Method for refining silybum marianum seed oil by enzymic-method degumming

A technology for refining water and milk thistle, which is applied in the direction of fat oil/fat refining and fat production. It can solve the problems of oil emulsification and phospholipid separation difficulties, and achieve the effects of avoiding high-temperature vacuum decolorization, low oil loss, and strong adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

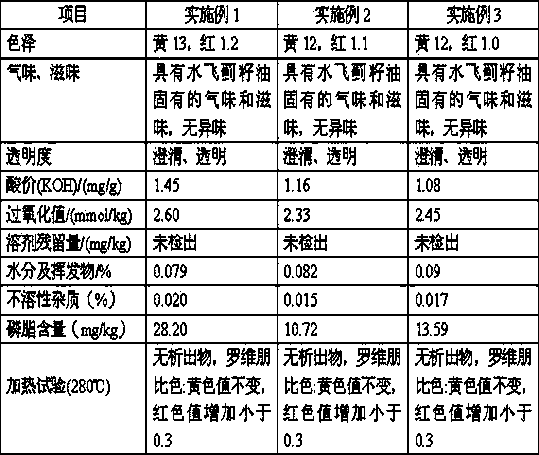

Examples

Embodiment 1

[0029] Place the container containing silymarin seed crude oil in a drying oven at 50°C. When the temperature of the sample reaches 50°C, keep it for 1 hour to separate the impurities from the oil, and remove the impurities by suction filtration. Take 100g crude oil, heat it in a water bath to 70-80°C, add 45% (w / v) citric acid solution at the same temperature according to the dosage ratio of 0.12mL / 100g crude oil, and maintain it for 20-30min under mechanical stirring at 500r / min. Lower the temperature of the crude oil to 50-55°C, and add 4% (w / v) NaOH solution to adjust the pH to 5-5.3. Add phospholipase according to the addition amount of 80mg / kg crude oil, keep warm for 4 hours, separate and remove peptized impurities, and obtain degummed oil;

[0030] Heat the degummed oil obtained above in a water bath to the set initial temperature of alkali refining (40°C), add a calculated amount of NaOH solution (concentration 10% (w / v)) under stirring conditions, and the total amoun...

Embodiment 2

[0034] Place the container containing silymarin seed crude oil in a drying oven at 50°C. When the temperature of the sample reaches 50°C, keep it for 1 hour to separate the impurities from the oil, and remove the impurities by suction filtration. Take 100g crude oil, heat it in a water bath to 70-80°C, add 45% (w / v) citric acid solution at the same temperature according to the dosage ratio of 0.12mL / 100g crude oil, and maintain it for 20-30min under mechanical stirring at 500r / min. Lower the temperature of the crude oil to 50-55°C, and add 4% (w / v) NaOH solution to adjust the pH to 5-5.3. Add phospholipase according to the addition amount of 120mg / kg crude oil, keep warm for 8 hours, separate and remove peptized impurities, and obtain degummed oil;

[0035] Heat the degummed oil obtained above in a water bath to the set initial temperature of alkali refining (40°C), add a calculated amount of NaOH solution (concentration 12% (w / v)) under stirring conditions, and the total amou...

Embodiment 3

[0039] Place the container containing the crude milk thistle seed oil in a drying oven at 50°C, and keep it for 1h after the sample temperature reaches 50°C. Separation of impurities and grease, suction filtration. Take 100g crude oil, heat it in a water bath to 70-80°C, add 45% (w / v) citric acid solution at the same temperature according to the dosage ratio of 0.12mL / 100g crude oil, and maintain it for 20-30min under mechanical stirring at 500r / min. Lower the temperature of the crude oil to 50-55°C, and add 4% (w / v) NaOH solution to adjust the pH to 5-5.3. Add phospholipase according to the addition amount of 100 mg / kg crude oil, keep warm for 6 hours, separate and remove peptized impurities, and obtain degummed oil;

[0040] Heat the degummed oil obtained above in a water bath to the set initial temperature of alkali refining (40°C), add a calculated amount of NaOH (alkali concentration 13% (w / v)) under stirring conditions, and the total amount of lye is the theoretical alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com