Patents

Literature

63results about How to "Low connection temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

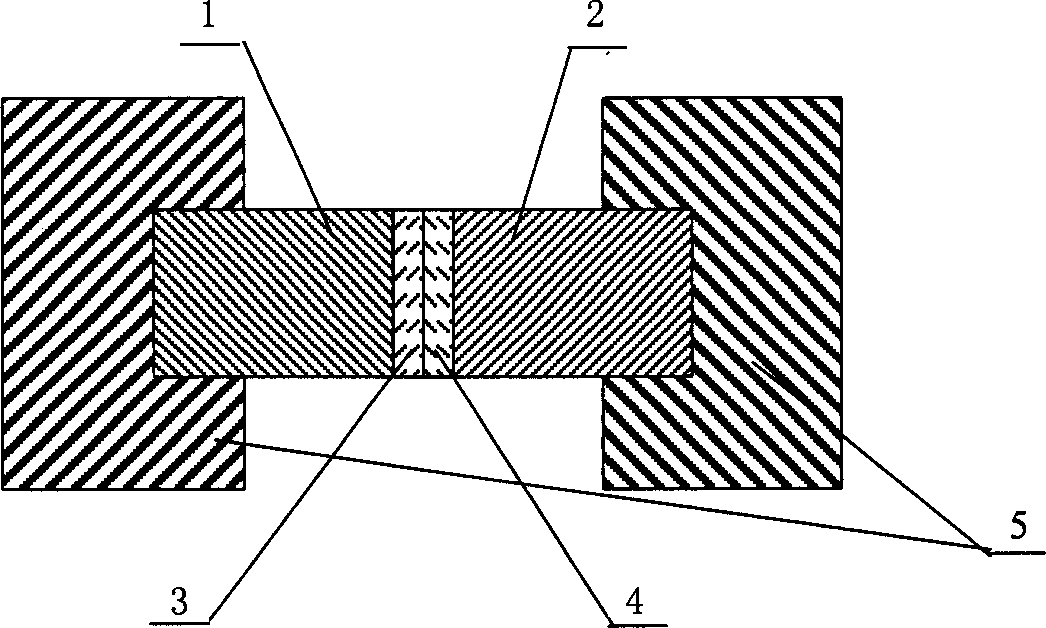

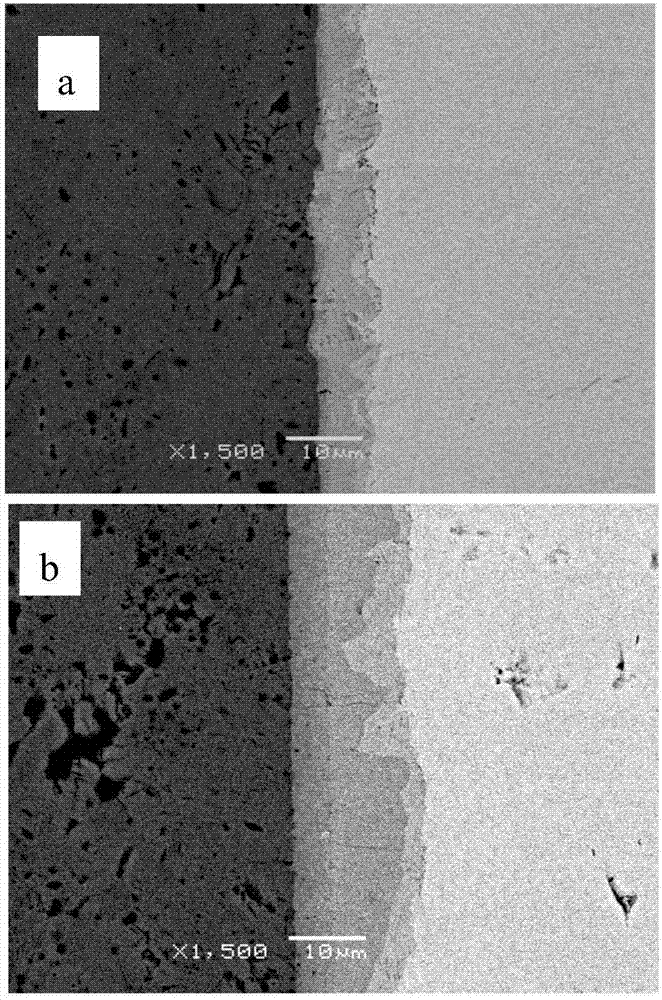

Ultrasonic brazing method for high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy

ActiveCN102658411APromote wettingLow connection temperatureSoldering apparatusRoom temperatureMaterials science

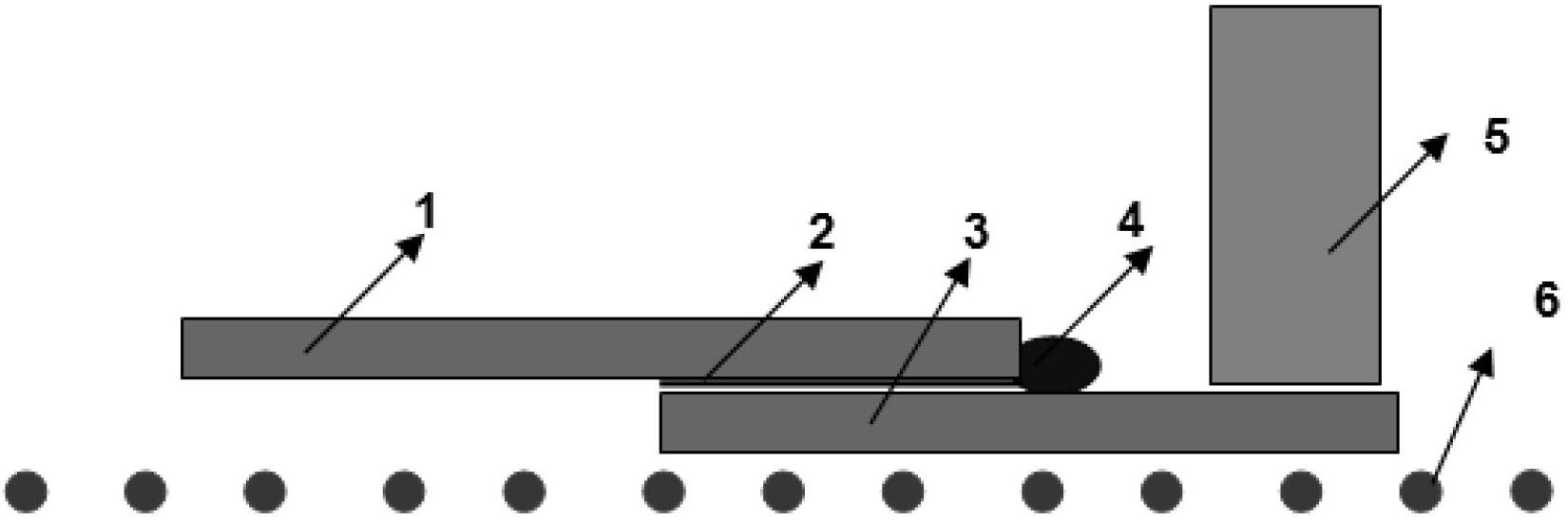

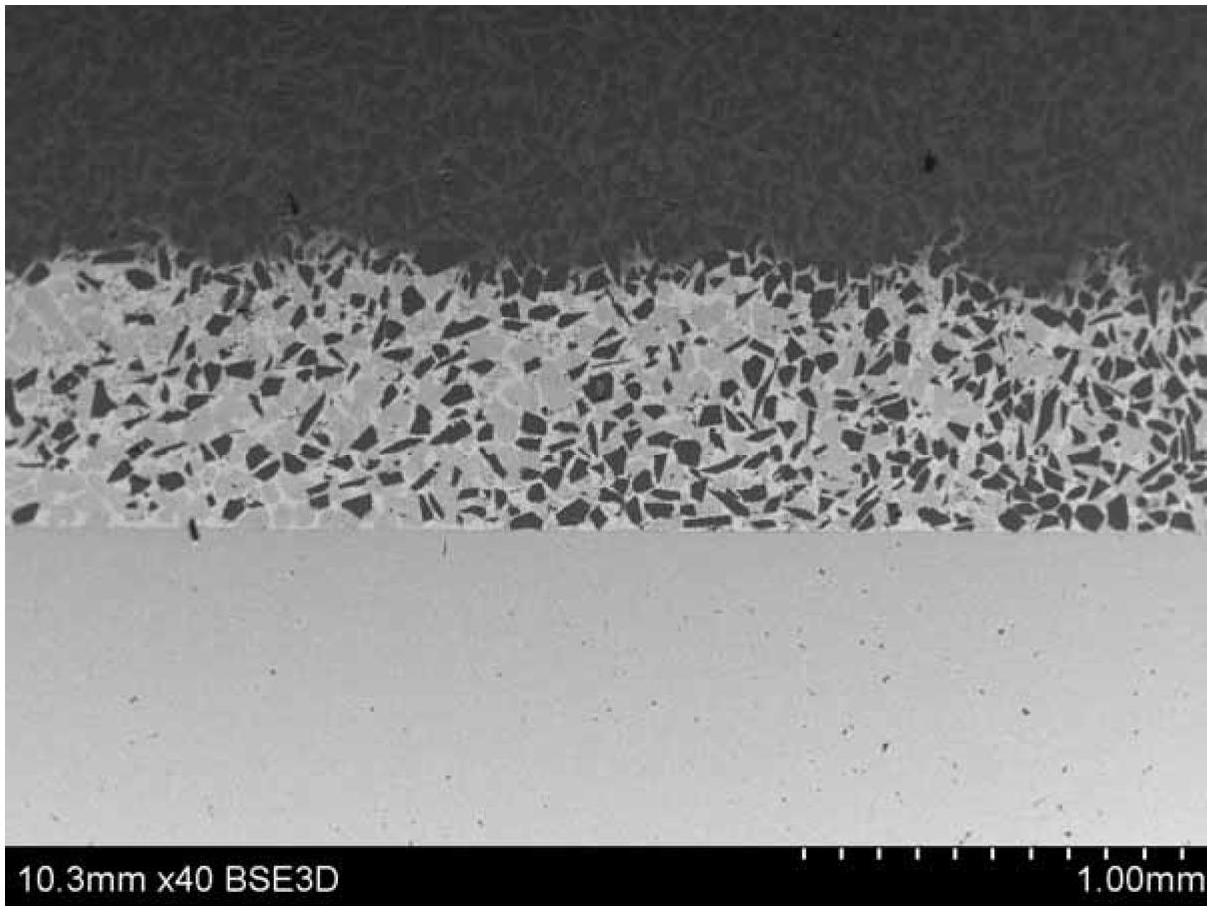

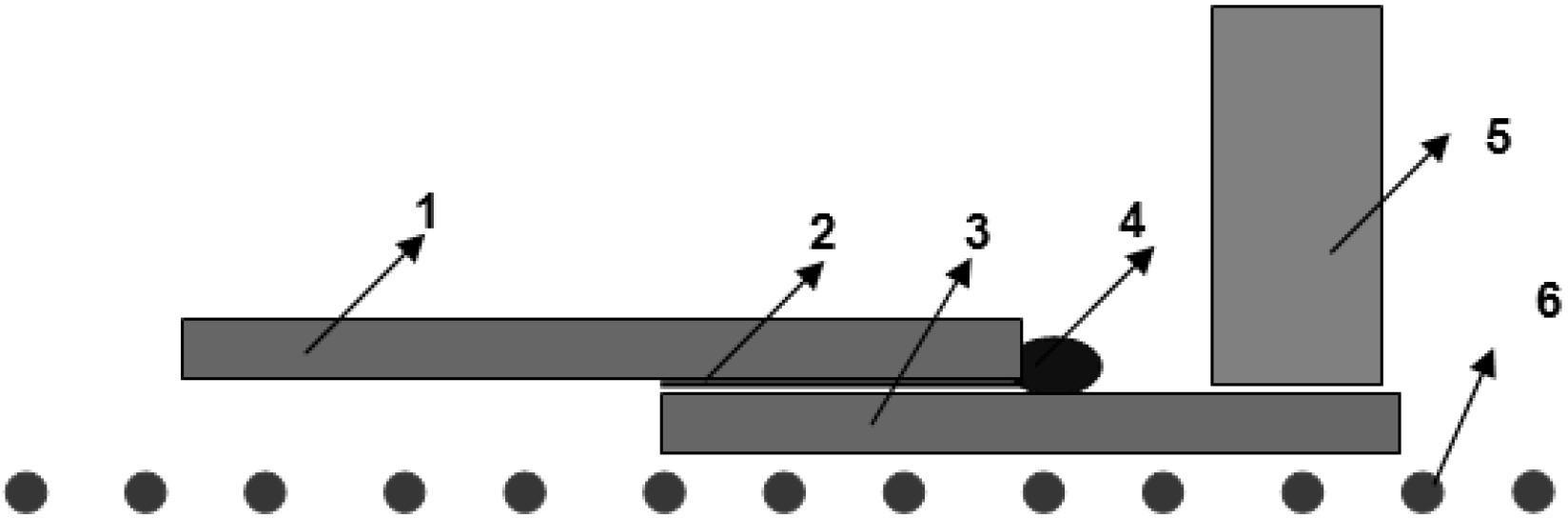

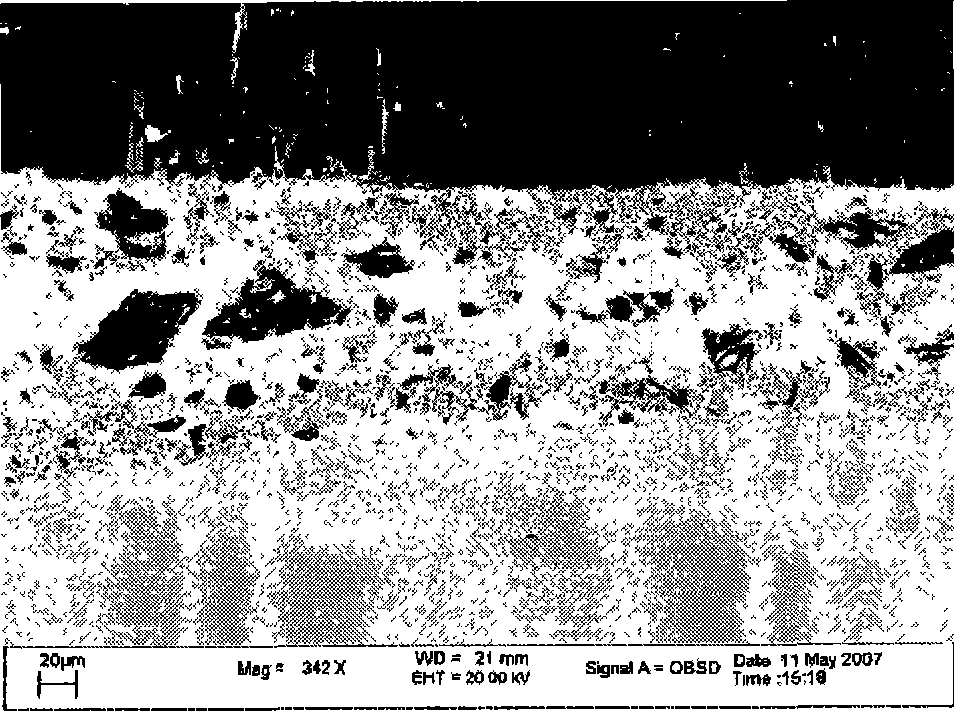

The invention relates to an ultrasonic brazing method for an aluminum-base composite and low-expansion alloy, in particular to an ultrasonic brazing method for a high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy. The ultrasonic brazing method solves the problems that existing brazing methods for connection of the high-volume-fraction silicon carbide particle enhanced aluminum-base composite and the low-expansion alloy are complex in process and high in cost, connection temperature and joint residual stress. The method includes: firstly, cleaning to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy; secondly, coating a metal layer on the to-be-brazed surface of the low-expansion alloy; thirdly, lapping the to-be-brazed surfaces of the aluminum-base composite and the low-expansion alloy, wherein brazing materials are arranged on the lateral side of a lapping joint to form a to-be-brazed part; and fourthly, heating the to-be-brazed part, ultrasonically vibrating, heating, preserving heat, pressurizing at the joint while ultrasonically vibrating, and performing furnace cooling to the room temperature, so that ultrasonic brazing is completed. The ultrasonic brazing method is simple in process, low in cost, low in connection temperature and high in joint residual stress. The ultrasonic brazing method is used for the brazing field.

