Patents

Literature

58results about How to "Inhibit browning reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

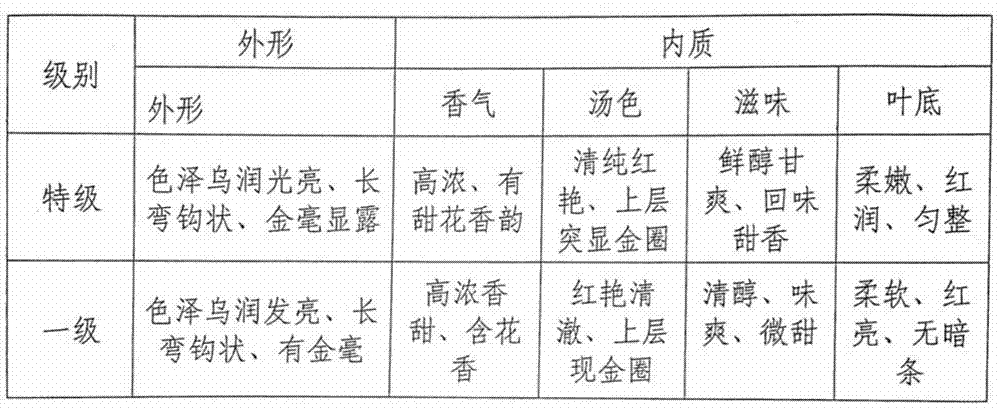

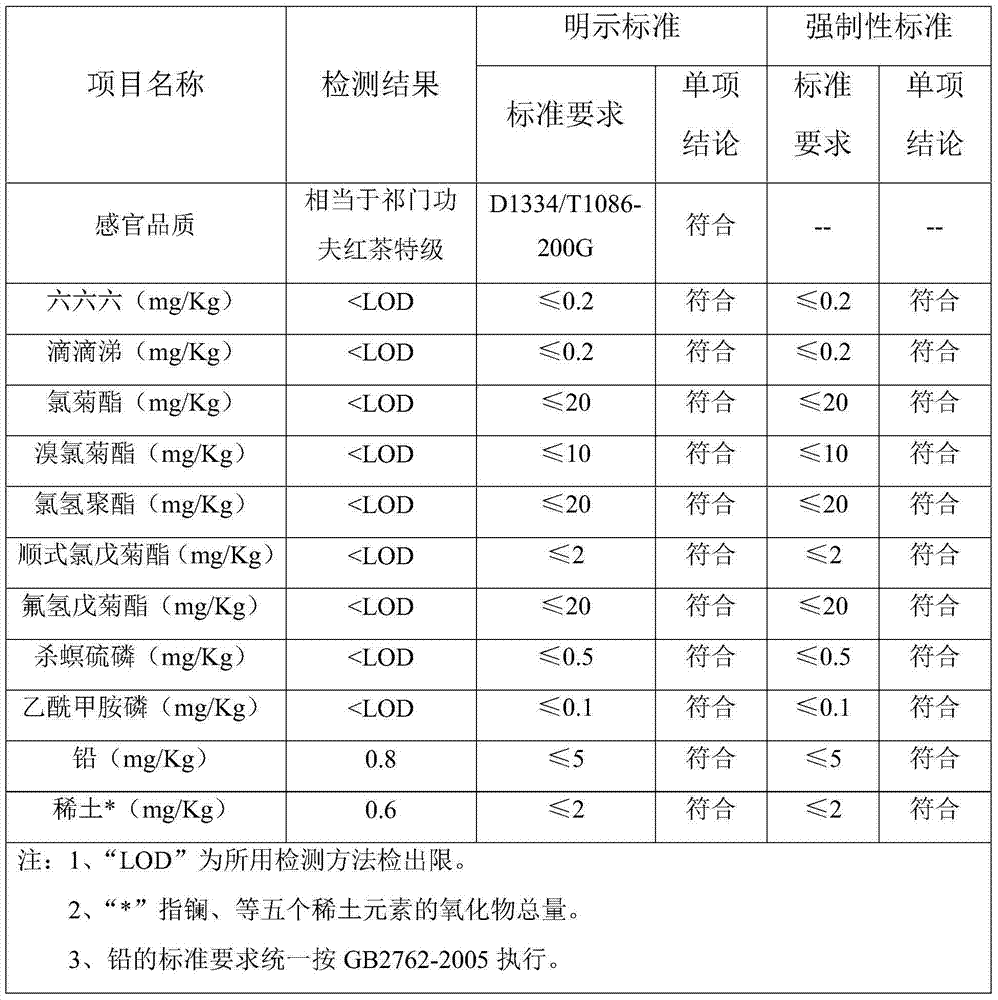

Processing method of keemun golden hook black tea

ActiveCN104489142AIncrease the "Golden Circle" degreeDark and bright colorPre-extraction tea treatmentSocial benefitsBeta-Carotene

The invention discloses a processing method of keemun golden hook black tea. The keemun golden hook black tea is prepared by a series of procedures of natural withering, withering by virtue of a withering tank, rolling, deblocking, fermenting, roll forming, arranging, shaping, shape solidifying and fragrance extracting. Beta-carotene is added in the rolling procedure to increase the golden yellow; and glucose oxidase is added to prevent the black tea from further fermenting after the fermentation is ended. The black tea prepared by adopting the method has the advantages of having the long-hook-shaped appearance, black and bright color and luster, revealable hairy tips, has the clear and high fragrance, obvious sweet scented taste, fresh and mellow taste, sweetness in aftertaste, red and bright soup and obvious golden circle after being brewed, and has a unique flavor and relatively high economic and social benefits.

Owner:黄山王光熙松萝茶业股份公司

Method for preventing banana pulp from browning

