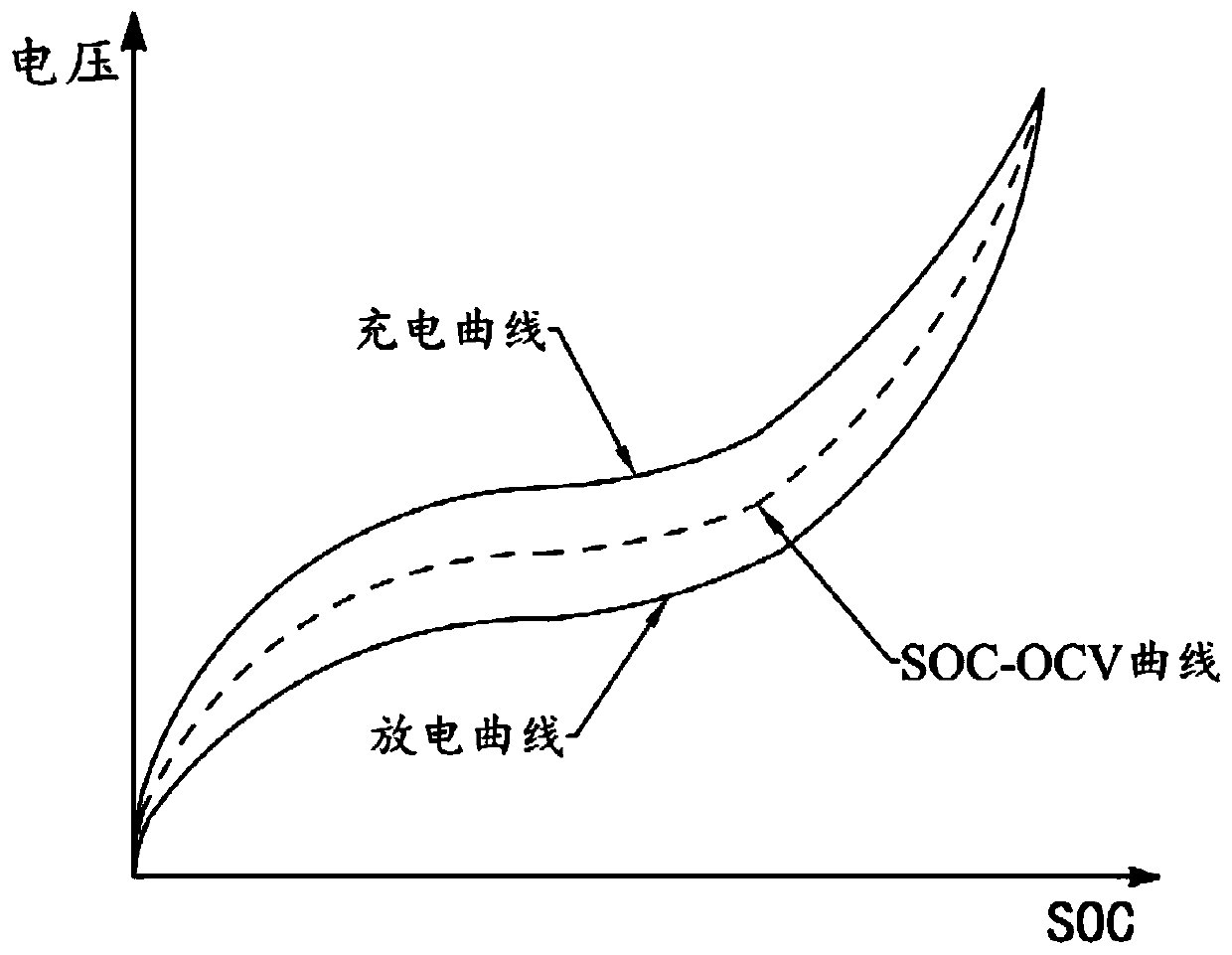

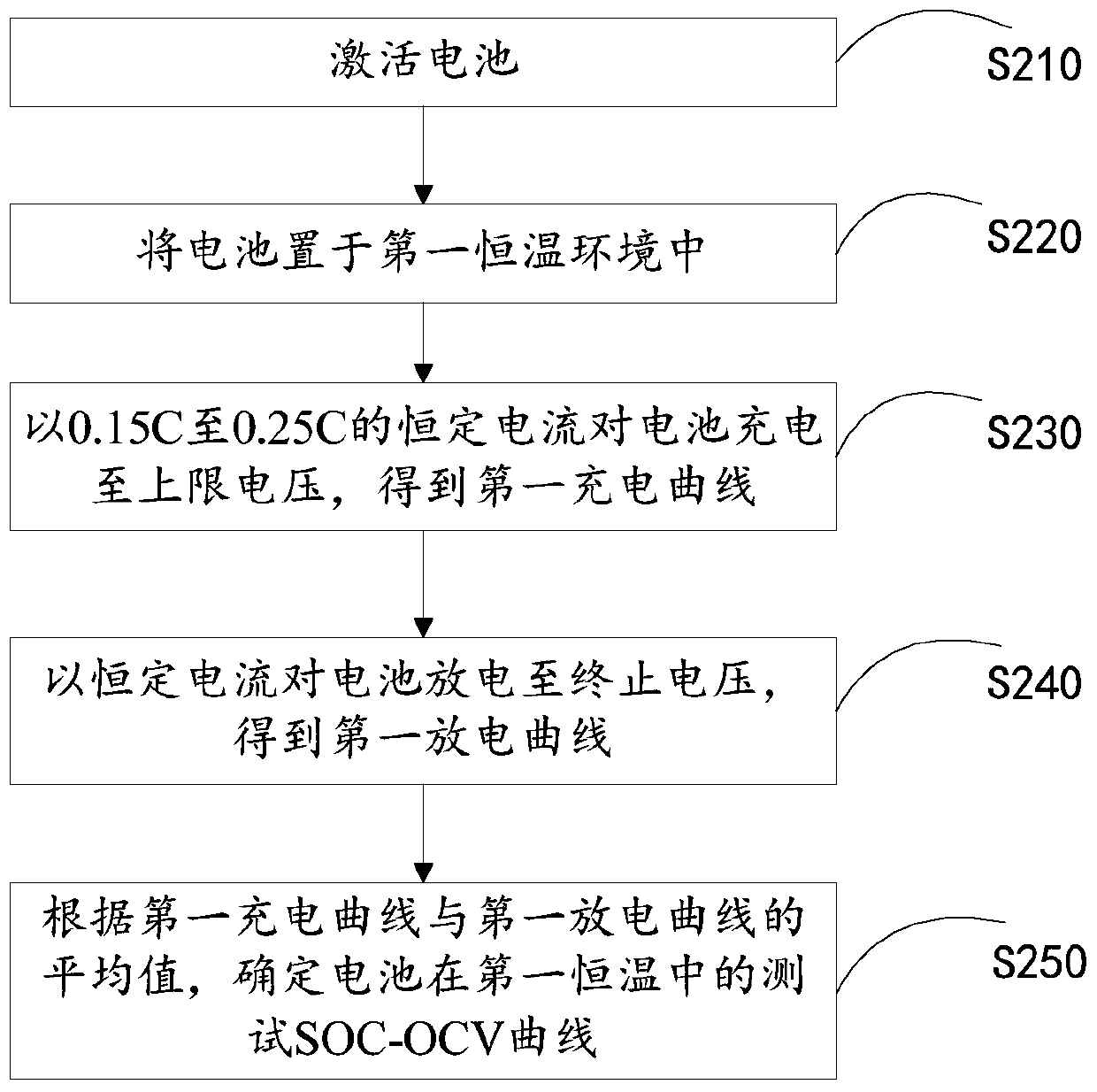

Method for testing battery SOC-OCV curve and equipment for testing battery SOC-OCV curve

InactiveCN110618389AThe testing process is simpleReduce the number of standingElectrical testingTest efficiencyElectricity

The application discloses a method for testing a battery SOC-OCV curve, and the method comprises the following steps of charging the battery to the upper limit voltage with a constant current of 0.15Cto 0.25C to obtain a first charge curve, wherein the upper limit voltage refers to the voltage when the battery is fully charged; discharging the battery to the termination voltage with the constantcurrent to obtain a first discharge curve, wherein the termination voltage refers to the lowest voltage when the battery is discharged; and determining the test SOC-OCV curve of the battery at the first constant temperature according to the average of the first charge curve and the first discharge curve. The method for testing the battery SOC-OCV curve provided by the application greatly saves thenumber of times the battery needs to stand, thereby saving the entire test time and improving the test efficiency. The application also discloses equipment capable of testing the battery SOC-OCV curve by performing the test method.