Owner:HARBIN INST OF TECH

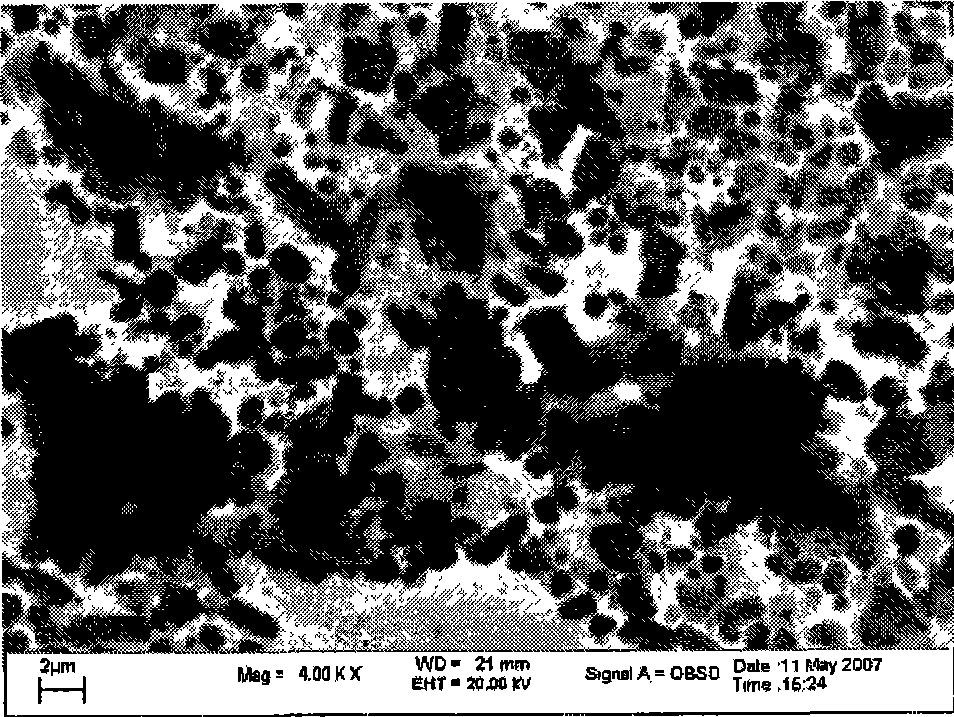

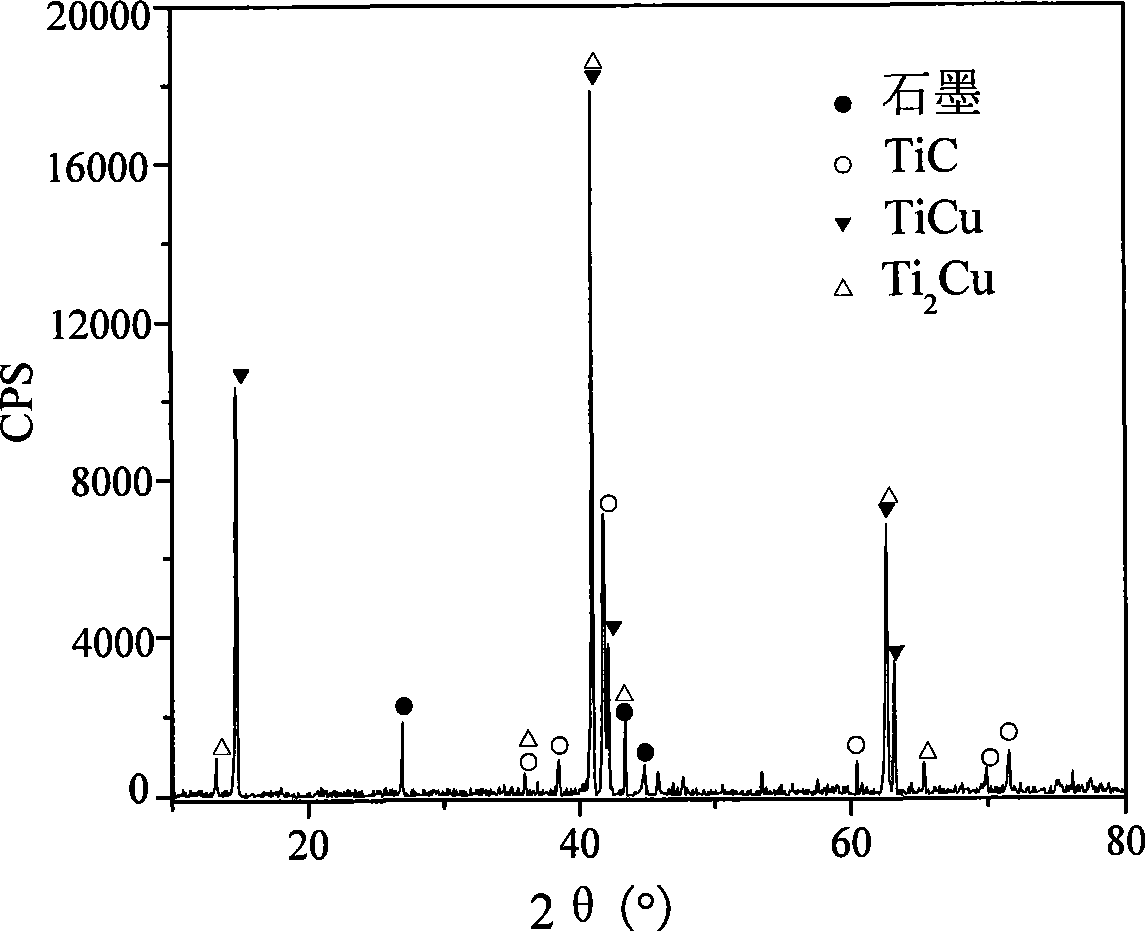

Connecting method for Cf/SiC composite material and titanium alloy

InactiveCN101462890ASmall coefficient of thermal expansionRelief of residual thermal stressRoom temperatureGraphite

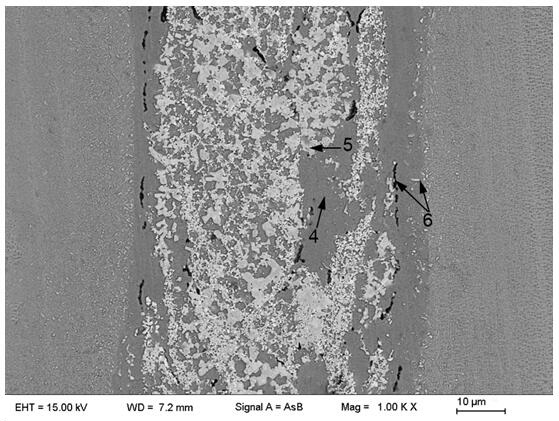

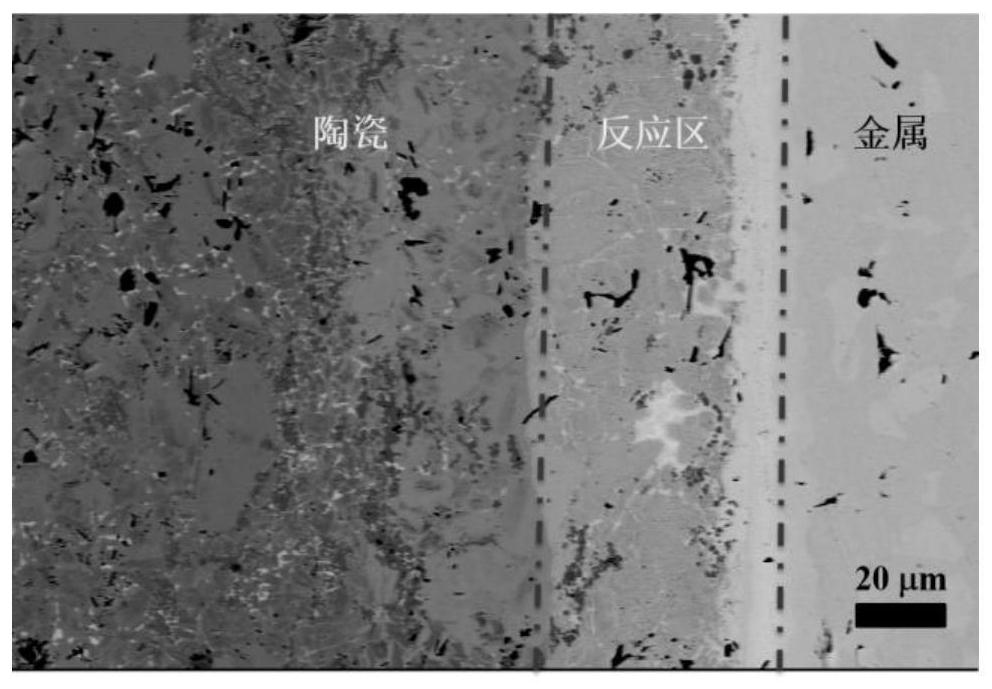

A connection method of a Cf / SiC composite material and a titanium alloy belongs to the technical field of dissimilar material connection. The method comprises the following steps: Cu, Ti and graphite powder are evenly mixed at certain proportion and prepared to a pasty solder with alcohol, the prepared pasty solder is spread between the materials to be soldered to solder the Cf / SiC ceramic-based composite material with the titanium alloy in vacuum without applying pressure. A reaction in situ occurs in a connection layer to produce a high-melting-point TiC wild phase in soldering and form a composite connection layer which is similar to a particle reinforced metal-based composite material, thus reducing the thermal expansion coefficient of the whole connection layer, relieving thermal stress of a joint and significantly improving the strength of the joint at room temperature and high temperature. The connection method has the advantages of simple process, easy preparation of connection materials, low cost, low soldering temperature, good joint performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

SPS diffusion welding method for dissimilar material of TZM and graphite

ActiveCN109048030AHigh bonding strengthImprove cooling effectNon-electric welding apparatusHeat resistanceRoom temperature

The invention discloses an SPS diffusion welding method for a dissimilar material of TZM and graphite. The SPS diffusion welding method comprises the following steps: taking a Ti foil as an active intermediate layer, and carrying out diffusion welding on a TZM alloy and graphite at a temperature lower than a recrystallization temperature for base metal through a spark plasma sintering technology to obtain a connection element of the TZM alloy and graphite. Through the welding method, the connection element made from the TZM / graphite dissimilar material, and with high bonding strength, heat dissipation performance and heat resistance can be obtained; and the room-temperature shear strength of a joint can achieve 49.0MPa.

Owner:安徽尚欣晶工新材料科技有限公司

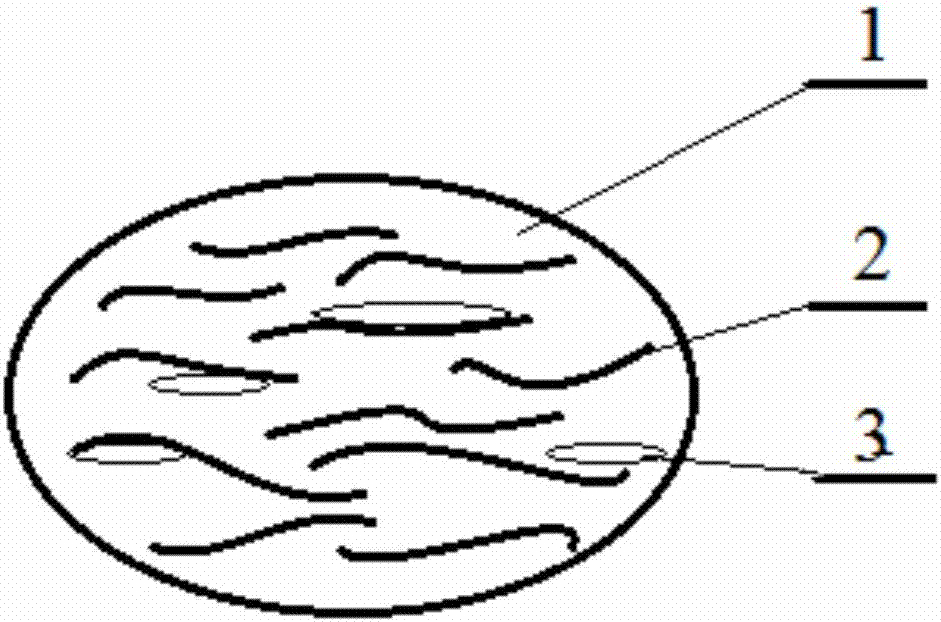

Silicon carbide granules reinforced aluminium base composite material connection method

InactiveCN1654155AAvoid damageSurface pretreatment requirements are not highWelding/cutting media/materialsSoldering mediaSlurryPre treatment

The present invention relates to the connection method of SiC particle reinforced Al-base composite material (SiCp / Al), and is especially instantaneous liquid phase diffusion connecting technology of SiCp / Al. The present invention realizes the metallurgical combination between samples with mixed Al, Ag, Cu and Ti powder as the intermediate layer, and through the ternary eutectic reaction of Al, Ag and Cu and certain time of component diffusion and homogenization. The technological process includes compounding the intermediate layer, surface treatment of the mother material to be connected, setting the mixed powder slurry compounded with anhydrous alcohol to the surface of the mother material, heating in vacuum furnace for certain time and cooling in the furnace. The said process can connect SiCp / Al parts with complicated structure and has the features of low connection temperature, less damage to mother material, etc.

