The design of laminated composite interlayers introduces a method for joining magnesium alloys to aluminum alloys

A composite intermediate layer and connection method technology, applied in the field of connection between magnesium and aluminum, to achieve the effect of reducing oxidation, reducing connection difficulty and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

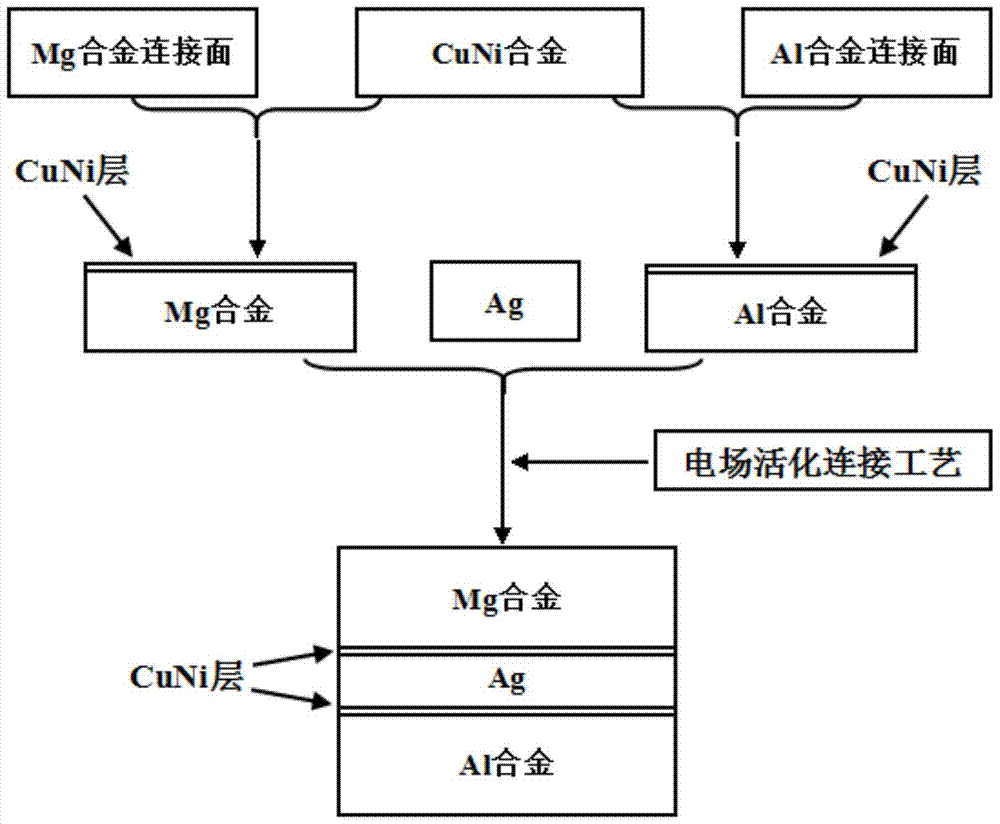

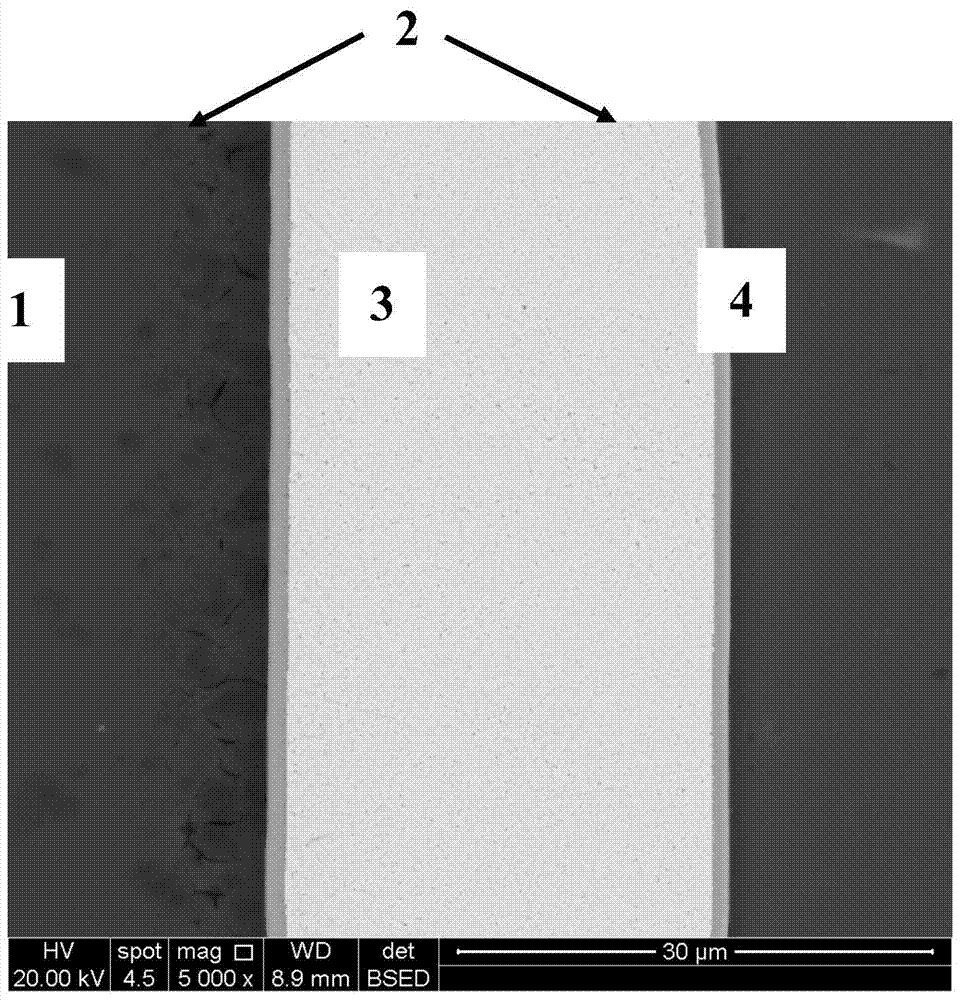

[0028] figure 1 It is a process flow diagram of the present invention. The magnesium alloy to be welded is MB2 magnesium alloy with a size of Φ25mm×5mm, the aluminum alloy to be welded is LY12 aluminum alloy with a size of Φ25mm×5mm, the size of silver foil is Φ25mm×30μm, and the CuNi alloy deposited by magnetron sputtering Cu atoms accounted for 50% (at%), and the film thickness was 1.5 μm. Diffusion welding process conditions are: welding temperature 400 ℃, welding pressure 5MPa, holding time 600s.

[0029] The specific steps are as follows:

[0030] 1. Machining and surface cleaning of raw material magnesium alloy and aluminum alloy:

[0031]Magnesium alloy and aluminum alloy are processed into circular slices with ultra-precision surface grinder, and the surface to be welded is polished with 1000#, 1500#, 2000# SiC sandpaper before welding, and then polished with a high-precision polishing machine. The silver foil and the polished magnesium-aluminum alloy were ultrason...

Embodiment 2

[0039] The magnesium alloy to be welded is MB2 magnesium alloy with a size of Φ25mm×5mm, the aluminum alloy to be welded is LY12 aluminum alloy with a size of Φ25mm×5mm, the size of silver foil is Φ25mm×30μm, and the CuNi alloy deposited by magnetron sputtering Cu atoms accounted for 50% (at%), and the film thickness was 1.5 μm. Diffusion welding process conditions are: welding temperature 380 ℃, welding pressure 5MPa, holding time 600s.