Owner:宝能汽车集团有限公司

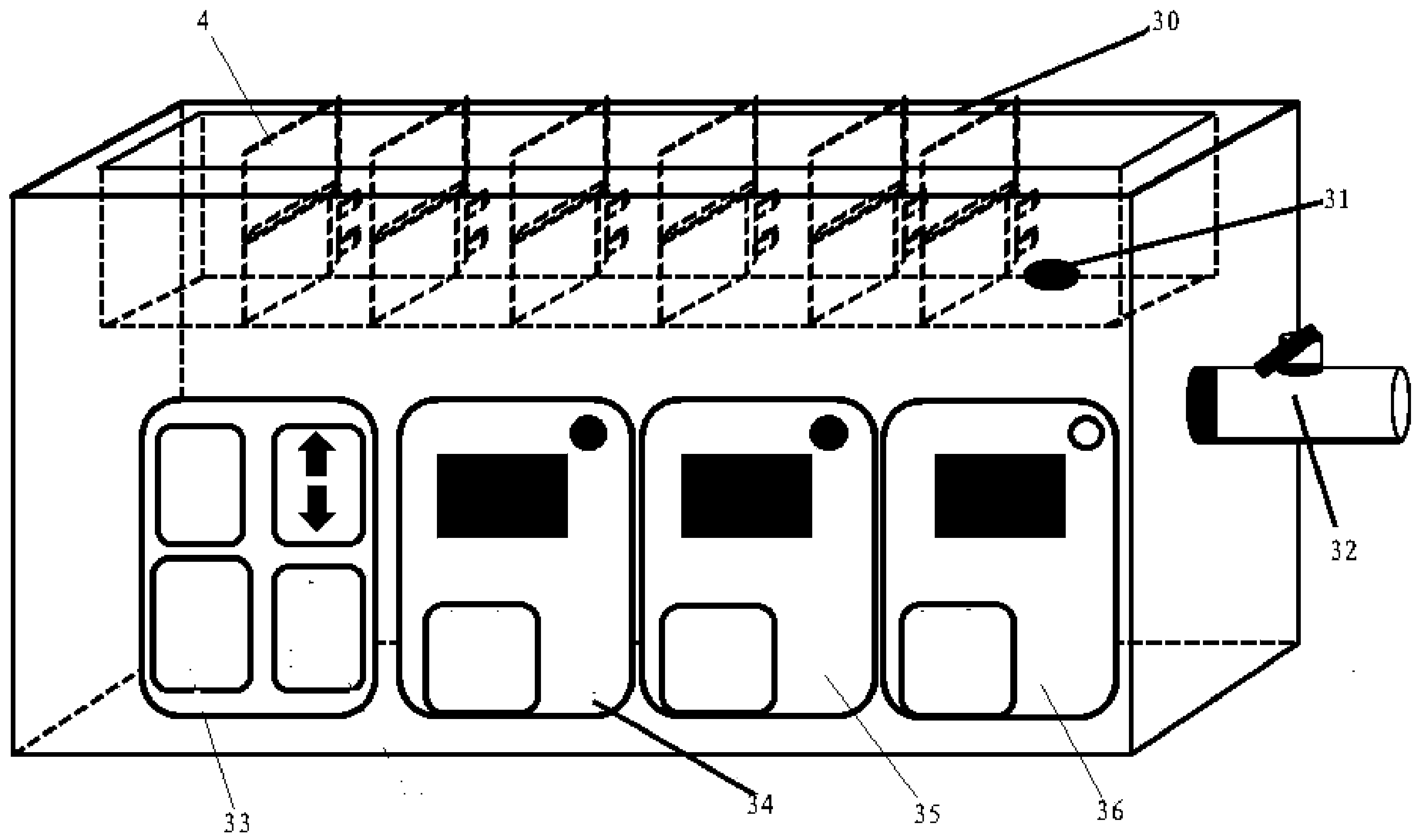

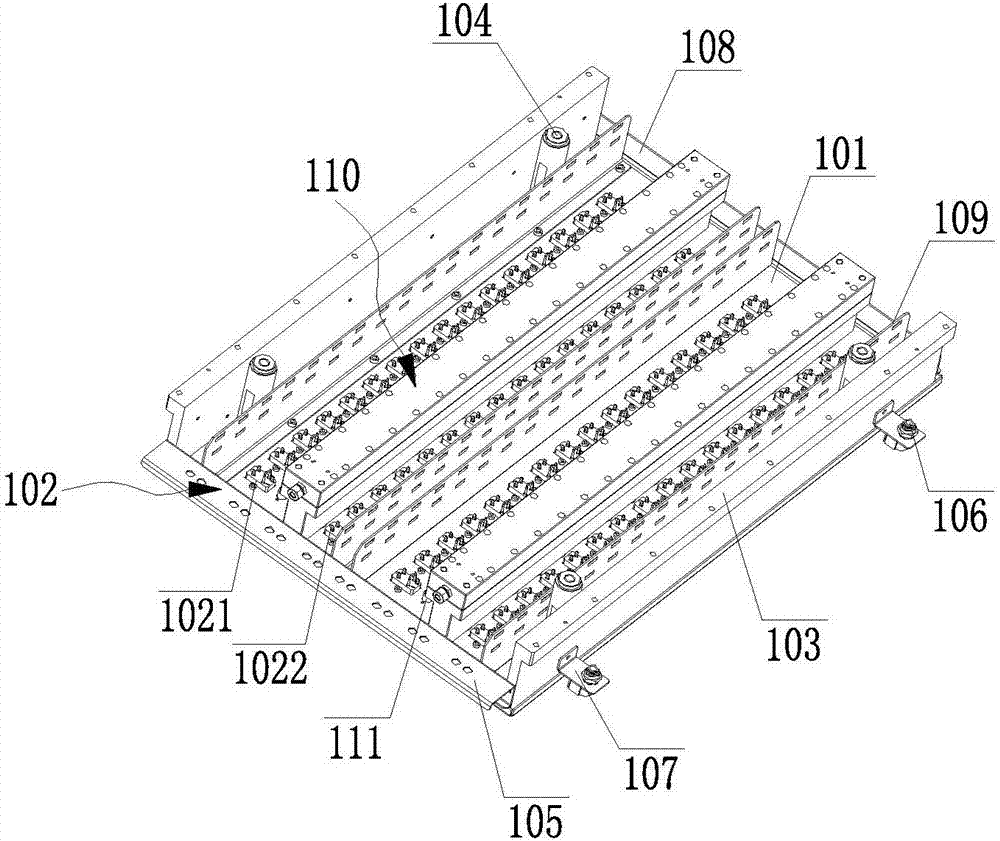

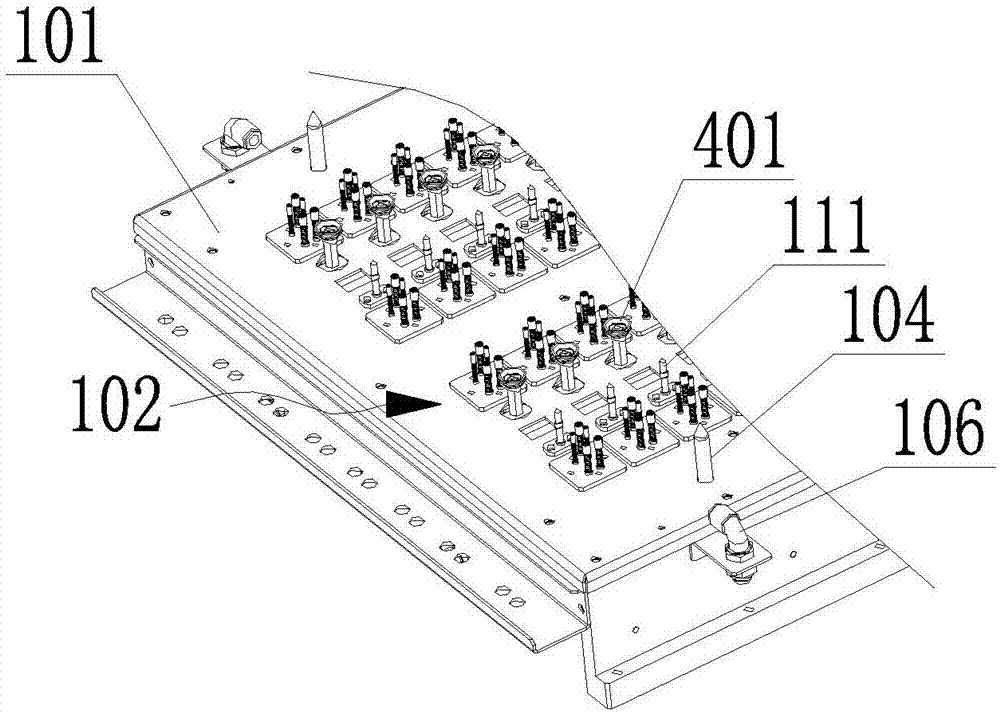

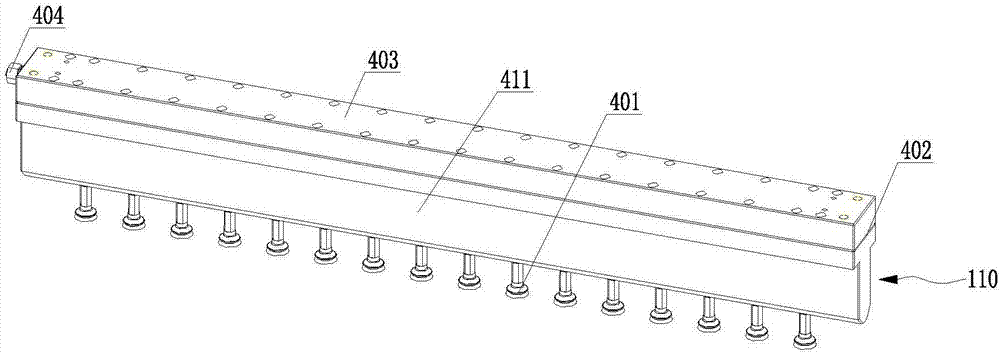

Novel formation needle bed probe module

ActiveCN107275679AWill not polluteImprove the operating environmentFinal product manufactureCell component detailsPressure systemEngineering

The invention relates to a novel formation needle bed probe module, which comprises a baseplate (101). A negative pressure device is disposed between a positive probe (1021) and a negative probe (1022) above the baseplate (101), the negative pressure device passes through the baseplate (101) and is located right above a lithium battery (802) liquid injection port (805) below the baseplate (101) bottom, the negative pressure device seals the liquid injection port (805) to form a negative pressure system. According to the invention, the liquid injection port is sealed in