Ultrasonic brazing method for high-volume-fraction silicon carbide particle enhanced aluminum-base composite and low-expansion alloy

An aluminum-based composite material and low-expansion alloy technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large residual stress of joints, high connection temperature, complicated process, etc., and achieve firm metallurgical bonding and connection temperature. The effect of low, low coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

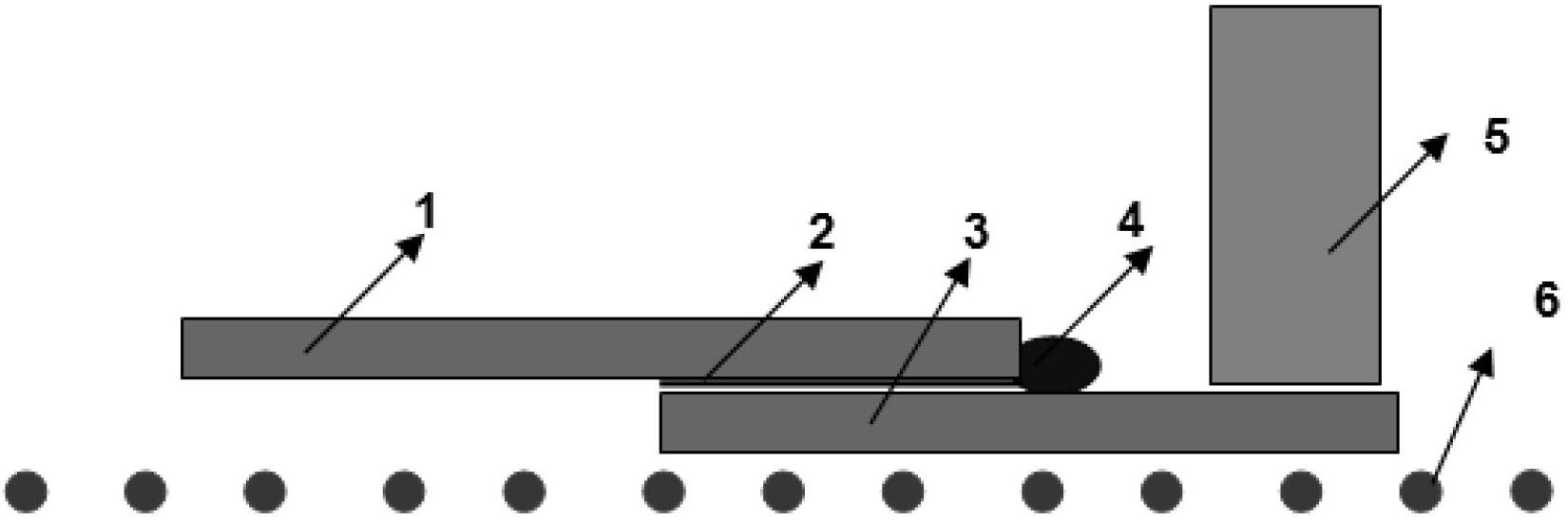

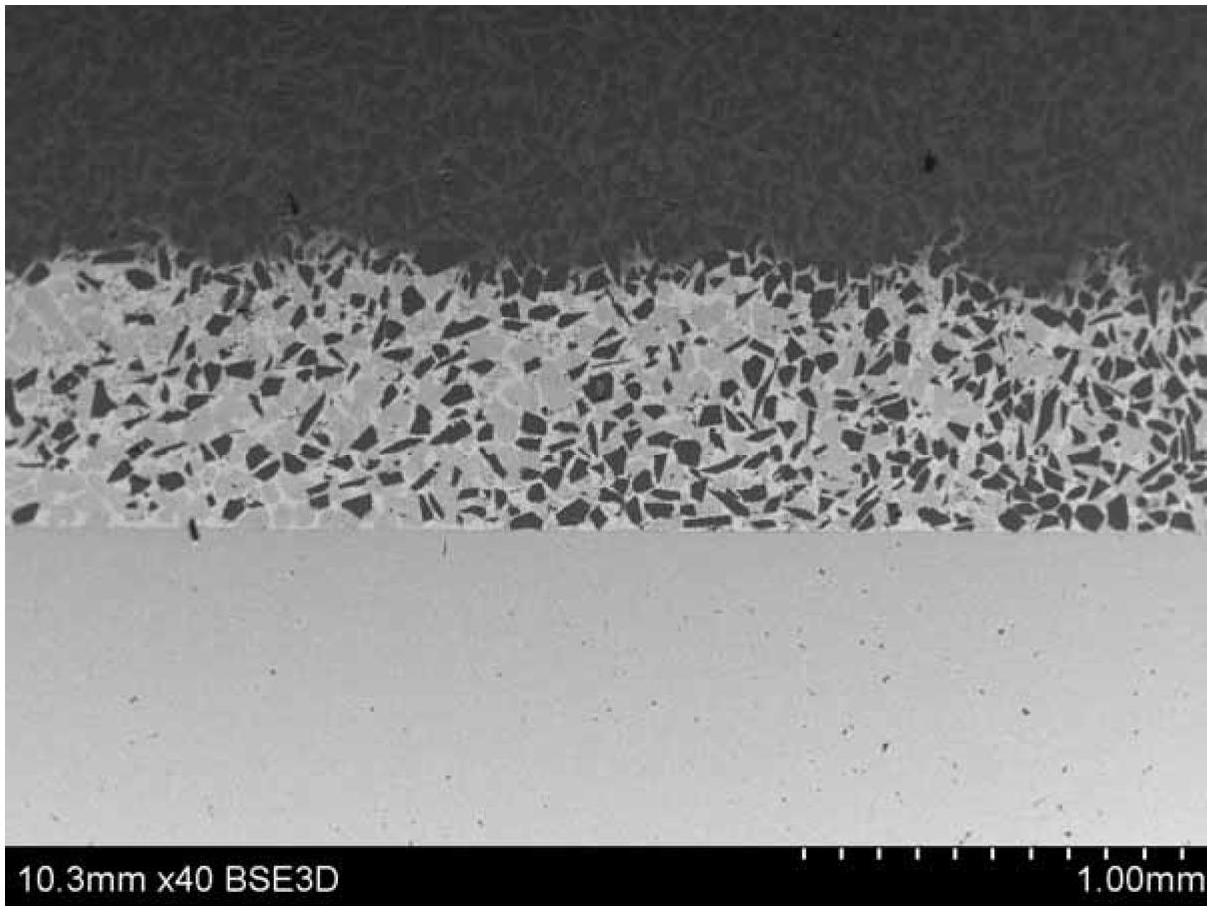

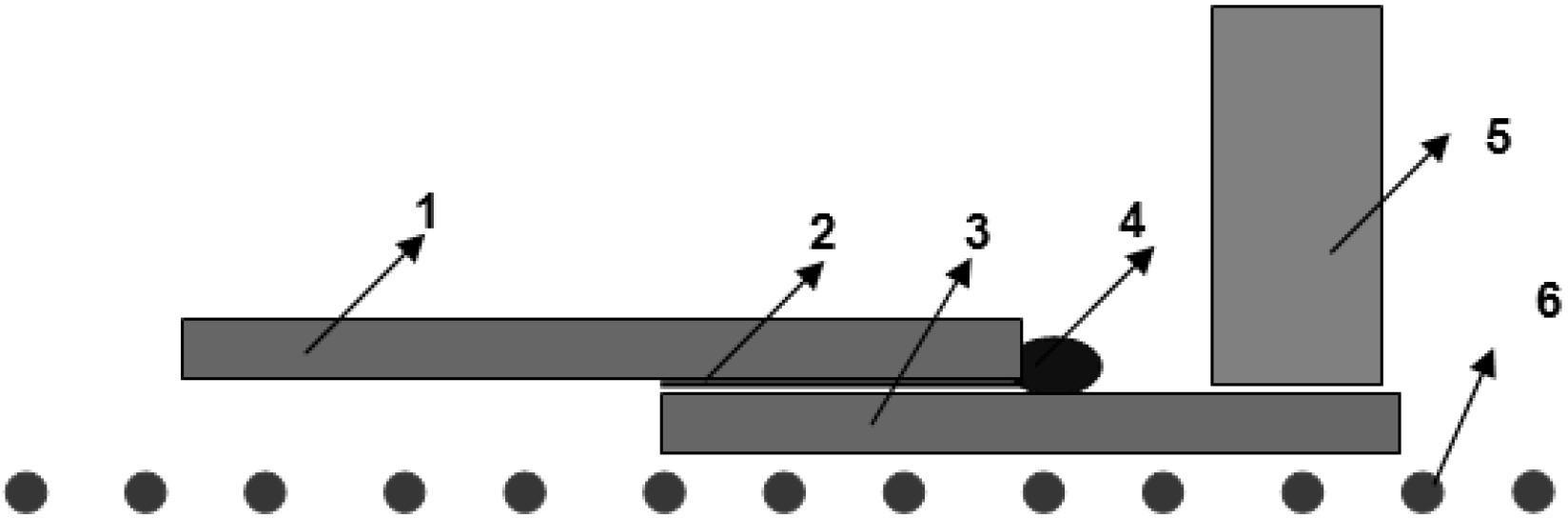

[0017] Specific embodiment one: the ultrasonic brazing method of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and low expansion alloy in this embodiment is carried out according to the following steps: 1. Perform welding on the surface to be welded of aluminum matrix composite material and low expansion alloy Surface cleaning; 2. Put metal on the surface to be welded of the low expansion alloy obtained in step 1, heat until the metal melts, apply ultrasonic vibration for 0.5-60s, form a metal layer after cooling, and machine the metal layer to a thickness of 0.1- 0.5mm; 3. Lap the surface to be welded of the low-expansion alloy processed in step 2 and the aluminum-based composite material cleaned in step 1, place the aluminum-based composite material below, and adjust the distance between the low-expansion alloy and the aluminum-based composite material. The size of the gap is 50-500μm, and the solder is placed on the aluminum matr...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific method for cleaning the surface of the aluminum-based composite material to be welded in step 1 is: use 150# and 500# water sandpaper to polish the aluminum layer by step. The surface to be welded of the matrix composite material was polished with a 2.5 μm diamond polishing agent, and then ultrasonically cleaned in acetone for 10 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the specific method for cleaning the surface of the low-expansion alloy surface to be welded is: using 150#, 500#, 1000# and 1500# Polish the surface of the low-expansion alloy to be welded step by step with water sandpaper, and then ultrasonically clean it in acetone for 10 minutes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com