Method for preparing silybin

A technology for silibinin and silymarin, which is applied to the field of extraction and purification of silibinin, can solve the problems of high production cost, harm to the human body, large dosage, etc., achieves low energy consumption, improves product purity and toxicity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

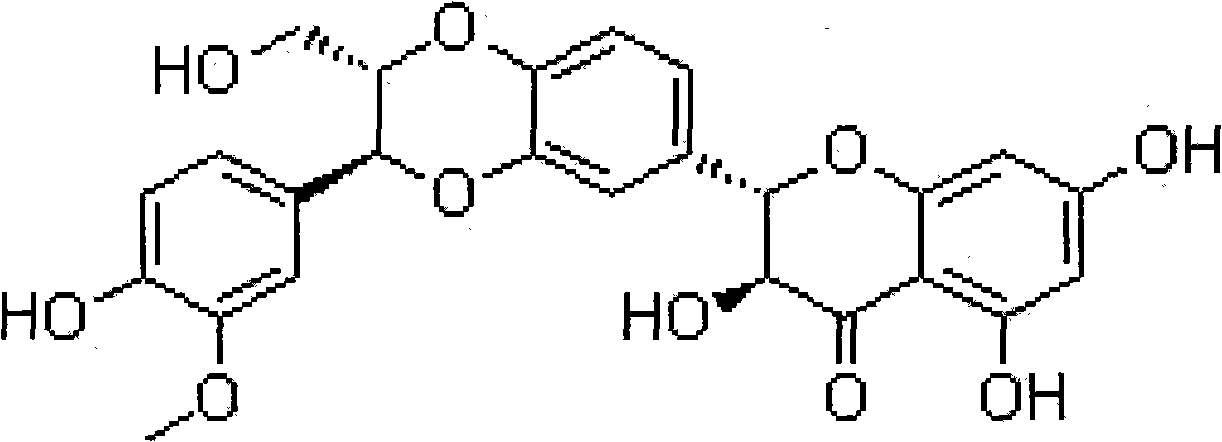

Image

Examples

Embodiment 1

[0033] The milk thistle seeds were pulverized into 20 meshes, 10 kg (0.96% of silybin content) was added to 80 L of n-hexane, defatted 3 times, each time for 1.5 hours, and the dregs were filtered out as defatted coarse material. Add 40L of 40% dilute ethanol to the degreased crude material for reflux extraction three times, combine the extracts, concentrate under reduced pressure until there is no alcohol smell, add 30L of ethyl acetate for extraction, and obtain the extract. The extract was mixed with 200-300 mesh silica gel, and then put on a 5L silica gel column, and eluted sequentially with benzene, 4:1 and 2:1 (v / v) benzene-ethyl acetate at a flow rate of 5L / h. Take the colorless effluent as the end point, collect 2:1 (v / v) benzene-ethyl acetate eluent in sections of 200ml each, and detect with ultraviolet light after the elution is completed, and the 13~ The 21 eluents were combined, and the solvent was recovered under reduced pressure to obtain 113 g of extract. Add 8...

Embodiment 2

[0035] The milk thistle seeds were pulverized into 40 meshes, 10 kg (0.99% of silybin content) was added to 90 L of n-hexane, defatted 3 times, each time for 1.5 hours, and the dregs were filtered out as defatted coarse material. Add 50L of 45% dilute ethanol to the degreased crude material for reflux extraction for 3 times, combine the extracts, concentrate under reduced pressure until there is no alcohol smell, add 35L of ethyl acetate for extraction, and obtain the extract. The extract was mixed with 200-300 mesh silica gel, then put on a 5L silica gel column, and eluted with benzene, 5:1 and 1:1 (v / v) benzene-ethyl acetate successively at a flow rate of 5L / h. Respectively take the colorless effluent as the end point, collect 1:1 (v / v) benzene-ethyl acetate eluent in sections of 200ml each, and detect with ultraviolet light after the elution is completed, and the 13~ The 21 eluents were combined, and the solvent was recovered under reduced pressure to obtain 119 g of extrac...

Embodiment 3

[0037] The milk thistle seeds were pulverized into 40 meshes, 10 kg (0.98% of silybin content) was added to 100 L of n-hexane, defatted 3 times, each time for 2 hours, and the dregs were filtered out as defatted coarse material. Add 55L of 50% dilute ethanol to the degreased crude material for reflux extraction twice, combine the extracts, concentrate under reduced pressure until there is no alcohol smell, add 35L of ethyl acetate for extraction, and obtain the extract. The extract was mixed with 200-300 mesh silica gel, then put on a 5L silica gel column, and eluted sequentially with benzene, 6:1 and 2:1 (v / v) benzene-ethyl acetate at a flow rate of 5L / h. Take the colorless effluent as the end point, collect 2:1 (v / v) benzene-ethyl acetate eluent in sections of 200ml each, and detect with ultraviolet light after the elution is completed, and the 13~ The 21 eluents were combined, and the solvent was recovered under reduced pressure to obtain 124 g of extract. Add 1000ml of 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com