the formation process to form negative pressure, the negative pressure device collects toxic and corrosive gas generated in the formation process, performs centralized treatment, and does not discharge the toxic and corrosive gas into workshops and natural environment, thus improving the operation environment of operation staff, causing no pollution the environment, and being beneficial to environmental protection.

Owner:GUANGDONG HYNN TECH CO LTD

Lead storage battery matching method

ActiveCN110085933AExtended service lifeAccurate removalAssembling battery machinesFinal product manufactureCapacitanceEngineering

The invention discloses a lead storage battery matching method. The lead storage battery matching method comprises steps that (1), Lead battery formation is performed, after completion of the formation, capacitor check discharge is performed, first grading is performed according to a termination voltage value of capacitor check discharge; (2), after capacitor check discharge, an internal resistance value of the lead storage battery is detected; (3), the lead storage battery is supplemented with power; (4), the lead storage battery with abnormal internal resistance is eliminated, and second grading is performed according to the internal resistance value; and (5), lead storage batteries that are divided into the same grade are grouped together. The method is advantaged in that on the basis of capacity grading, secondary grading is performed on the basis of the internal resistance after storage battery discharge, batteries which are defective but difficult for defect discovery in the capacitance check voltage process can be effectively eliminated, accurate matching is achieved, consistency of a single battery in a lead battery pack in the use cycle process is improved, and a purpose of extending the service life of lead battery packs is achieved.

