Adhesive stick glue for thin sliced silicon slices and preparation method thereof

A technology of thinning silicon and sticking rods, applied in the direction of adhesive, adhesive type, epoxy resin glue, etc., can solve the problems of difficult to adapt to the thinning of diamond wire, not easy to reduce production cost, poor water resistance and easy to fall off. , to achieve the effect of shortening curing time, short curing time, degumming temperature and dirt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of adhesive stick glue for thin sliced silicon slices, comprising component A and component B, said component A including glycidyl ester type epoxy resin, bisphenol A epoxy resin, hydrogenated bisphenol A ring Oxygen resin, filler, defoamer, anti-settling agent and coupling agent; said component B includes polythiol, m-xylylenediamine prepolymer, accelerator, filler, defoamer and anti-settling agent ;

[0024] Wherein, the mass ratio of the component A to the component B is 1:1.

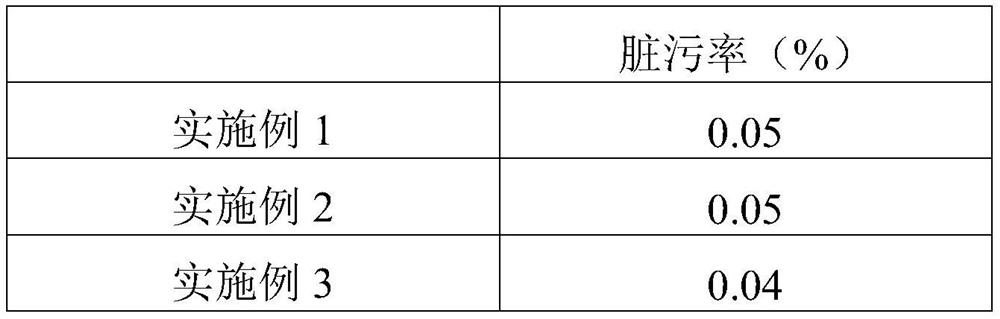

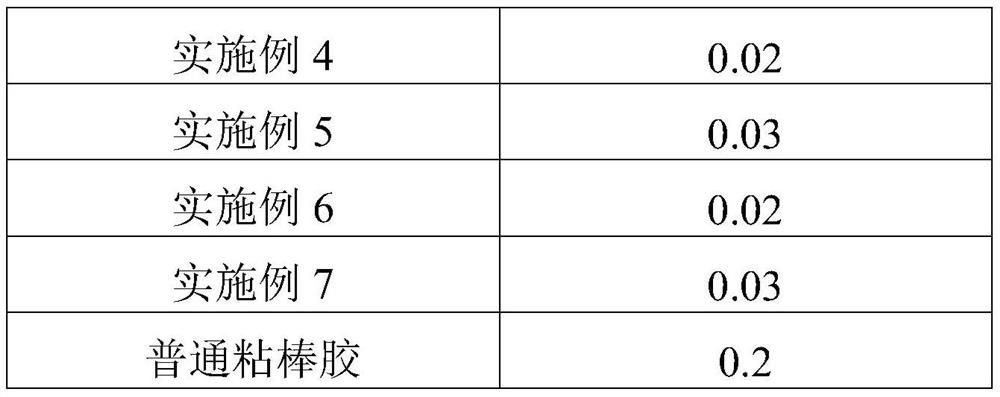

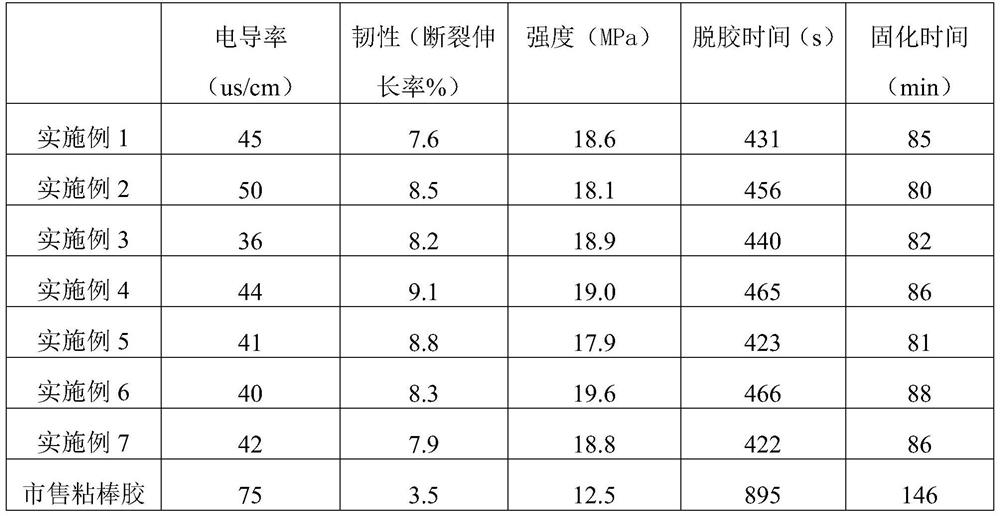

[0025] The cutting base used in the silicon wafer slicing industry has switched from resin boards to plastic boards. The degumming of plastic boards is easier than resin boards. The plastic plate falls off, so that the glue filament still sticks to the surface of the silicon wafer, which affects the subsequent production efficiency. Show through statistical result, use the defilament rate of commercially available viscose stick (glue thread falls off from the plastic plate and stick...

Embodiment 2

[0027] A kind of sticky glue that is used for thin slice silicon chip, comprises component A and component B, and component A contains the raw material of following mass fraction: glycidyl ester epoxy resin 5%, bisphenol A type epoxy resin Resin 66.94%, hydrogenated bisphenol A epoxy resin 5%, defoamer 3%, anti-settling agent 0.05-%, coupling agent 0.01%, filler 20%;

[0028] Component B contains the following raw materials in mass fractions: polythiol 50%, m-xylylenediamine prepolymer 5%, accelerator 10%, filler 27%, defoamer 3%, anti-settling agent 5%;

[0029] Wherein, the mass ratio of the component A to the component B is 1:1.

[0030] Show through statistical result, use the defilament rate of commercially available viscose stick (glue thread falls off from the plastic plate and stick on the silicon wafer) ≥ 3%, and use the defilament rate of the viscose stick prepared by the present embodiment ≤0.01%. It can be seen that the glue stick prepared in this example has goo...

Embodiment 3

[0032] A kind of sticky glue that is used for thin slice silicon chip, comprises component A and component B, and component A contains the raw material of following mass fraction: glycidyl ester epoxy resin 5%, bisphenol A type epoxy resin Resin 35%, hydrogenated bisphenol A epoxy resin 5%, silicone defoamer 0.01%, fumed silica 0.05%, KH-550 0.01%, calcium carbonate 54.93%;

[0033] Component B contains the following raw materials in mass fractions: 47% polythiol, 5% m-xylylenediamine prepolymer, 10% accelerator, 30% calcium carbonate, 3% organosilicon defoamer, fumed silica 5%;

[0034] Wherein, the mass ratio of the component A to the component B is 1:1.

[0035] Show through statistical result, use the defilament rate of commercially available viscose stick (glue thread falls off from the plastic plate and stick on the silicon wafer) ≥ 3%, and use the defilament rate of the viscose stick prepared by the present embodiment ≤0.02%. It can be seen that the glue stick prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com