Positive plate, positive plate and solid-state battery

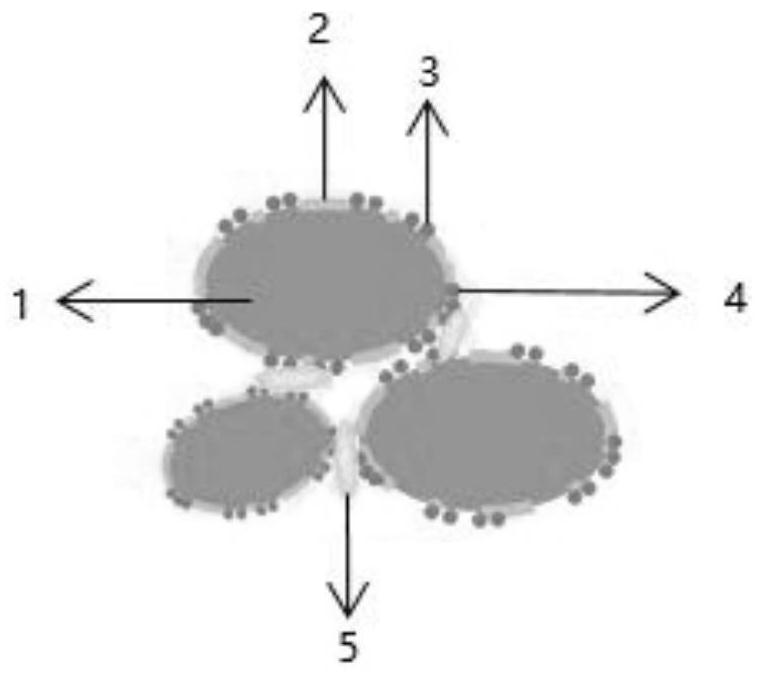

A solid-state battery and positive electrode technology, which is applied in secondary batteries, battery electrodes, lithium batteries, etc., can solve the problems of not being able to maximize the benefits of solid-state batteries, achieve enhanced interface ion conductivity, improve processability, and reduce interface stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] The following example provides a preparation process for a solid-state battery, and the specific preparation method is as follows:

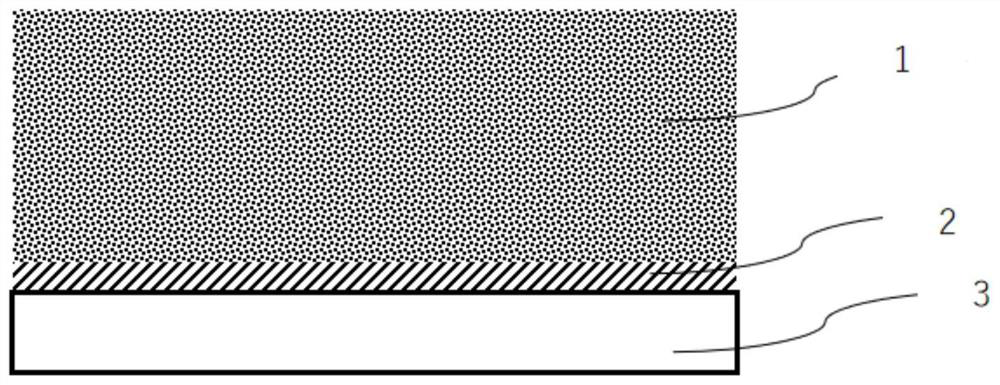

[0076] 1. Preparation of positive electrode sheet and positive electrode plate:

[0077] (1) Preparation of raw materials:

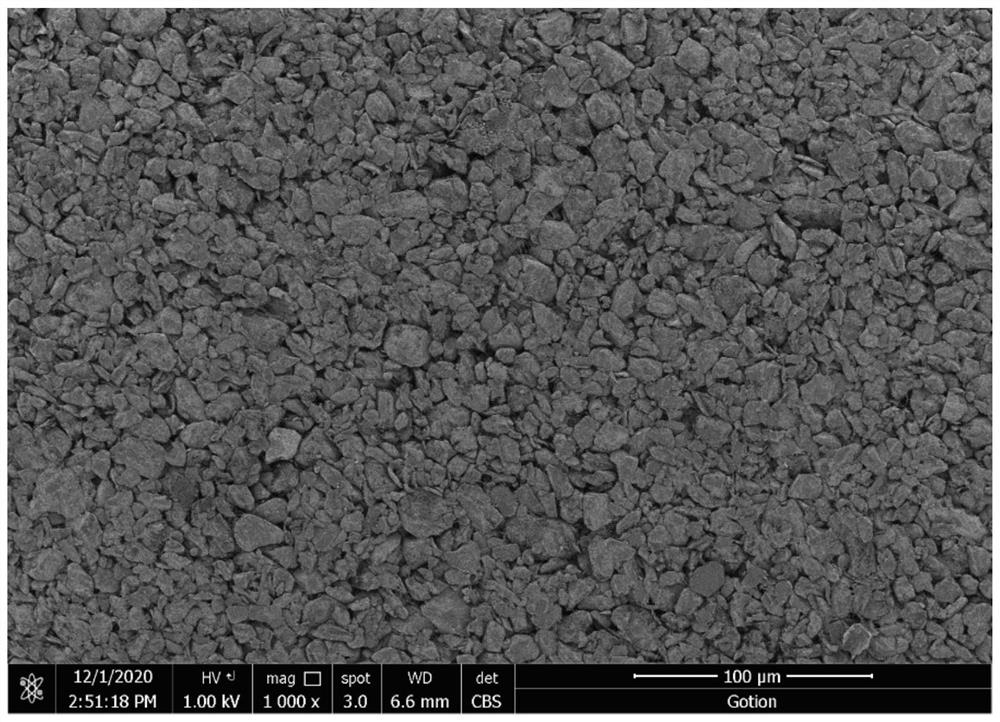

[0078] Active electrode material: ceramic-based ionic conductor Li1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) The single crystal nickel-cobalt-manganese oxide positive electrode material NCM811 was coated with a coating thickness of 50 nm by spray drying method to obtain the active electrode material.

[0079] The single crystal nickel-cobalt-manganese oxide cathode material NCM811 was directly used as the active electrode material for comparison.

[0080] Electron conductive agent: single-walled carbon nanotubes.

[0081] Auxiliary: Polypropylene carbonate.

[0082] Ion-conducting agent: poly-p-phenylene sulfide (PPS), tetraphenylporphine tetrasulfonic acid, succinonitrile (SN), and lithium salt are mixed in a mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com