Cross-linked modified polyimide single-ion polymer and gel polymer electrolyte thereof

A technology of polyimide single and ionic polymers, which is applied in the manufacture of composite electrolytes, non-aqueous electrolyte batteries, and electrolyte batteries, and can solve the problems of polymer electrolyte thermal stability and ion conductivity that are difficult to balance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

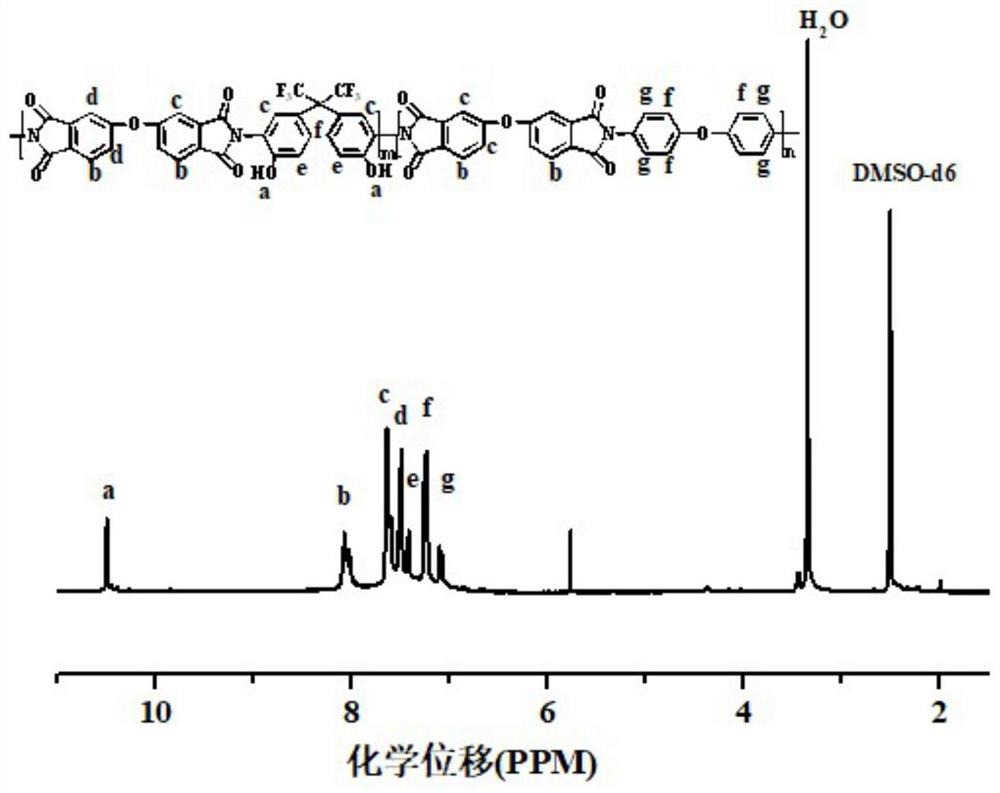

[0053] A. Synthesis of polyimide with 50% hydroxyl content:

[0054] 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (AHHFP), 4,4'-oxydiphthalic anhydride (ODPA), and 4,4'-diaminobis Add 1.83g, 3.10g, and 1.00g of phenyl ether (ODA) respectively (molar ratio is 1:2:1), add 35mL of m-cresol, pass nitrogen, add a drying tube, stir evenly, heat up to 80°C and heat and stir 4h, then add 3.5mL of isoquinoline, stir evenly, heat to 180°C, react for 18h, pour the reaction liquid into ethanol, form fibers, wash with water and ethanol alternately, and dry for later use.

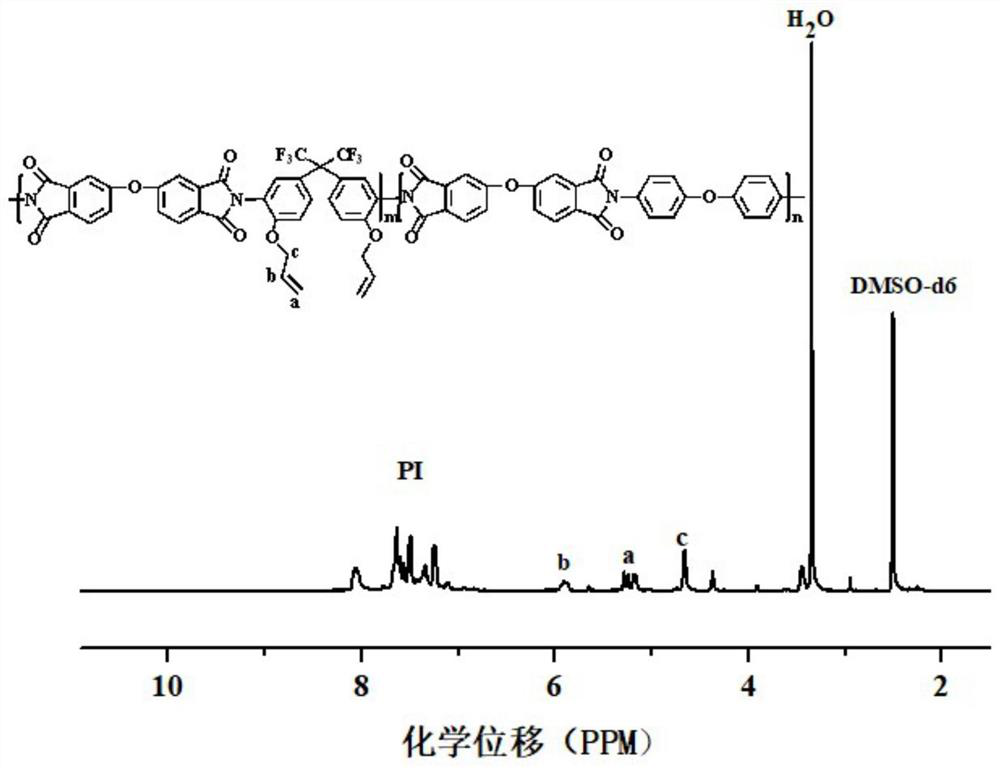

[0055] B. Preparation of polyimide containing double bonds:

[0056] Get 0.5g of polyimide obtained in step A, add it to a three-necked flask, dissolve in dimethylformamide (DMF), stir and add 1.07g of K 2 CO 3 , condensed and refluxed with nitrogen gas, heated to 100°C, continued to stir for 13 hours, poured the above reaction solution into deionized water, washed with ethanol and water alternately, and dried i...

Embodiment 2

[0066] A. Synthesis of polyimide with 70% hydroxyl content:

[0067] 2,2'-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (AHHFP), 4,4'-oxydiphthalic anhydride (ODPA), and 4,4'-diaminobis Add 2.56g, 3.10g, and 0.60g of phenyl ether (ODA) respectively (the molar ratio is 7:10:3), add 25mL of m-cresol, pass nitrogen, add a drying tube, stir evenly, heat up to 80°C and heat and stir 4h, then add 2.5mL of isoquinoline, stir evenly, heat to 180°C, react for 18h, pour the reaction liquid into ethanol, form fibers, wash with water and ethanol alternately, dry for later use.

[0068] B. Preparation of polyimide containing double bonds:

[0069] Get 0.529g of the polyimide of step B, add it in the three-necked flask, dissolve in dimethylformamide (DMF), stir and add 1.07g of K 2 CO 3 , pass nitrogen gas to condense and reflux, heat up to 100°C, continue to stir and react for 13h, pour the above reaction solution into deionized water, wash with ethanol and water alternately, and vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com