Owner:UNIV OF SCI & TECH BEIJING

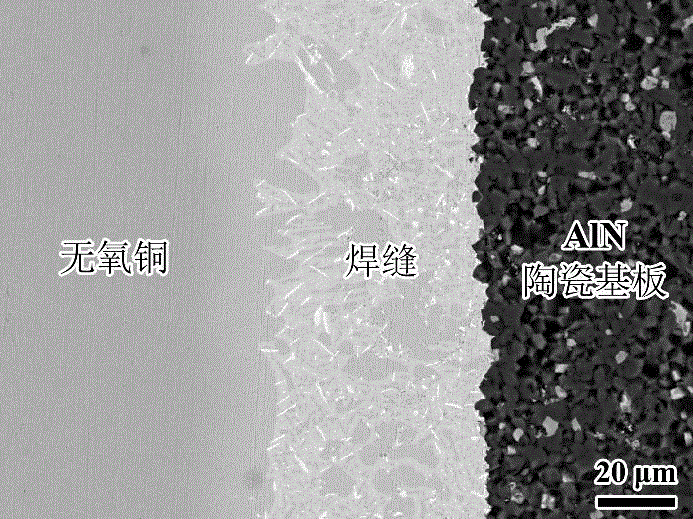

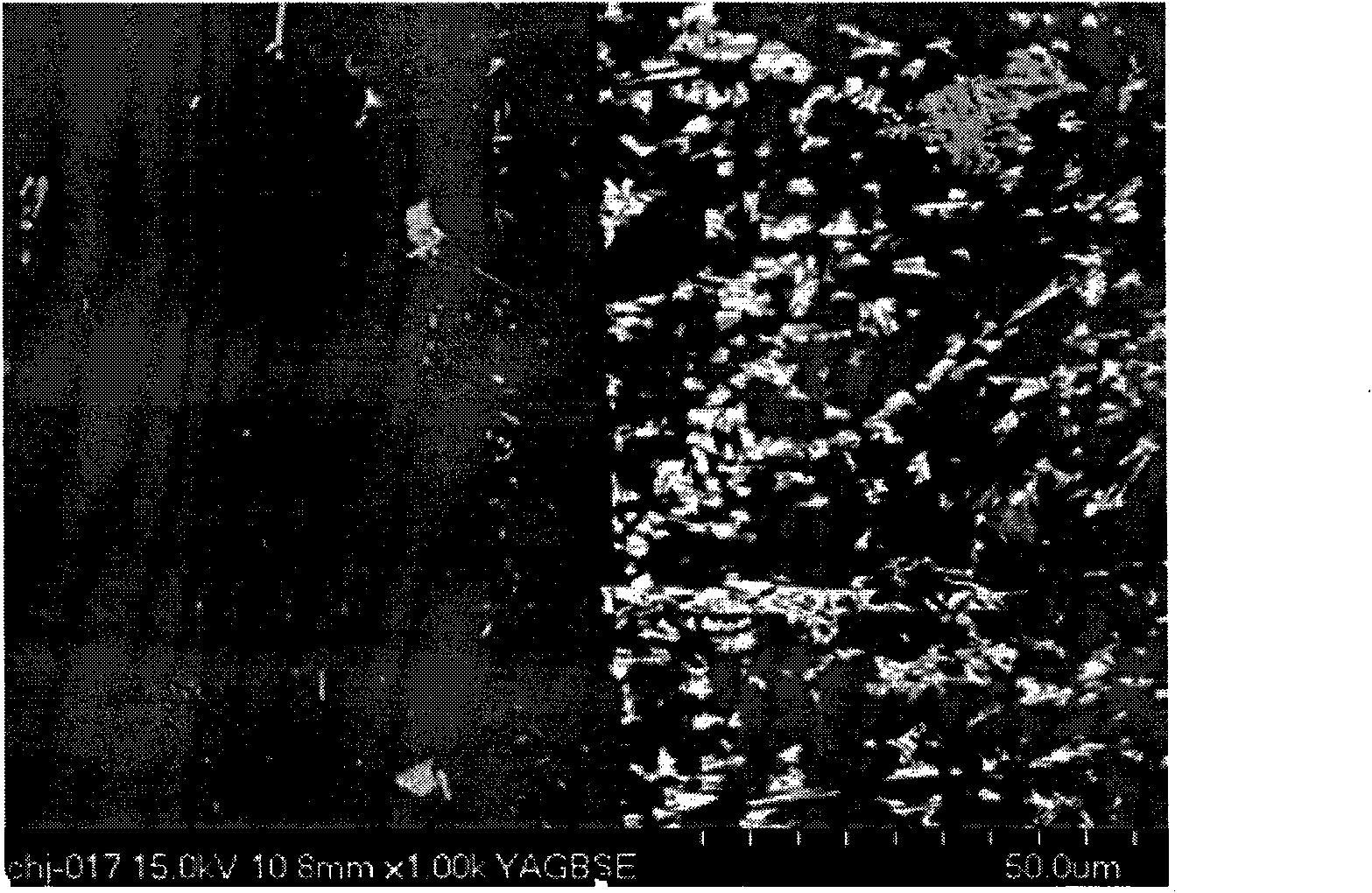

Ceramic substrate copper cladding low-temperature connection method for power module

InactiveCN106312220AReduce residual stressLow connection temperatureWelding/cutting media/materialsWelding/soldering/cutting articlesMetal powderFiller metal

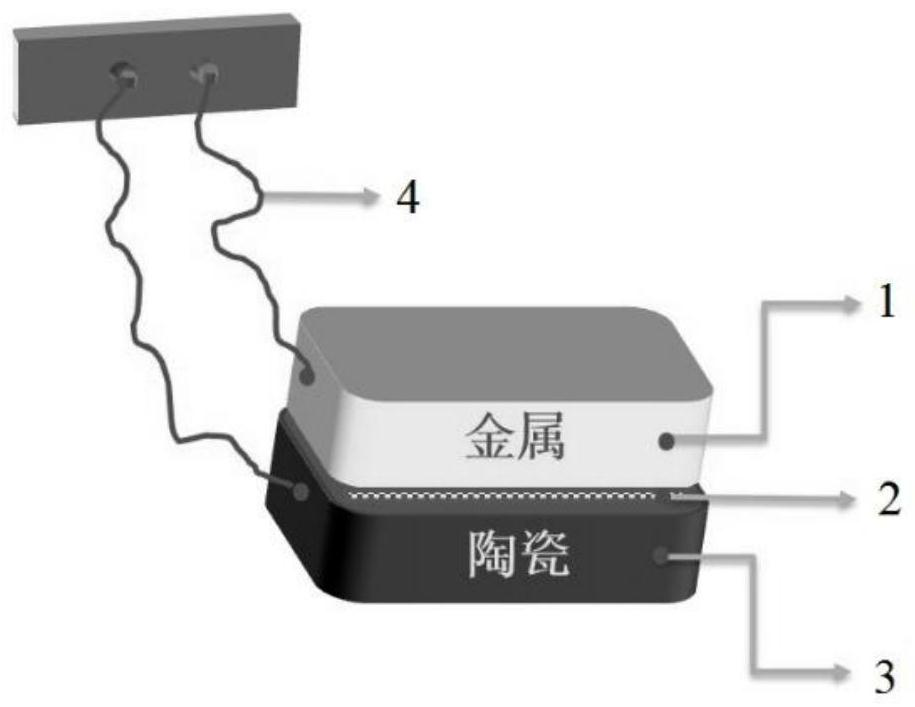

The invention discloses a ceramic substrate copper cladding low-temperature connection method for a power module. The method includes the following steps that firstly, a ceramic substrate and oxygen-free copper are subject to surface treatment, and then are subject to acetone washing; secondly, Ag powder, Cu powder, Sn powder and Ti powder or the Ag powder, the Cu powder, In powder and the Ti powder are mixed to form metal powder, an organic binder is added into the metal powder, and a mixture is placed into a ball milling tank for mechanical ball milling so as to prepare active brazing filler metal paste; and thirdly, samples are assembled from top to bottom according to the sequence of the oxygen-free copper / active brazing filler metal / the ceramic substrate, and connection is achieved in a vacuum brazing furnace. According to the method, the manner that low-melting-point elements are added into the active brazing filler metal is adopted, the connection temperature of the oxygen-free copper and the ceramic substrate is reduced, residual stress in the substrate is reduced, and the service life is prolonged.

Owner:HARBIN INST OF TECH AT WEIHAI

Tungsten and low-activation stainless steel nano-gradient composite connection method

The invention relates to a tungsten and low-activation stainless steel nano-gradient composite-diffusion connection method. According to the method, firstly, a nano composite W-Fe gradient transition layer of a two-layer structure or a three-layer structure is designed, nano composite W-Fe powder is prepared through a collosol-spray drying-thermal recovery or high energy ball milling method, and the granularity of the powder of different ingredients and sintering activity are controlled, so that the purpose that the powder of different ingredients is sintered to be close to fully dense at the same temperature is achieved; then, the W-Fe which is good in interlayer combination and close to the fully dense gradient is prepared through layered powder laying-pressing forming-high-temperature sintering forming; and finally, a W-Fe gradient transition layer high-tungsten alloy end and a W-Fe gradient transition layer low-tungsten alloy end are subjected to diffusion connection with tungsten and stainless steel in sequence correspondingly, and a W / gradient W-Fe / stainless steel connection sample piece is obtained. By means of the tungsten and low-activation stainless steel nano-gradient composite-diffusion connection method, the tungsten and stainless steel connection interface forms dense metallurgical bonding at a low temperature, connection strength is above 200 MPa, and interface stress concentration and stainless steel base material performance deterioration caused by direct connection or brazing are avoided.

Owner:CENT SOUTH UNIV +1

Braze-welding method using two-stage contact reaction of aluminum alloy

The invention relates to a braze-welding method, in particular to a braze-welding method using a two-stage contact reaction of an aluminum alloy. By taking a Zn / Cu compound intermediate layer as the liquid-phase generating source, the invention solves the problems that the welding precision is difficult to control and the welded rate is low in the existing welding method. The method of the invention comprises the following steps: forming a workpiece group to be welded which is composed of an aluminum alloy, on which a Zn / Cu compound layer is pre-formed, and a piece group to be welded, and placing the workpiece group to be welded on a brazing furnace; heating and keeping warm under the condition that the vacuum degree is no lower than 1.33*10 Pa, or the pressure of the connecting surface is 0.02MPa under the protection of argon with the purity as high as 99.999% (volume); further heating and keeping warm; stop heating, and cooling with the furnace to the temperature of 200 to 50 DEG C; then, taking out the welded workpiece group to complete the braze-welding process. The connector welded by the method of the invention has the advantages that the parent metal strength of the aluminum alloy is above 90% and the welded rate is above 98%.

Owner:HARBIN INST OF TECH

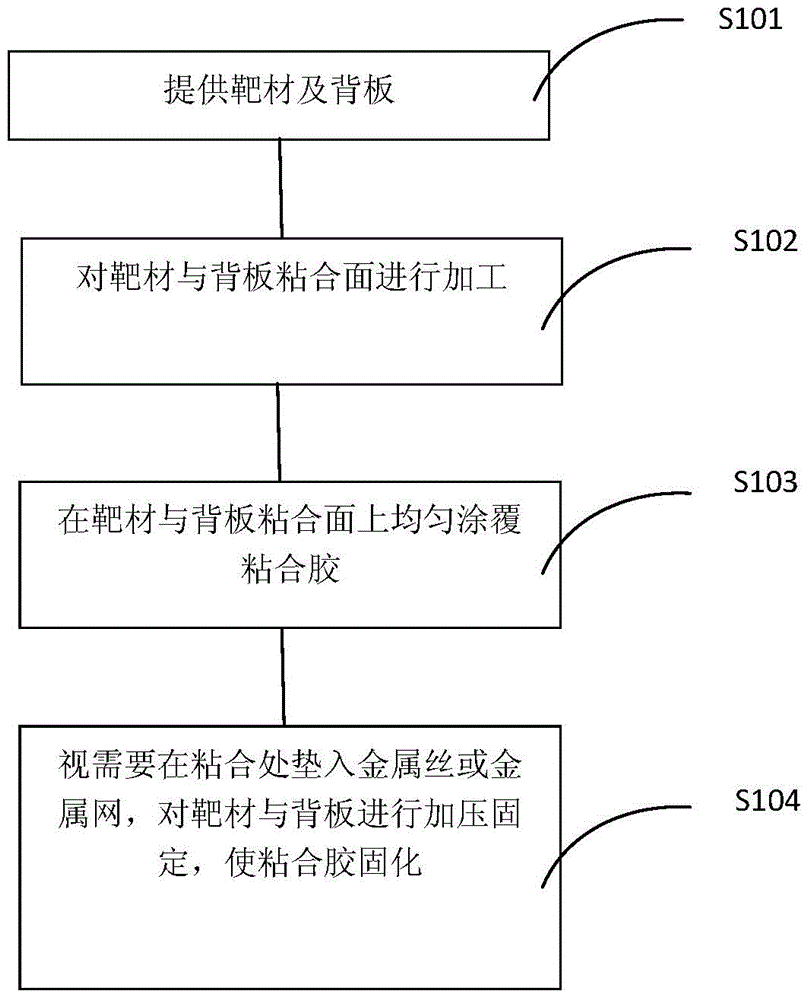

Method for adhesively connecting target and backboard

InactiveCN104690487AGuaranteed thermal and electrical conductivityFirmly connectedMetal working apparatusManufacturing technologyRoom temperature

The invention belongs to the technical field of manufacturing of targets, and particularly relates to a method for adhesively connecting a target and a backboard. The method comprises the following steps: providing the target and the backboard; processing an adhesion surface of the target and the backboard; evenly coating and adhering required organic glue on the adhesion surface of the target and the backboard; adhering the target and the backboard, and using a normal-temperature solidifying or low-temperature solidifying mode to guarantee reliable adhesion. The organic glue is used in adhesion to achieve the reliable connection of the target at the normal temperature or low temperature, the excellent thermal conductivity and electric conductivity and the enough connection strength are guaranteed in the sputtering process of the target, meanwhile, the connection temperature is reduced, so that the problems of target fragmentation, deformation and the like possibly caused by high-temperature heating are avoided, the requirement of connection of the special target at the normal temperature is met, meanwhile, the operation difficulty is lowered, and the yield is improved.

Owner:GRIKIN ADVANCED MATERIALS

Superplastic diffusion process for joining different alloys and its application

InactiveCN1346725APerformance is not affectedMeet fine grain requirementsMetallic material coating processesLaser beam welding apparatusMetallurgyAlloy

A superplastic diffusion process for joining different alloys includes high-speed laser fusing or alloying the surfaces of alloys to be joined, and superplastic diffusion. The alloy component used in laser alloying is same as the alloy with superplastic potential at lower temp. It combines laser surface modification with superplastic diffusion join.

