Standing method for soft package lamination lithium ion power battery after liquid injection

A power battery and lithium-ion technology, which is applied in the field of soft-pack laminated lithium-ion power batteries after liquid injection, can solve the problems of long time consumption and poor effect, and achieve the goals of reducing production costs, uniform liquid distribution, and shortening the standing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

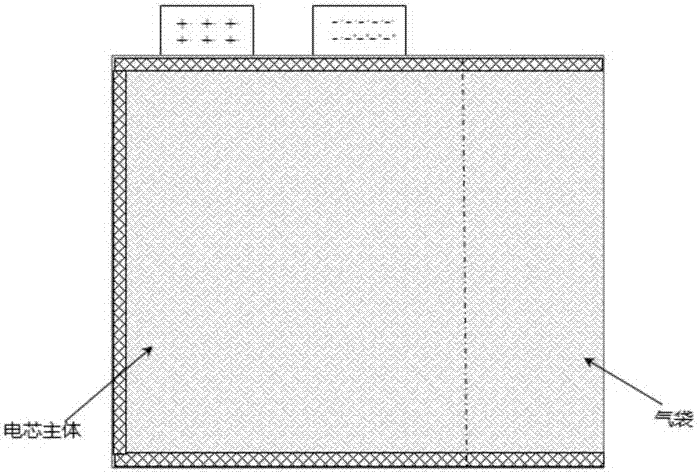

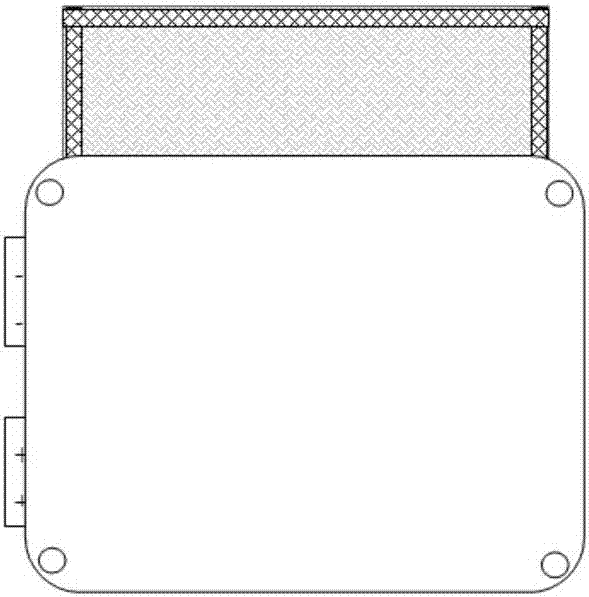

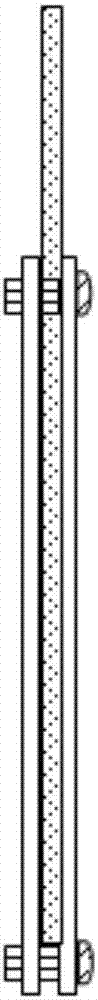

Embodiment 1

[0037] A method for shelving a soft-packed laminated lithium-ion power battery after liquid injection, wherein the manufacturing process of the lithium-ion battery includes the following steps: separately homogenizing the positive and negative electrode slurries of the lithium-ion battery, and the active positive electrode used in the homogenizing process Substance material is LiNi 0.5 co 0.2 mn 0.3 o 2 , the material of the negative electrode active material is graphite, and after homogenization, the coating operation is carried out on the positive electrode current collector / negative electrode current collector respectively, and the positive and negative electrode sheets are obtained by rolling, and then the positive and negative electrode sheets are dried, die-cut, and the positive electrode sheet , diaphragm, and negative electrode sheet are laminated to make lithium-ion battery cells, in which the diaphragm is double-sided coated with ceramic polyethylene diaphragm, and...

Embodiment 2

[0040] A method for shelving a soft-packed laminated lithium-ion power battery after liquid injection, wherein the manufacturing process of the lithium-ion battery includes the following steps: separately homogenizing the positive and negative electrode slurries of the lithium-ion battery, and the active positive electrode used in the homogenizing process Substance material is LiNi 0.5 co 0.2 mn 0.3 o 2 , the material of the negative electrode active material is graphite, and after homogenization, the coating operation is carried out on the positive electrode current collector / negative electrode current collector respectively, and the positive and negative electrode sheets are obtained by rolling, and then the positive and negative electrode sheets are dried, die-cut, and the positive electrode sheet , diaphragm, and negative electrode sheet are laminated to make lithium-ion battery cells, in which the diaphragm is double-sided coated with ceramic polyethylene diaphragm, and...

Embodiment 3

[0043] A method for shelving a soft-packed laminated lithium-ion power battery after liquid injection, wherein the manufacturing process of the lithium-ion battery includes the following steps: separately homogenizing the positive and negative electrode slurries of the lithium-ion battery, and the active positive electrode used in the homogenizing process Substance material is LiNi 0.33 co 0.33 mn 0.34 o 2 , the negative electrode active material is obtained by mixing graphite and hard carbon in a mass ratio of 1:1. After homogenizing, coating operations are carried out on the positive electrode current collector / negative electrode current collector respectively, and the positive and negative electrodes are obtained by rolling. The pole piece is dried, die-cut, and the positive pole piece, diaphragm, and negative pole piece are laminated to make a lithium-ion battery cell. The diaphragm is a single-sided ceramic-coated polyethylene diaphragm, and the battery cell is packed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com