Paint spraying equipment

A technology of spray painting equipment and support frame, which is applied in painting room, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of heavy wood strips, labor consumption, and easy generation of wood chips, so as to save drying space and shorten the time. The effect of resting time and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

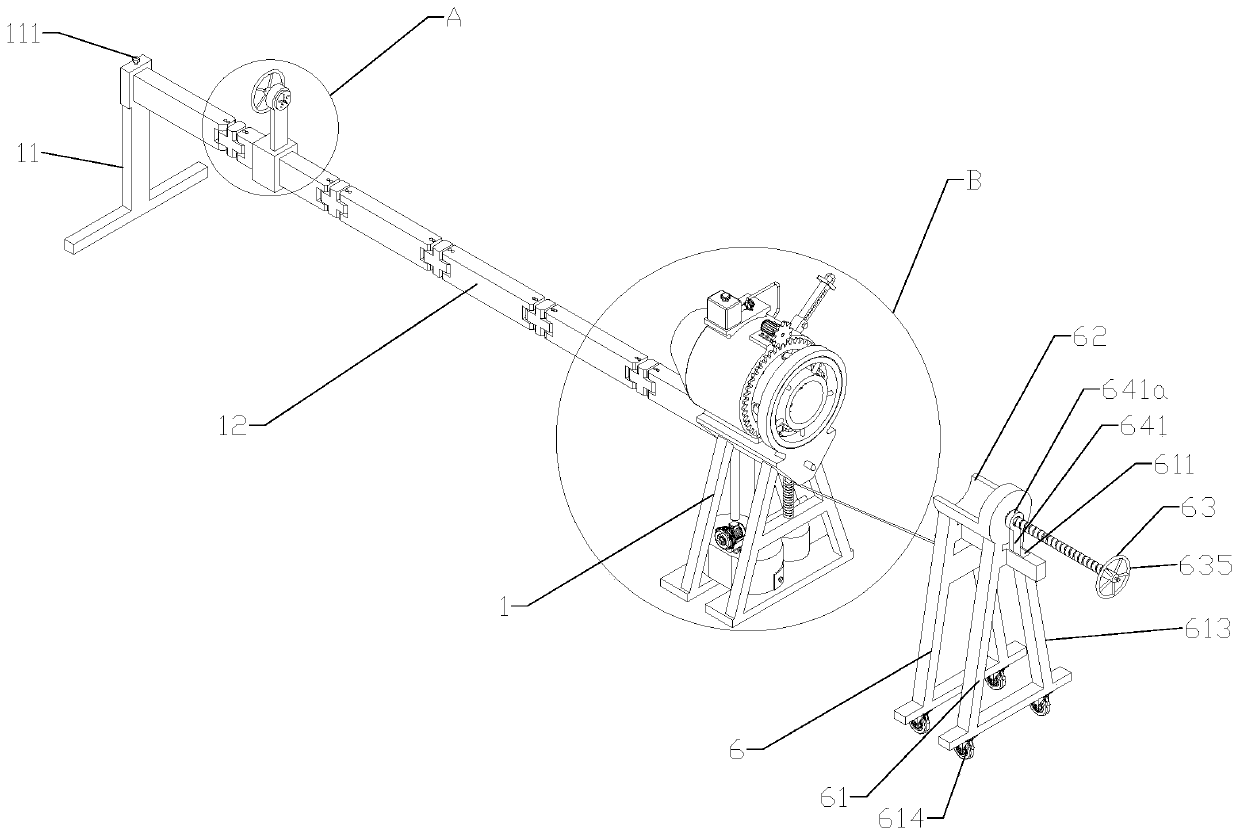

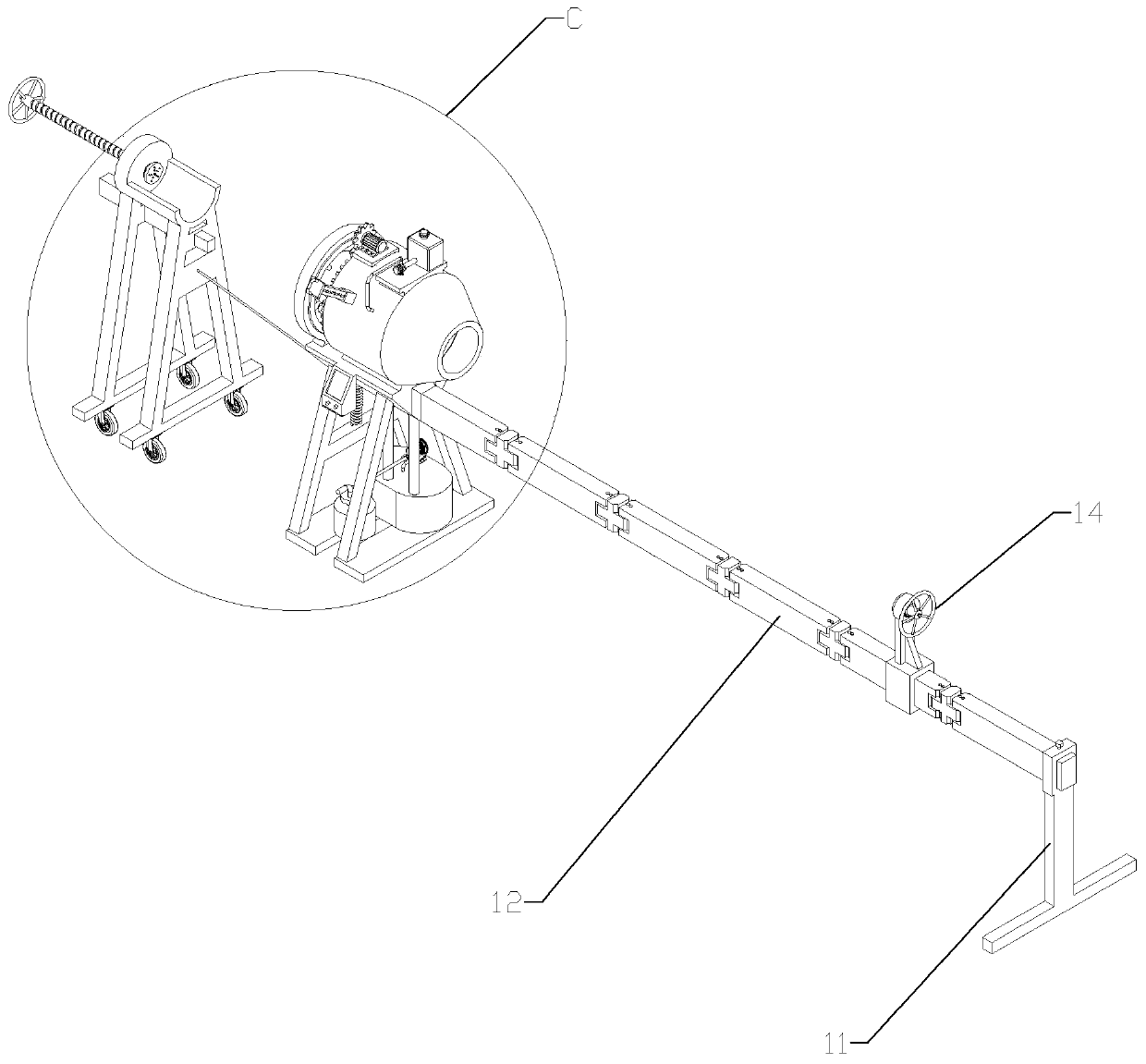