Owner:BEIHANG UNIV

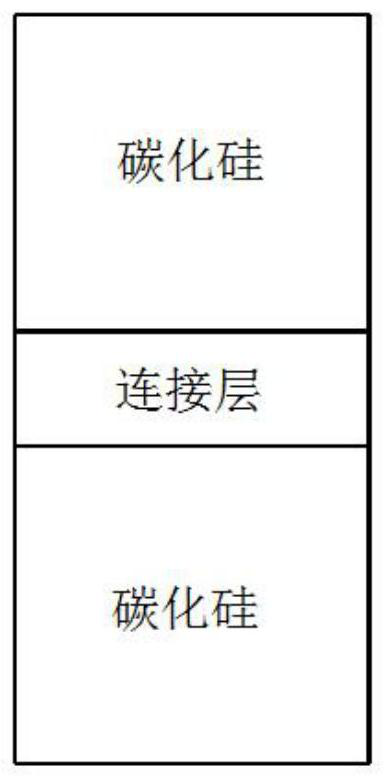

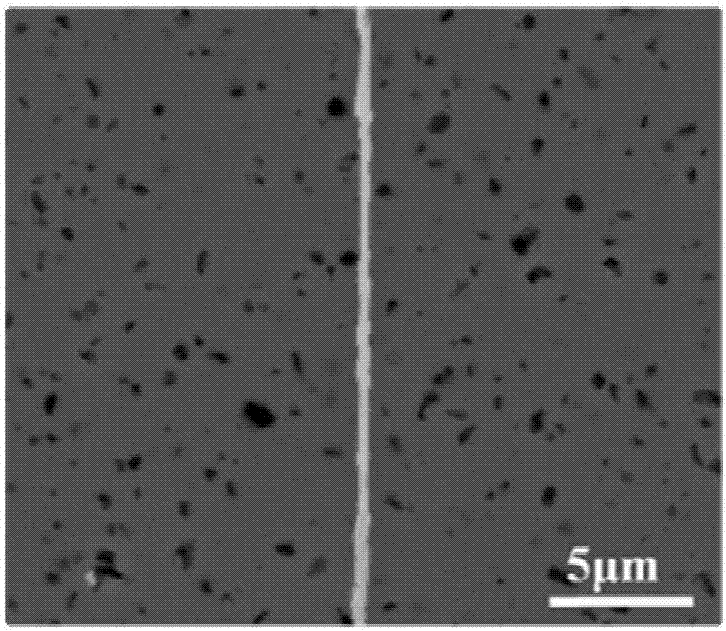

Connecting material for connecting silicon carbide ceramics and application method thereof

InactiveCN111892418AIncrease the surface energy of the interfaceInterface surface energy increaseCarbide siliconHigh entropy alloys

The invention discloses a method for electric field assisted connection of silicon carbide ceramic and a connecting material adopted by the method, and belongs to the field of silicon carbide ceramicmaterial. The method comprises the following steps: clamping a connecting layer between to-be-connected silicon carbide ceramic materials, and connecting the to-be-connected SiC materials together byheating a connecting interface to a connecting temperature of 1000 DEG C or above under the assistance of an external electric field; wherein the connecting layer is a high-entropy alloy sheet with the thickness smaller than 1 mm. And the connecting layer is made of a CoFeCrNiCuTix high-entropy alloy. The requirement for an external heat source is low, the connecting speed is high, the mechanicalstrength performance of the connected silicon carbide ceramic material is good, cost saving is facilitated, the industrial production difficulty is lowered, and rapid and high-quality connection is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Copper/tin nano composite powder active solder and preparation method thereof

ActiveCN107350655AWide variety of sourcesLow priceWelding/cutting media/materialsSoldering mediaHigh energyTemperature resistance

The invention discloses copper / tin nano composite powder active solder and a preparation method thereof, and belongs to the technical field of electronic packaging. The copper / tin nano composite powder active solder is formed by mechanical activation compounding of copper and tin, and the molar ratio of the copper to the tin is 1:1-3:1. The particle size of composite powder is tens of to hundreds of microns, and the composite powder is formed by alternately arraying the copper and the tin in a layering mode. The thickness of each layer is tens of to thousands of nanometers. A small amount of copper and tin intermetallic compound can be formed in particles of the composite powder. The mechanical activation preparation method of the composite powder active solder refers to high energy ball milling. According to the high energy ball milling, pure copper powder and pure tin powder are used as raw materials, the molar ratio of the copper powder raw material to the tin powder raw material is 1:1-3:1, vacuum or atmosphere protection is used, and ball milling time is 0.5-8h. The copper / tin nano composite powder active solder and the preparation method thereof have the advantages of being simple in preparation technology, low in connecting temperature and short in connecting time and thus can be used for electronic packaging of a new generation of chips and high-temperature-resistance electron devices of the chips.

Owner:UNIV OF SCI & TECH BEIJING

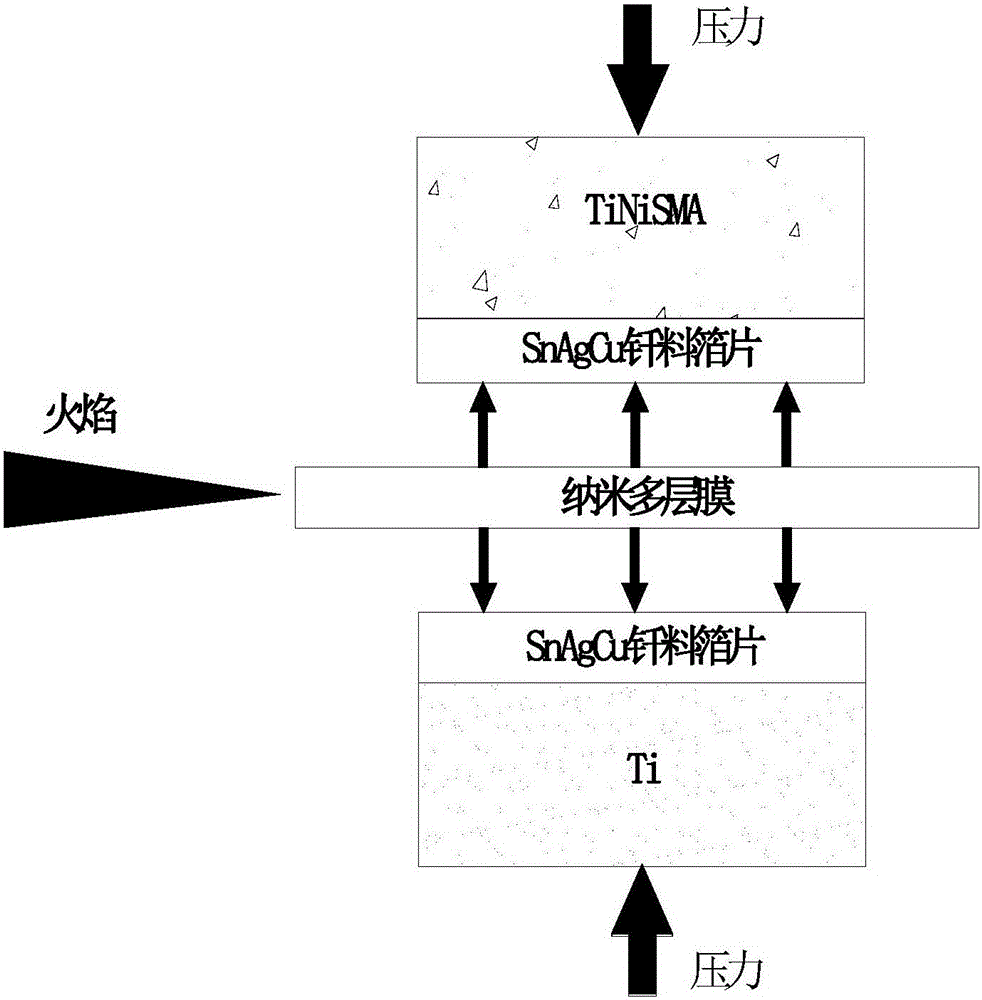

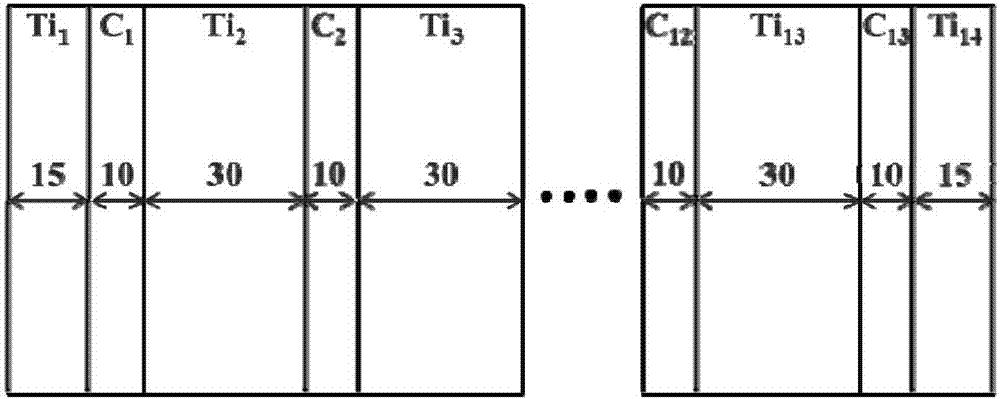

Method for connecting TiNi SMA with titanium or titanium alloy through nano multilayer film self-propagating reaction

ActiveCN106238851AHigh strengthLow connection temperatureSoldering apparatusWelding/soldering/cutting articlesSputteringHeat-affected zone

Disclose is a method for connecting titanium-nickel SMA (shape memory alloy) with titanium or TC4 through self-propagating reaction. The method comprises the steps that 1, an active nano thin film is prepared, specifically, a magnetron sputtering machine is used for conducting alternative sputtering of titanium and nickel, finally the total thickness of the thin film is 4 [mu]m-15 [mu]m, and sealing storage is conducted; 2, surface treatment is conducted, specifically, the polished TiNiSMA, two SnAgCu brazing filler metal foil pieces with the thickness of 30-70 [mu]m and metal are put into ethyl alcohol for ultrasonic cleaning and then dried, and the metal is the titanium or the TC4; and 3, ignition is conducted, specifically, the TiNiSMA, one SnAgCu brazing filler metal foil piece, the active nano thin film, the other SnAgCu brazing filler metal foil piece and the metal are overlapped sequentially, then ignition is conducted under the pressure of 2 MPa-7 MPa, and connection of the TiNiSMA with the metal titanium or the TC4 material is completed though heat emitted by the active nano multilayer film. According to the method, the speed, the connector strength and the efficiency are high, integral heating is not needed, a heat affected zone is small, and the performance of the two materials is not influenced.

Owner:BEIJING UNIV OF TECH

SPS connecting method of WRe/TZM/graphite

The invention discloses an SPS connecting method of WRe / TZM / graphite. The SPS connecting method comprises the steps that a graphite gradient mould is adopted, gradient sintering of WRe alloy powder and TZM alloy powder is achieved through an SPS technology, and a titanium foil serves as an intermediate transition layer to achieve dissimilar material connection between the TZM alloy powder and a graphite block body, so that a WRe / TZM / graphite dissimilar material connecting piece is obtained. Through the connecting method, the WRe / TZM / graphite dissimilar material connecting piece which is densein sintering, uniform in connecting surface diffusion, high in bonding strength, good in heat dissipation performance and good in thermal shock resistance can be obtained, the density of a WRe alloy layer reaches 98.07%, the density of a TZM alloy layer reaches 97.98%, the connecting surface diffusion is uniform, the connector room temperature shearing strength of the WRe / TZM side can reach 303.9MPa, and the connector room temperature shearing strength of the TZM / graphite side can reach 31.2 MPa.

Owner:HEFEI UNIV OF TECH

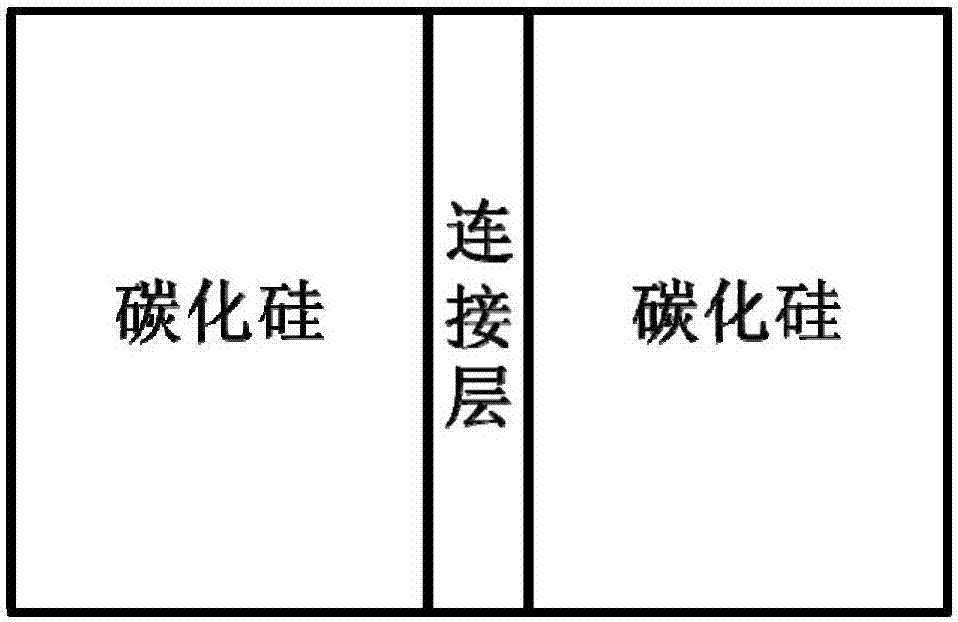

Connection material for connecting silicon carbide ceramics, and method for connecting silicon carbide ceramics

ActiveCN107488046APromotes sintering densificationIncrease the surface energy of the interfaceCarbide siliconCarbon layer

The present invention provides a connection material for connecting silicon carbide ceramics. The connection material has a left-right stacked structure, and comprises at least two titanium layers, wherein a carbon layer is arranged between the adjacent titanium layers. According to the present invention, the connection material is sandwiched between silicon carbide ceramic materials to be connected, and the nanometer titanium layer and the nanometer carbon layer are subjected to an exothermic reaction when the SiC materials to be connected are integrally connected by heating the connection interface through an external heat source, such that the middle connection layer can release the partial heat so as to reduce the energy supply of the external heat source, easily save the cost, and reduce the industrial production difficulty.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

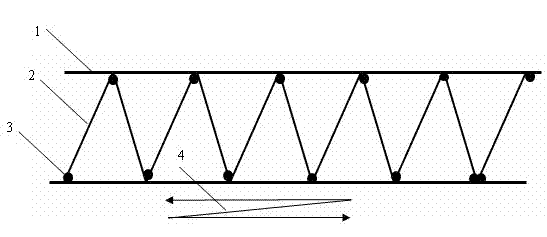

Magnesium alloy honeycomb structure material and preparation method thereof

InactiveCN103240924ASmall heat affected zoneLow connection temperatureLayered productsSoldering apparatusTemperature resistanceHoneycomb structure

The invention relates to a magnesium alloy honeycomb structure material and a preparation method thereof, belonging to the technical field of composite materials, and characterizing in that the magnesium alloy honeycomb structure material has high bonding strength, can be used without finish machining of a connecting interface and has high-temperature resistance, and the method is a semi-solid soldering method based on ultrasonic assistance. The magnesium alloy honeycomb structure material is formed by connecting upper and lower panels with ultrasonic assisted liquid with a honeycomb core structure together, wherein the thickness of the upper and lower panels is 1-4.5mm, the thickness of a magnesium alloy thin plate of the honeycomb core structure is 0.5-0.8mm, and the width of the thin plate is 10-50mm. The magnesium alloy honeycomb structure material manufactured by using the ultrasonic assisted liquid for connection can be used at a high temperature, and the strength of the magnesium alloy honeycomb structure material is 25-35Mpa. A magnesium alloy honeycomb plate prepared from the magnesium alloy honeycomb structure material is high in strength, lightweight and high-temperature resistant, can be widely used in modern means of communication and transportation such as space vehicles, aerial vehicles, high-speed rails, urban rail trains and the like, and can be used as components of wall plates, floors, sound-proof materials and the like.