Owner:TIANNENG BATTERY GROUP

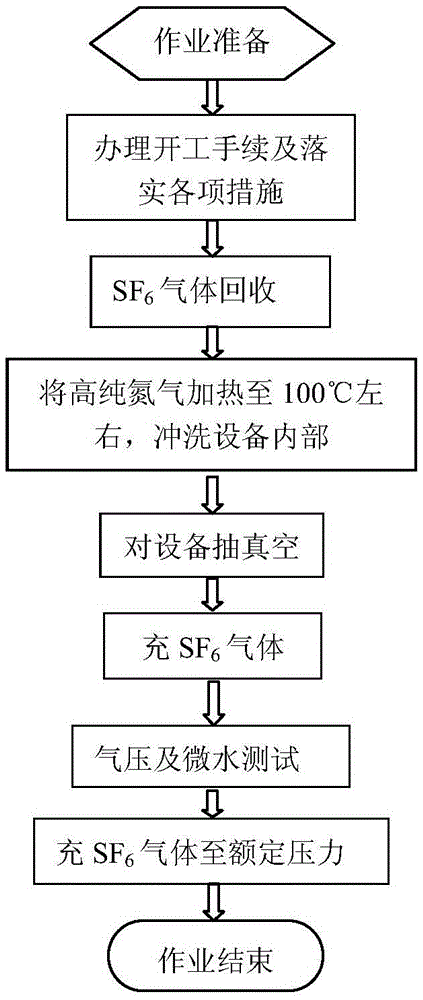

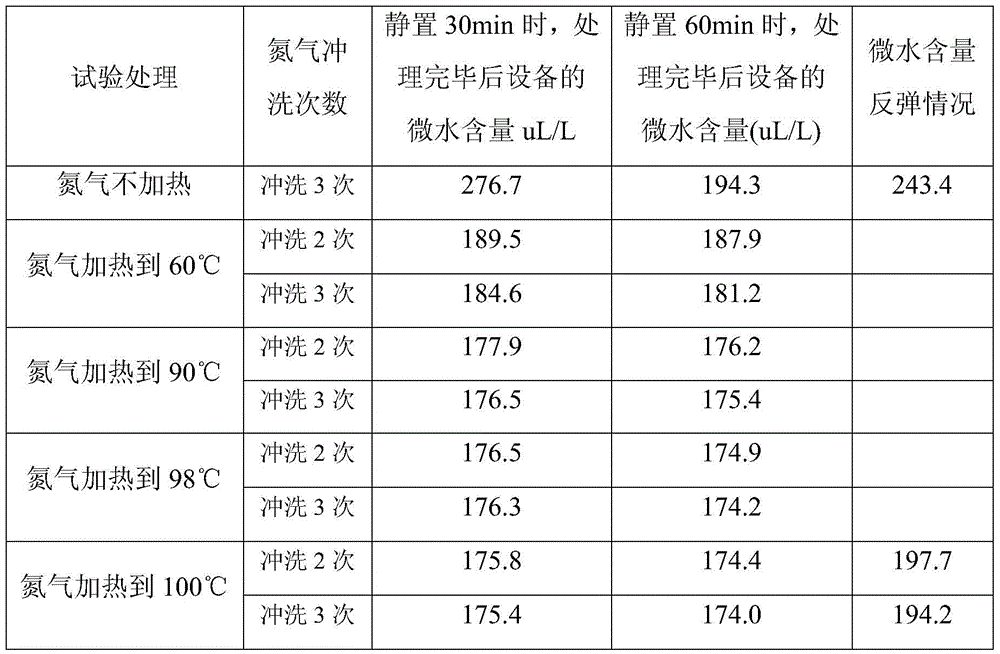

Treatment process aiming at moisture standard exceeding in SF6 device

ActiveCN105536448AImprove solubilityImprove exchange efficiencyDispersed particle separationFlushing timeTemperature control

The invention relates to a treatment process aiming at moisture standard exceeding in an SF6 device. The process comprises: before nitrogen inflation for flushing the SF6 device, heating nitrogen to 98-102 DEG C through a gas temperature control system; inflating nitrogen into the SF6 device for flushing for 30 min; discharging nitrogen through a vacuum duct after flushing; performing flushing twice; inflating SF6 gas into the SF6 device; performing an air-pressure-and-moisture test; and inflating SF6 gas into the SF6 device till a rated pressure is reached. Through the process, time of nitrogen standing in the SF6 device is effectively shortened, and flushing times with nitrogen during the flushing process is reduced, thereby improving the treatment effect and efficiency of moisture standard exceeding in the SF6 device. Through treatment of moisture standard exceeding, the moisture content in coil devices can be effectively inhibited from rebounding.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