InactiveCN104305161AEfficient productionContinuous productionFood preparationEnzymeProtective Agents

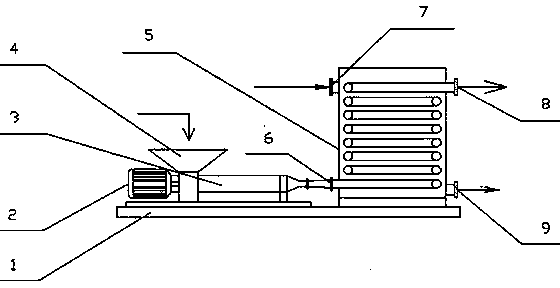

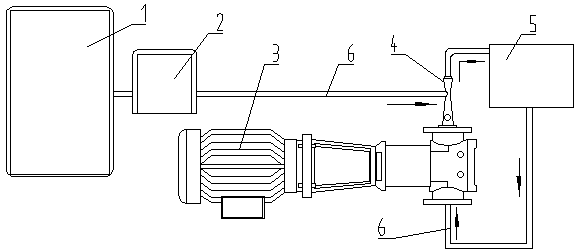

The invention discloses a method for preventing banana pulp from browning. During deep banana processing, bananas can be oxidized to cause browning very easily, and further the loss of color, fragrance and taste is caused. Therefore, preventing browning during the banana processing is very important. The method provided by the invention achieves the purposes of enzyme deactivation and browning prevention through the procedures of batch charging, enzyme deactivating, pulping, filtering, sterilizing and bulking. The entire banana pulp processing process is performed in a sealed state, the banana pulp is not in contact with air, on one aspect, browning reaction cannot be easily caused under an anaerobic condition, on the other aspect, enzymatic browning inactivation is achieved, and the browning reaction is stopped fundamentally. During the processing, the bananas quickly enter into a coil heat exchanger under the pushing of a screw pump to be heated to reach a temperature of 100 to 120 DEG C, and the temperature is kept for 5 to 6 minutes, therefore, a color-protecting effect is played. The method provided by the invention can achieve high efficiency and continuous scale production under a state of not adding any protective agents.