Owner:TAIYUAN UNIV OF TECH

Low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum

InactiveCN104191085APrecise control of process parametersLow costWelding/soldering/cutting articlesNon-electric welding apparatusParacrystallineAlloy

The invention discloses a low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum. The method includes the main steps that quasi-crystal aluminum silicon copper middle transition alloy foil sheets are arranged between contact interfaces to be welded of aluminum plates and contact interfaces to be welded of a low-carbon steel plate, vacuum diffusion bonding is conducted, processing parameters are that the bonding temperature is controlled in the range of 420 degrees to 490 degrees, the heat preservation time under the bonding temperature ranges from 15 min to 25 min, the pressure ranges from 0.3 MPa to 0.9 MPa, and the vacuum degree is 1.33*10<-3> Pa-1.33*10<-2> Pa. By means of the method, low-temperature diffusion bonding of the aluminum and the low-carbon steel can be achieved, the diffusion interfaces of the formed aluminum-steel-aluminum composite structure is firm in combination, reliable in bonding quality and high in production efficiency. The low-temperature diffusion bonding method for adding the quasi-crystal interlayers to aluminum-steel-aluminum has the advantages of being precise in processing parameter control, low in cost and the like, and the bonding temperature can be reduced.

Owner:SHANDONG UNIV

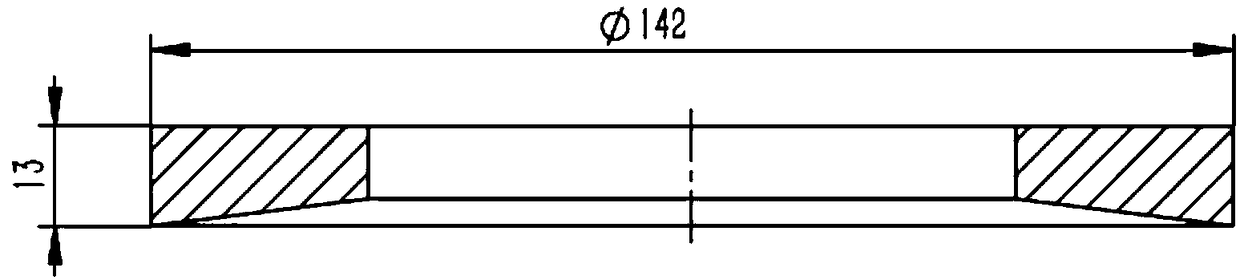

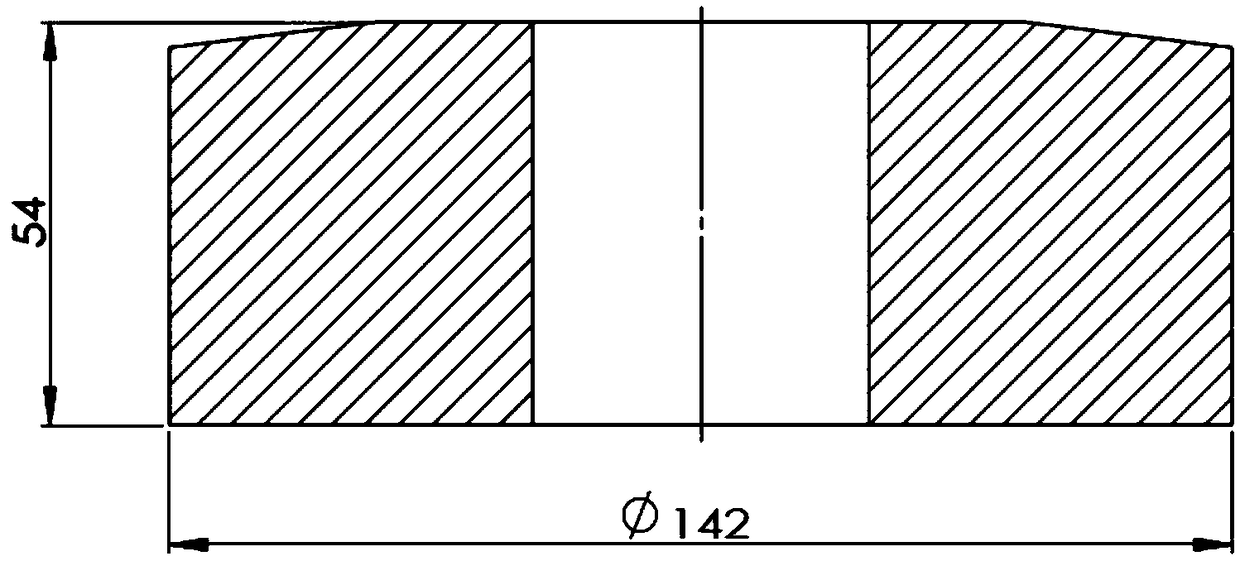

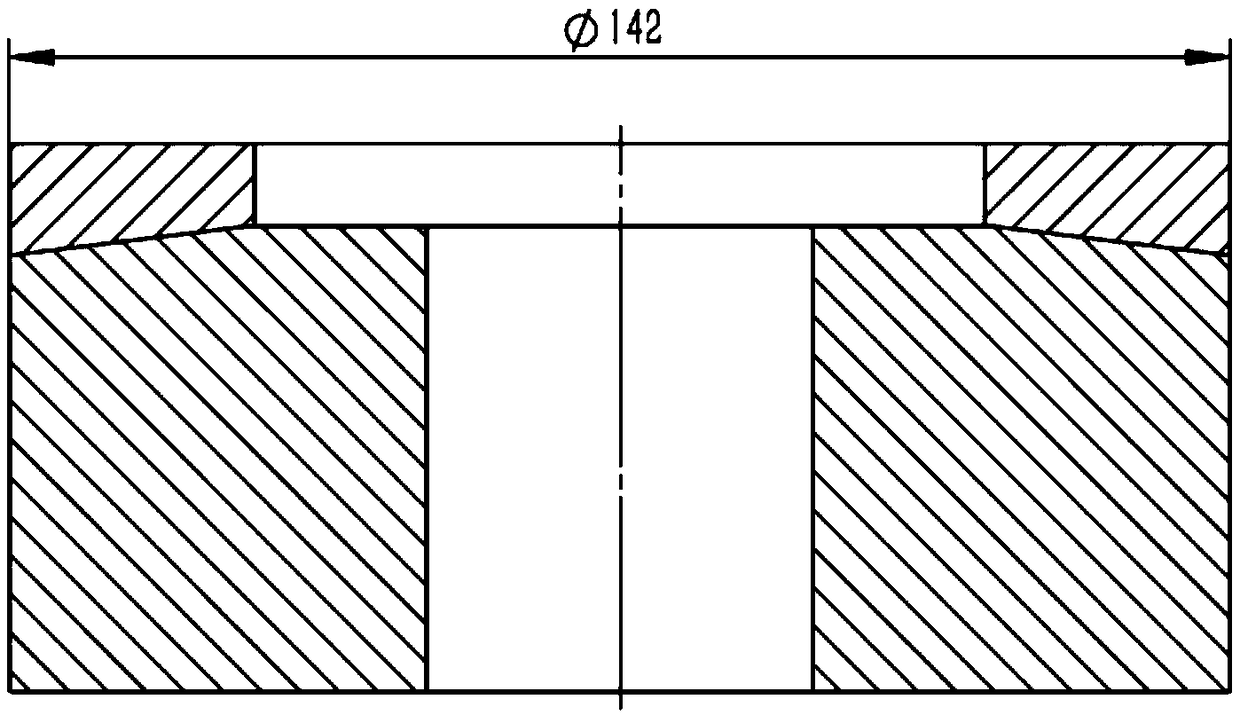

Manufacturing method of W/Mo/graphite composite anode target material for X-ray tube of CT machine

ActiveCN108907630AHigh densityHigh bonding strengthNon-electric welding apparatusAlloyVolumetric Mass Density

The invention discloses a manufacturing method of a W / Mo / graphite composite anode target material for an X-ray tube of a CT machine. According to the manufacturing method, a tungsten plate, a molybdenum cylinder and a graphite block are used as raw material. The manufacturing method comprises the step 1 of machining the tungsten plate and the molybdenum cylinder according to the required shape andsize of the anode target material, ensuring that the size of the outer circumferences of the machined tungsten plate and molybdenum cylinder have allowance on the basis of the required size of the outer circumference of the anode target material; the step 2 of performing SPS diffusion connection on the machined tungsten plate and molybdenum cylinder to obtain a W / Mo connecting piece; and the step3 of machining the W / Mo connecting piece and the graphite block according to the required shape and size of the anode target material, and performing SPS diffusion connection on the machined W / Mo connecting piece and the graphite block to obtain the W / Mo / graphite composite anode target material. According to the manufacturing method, the W / Mo / graphite composite anode target material has the advantages of being high in density, high in bonding strength of the W / Mo alloy layer and the Mo / graphite alloy layer, good in heat dissipation, good in resistance to heat shock, long in service life and the like.

Owner:安徽尚欣晶工新材料科技有限公司

Low-temperature glass brazing method aided by micro-arc oxidation

ActiveCN105499733AReduce complexityLow connection temperatureSoldering ironMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a low-temperature glass brazing method aided by micro-arc oxidation. The invention aims at solving the problems that the spreadability and the wettability are insufficient and the strength of a brazed joint is relatively low due to poor chemical compatibility or low brazing temperature between a brazing material and masterbatch and high viscosity of a molten glass brazing material in a process of brazing using the low-temperature glass brazing material. The brazing method comprises the following steps: 1, mixing low-temperature sealing glass powder and an adhesive to obtain brazing paste; 2, carrying out cutting molding on masterbatch to be brazed; 3, carrying out ultrasonic cleaning and polishing on a weldment; 4, carrying out micro-arc oxidation and hole sealing on the weldment; 5, coating the surface of the weldment subjected to micro-arc oxidation with the brazing paste; 6, constituting a piece to be brazed; 7, carrying out high-pressure brazing in an argon atmosphere or under a negative pressure condition. The low-temperature sealing glass used in the brazing process is low in sealing temperature and small in linear expansion coefficient; the obtained brazed joint has no cracks and pores, and has small residual stress, high strength and good air tightness; meanwhile, a compact ceramic film layer formed by micro-arc oxidation has a favorable protection effect on the masterbatch.

Owner:HARBIN INST OF TECH

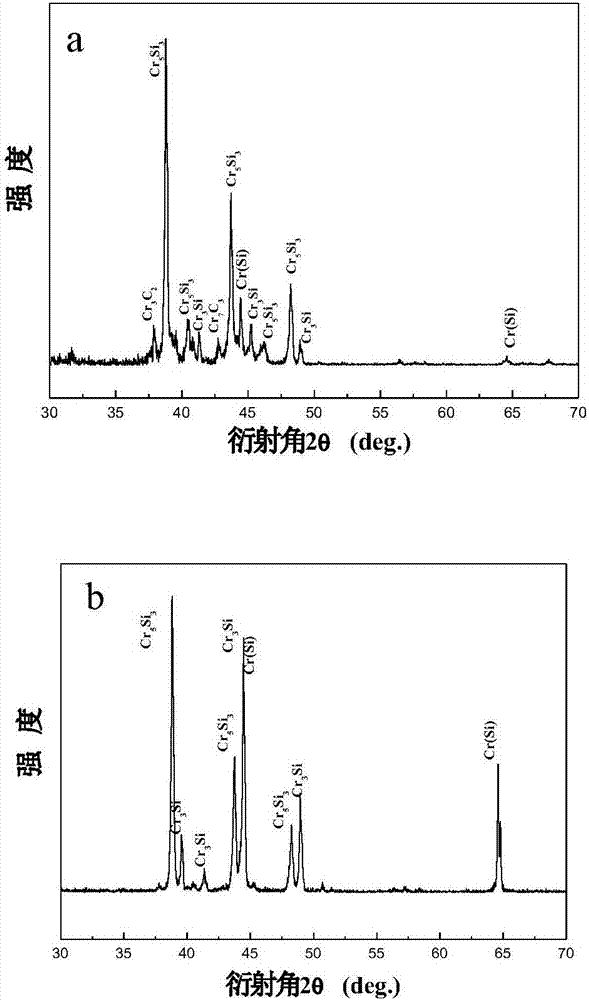

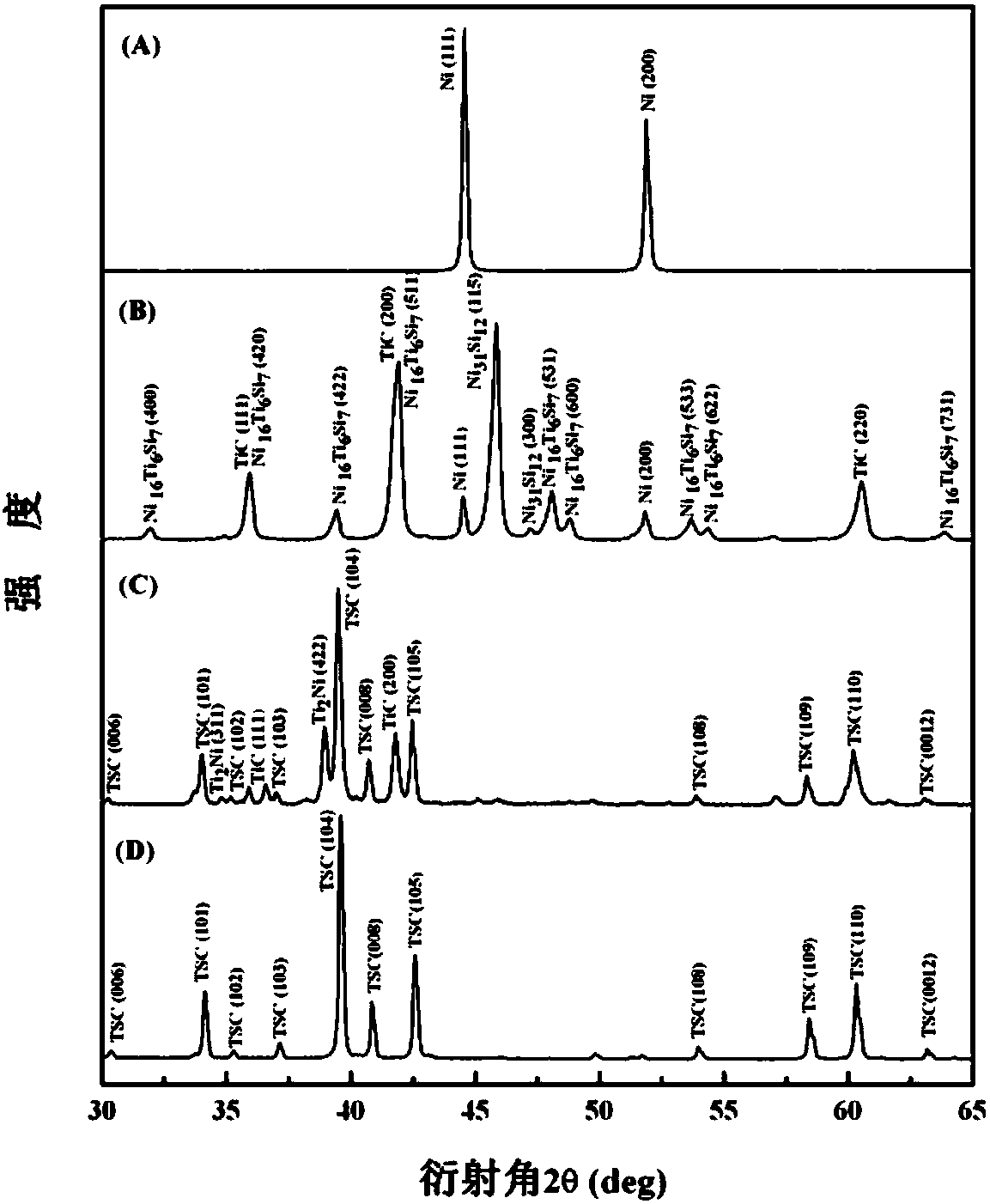

Diffusion connection method of ternary layered ceramic carbon silicide and metallic chromium