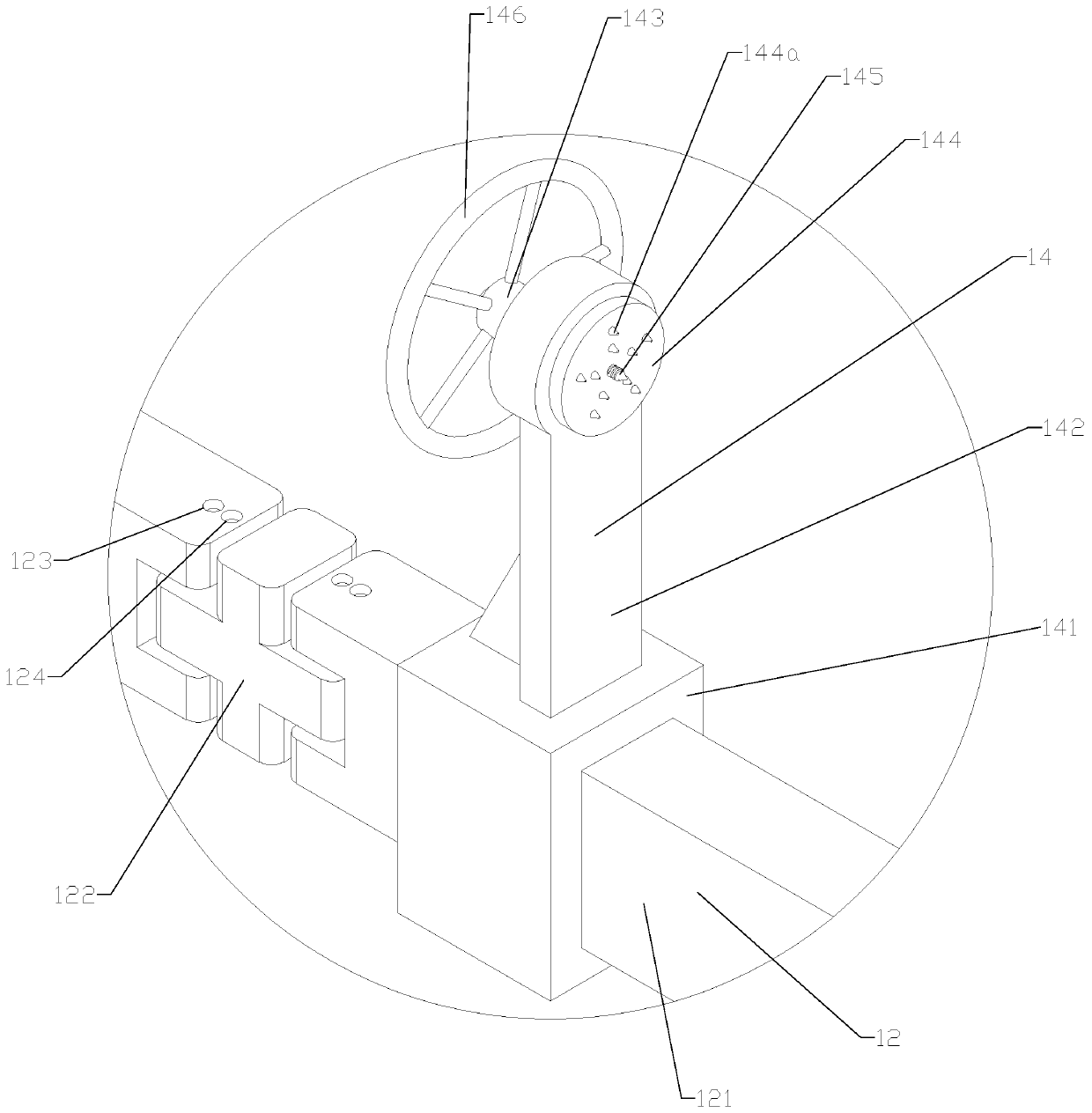

[0038] as attached figure 1 to attach Figure 15 Shown painting equipment, it comprises first supporting frame 1 and second supporting frame 6, and first supporting frame 1 comprises front supporting leg 11, folding rod 12 and rear supporting leg 13 successively from front to rear, the upper end of front supporting leg 11 Sleeved on the folding rod 12, the upper end of the front leg 11 is threaded with a bolt 111, and the bolt 111 moves downward to tighten the folding rod 12. During use, the front leg 11 is fixed by screwing the bolt 111. The folding rod 12 includes a connecting rod 121 and a cross-shaped connecting head 122. The connecting rod 121 and the cross-shaped connecting head 122 are respectively provided with a hinged connection hole 123 and a limiting hole 124. Remove pins....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com