Owner:合浦果香园食品有限公司

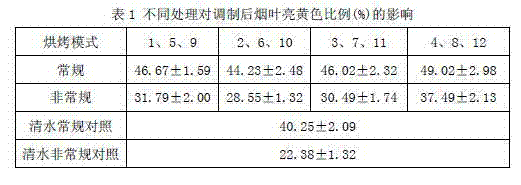

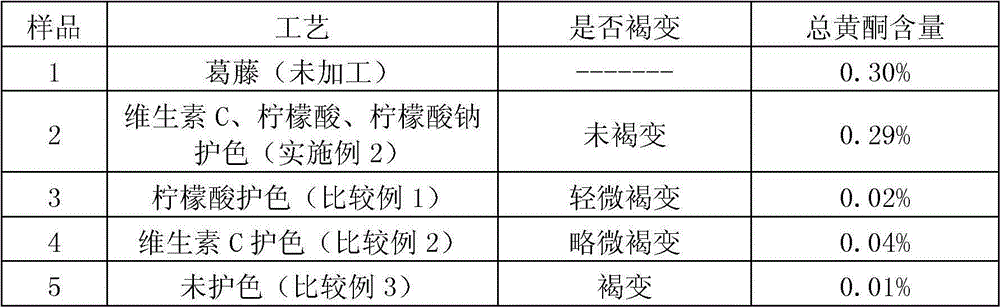

Method for preventing browning reaction caused by improper tobacco leaf curing

InactiveCN103478895AInhibit browning reactionInhibitory activityTobacco treatmentOrganic acidKojic acid

The invention discloses a method for preventing a browning reaction caused by improper tobacco leaf curing, and belongs to the technical field of cigarette making. The method comprises the following steps: picking tobacco leaves, soaking and curing, wherein the soaking step comprises the following sub-steps: flatly laying the tobacco leaves in a rectangular water tank filled up with a polyphenol oxidase inhibitor solution, and soaking for 5-8 minutes, so that the activity of the polyphenol oxidase (PPO) can be inhibited, the browning reaction can be reduced, and a tobacco leaf curing effect can be improved. A polyphenol oxidase inhibitor is one or more of kojic acid, ferulic acid and ascorbate, and also can contain other organic acids. By applying kojic acid, ferulic acid, ascorbate and other organic acid combinations, the browning reaction of the tobacco leaves can be effectively inhibited and the proportion of bright yellow tobacco leaves can be increased to 6%-15%.

Owner:SHANDONG LINYI TOBACCO

Chinese chestnut brown stain preventing processing technology

ActiveCN102084894AIncrease the degree of glycationImprove the flavor of the valleySeed preservation using chemicalsSeed preservation by heatingAlcoholSweetness

The invention discloses a Chinese chestnut brown stain preventing processing method which comprises the following steps of: 1, screening Chinese chestnuts; 2, processing at low temperature; 3, processing with CO2: putting the Chinese chestnuts in an environment with the CO2 concentration of 5-30 percent (volume) and temperature of 10-20 DEG C and relative humidity of 85-95 percent for 2-20 days; 4, carrying out gas stifling treatment on the Chinese chestnuts by adopting ethylene or alcohol; 5, removing hulls and red skins; 6, inactivating enzyme: putting Chinese chestnut kernels in food-grade acidic liquid with the temperature of 80-100 DEG C or food-grade acidic stream with the temperature of 100-110 DEG C, and controlling the pH value of the liquid or stream to be 1-6 and the processing time to be 5-20min; 7, curing: putting the Chinese chestnut kernels into food-grade alkali liquid with pH value of 7-12 at a temperature of 90-100 DEG C, and processing for 5-20min; 8, bagging and sealing; 9, sterilizing with back pressure at high temperature and high pressure; and 10, cooling to normal temperature for storing. The Chinese chestnuts processed by using the technology maintain the special grain flavor and the sweetness while keeping the natural yellow color, and is best in color, favor and taste.

Owner:TIANJIN UNIV OF SCI & TECH +3

Method for jointly drying cucumbers by vacuum pulse and negative-pressure pulse-spouted microwave

ActiveCN108936424AInhibit browning reactionReduce browning reactionFood dryingFood ingredient functionsUltrasonic assistedEngineering

The present invention relates to a method for jointly drying cucumbers by vacuum pulse and negative-pressure pulse-spouted microwave, and belongs to the technical field of fruit and vegetable processing. The processing method comprises the following operation steps: cucumber selection, cleaning and slicing, ultrasonic-assisted color protection with a color-fixing liquid, blanching enzyme-deactivation sterilization treatment with ultrasonic-assisted high-temperature and high-humidity superheated steam, vacuum pulse drying, two-stage negative-pressure pulse-spouted microwave drying, and vacuum packaging. The cucumber product processed by the method has the advantages of short drying time, high effective component retention rate, good quality, cleanness and sanitation.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method of fermenting dried lichee liquor with high sugar