The invention discloses a diffusion connection method of a ternary layered ceramic carbon silicide and metallic chromium and belongs to the technical field of connection between the ceramic and metal.The method comprises carrying out surface treatment on ternary layered ceramic and metallic chromium, then carrying out grinding, polishing and ultrasonic cleaning, then installing the ternary layered ceramic and metallic chromium in a hot press furnace, vacuumizing the hot press furnace, carrying out heating when the vacuum degree in the hot press furnace is 5*10<-2> Pa, carrying out heat preservation at a temperature of 1000-1200 DEG C under the constant pressure of 20-30 MPa for 30-90min so that the diffusion connection of the ternary layered ceramic and metallic chromium is realized, thencarrying out cooling to 200 DEG C under original vacuum conditions and releasing the pressure. The joint obtained by the method has good interface bonding and satisfies practical application requirements. The method widens a ternary layered ceramic carbon silicide application range.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

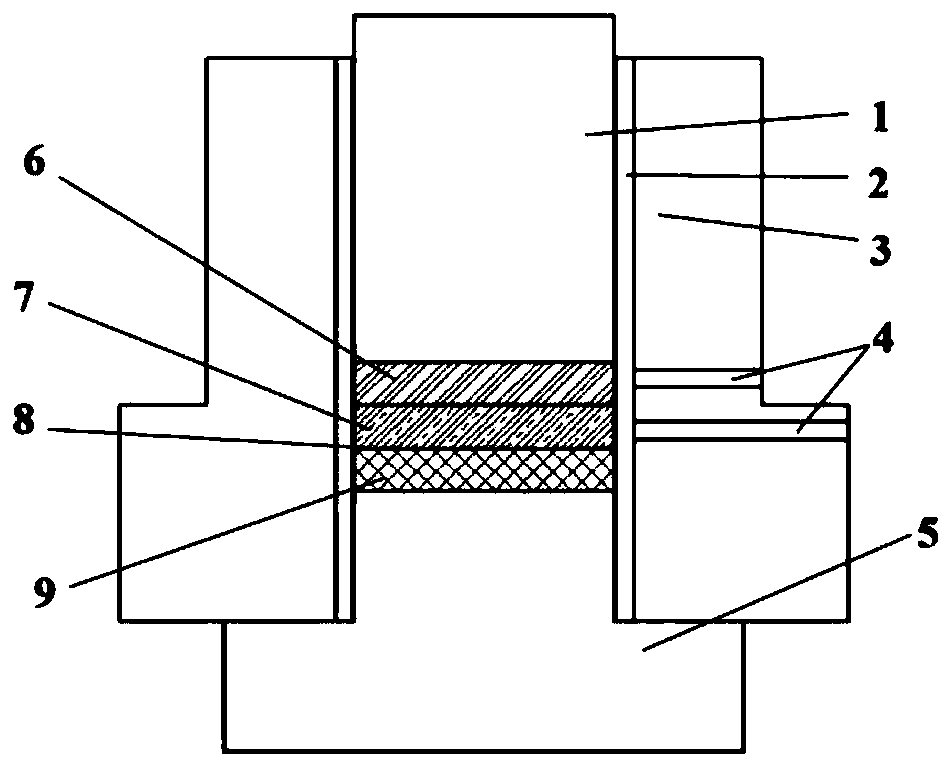

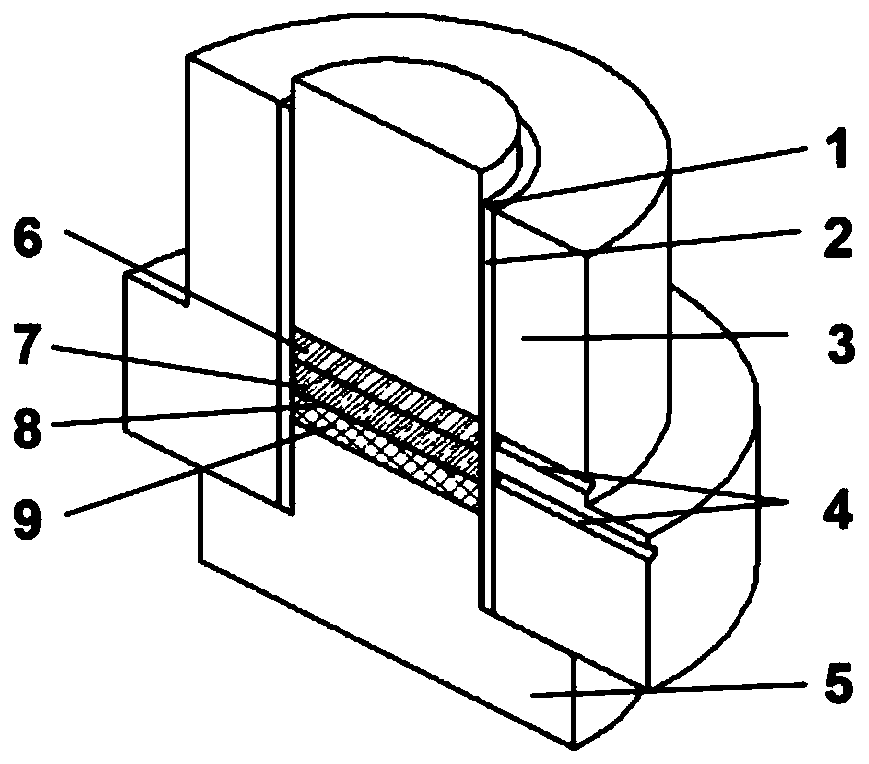

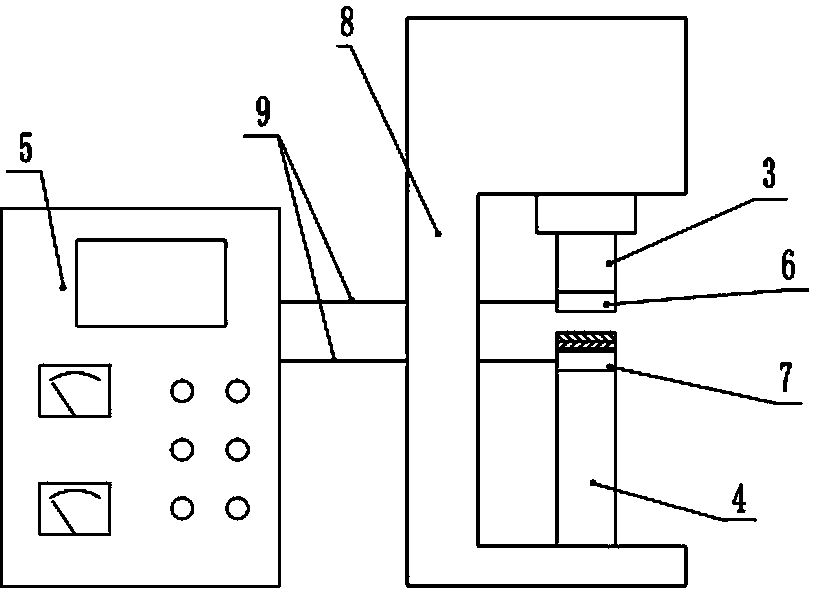

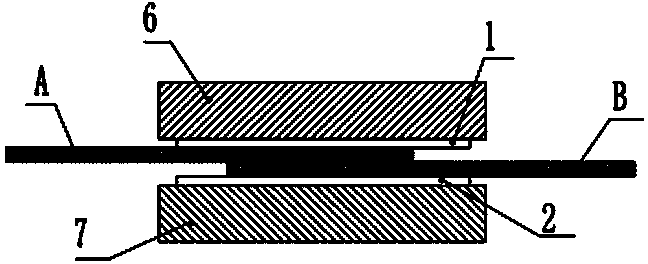

Connection method of silver, copper and zinc belt-shaped solder and special connection device used in connection method

ActiveCN104191112AUniform materialReduce volatilityWelding/cutting media/materialsSoldering mediaSolder ballZinc

The invention discloses a connection method of silver, copper and zinc belt-shaped solder and a special connection device used in the connection method. According to the connection method, firstly, oxides on connection faces, to be connected, of two solder belts are removed; the connection portions of the solder belts are placed between an upper copper plate and a lower copper plate after being clamped and overlapped through the upper copper plate and the lower copper plate, and the contact faces of the solder belts are coated with silver solder flux and are placed between an upper pressure column and a lower supporting column; the upper pressure column falls downwards so as to tightly press the connection portions and keeps certain pressure; the upper copper plate and the lower copper plate are heated through an upper conductive electrode and a lower conductive electrode, so that the connection portions of the overlapped solder belts are heated and melted, the surfaces of the upper and lower copper plates are wetted through the melted solder, the surfaces of the copper plates are uniformly laid, the connection portions become thinner under pressure of the upper copper plate and the lower copper plate, redundant solder forms flash, the flash is cut off, the upper copper plate and the lower copper plate are worn off, and then connection is achieved. Materials of connectors of the solder belts are uniform, strength of the materials of the connectors of the solder belts is the same as that of base metal, and connection requirements in the rolling process of the silver, copper and zinc belt-shaped solder can be met. Meanwhile, the special connection device for the method is simple in structure and convenient to operate.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

SPS diffusion welding method for DD98 congeneric nickel-based mono-crystalline high-temperature alloy

ActiveCN113182660ALow melting pointPromote wettingNon-electric welding apparatusSingle crystal superalloySingle crystal

The invention discloses an SPS diffusion welding method for DD98 congeneric nickel-based mono-crystalline high-temperature alloy. A Ni-Cr-W-B-Si-Fe powder solder is used as a middle transition layer, and effective connection of the DD98 congeneric nickel-based mono-crystalline high-temperature alloy is achieved at low temperature within short time through the spark plasma sintering technology. Through the welding method, it can be ensured that a base metal is not crystallized, stable and reliable joints with refined welding line crystalline grains and uniformly dispersed connecting faces are obtained, and the room-temperature shear strength of the joints can reach 301 MPa.

Owner:ZHEJIANG UNIV OF TECH

Diffusion connection method for Al2O3/Ti with biocompatibility

The invention discloses a diffusion connection method for Al2O3 / Ti with biocompatibility. The method comprises the following steps: S1, preparing substrate sheets from an Al2O3 ceramic base material and a Ti metal base material, polishing the Al2O3 ceramic substrate sheets and the Ti substrate sheets separately, and then performing ultrasonic cleaning; S2, sputtering a Pd layer on the Al2O3 ceramic substrate sheets; S3, successively sputtering an Mo layer and a Pd layer on the Ti substrate sheets; S4, performing presintering on the Pd layer-sputtered Al2O3 ceramic base material obtained in thestep S2 and the Mo / Pd bimetal layer-sputtered Ti base material obtained in the step S3 for a period of time separately before welding, and performing cooling to room temperature; and S5, arranging the Pd-containing surface of the Al2O3 ceramic base material prepared in the step S3 opposite to the Mo / Pd bimetal layer-containing surface of the Ti base material prepared in the step S4, adding an Aulayer between the two opposite surfaces, then performing vacuum heating, applying a certain connection pressure while heating, and performing cooling to room temperature after heating of a period of time. Through the method, an adverse reaction between Ti and the Au solder can be prevented effectively, a union joint has a small participation stress, and the union joint has high air tightness and strength.

