Method for connecting TiNi SMA with titanium or titanium alloy through nano multilayer film self-propagating reaction

A nano-multilayer, self-propagating technology, used in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of harsh external auxiliary equipment, inability to form large-area connections, and limited heating temperature. Achieve the effect of saving connection time, wide range of use and fast burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

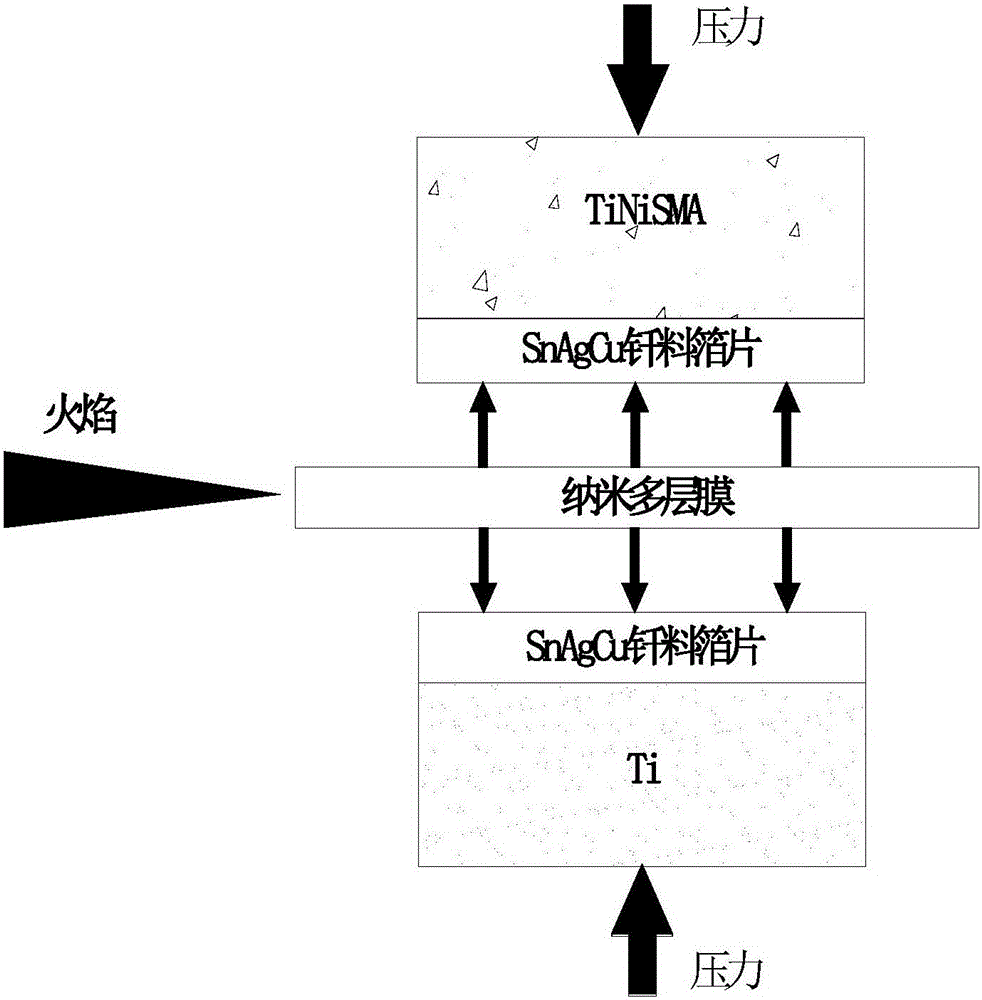

[0012] Specific implementation mode 1: In this implementation mode, a method for connecting TiNiSMA and titanium or titanium alloys using a self-propagating reaction of a nano-multilayer film is specifically completed according to the following steps:

[0013] One, prepare active nano film: Alternately sputter titanium and nickel with magnetron sputtering machine, titanium layer monolayer thickness 25nm-100nm, nickel layer monolayer thickness 25nm-50nm, the thickness ratio of nickel layer and titanium layer is (1- 3): 2, Alternate sputtering for 80-120 cycles, the final total film thickness is 4μm-15μm, secret storage;

[0014] 2. Surface treatment: use #400 sandpaper, #600 sandpaper and #800 sandpaper to polish the TiNi SMA surface and the metal surface layer by layer until the surface is smooth and flat, and obtain the TiNi SMA and metal with surface pretreatment. The polished TiNi SMA, Put 2 SnAgCu solder foils and metals with a thickness of 30-70μm into alcohol and ultraso...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the thickness ratio of nickel layer and titanium layer described in step 1 is 100 cycles, and the final total film thickness is 5-15 μm, and it is sealed and stored. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment 3: The difference between this embodiment and one of specific embodiments 1 to 2 is that the thickness ratio of nickel layer and titanium layer described in step 1 is 100 cycles, and the final total film thickness is 5-15 μm. Keep airtight. Others are the same as one of the specific embodiments 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com