ActiveCN104130900AReduce lossesInhibit browning reactionMicroorganism based processesAlcoholic beverage preparationBiotechnologyAcetic acid

The invention relates to a method of fermenting dried lichee liquor with high sugar. The method comprises the following steps: selecting fruits; cleaning; removing peels and denucleating; squeezing and taking juice; filtering; freezing and concentrating; freezing and defreezing; controlling temperature and fermenting; aging; clarifying and filtering; finally, obtaining the dried lichee liquor. According to the method, high sugar fruit juice is frozen and defrozen to separate out part of astringent matters in form of precipitates, so that the obtained dried lichee liquor is strong in fruity aroma, gentle and comfortable and tasty. The alcoholic strength of the dried lichee liquor is 14-15%vol, the content of total sugar is 2-4g / L, the total acid content is 6-7.5g / L (based on tartaric acid), the content of volatile acid is 0.4-0.6g / L (based on acetic acid), and the content of dried extracts is 20-30g / L.

Owner:GUANGDONG ZHENZHOU LYCHEE IND

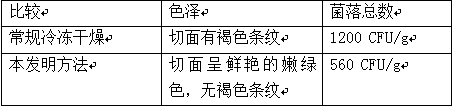

Processing method of fresh and crispy freeze-dried jujubes and jujube slices

The invention discloses a processing method of fresh and crispy freeze-dried jujubes and jujube slices. By adopting acidic electrolyzed water and sterilization and enzyme deactivation treatment and freeze-drying technologies, the dried jujube products have the advantages of intact shape, bright color, high nutrient content, aromatic flavor and good taste. The total number of bacterial colonies ofthe prepared finished products are less than 1000 CFU / g, the number of coliform bacteria of the finished products is less than 30 MPN / 100g, the cross sections of the finished products show vivid verdant color, and the finished products have no band-shaped brown stripes which are usually shown in common freeze-dried products; by adjusting a freeze-drying curve, the moisture content of the productsis controlled to be 4%-10%, the products have rich fresh and aromatic flavor, and the taste of the products is similar to the taste of fresh jujubes; the finished products have crispy taste similar tothe taste of vacuum puffed products and low-temperature fried products and have no greasy feeling; and nutrients are better kept, and the retention rate of vitamin C is higher than 90%.

Owner:早康枸杞股份有限公司

Processing method of granny smith apple juice

InactiveCN107691913AReduced activityDoes not affect BrixFood ingredient as antioxidantFood adsorptionFiberFruit juice

The invention relates to a processing method of a granny smith apple juice. The method is characterized in that polyphenol enzyme activity is reduced by pretreatment such as blanching; nitrogen is filled during a squeezing process, so that a juice is isolated from the oxygen as much as possible before enzymolysis, and a browning reaction is inhibited; pectase is added for enzymolysis so as to enhance clarity; pH value is reduced by the action of ascorbic acid and malic acid; and the color value of the juice is improved by ion-exchange fiber adsorption.

Owner:ANHUI FUNAN CHANGHUI FOOD

Preparation method of preserved apricots

InactiveCN106900967AMaintain colorKeep the tasteClimate change adaptationConfectioneryAdditive ingredientSugar

The invention discloses a preparation method of preserved apricots. The preparation method comprises the following steps: raw material pretreatment, brining, apricot seed removal, color protection, enzyme deactivation, primary sugaring, secondary sugaring, drying and vacuum packaging. The provided preparation method can keep special color, taste and nutrients of apricot pulp. The problems of nutrient loss due to hot water blanching, candying and sugaring and excessive sulphur content due to stoving are overcome, and the prepared preserved apricots are low in sugar content.