Owner:HARBIN INST OF TECH +1

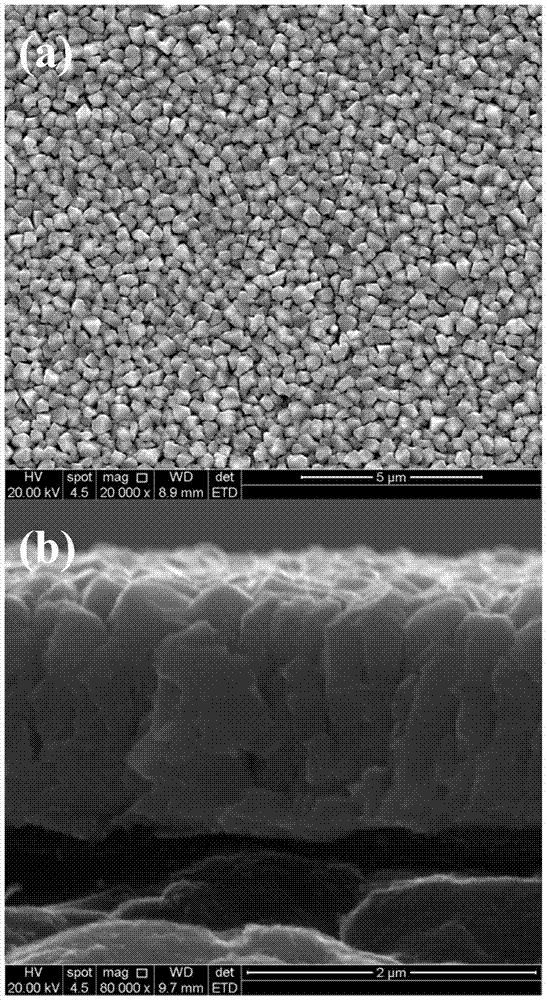

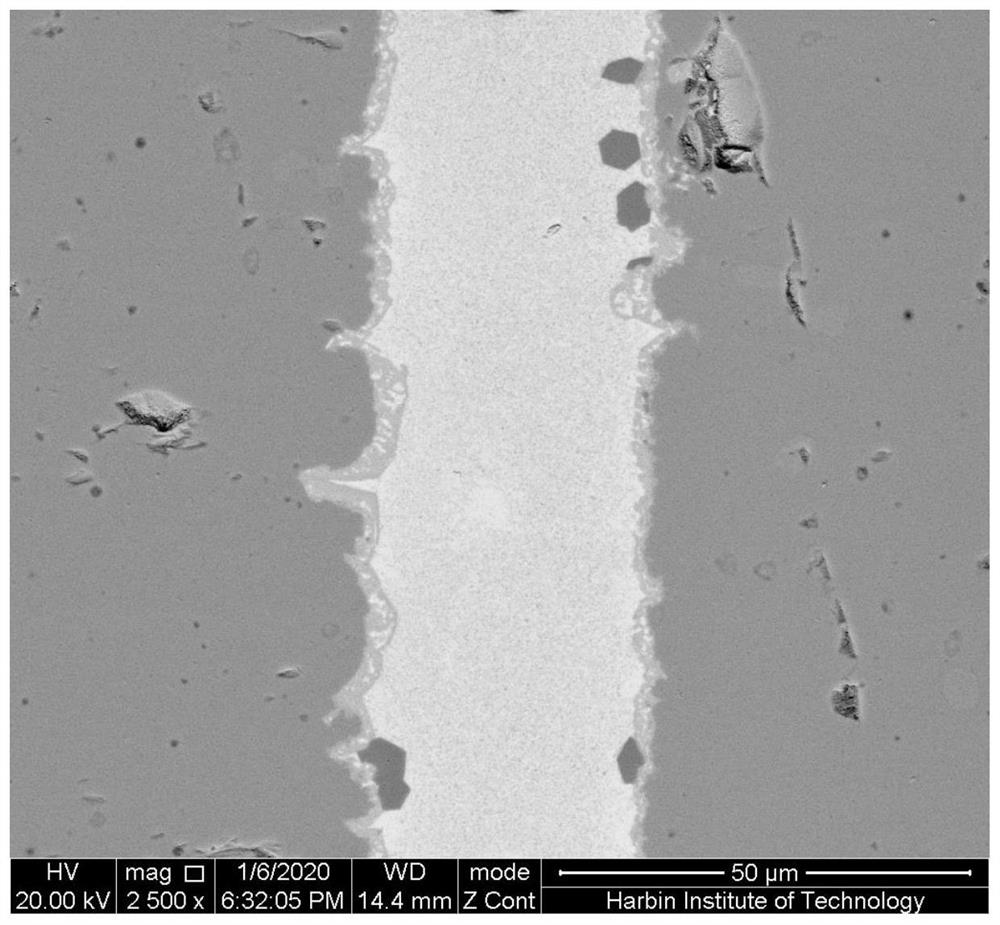

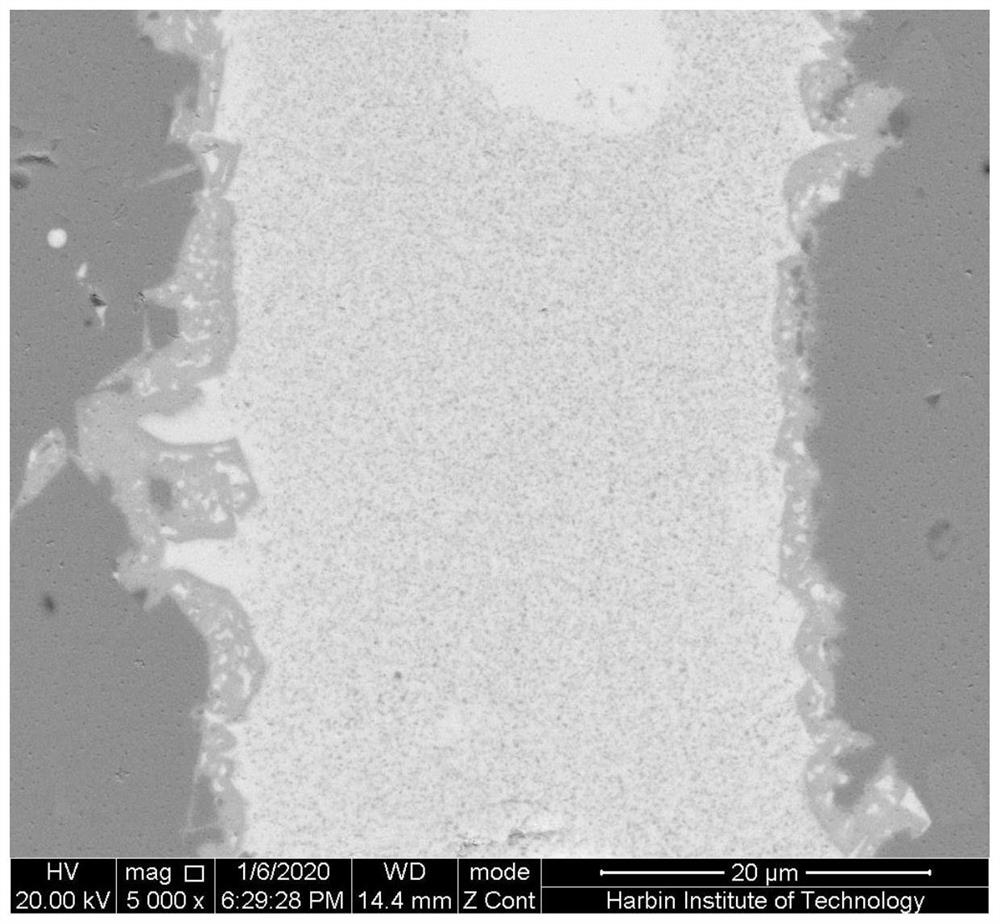

Diffusion bonding method of ternary layered ceramic titanium-silicon-carbon and solid solution thereof and ferritic stainless steel based on Ni foil intermediate layer

ActiveCN112209729ALow connection temperatureGood antioxidant propertiesFinal product manufactureSolid electrolyte fuel cellsCeramicEmery paper

The invention relates to a diffusion bonding method of ternary layered ceramic titanium-silicon-carbon and solid solution thereof and ferritic stainless steel based on a Ni foil intermediate layer. The method comprises the following steps: gradually polishing the to-be-bonded surfaces of ternary layered ceramic and ferritic stainless steel by using metallographic abrasive paper, and polishing by using diamond abrasive paste; cleaning the Ni foil to remove impurities such as oil stains on the surface; arranging according to the sequence of ternary layered ceramic / Ni foil / ferritic stainless steel, welding a temperature measuring platinum wire on the side surface of the sample, and carrying out diffusion bonding on the welded sample; and after the connection experiment is completed, performing cooling and pressure relief to obtain the diffusion connection joint. The joint obtained by adopting the method provided by the invention is good in interface bonding, low in connection temperatureand good in use performance and mechanical property, a continuous reaction layer is generated on the interface, welding defects such as cracks and air holes are avoided, the problem of Cr volatilization of an alloy connector can be solved, and the preparation and processing cost of a ceramic connector is reduced; and the application range of the ternary layered ceramic Ti3SiC2 and the solid solution material thereof is expanded.

Owner:OCEAN UNIV OF CHINA +2

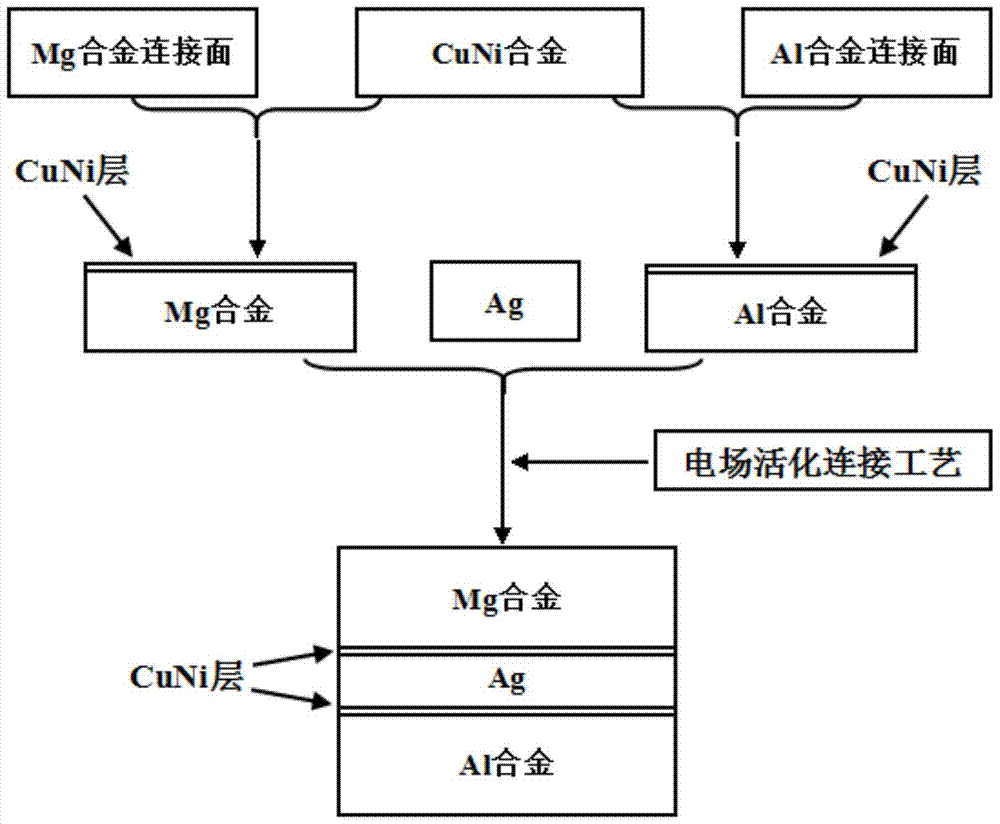

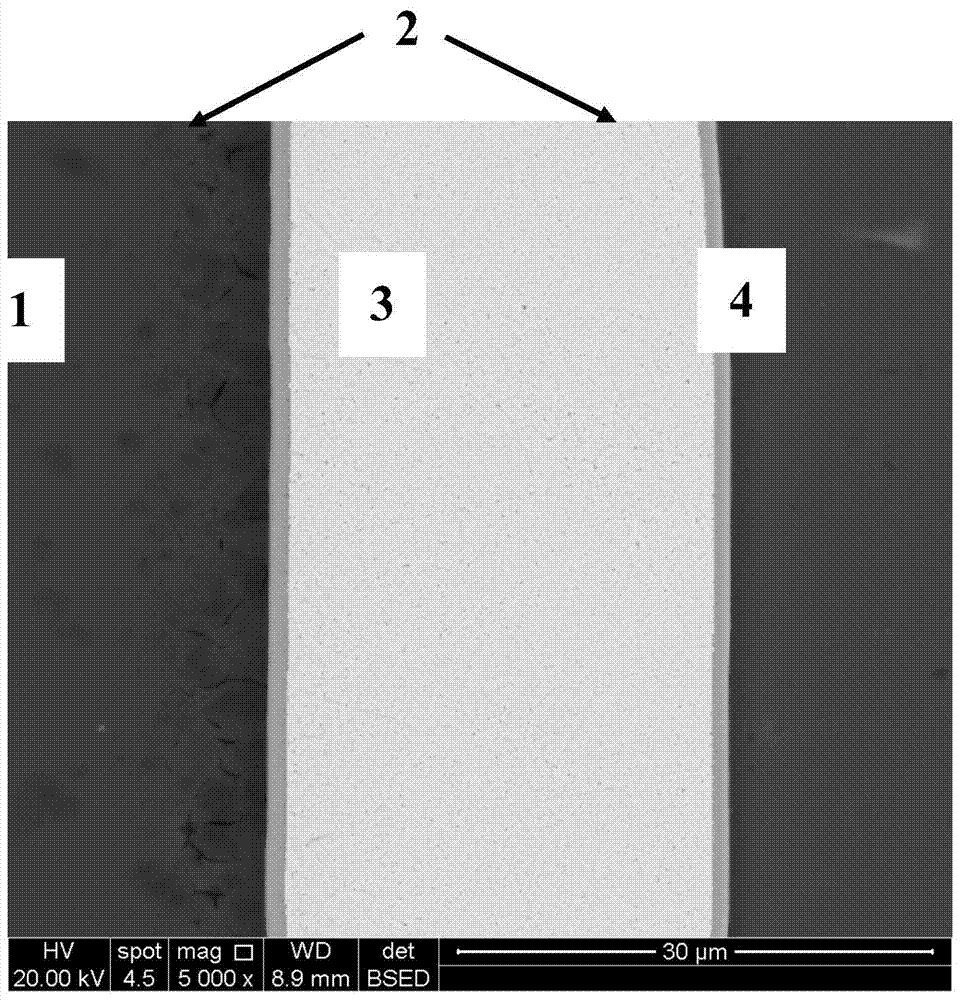

The design of laminated composite interlayers introduces a method for joining magnesium alloys to aluminum alloys

ActiveCN105149769BReduce oxidationIncrease contactWelding/soldering/cutting articlesNon-electric welding apparatusSurface oxidationAlloy thin film

The invention provides a method for introducing the design of laminated compound interlayers to enable magnesium alloy and aluminium alloy to be connected. The method comprises the steps that first, CuNi alloy thin films are deposited on the surface of the magnesium alloy and the surface of the aluminium alloy to be used as obstructing interlayers for preventing surface oxidation of aluminium and magnesium matrixes and intermetallic compound generation; then Ag is added between CuNi alloy thin film layers to lower the connecting temperature of a CuNi interlayer, and a CuNi-Ag-CuNi laminated compound interlayer is formed; and then a to-be-connected magnesium alloy piece and a to-be-connected aluminium alloy piece of the compound interlayer are assembled and are subjected to heat preservation for 0-750 s at the temperature of 380-420 DEG C. According to the method, the compound interlayer avoids the generation of Mg-Al-based intermetallic compounds with connecting interface brittleness and other intermetallic compounds; an electric field activation connecting technology is adopted, so that quick low-temperature and high-strength welding of the magnesium alloy and the aluminium alloy is achieved under vacuum, the connecting temperature is lowered, the connecting technology cycle is shortened, and the reliability of connecting joints is improved.