[0040] The specific steps are as follows:

[0041] 1. Machining and surface cleaning of raw material magnesium alloy and aluminum alloy:

[0042] Magnesium alloy and aluminum alloy are processed into circular slices with ultra-precision surface grinder, and the surface to be welded is polished with 1000#, 1500#, 2000# SiC sandpaper before welding, and then polished with a high-precision polishing machine. The silver foil and the polished magnesium-aluminum alloy were ultrasonically cleaned in an organic solvent for 5 minutes.

[0043] 2. ...

Embodiment 3

[0050] The magnesium alloy to be welded is MB2 magnesium alloy with a size of Φ25mm×5mm, the aluminum alloy to be welded is LY12 aluminum alloy with a size of Φ25mm×5mm, the size of silver foil is Φ25mm×30μm, and the CuNi alloy deposited by magnetron sputtering Cu atoms accounted for 50% (at%), and the film thickness was 1.5 μm. Diffusion welding process conditions are: welding temperature 420 ℃, welding pressure 5MPa, holding time 600s.

[0051] The specific steps are as follows:

[0052] 1. Machining and surface cleaning of raw material magnesium alloy and aluminum alloy:

[0053] Magnesium alloy and aluminum alloy are processed into circular slices with ultra-precision surface grinder, and the surface to be welded is polished with 1000#, 1500#, 2000# SiC sandpaper before welding, and then polished with a high-precision polishing machine. The silver foil and the polished magnesium-aluminum alloy were ultrasonically cleaned in an organic solvent for 5 minutes.

[0054] 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com