Owner:湖南双晟科技信息咨询有限公司

Kudzu tea and method for preparing same

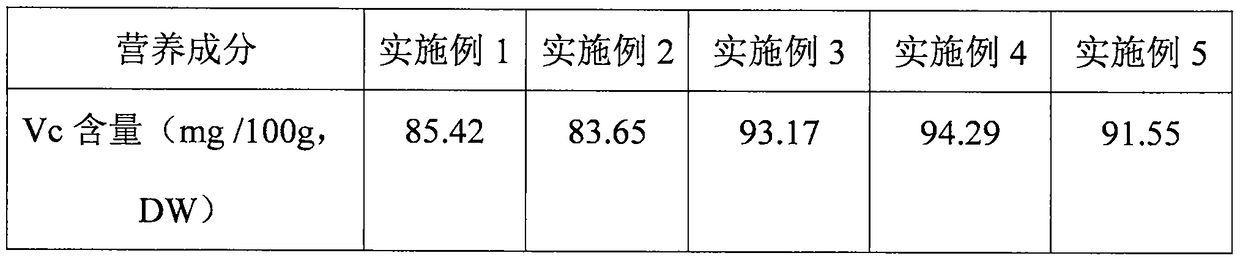

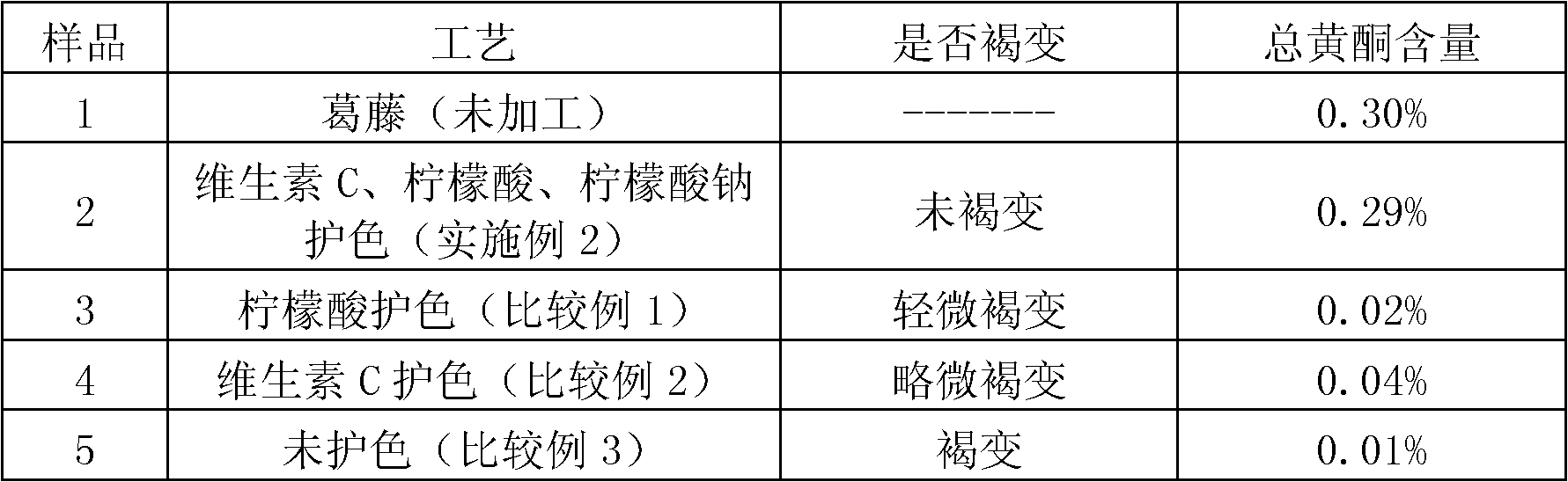

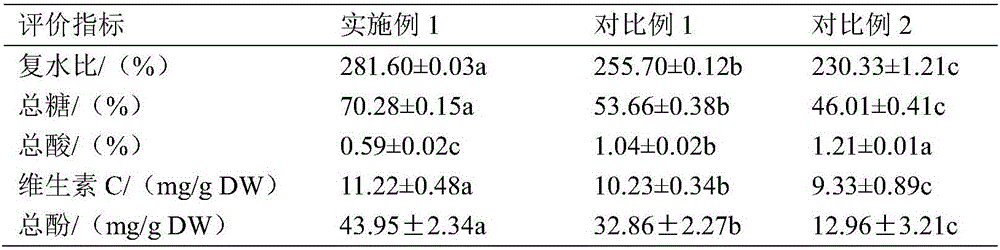

The invention discloses kudzu tea. The kudzu tea is flake-shaped, and the total flavonoid content of kudzu is 0.21 to 0.29 percent. The method for preparing the kudzu tea comprises the steps of cleaning fresh kudzu, removing leaves, slicing, performing color protection, drying, stir-frying, baking, performing flavor distilling and the like. The waste kudzu is used as a raw material, and the freshkudzu is soaked in a proper compound color-protecting solution for color protection treatment in the preparation process, so that resources are fully utilized, the pollution of wastes to natural environment is avoided, the browning reaction of kudzu is effectively inhibited, the kudzu tea keeps original color of the kudzu, the visual effect is quite good, the flavonoid content of the kudzu tea ishigh, the nutritional value is also quite high, more added values are given to the product, and the market competitiveness of the kudzu tea is higher. The preparation method has the advantages of simple process, short flow and convenience in operation and control.

Owner:达州市山参葛业有限责任公司

Ready-to-eat large yellow croaker vacuum deep-fried food and production technology thereof

The invention relates to a ready-to-eat large yellow croaker vacuum deep-fried food. The raw materials of the ready-to-eat large yellow croaker vacuum fried food comprise the following components in parts by weight: 120-150 parts of fish meat of large yellow croakers, 20-35 parts of bone glue, 10-25 parts of pomelo peel, 3-5 parts of olive oil, 4-7 parts of corn oil, 5-15 parts of seasonings, 20-35 parts of black bean powder, 10-20 parts of honeycombs, 25-45 parts of nori and sesame seed powder, 2-5 parts of lemons, 5-9 parts of an additive, 5-10 parts of okra, 5-10 parts of ginseng fruits and 5-10 parts of arctium lappa. According to the