Manufacturing method of W/Mo/graphite composite anode target material for X-ray tube of CT machine

A composite anode and manufacturing method technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of high cost, difficult to meet the requirements of density, complex process, etc., and achieve short holding time and good thermal shock resistance. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment manufactures CT machine X-ray tube W / Mo / graphite composite anode target material according to the following steps:

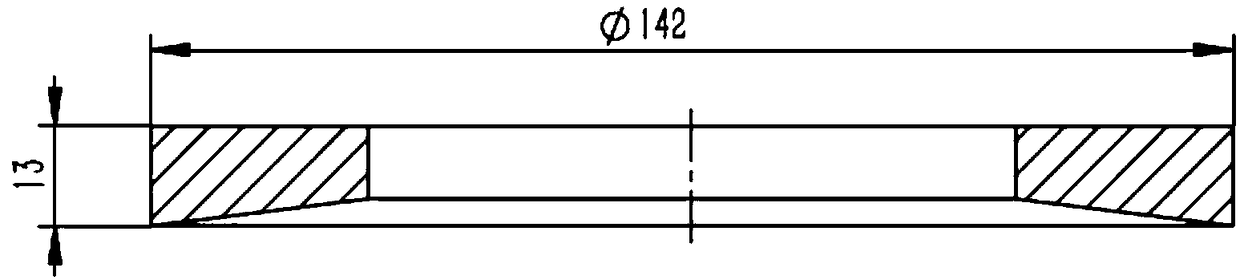

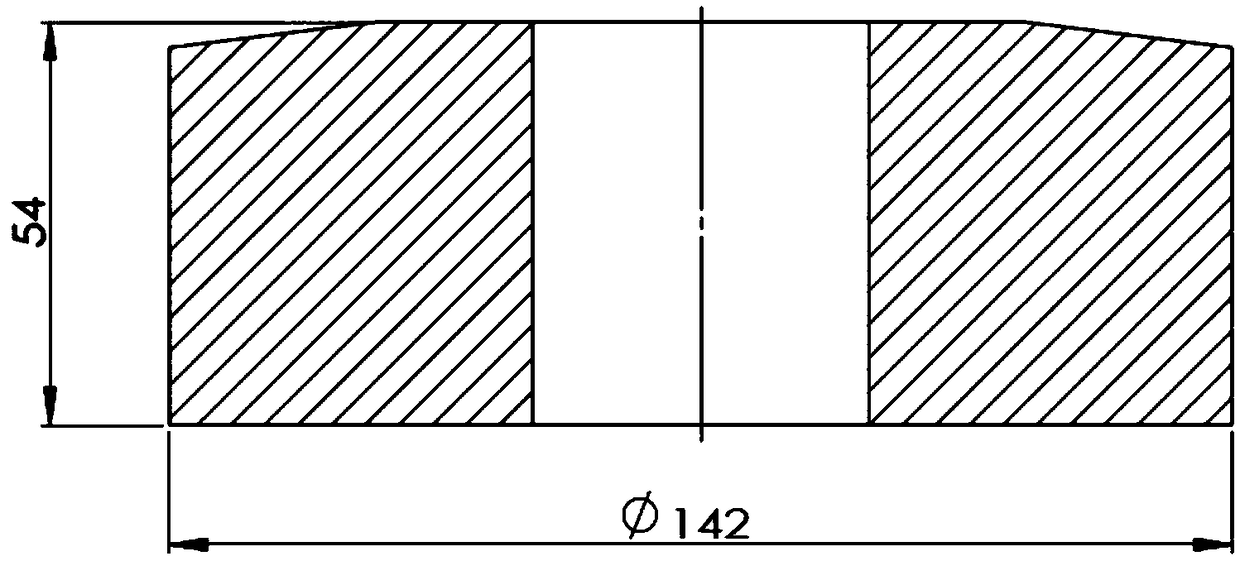

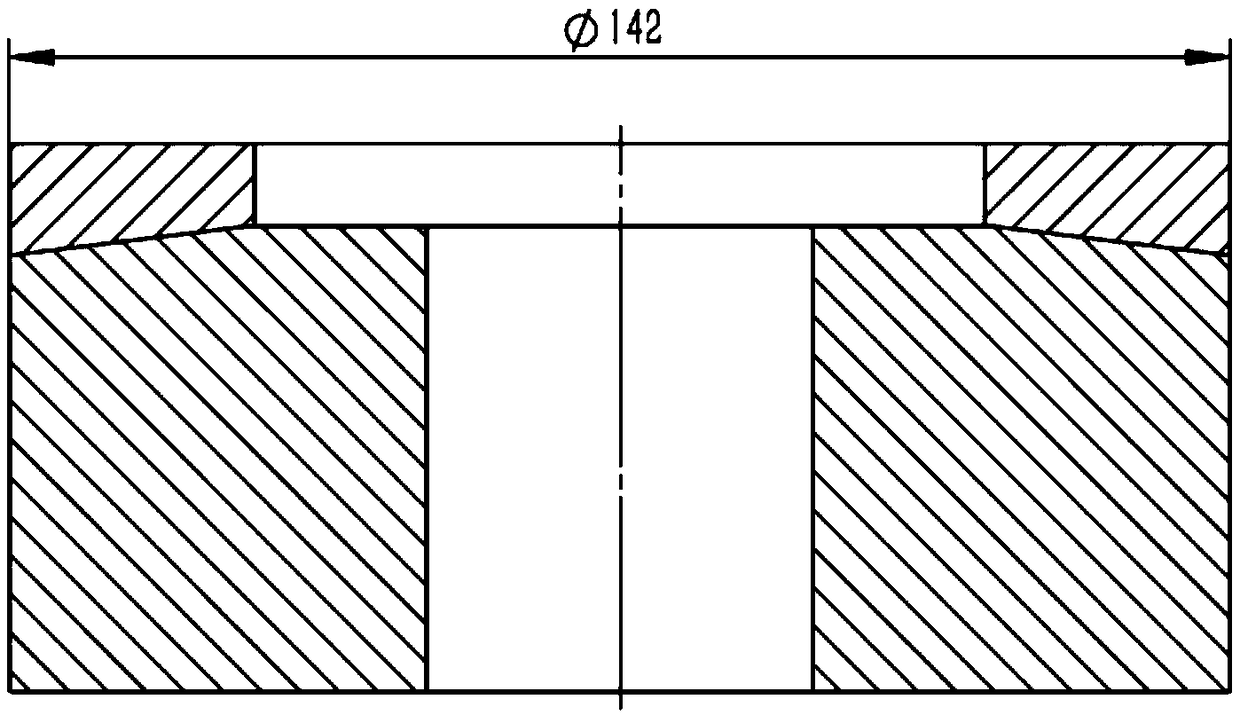

[0037] (1), press figure 1 and figure 2 As shown, according to the required shape and size of the anode target, the tungsten plate and the molybdenum cylinder are machined, and the outer circumference dimensions of the processed tungsten plate and molybdenum cylinder are kept on the basis of the outer circumference size required by the anode target. have margin;

[0038] After grinding and polishing the welding surface of the machined tungsten plate and the molybdenum cylinder, it is cleaned ultrasonically with acetone solution;

[0039] (2) Put the tungsten plate and the molybdenum cylinder processed in step (1) into the SPS furnace chamber with the tungsten plate on the bottom and the molybdenum cylinder on the top. When the vacuum is pumped to 5Pa, the diffusion connection is started to obtain W / Mo connector;

[0040] The pro...

Embodiment 2

[0058] The present embodiment manufactures CT machine X-ray tube W / Mo / graphite composite anode target material according to the following steps:

[0059] (1), press figure 1 and figure 2 As shown, according to the required shape and size of the anode target, the tungsten plate and the molybdenum cylinder are machined, and the outer circumference dimensions of the processed tungsten plate and molybdenum cylinder are kept on the basis of the outer circumference size required by the anode target. have margin;

[0060] After grinding and polishing the welding surface of the machined tungsten plate and the molybdenum cylinder, it is cleaned ultrasonically with acetone solution;

[0061] (2) Put the tungsten plate and the molybdenum cylinder processed in step (1) into the SPS furnace chamber with the tungsten plate on the bottom and the molybdenum cylinder on the top. When the vacuum is pumped to 5Pa, the diffusion connection is started to obtain W / Mo connector;

[0062] The p...

Embodiment 3

[0080] The present embodiment manufactures CT machine X-ray tube W / Mo / graphite composite anode target material according to the following steps:

[0081] (1), press figure 1 and figure 2 As shown, according to the required shape and size of the anode target, the tungsten plate and the molybdenum cylinder are machined, and the outer circumference dimensions of the processed tungsten plate and molybdenum cylinder are kept on the basis of the outer circumference size required by the anode target. have margin;

[0082] After grinding and polishing the welding surface of the machined tungsten plate and the molybdenum cylinder, it is cleaned ultrasonically with acetone solution;

[0083] (2) Put the tungsten plate and the molybdenum cylinder processed in step (1) into the SPS furnace cavity for diffusion connection with the tungsten plate on the bottom and molybdenum on top. When the vacuum is pumped to 5Pa, the diffusion connection is started , get the W / Mo connector;

[0084]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com