Preparation method of scented tea

A fragrant tea and time technology, which is applied in the field of fragrant tea preparation, can solve the problems of poor quality of Longjing tea, and achieve the effects of transparent soup color, green leaf bottom, and strong and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

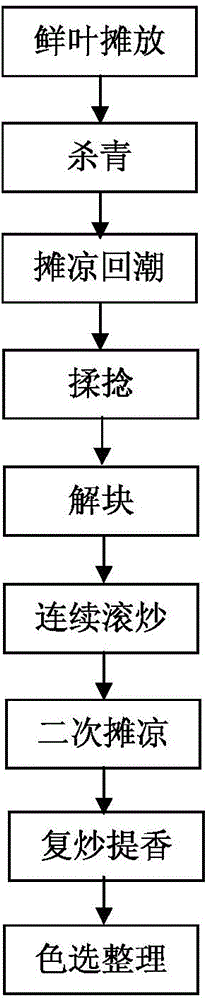

[0029] A method for preparing fragrant tea, comprising the following steps:

[0030] (1) Select the green tea variety Yingshuang, pick fresh leaves, and measure the water content of the fresh leaves three times to be 77.45%, 76.37% and 75.31%, respectively. The mechanical composition of the fresh leaves is 4% single bud, 10% one bud and one leaf , 20% of one bud with two leaves, 61% of one bud with three leaves, and 5% of a single piece; in an environment with a temperature of 28°C and a humidity of 43%, it is spread on greening equipment for 5 hours, and the thickness of the spread is 10cm;

[0031] (2) Put the fresh leaves into the drum greening machine with a dosage of 80kg / h for continuous greening, and green them at a cylinder temperature of 300°C for 1 minute and 15 seconds, and measure the water content to be 47.2%;

[0032] (3) Cool for 30 minutes, and the thickness of cooling is ≤0.5cm; after the leaves are cooled, they are piled up in piles and rehydrated for 120 mi...

Embodiment 2

[0041] A method for preparing fragrant tea, comprising the following steps:

[0042] (1) Select the green tea variety Yingshuang, pick fresh leaves, and measure the water content of the fresh leaves three times to be 77.69%, 76.37% and 76.4%, respectively. The mechanical composition of the fresh leaves is 7% single bud, 18% one bud and one leaf , 45% of one bud with two leaves, 25% of one bud with three leaves, and 5% of a single piece; the temperature is 27°C and the humidity is 46% and the environment is spread for 5 hours, and the thickness of the spread is 6cm;

[0043] (2) Put the fresh leaves into the drum fixer at a dosage of 75kg / h for continuous fixation, fix them at a cylinder temperature of 310°C for 1 minute and 18 seconds, and measure until the moisture content is 43.1%;

[0044] (3) Spread it to cool for 20 minutes, then rehydrate for 60 minutes, and cover it with cloth and plastic film when it rehydrates.

[0045] (4) Put the green leaves that have been cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com