Connection method of silver, copper and zinc belt-shaped solder and special connection device used in connection method

A strip-shaped solder and connection method technology, which is applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problem that the connection requirements of the solder strip cannot be met, the solder strip is not melted and connected, and the size of the solder strip is not accurate, etc. problem, to achieve the effect of simple structure, not easy to break and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

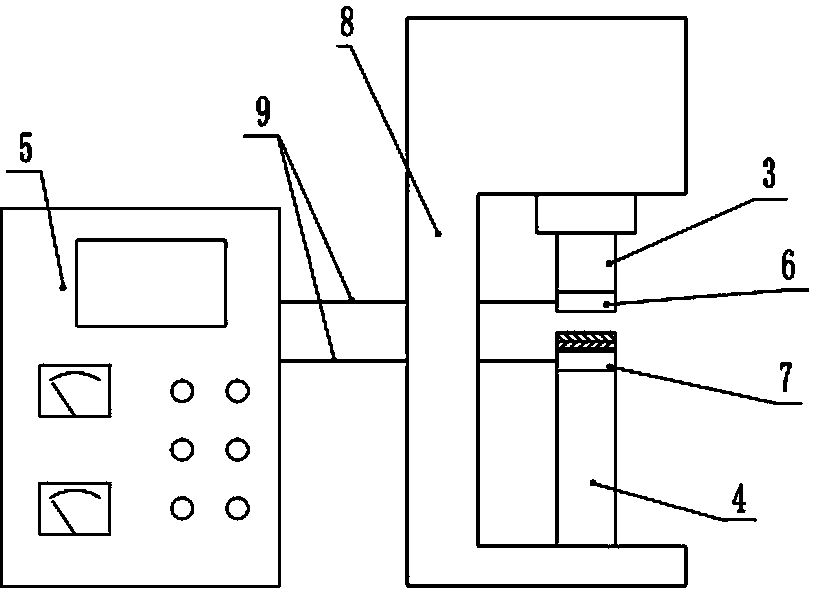

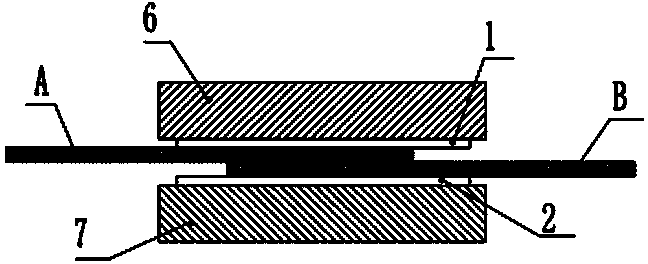

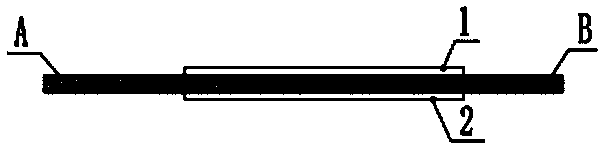

[0026] Such as figure 1 , 2 , 3, the connecting method of silver-copper-zinc strip-shaped solder of the present invention is used to connect solder strip A and solder strip B (the width of solder strip A and B is 25 ~ 50mm, and the thickness is 1.8 ~ 2.5mm mm ), the connection method includes the following steps:

[0027] The first step is to use a steel brush to remove the oxides on the surface of the connecting surface of the solder strip A and the solder strip B, and clean it with alcohol;

[0028] In the second step, take the upper copper plate 1 and the lower copper plate 2 with the same width as the brazing material strip A and the brazing material strip B, the length of the upper copper plate 1 and the lower copper plate 2 is 60mm, and the thickness is 1mm, and the The connecting parts of B are clamped and overlapped and placed between the upper and lower copper plates 1 and 2. The overlapping length of the solder strips A and B is 20mm; and the contact surfaces of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com