A kind of production method of banana stalk fiber fine-dried hemp

A banana stalk and production method technology, which is applied in the direction of producing bast fiber by chemical method, can solve the problems that the degumming of banana stalk fiber is difficult to achieve satisfactory results, the content of hemicellulose and lignin is high, and the crystallinity of cellulose is low. , achieve great economic value and social benefits, reduce degumming temperature, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

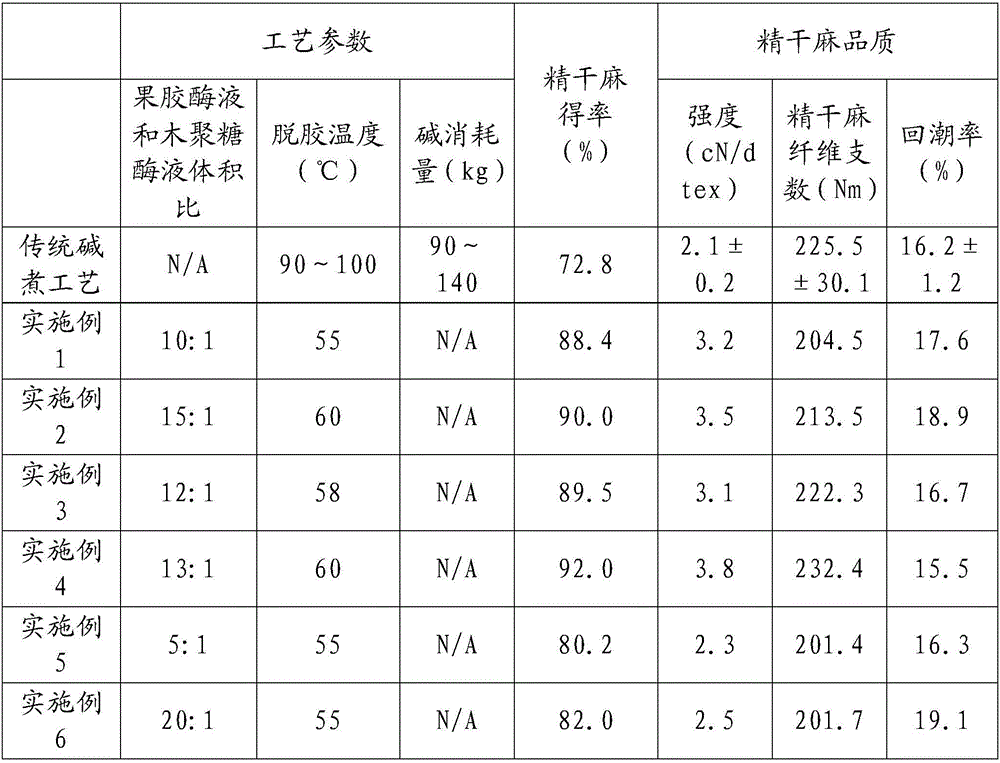

Examples

Embodiment 1

[0016] A method for producing banana stalk fiber refined hemp, comprising the following steps:

[0017] (1) Scraping: cut the banana stalks into flakes, feed them into the stalk machine, pull out when the length of the stalk is about half of the length, hold the fiber end, and feed the other section of the stalk to complete the whole scraping Hemp process to get banana stalk fiber;

[0018] (2) cage: get step (1) banana stalk fiber total amount is 500kg, carry out cage, wherein the weight of every banana stalk fiber is 0.5kg;

[0019] (3) Foaming enzyme: first prepare the degumming enzyme solution: take 400ml of pectinase solution and 40ml of xylanase solution (i.e. the volume ratio is 10:1) and mix and prepare to obtain the degumming enzyme solution; add 10 tons to the cooking pot Hot water, adjust the water temperature to 55°C, pH to 7.0; into the hot water in the boiling pot, add 35g of degumming aid magnesium sulfate, 350ml of degumming enzyme solution (that is, add 0.7ml...

Embodiment 2

[0024] A method for producing banana stalk fiber refined hemp, comprising the following steps:

[0025] (1) Scraping: cut the banana stalks into flakes, feed them into the stalk machine, pull out when the length of the stalk is about half of the length, hold the fiber end, and feed the other section of the stalk to complete the whole scraping Hemp process to get banana stalk fiber;

[0026] (2) cage: get step (1) banana stalk fiber total amount is 650kg, carry out cage, wherein the weight of every banana stalk fiber is 1kg;

[0027] (3) Foaming enzyme: first prepare the degumming enzyme solution: take 1050ml of pectinase solution and 70ml of xylanase solution (i.e., the volume ratio is 15:1) and mix and prepare to obtain the degumming enzyme solution; add 10 tons to the cooking pot Hot water, adjust the water temperature to 60 ℃, pH to 8.0; to the hot water in the boiling pot, add 244g of degumming aid magnesium sulfate, 975ml of degumming enzyme solution (that is, add 1.5ml ...

Embodiment 3

[0032] A method for producing banana stalk fiber refined hemp, comprising the following steps:

[0033] (1) Scraping: cut the banana stalks into flakes, feed them into the stalk machine, pull out when the length of the stalk is about half of the length, hold the fiber end, and feed the other section of the stalk to complete the whole scraping Hemp process to get banana stalk fiber;

[0034] (2) cage: get step (1) banana stalk fiber total amount is 600kg, carry out cage, wherein the weight of every banana stalk fiber is 0.8kg;

[0035] (3) Foaming enzyme: first prepare the degumming enzyme solution: take 600ml of pectinase solution and 50ml of xylanase solution (that is, the volume ratio is 12:1) and mix and prepare to obtain the degumming enzyme solution; add 10 tons to the cooking pot Hot water, adjust the water temperature to 58°C, and pH to 7.5; add 90g of degumming aid magnesium sulfate and 600ml of degumming enzyme solution to the hot water in the boiling pot (that is, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com