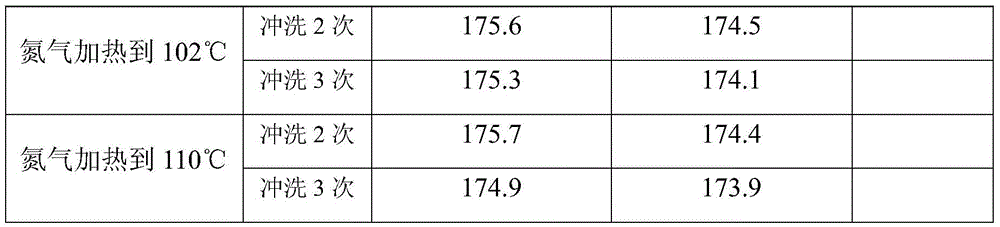

Soft-packed lithium ion battery manufacturing process

InactiveCN110718669APromote reabsorptionShorten production timeFinal product manufactureCell component detailsElectrolytic agentPhysical chemistry

The invention provides a soft-packed lithium ion battery manufacturing process which comprises the following steps: S1, after a bare cell is wound, the bare cell is put into an electrolyte tank in a dry and oxygen-free environment until the electrolyte level reaches the tab glue position of the bare cell, the bare cell is soaked for 10 seconds to 2 hours, and the temperature of electrolyte is maintained at 20 to 150 DEG C; S2, the soaked bare cell is taken out, and the bare cell is dried at 20-150 DEG C until the bare cell does not drop electrolyte anymore and the content of the electrolyte meets a preset value; and S3, the bare cell is put into an aluminum-plastic film after being dried, top sealing is carried out first, and then, side sealing and air bag edge sealing are carried out at the same time, and thus, packaging is completed. Compared with the prior art, the bare cell is directly placed and soaked in the electrolyte tank and dried, side sealing and air bag edge sealing are carried out at the same time, and by improving the existing process, the standing time is greatly shortened, the process flow is simplified, and the production efficiency is improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

