Treatment process aiming at moisture standard exceeding in SF6 device

A treatment process, SF6 technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems affecting work progress, complicated operation process, discharge of conductors to the cylinder wall, etc., to reduce the number of flushing and improve treatment effect, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings. The nitrogen described in the present invention is high-purity nitrogen with a purity of 99.999%.

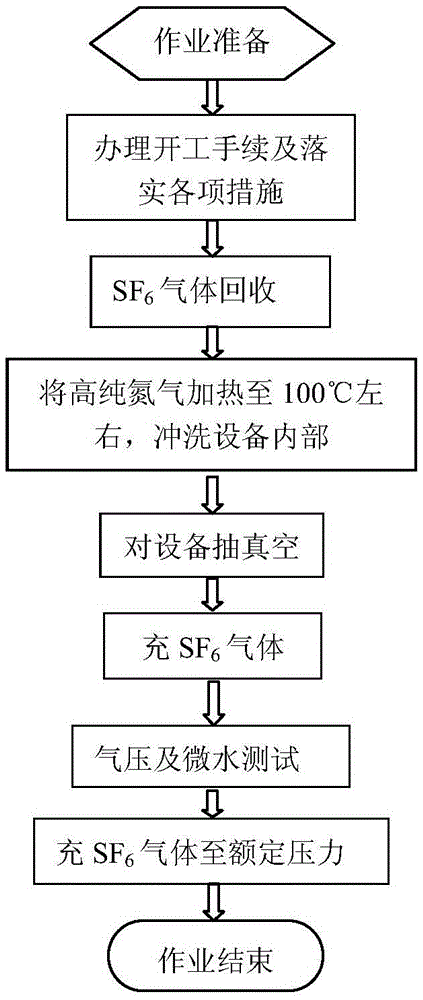

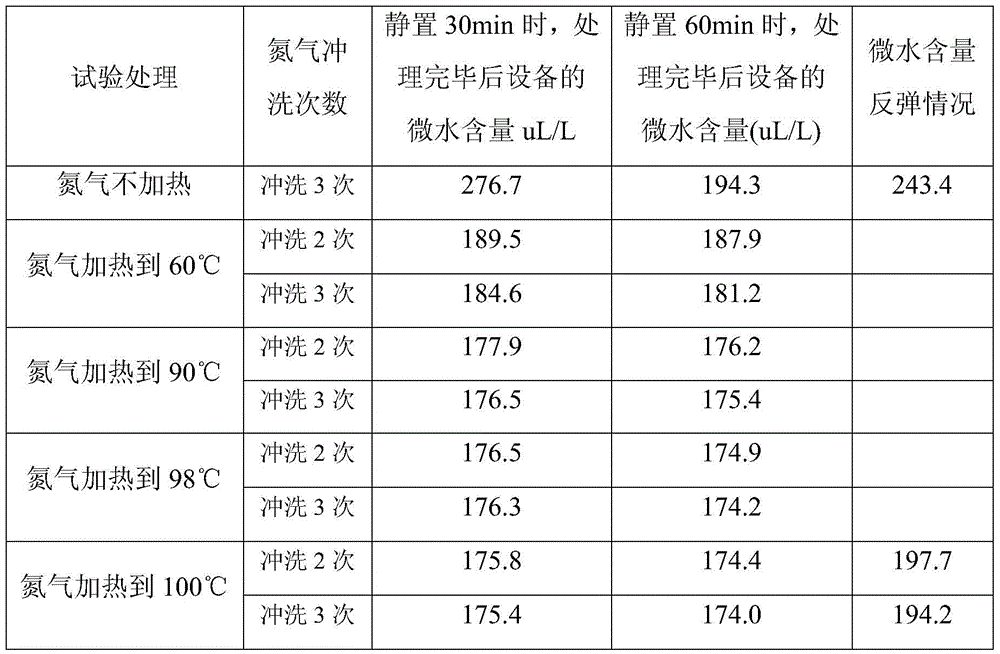

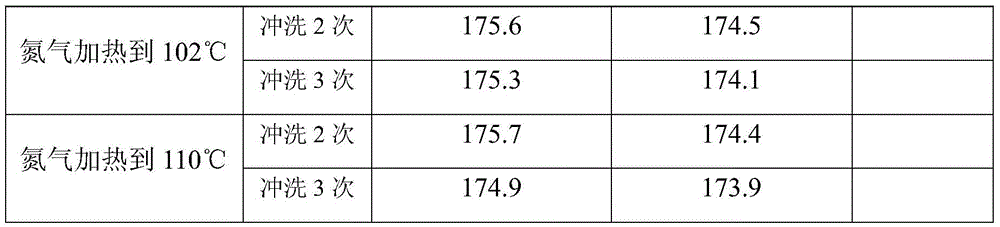

[0017] Such as figure 1 As shown, the invention described for SF 6 The treatment process steps for equipment micro water exceeding the standard are: make preparations for operation, go through the start-up procedures and implement various measures; put SF 6 SF in the device 6 The gas is recovered; flush the SF with nitrogen 6 Before the equipment, use the gas temperature control system to heat the nitrogen to 98°C-102°C; fill the heated nitrogen into the SF 6 The equipment was flushed for 30 minutes, and then the nitrogen gas was discharged with a vacuum catheter, and the nitrogen was flushed twice; 6 Charge the device into SF 6 Gas, and do air pressure and micro water test, fill SF 6 Gas to SF 6 The rated pressure of the equipment is suff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com