ready-to-eat large yellow croaker vacuum deep-fried food disclosed by the invention, a vacuum deep-frying manner is used for replacing a conventional high-temperature deep-frying technology, so that the loss of nutrient substances is greatly reduced, the detrimental effects of microbes and enzymes are restrained, and the original fragrance and the original nutrition are sufficiently reserved. The ready-to-eat large yellow croakers prepared by the production technology disclosed by the invention are good in mouth feel, long in storage period, free from preservatives, convenient to eat and carry and simple in production method and technology, and industrialized production is easy to realize.

Owner:ZHEJIANG OCEAN UNIV

Quick drying processing method of raisin

InactiveCN102669255AExtended processing timeIncrease productivityFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationHigh humidityRoom temperature

The invention belonging to the technical field of fruit and vegetable processing, and relates to a quick drying processing method of raisin, which comprises the following steps of (1) selecting fresh grapes without rot or deterioration; (2) washing surface with clean water to remove dust, impurities and the like; (3) blanching cleaned grape in a high-temperature high-humidity gas jet impulse blancher, wherein the blanching temperature is 90-130 DEG C, the relative humidity of the high-humidity gas is 20-70%, the gas flow rate is 6-30 m / s, and the blanching time is 30-240 s; (4) drying the blanched grape in a gas jet impulse drying box, wherein the drying temperature is 50-80 DEG C, the air speed is 6-30 m / s, and drying is stopped when the wet basis water content of the grape is below 20%; and (5) packaging after the raisin is cooled to room temperature. The quick drying processing method has the advantages of high drying efficiency, simplicity and convenience in operation, cleanliness and hygiene, capability of effectively inhibiting browning during drying and the like.

