Connecting method for Cf/SiC composite material and titanium alloy

A composite material and connection method technology, which is applied in the field of heterogeneous material connection, can solve the problems of complex connection process, low joint strength, poor high temperature performance, etc., and achieve simple process, increase room temperature and high temperature strength, and improve high temperature performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

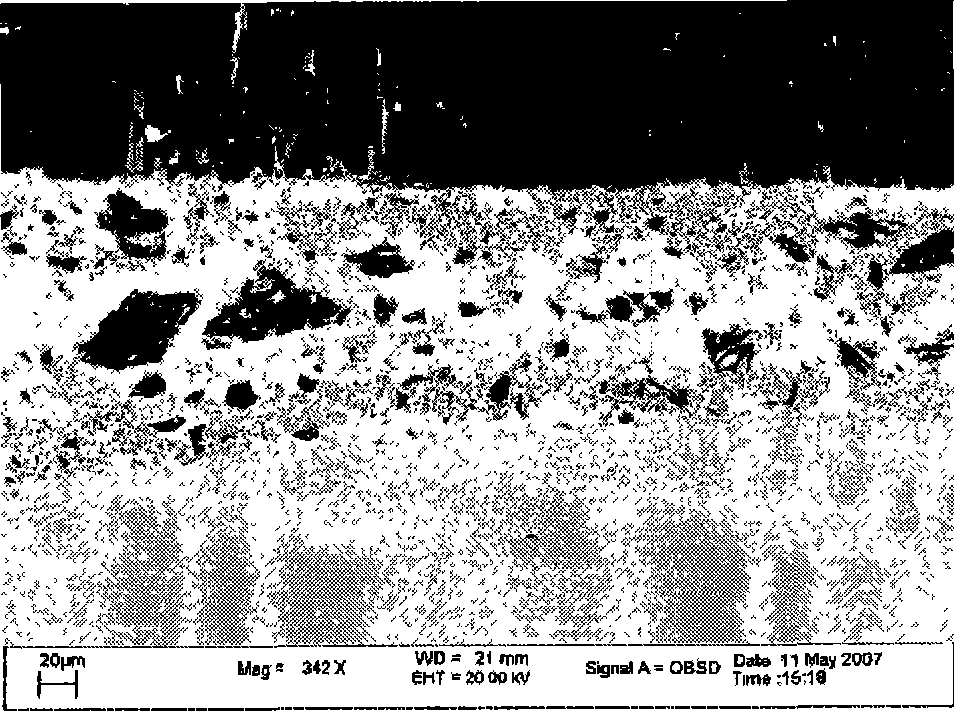

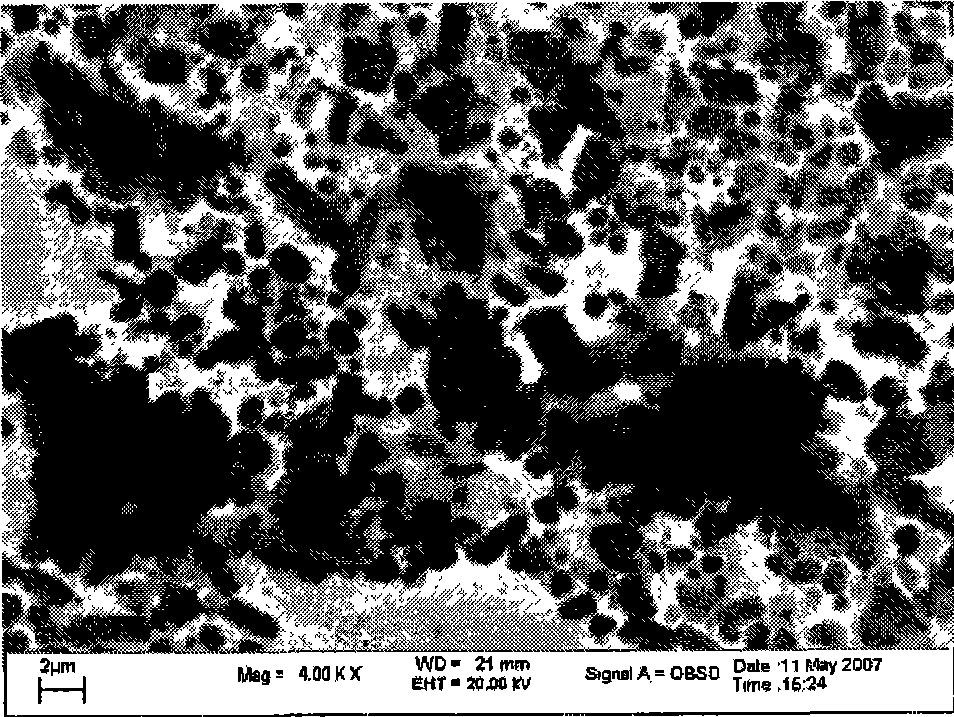

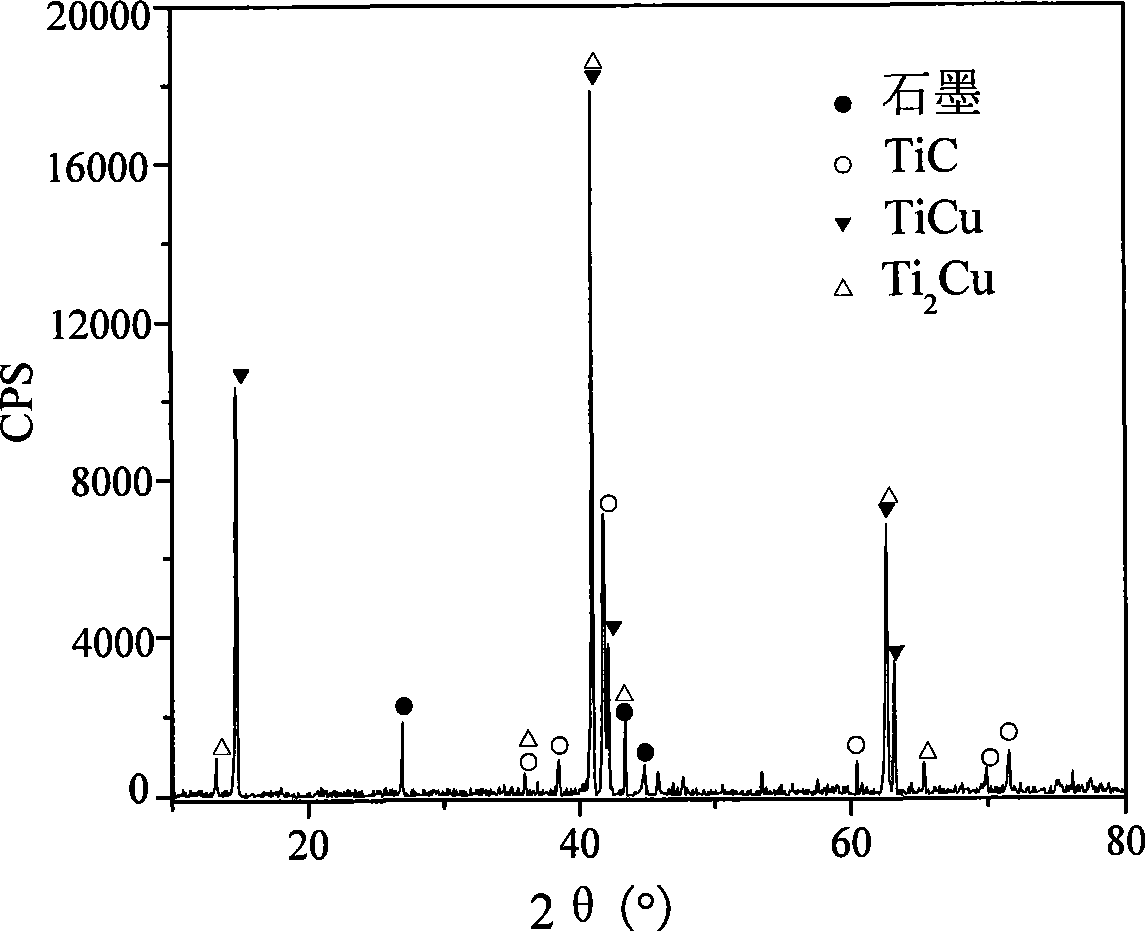

[0019] The specific test implementation steps are as follows:

[0020] 1.C f / SiC ceramic matrix composite material density is 2.0~2.1g / cm 3 , the porosity is 10% to 15%, the fiber bundle is 3K, the fiber volume accounts for 45% to 50%, the bending strength at room temperature is about 400MPa, and it is cut into squares of 6×5×4mm. The titanium alloy (TC4) component is Ti-6AI-4V (wt%), and the titanium alloy is a rod shape of φ15, which is cut into a 5mm thick cylinder;

[0021]2. The raw material Cu powder particle size is about 250 mesh, Ti powder particle size is about 400 mesh, C powder is colloidal graphite powder, the average particle size is 7μm, and the moisture content is lower than 0.5wt%;

[0022] 3.C f / SiC composite material to be welded with 400-grit sandpaper to remove surface debris, and then cleaned with acetone, titanium alloy to be welded with 60-grit sandpaper to remove the surface oxide layer, and then cleaned with acetone. Put the soldering material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com