Owner:WUHAN UNIV OF TECH

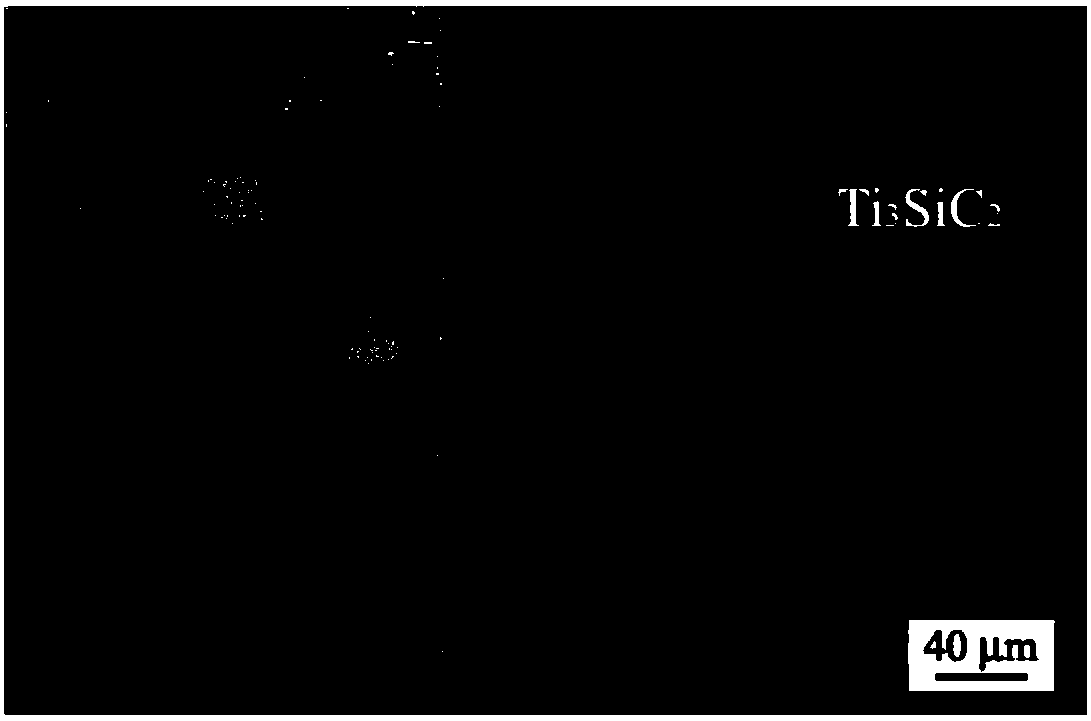

Ternary lamellar ceramic titanium silicon carbide and metallic nickel diffusion bonding method

The invention discloses a ternary lamellar ceramic titanium silicon carbide and metallic nickel diffusion bonding method and belongs to the technical field of ceramic and metal bonding. The method comprises the steps that firstly, surface treatment is conducted on ternary lamellar ceramic and metallic nickel, and then the ternary lamellar ceramic and the metallic nickel are grinded, polished and ultrasonically cleaned; then, the ternary lamellar ceramic and the metallic nickel are installed in a hot-pressing furnace, and the hot-pressing furnace is vacuumized; when the vacuum degree of the hot-pressing furnace is up to 5*10-2 Pa, heating begins, constant-pressure heat preservation is performed at the temperature of 800-1100 DEG C and under the pressure of 6-20 MPa, so that diffusion bonding is conducted on the ternary lamellar ceramic and the metallic nickel; after bonding is completed, cooling is performed under the original vacuum condition to reach 200 DEG C, and then pressure relief is performed. The shear strength of a diffusion bonding joint obtained by adopting the method can be up to 121 MPa and is approximate to the shear strength of Ti3SiC2 ceramic, the actual application demand can be met, and accordingly the application range of ternary lamellar ceramic titanium silicon carbide is widened.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Magnetic nanocrystalline glass solder, preparation method thereof and method for connecting ferrite by using magnetic nanocrystalline glass solder

ActiveCN112456804AUnified electromagnetic propertiesGood weld electromagnetic propertiesGlass furnace apparatusFerrite (magnet)Filler metal

The invention relates to magnetic nanocrystalline glass brazing filler metal, a preparation method thereof and a method for connecting ferrite through the magnetic nanocrystalline glass brazing fillermetal, and belongs to the technical field of ferrite welding. The component of the glass brazing filler metal provided by the invention is xBi2O3-yCoO-yFe2O3-10B2O3 (mol.%, x=30-40 and y=25-35), andthe physical and chemical properties of the glass brazing filler metal are close to those of ferrite. The magnetic brazing filler metal sheet and the base metal obtained after low-temperature glass pre-melting are subjected to composite connection, and structural stability and performance stability of long-term service of the microwave ferrite device are achieved while reliable connection of ferrite and the magnetic performance of a weld joint are guaranteed. According to the method, the unification of the electromagnetic properties of the glass weld joint and the ferrite base metal can be realized, the green concept of energy conservation and sustainable development is met, and the method has important application value for ferrite connection and even microwave device processing.

Owner:HARBIN INST OF TECH

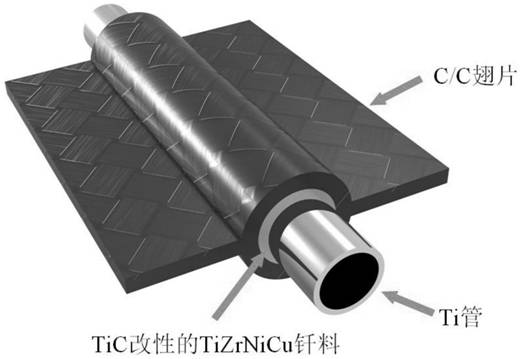

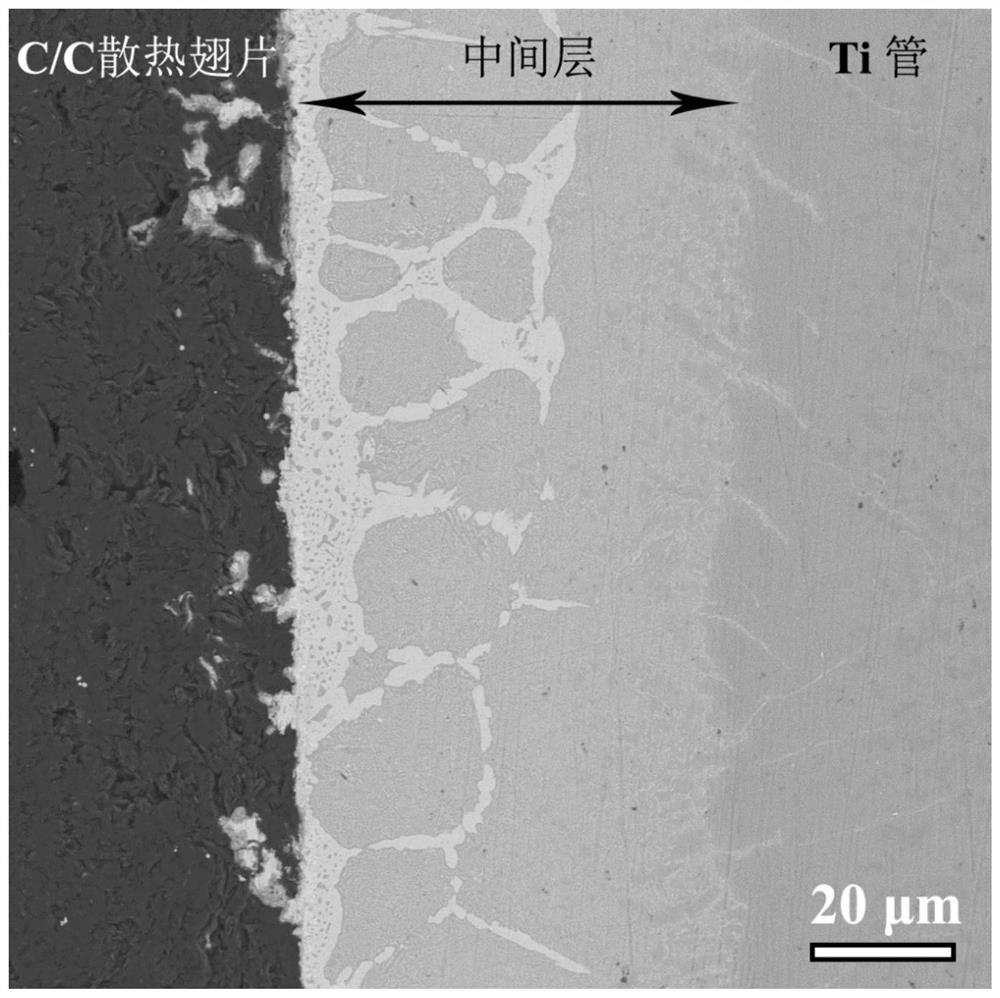

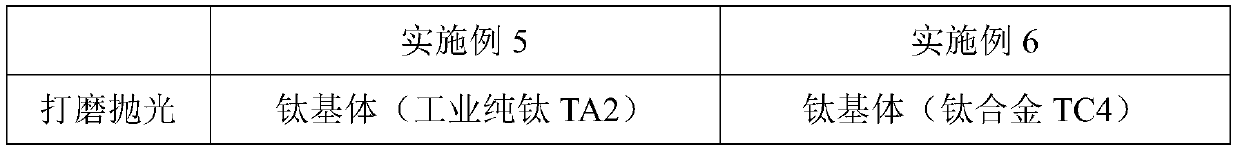

Vacuum brazing connection method for C/C radiating fins and Ti tubes

ActiveCN114247947AMeet the structureMeet compactnessWelding/soldering/cutting articlesHeat exchange apparatusGraphiteAlloy

The invention discloses a vacuum brazing connection method for C / C radiating fins and Ti tubes. The method comprises the following specific process steps: grinding and polishing a Ti pipe to remove an oxide film, and performing vacuum drying for later use after ultrasonic cleaning; tiZrNiCu alloy powder and TiC powder with the mass percent being 3%-5% are mixed, then alcohol is added for ball milling for 15-18 h, the powder is dried and sieved after ball milling, then an oily binder with the mass percent being 8%-10% is added into sieved powder, the mixture is stirred into paste brazing filler metal, then the portion between the connecting surfaces of the C / C cooling fins and the Ti pipe is filled with the paste brazing filler metal, assembling is conducted, and the C / C cooling fins and the Ti pipe are assembled. And the assembly part is clamped by a graphite clamp and then placed in a vacuum furnace, the temperature is increased to 920 DEG C at the speed of 4-7 DEG C / min under the vacuum degree not lower than 1 * 10 <-3 > Pa, heat preservation is conducted for 10-20 min, and finally connection is completed after the furnace is cooled to the room temperature. The connecting method is simple in process, safe, free of pollution, low in cost and high in reliability, and the problems that in the welding process, due to large residual stress, a connecting piece cracks, and wettability between base metal is insufficient are effectively solved.

Owner:XIANGTAN UNIV +1

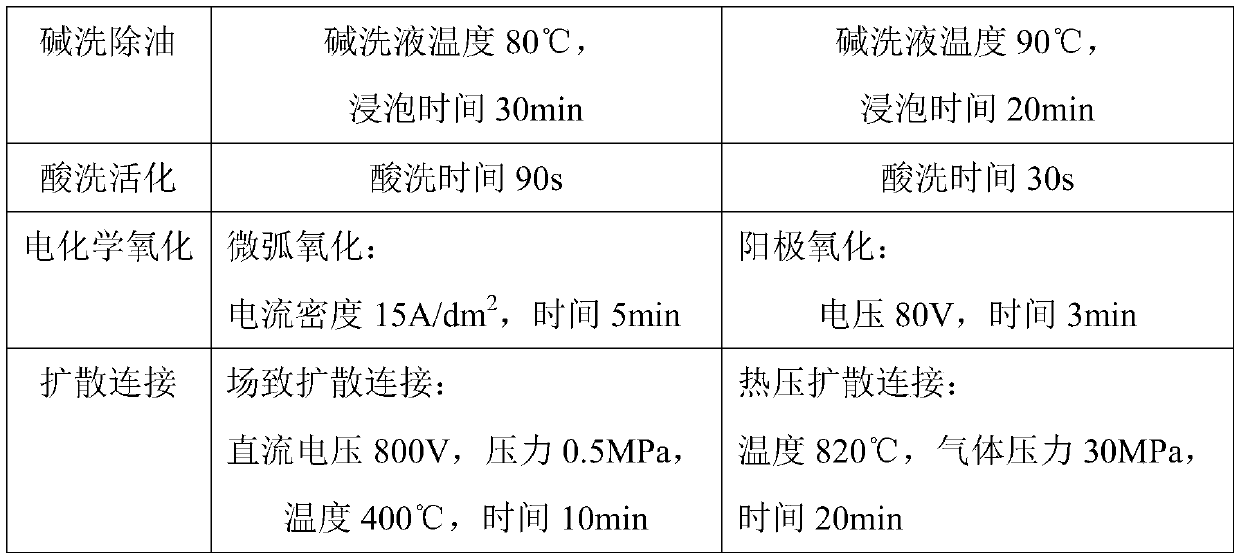

Method for preparing compound type light-weighted reflecting mirror blank and compound type light-weighted reflecting mirror blank

ActiveCN105506708AHigh bonding strengthLow connection temperatureSurface reaction electrolytic coatingBiological activationTitanium oxide

The invention discloses a method for preparing a compound type light-weighted reflecting mirror blank and the compound type light-weighted reflecting mirror blank. The preparation method comprises the steps: (1) acid pickling and activation, specifically, placing a titanium substrate into a pickling solution to be subjected to acid pickling and activation to obtain an activated substrate; (2) electrochemical oxidation, specifically, forming a titanium oxidation layer on a junction surface of the activated substrate through electrochemical oxidation, and obtaining an oxidized substrate; and (3) diffusion bonding, specifically, enabling the junction surface of glass to be closely attached to the oxidation layer of the oxidized substrate, and obtaining the compound type light-weighted reflecting mirror blank through hot-pressing diffusion bonding or field-assisted diffusion bonding. According to the preparation method, the compact and uniform titanium oxidation layer (a low-valence titanium oxide film) is formed on the surface of the substrate through electrochemical oxidation; the junction surface of the glass and the titanium oxidation layer of the substrate are closely attached to each other to be subjected to diffusion bonding; the process is stable, and the rate of finished products is high; the bonding strength of the titanium substrate and the glass in the reflecting mirror blank is high, and the compound type light-weighted reflecting mirror blank can be widely applied to optical fast scanning and tracking systems of numerous types of photoelectric detection equipment such as aircraft photoelectric reconnaissance radars and tank fire control stabilized sighting systems.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

A low-temperature joining method of tzm and wre dissimilar alloys

ActiveCN107081517BEfficient connectionLow connection temperatureWelding/soldering/cutting articlesNon-electric welding apparatusRoom temperatureAlloy

The invention provides a low-temperature connecting method of a TZM and WRe dissimilar alloy. Ti powder is adopted as an activated middle layer, a TZM alloy and a WRe alloy are subjected to diffusion welding at the temperature lower than the recrystallization temperature of base metal through the spark plasma sintering technology, and a connecting part of the TZM alloy and the WRe alloy is obtained. By means of the welding method, it can be guaranteed that the base metal is not recrystallized, meanwhile, the TZM / WRe dissimilar alloy connecting part high in strength and good in forming is obtained, and the room temperature shear strength of a connector can reach 263 MPa.

Owner:HEFEI UNIV OF TECH

A connection method of tzm alloy and wre alloy assisted by electric field

ActiveCN106825885BActive connectionEfficient connectionPlasma welding apparatusWelding/soldering/cutting articlesRoom temperatureFlexural strength

The invention discloses a method for connecting a TZM alloy and a WRe alloy under assistance of an electric field. On the premise that a middle transition layer is not added, diffusion connection under the assistance of the electric field is performed on the TZM alloy and the WRe alloy by use of a spark plasma sintering system, so that a connected part of the TZM alloy and the WRe alloy is obtained. By means of the connection method, the TZM-WRe dissimilar alloy connected part with high strength and good formation can be obtained, and the highest room-temperature three-point bending strength of a joint can reach 935 MPa.

Owner:HEFEI UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com