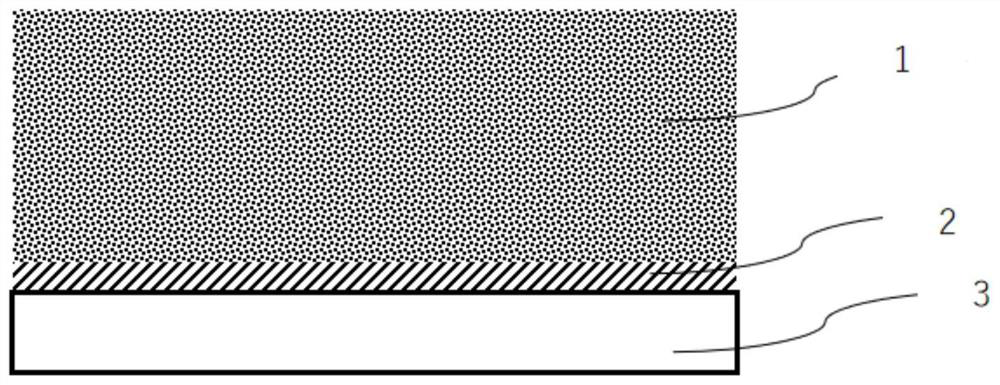

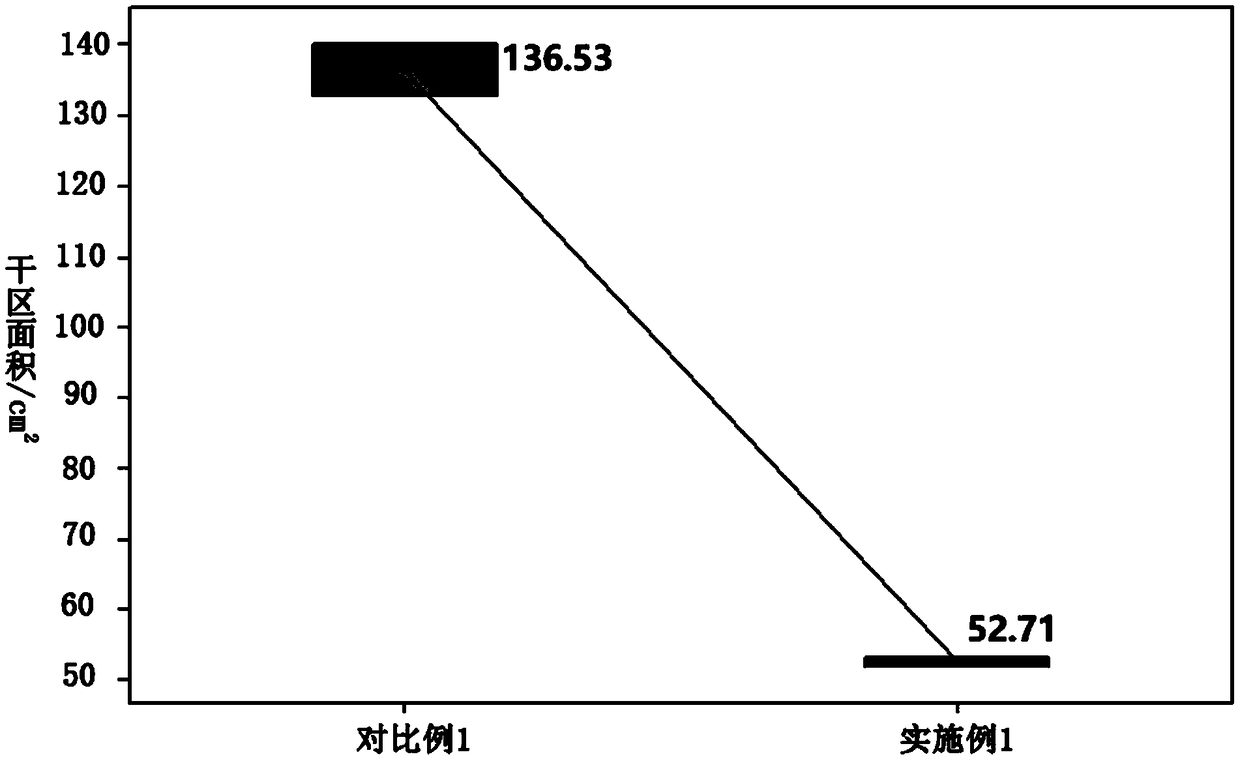

Positive plate with improved infiltration capacity and lithium ion battery

ActiveCN110504409AGood wettabilityShorten the resting timeElectrode rolling/calenderingElectrode thermal treatmentCurrent collectorLithium electrode

The invention provides a positive plate with improved infiltration capacity. The positive plate comprises a current collector, and n active matter layers with the same thickness are arranged on two sides of the current collector, wherein n is larger than or equal to 1 and smaller than or equal to 10; the contact angle of the surface of the current collector is theta 0, COS(theta 0) is larger thanor equal to 0.50 and smaller than 0.99, the contact angle of the surfaces of the active matter layers is theta n, and theta n is smaller than or equal to 30 degrees; when COS(theta 0) is larger than or equal to 0.50 and smaller than 0.94, theta 1 is equal to half of theta 0, and theta n is equal to the product of theta 1 and 0.9<n+1>; and when COS(theta 0) is larger than or equal to 0.94 and smaller than 0.99, theta 1 is equal to theta 0, and theta n is equal to the product of theta 1 and 0.9<n+1>. The positive plate with improved infiltration capacity obtains good plate infiltration, standingtime of a cell after the battery is injected with an electrolyte is shortened, the infiltration rate of the electrolyte for the positive plate with the improved infiltration capacity is increased, the production efficiency and yield are increased, a prepared battery electrode interface state is more uniform, and interfacial current density in the charging-discharging process is more uniform.

Owner:TIANJIN ENERGIES

Method for preparing sodium alginate based on powder form absorption and separation

The invention discloses a method for preparing sodium alginate based on powder form absorption and separation. The method comprises the following steps: S1, carrying out pretreatment; S2, carrying outabsorption and separating; S3, carrying out digestive foaming; S4, filtering; S5, carrying out calcification and decalcification; S6, neutralizing for realizing replacement. According to the method,silicon dioxide aerogel powder is added into powdered kelp liquid, the powdery kelp liquid is enabled to stand still so as to form a layered state by means of the absorption characteristics of the silicon dioxide aerogel powder, and a filtering membrane is cooperatively used for realizing filtration and separation; the method is ingenious in process, and enables the extraction of the powdered kelpnot to be affected while enabling the kelp to fully absorb formaldehyde for realizing fixation. The absorption way of the method provided by the invention is more convenient and quicker than that ofsponge.

Owner:江苏中大生物科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com