Method for wetting polymer lithium ion batteries

A lithium-ion battery and polymer technology, which is applied in the directions of cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids, etc., can solve the problems of difficult infiltration of electrolytes and difficulty of fully infiltration of active material particles by electrolytes, etc. Achieve the effect of strong practicability, shortening standing time and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

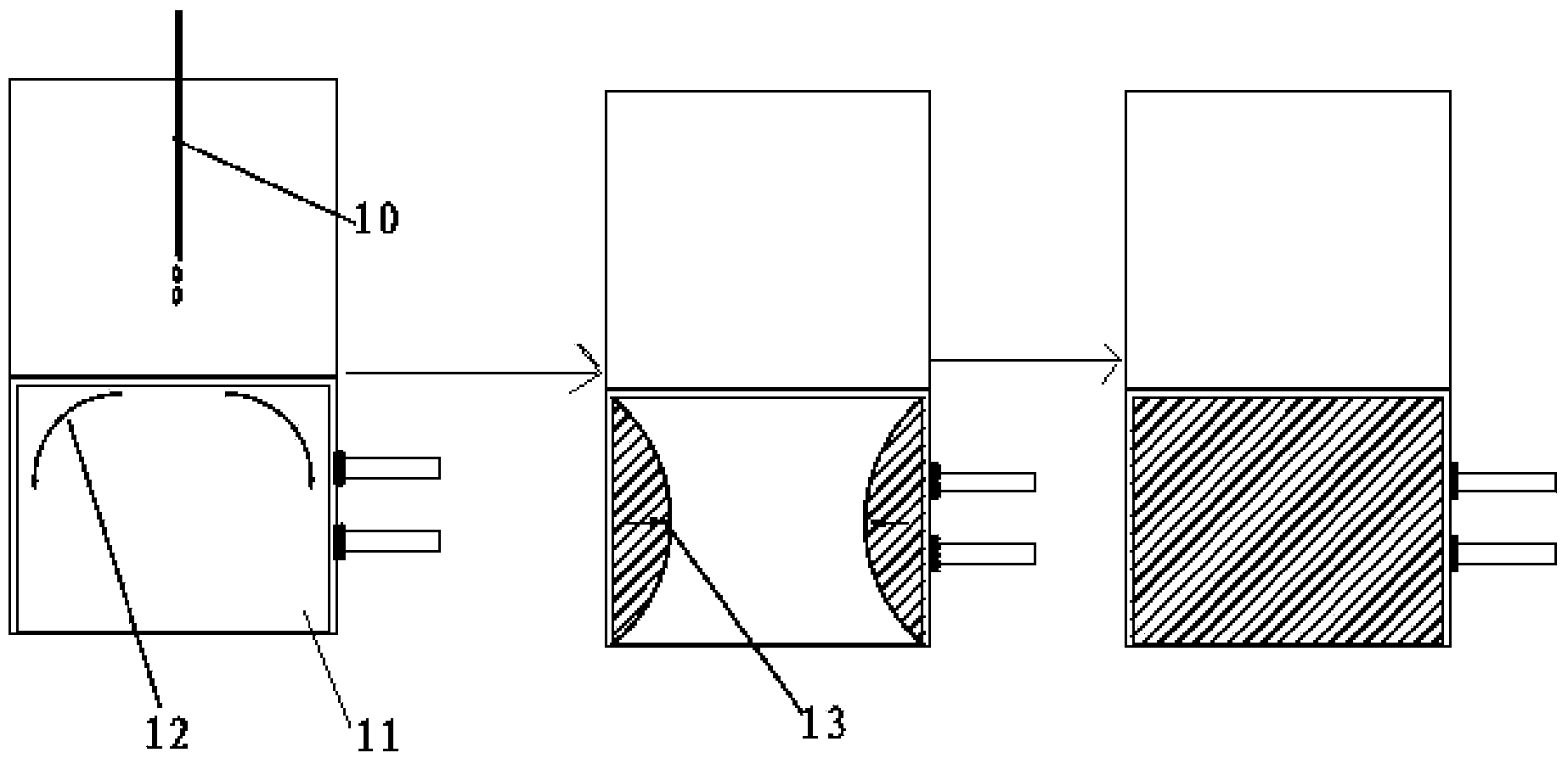

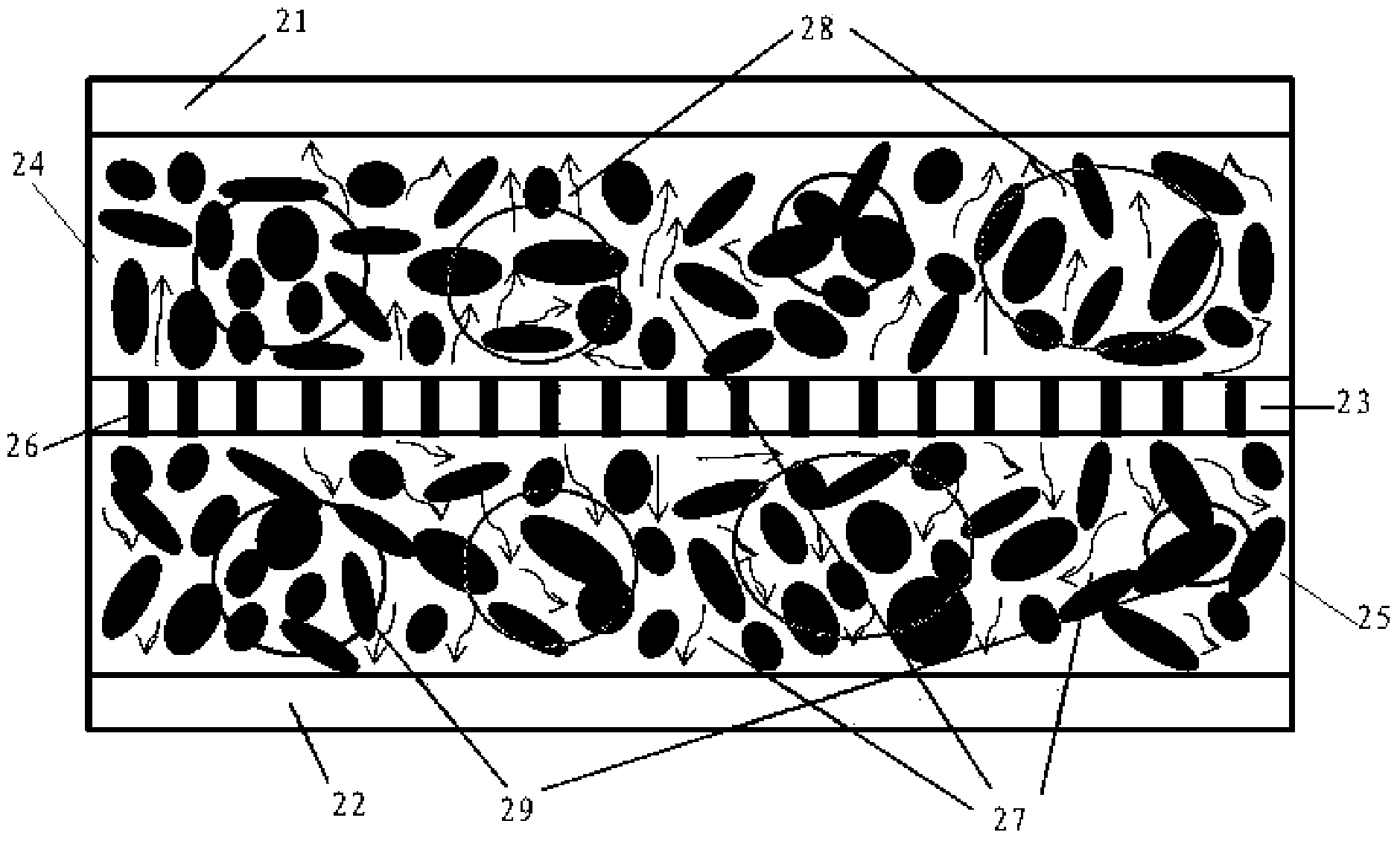

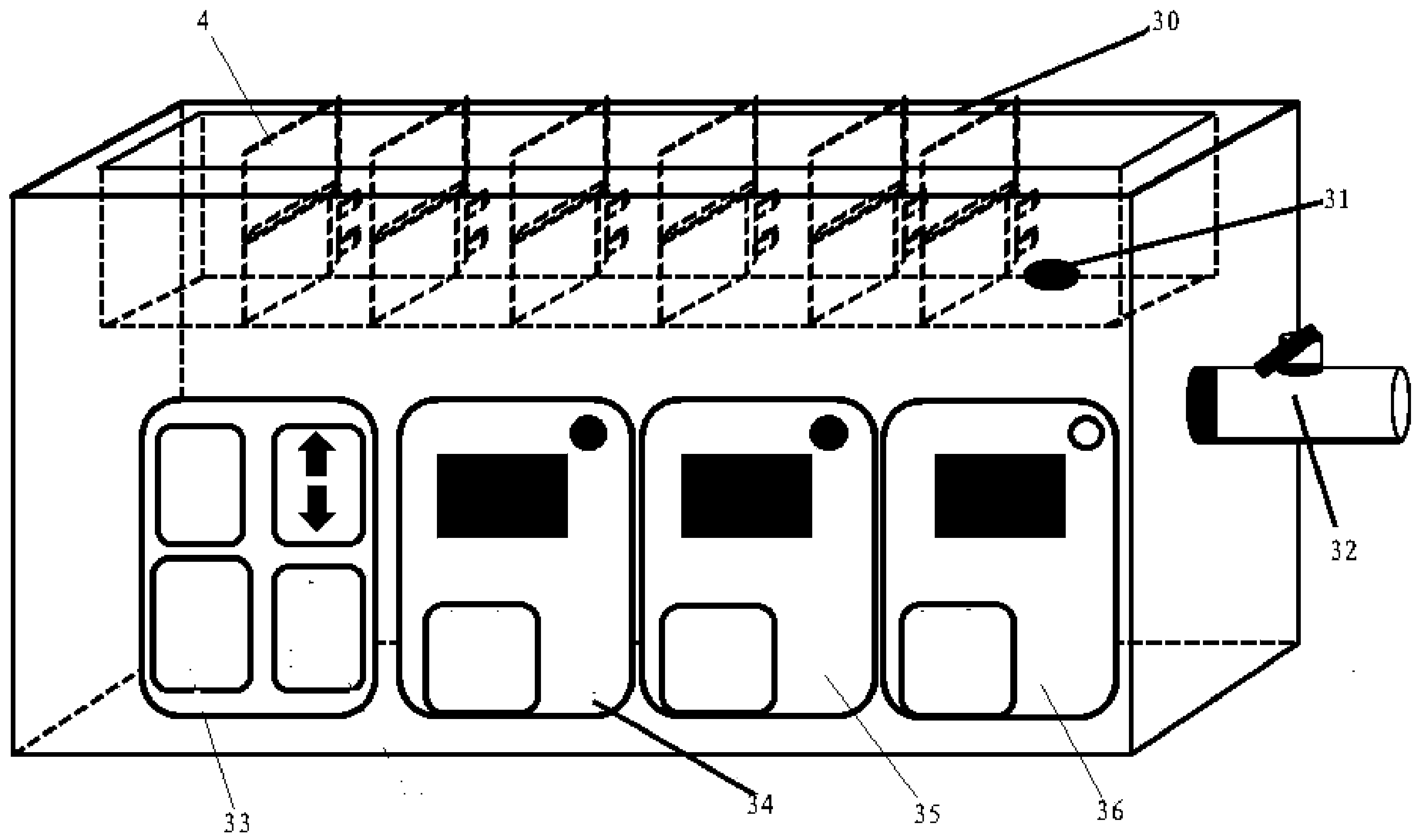

[0021] An infiltration method for a polymer lithium-ion battery, which uses an ultrasonic cleaning device to infiltrate, specifically includes the following steps:

[0022] Put the filled battery air bag upright in the sink of the ultrasonic cleaning device;

[0023] Injecting pure water into the water tank, controlling the liquid level of the pure water to submerge the electrode group of the battery;

[0024] Heat the pure water to control the temperature at 23-27°C, control the ultrasonic frequency at 50-70KHz, and ultrasonically infiltrate for 1.0-2.0 hours;

[0025] Take out the soaked battery and dry it with a hot air device.

[0026] Preferably, the temperature of the pure water is 25°C, and the frequency of the ultrasonic wave is 60KHz.

[0027] Preferably, the time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com