SPS diffusion welding method for DD98 congeneric nickel-based mono-crystalline high-temperature alloy

A nickel-based single crystal, high temperature alloy technology, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve problems such as poor weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] like figure 1 As shown, the present embodiment provides a SPS diffusion welding method of the same nickel-based single crystal superalloy of DD98, comprising the following steps:

[0027] (1) Surface treatment is carried out on DD98 nickel-based single crystal superalloy respectively. DD98 nickel-based single crystal superalloy includes the first DD98 nickel-based single crystal superalloy 1 and the second DD98 nickel-based single crystal superalloy 3; surface treatment The process is as follows: put two pieces of DD98 nickel-based single crystal superalloy in acetone and ultrasonically clean them to remove oil stains on the surface and dry them, then polish DD98 with 320#, 600#, 800#, 1000#, 1500# SiC sandpaper in sequence The surface of the nickel-based single crystal superalloy to be welded is then polished with a 3 μm diamond polishing agent, and finally the polished DD98 nickel-based single crystal superalloy is ultrasonically cleaned and dried in alcohol.

[0028...

Embodiment 2 and 3

[0031] A method of SPS diffusion welding of the same nickel-based single crystal superalloy of DD98. The steps of the method are repeated in Example 1 to obtain Examples 2 and 3. The difference is that the joining temperature of 950°C is replaced by 980°C and 1000°C respectively, and finally Complete the SPS solid phase diffusion connection between DD98 nickel-based single crystal superalloys.

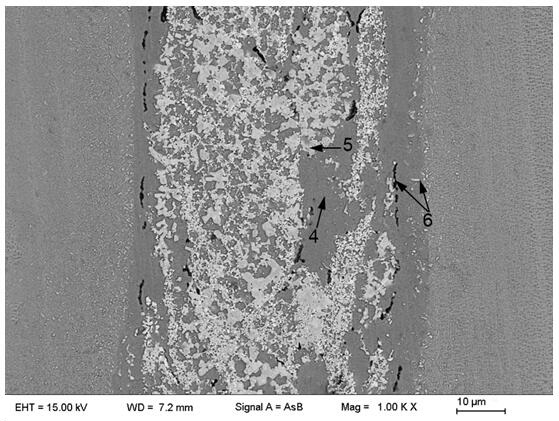

[0032] like figure 2 As shown, the method of embodiment 3 is used to connect two DD98 same nickel-based single crystal superalloys, and after spark plasma sintering is completed, the overall microstructure of the joint formed;

[0033] The performance testing of the shear strength of the DD98 nickel-based single crystal superalloy joints finally prepared in Examples 1 to 3 was performed at room temperature, and the results of the room temperature shear strength of the joints obtained in Examples 1 to 3 are shown in Table 1 .

[0034] Table 1 Shear strength of DD98 nickel-based single ...

Embodiment 4-6

[0037] A SPS diffusion welding method of the same nickel-based single crystal superalloy of DD98, the method steps are repeated in Example 3 to obtain Examples 4 and 5, the difference is that the time for holding the temperature at 1000°C is replaced by 0 min and 3min, the SPS solid phase diffusion connection between DD98 nickel-based single crystal superalloys is finally completed. The method steps of embodiment 6 are different from those of embodiment 3 in that the connection temperature is 1040° C. and the holding time is 10 min.

[0038] The performance test of the shear strength of the DD98 nickel-based single crystal superalloy joint finally prepared in Examples 4-6 was performed at room temperature, and the measured room temperature shear strength results are shown in Table 2, compared with Example 3.

[0039] Table 2 Average shear strength of DD98 Ni-based single crystal superalloy obtained under different holding times

[0040] detection group Holding tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com