All-solid-state polymer electrolyte containing high-concentration lithium salt and preparation method thereof

An all-solid-state polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc. High chemical window, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of 52wt.% Lithium Salt All-Solid Polymer Electrolyte

[0024] Add 1g polyvinylidene fluoride-hexafluoropropylene, 1.1g lithium salt LiTFSI and 5g solvent N,N-dimethylformamide into the reagent bottle, stir at 65°C for 6h to obtain a uniform solution. The mixed solution was cast on a clean glass plate, scraped with a scraper to form a film, dried under ventilated conditions for 16 hours, and vacuum dried at 60°C for 24 hours to remove residual solvents to obtain an all-solid polymer electrolyte with a thickness of 100 μm.

[0025] The morphology, mechanics and thermal stability analysis of the all-solid-state polymer electrolyte in this example were carried out.

[0026] figure 1 It shows that the lithium salt is uniformly dispersed in the polyvinylidene fluoride-hexafluoropropylene copolymer in the all-solid polymer electrolyte of this example.

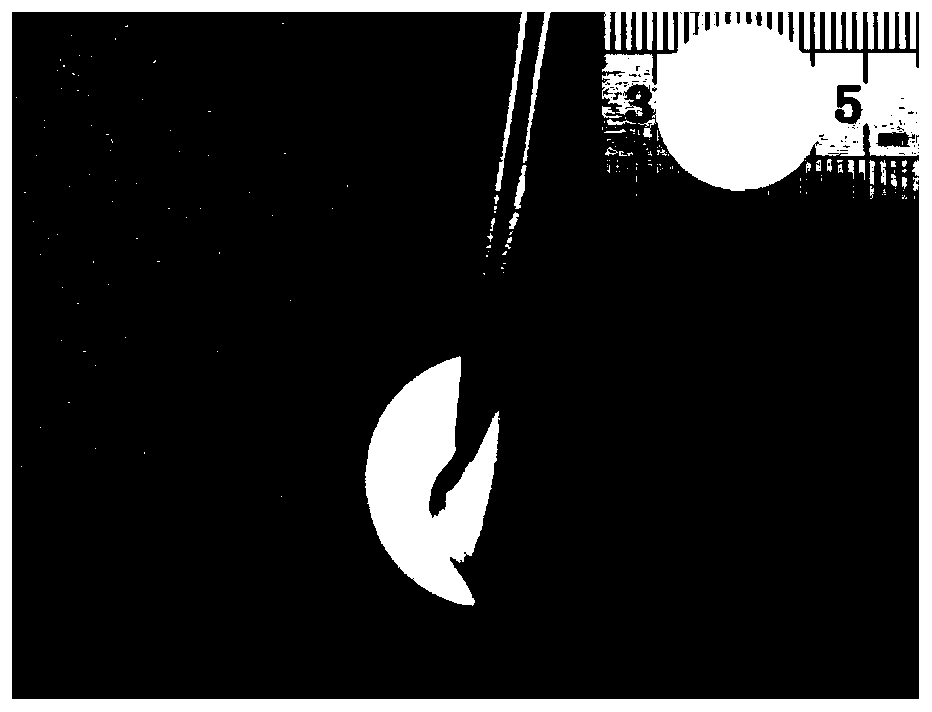

[0027] figure 2 It shows that the all-solid polymer electrolyte of this example is flexible.

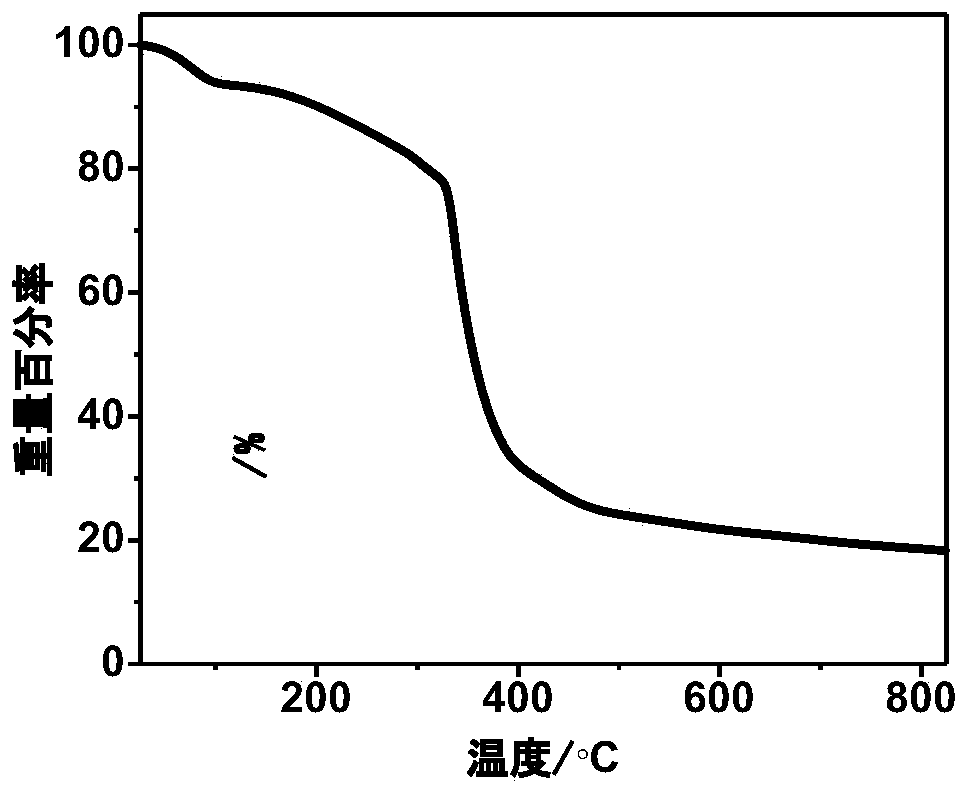

[0028] imag...

Embodiment 2

[0032] Preparation of 55wt.% Lithium Salt All-Solid Polymer Electrolyte

[0033] Add 1g polyvinylidene fluoride-hexafluoropropylene, 1.2g lithium salt LiTFSI and 5g solvent N,N-dimethylformamide into the reagent bottle, stir at 65°C for 6h to obtain a uniform solution. The mixed solution was cast on a clean glass plate, scraped with a scraper to form a film, dried under ventilated conditions for 16 hours, and vacuum dried at 60°C for 24 hours to remove residual solvents to obtain an all-solid polymer electrolyte with a thickness of 100 μm.

Embodiment 3

[0035] Preparation of 60wt.% Lithium Salt All-Solid Polymer Electrolyte

[0036] Add 1g polyvinylidene fluoride-hexafluoropropylene, 1.5g lithium salt LiTFSI and 5g solvent N,N-dimethylformamide into the reagent bottle, stir at 65°C for 6h to obtain a uniform solution. The mixed solution was cast on a clean glass plate, scraped with a scraper to form a film, dried under ventilated conditions for 16 hours, and vacuum dried at 60°C for 24 hours to remove residual solvents to obtain an all-solid polymer electrolyte with a thickness of 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com