Owner:CHINA AGRI UNIV

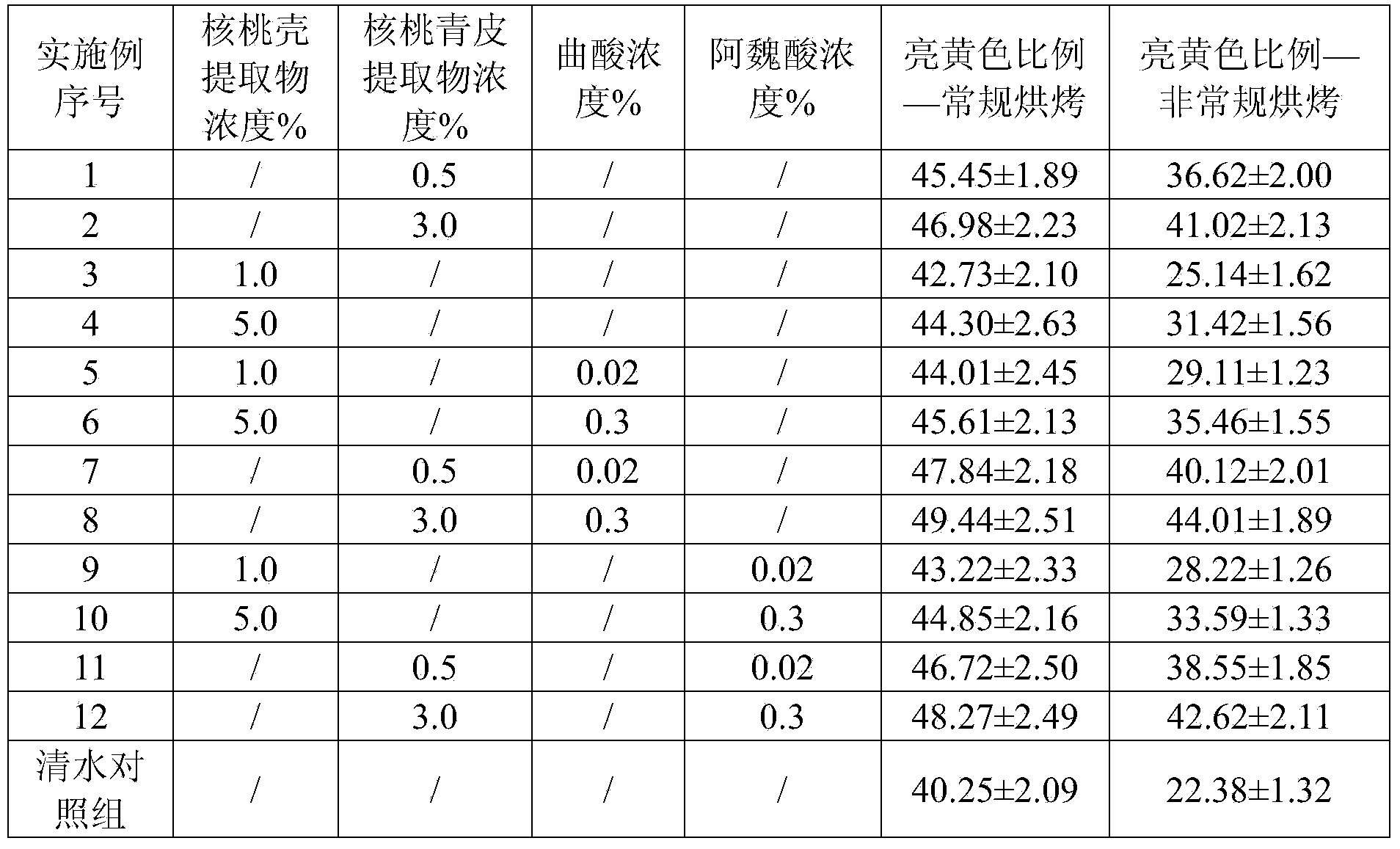

Method for preventing excessive browning reaction due to improper tobacco leaf curing

The invention discloses a method for preventing excessive browning reaction due to improper tobacco leaf curing and belongs to the technical field of cigarette manufacturing. The method for preventing the excessive browning reaction due to the improper tobacco leaf curing includes that soaking tobacco leaves after harvesting and before preparing, wherein the soaking method includes that flatly paving the tobacco leaves in a rectangular water tank full of walnut waste extract and synergist solution and soaking for 3 to 5 minutes. The soaking method is capable of inhibiting the activity of polyphenol oxidase (PPO), reducing the browning reaction and improving the tobacco leaf curing effect, and the walnut waste is walnut green husk or walnut shell. The tobacco leaf browning reaction can be effectively inhibited through combining the walnut waste extract with the synergist (kojic acid and ferulic acid), and the luminous yellow tobacco leaf proportion is improved by 5-20%.

Owner:SHANDONG LINYI TOBACCO

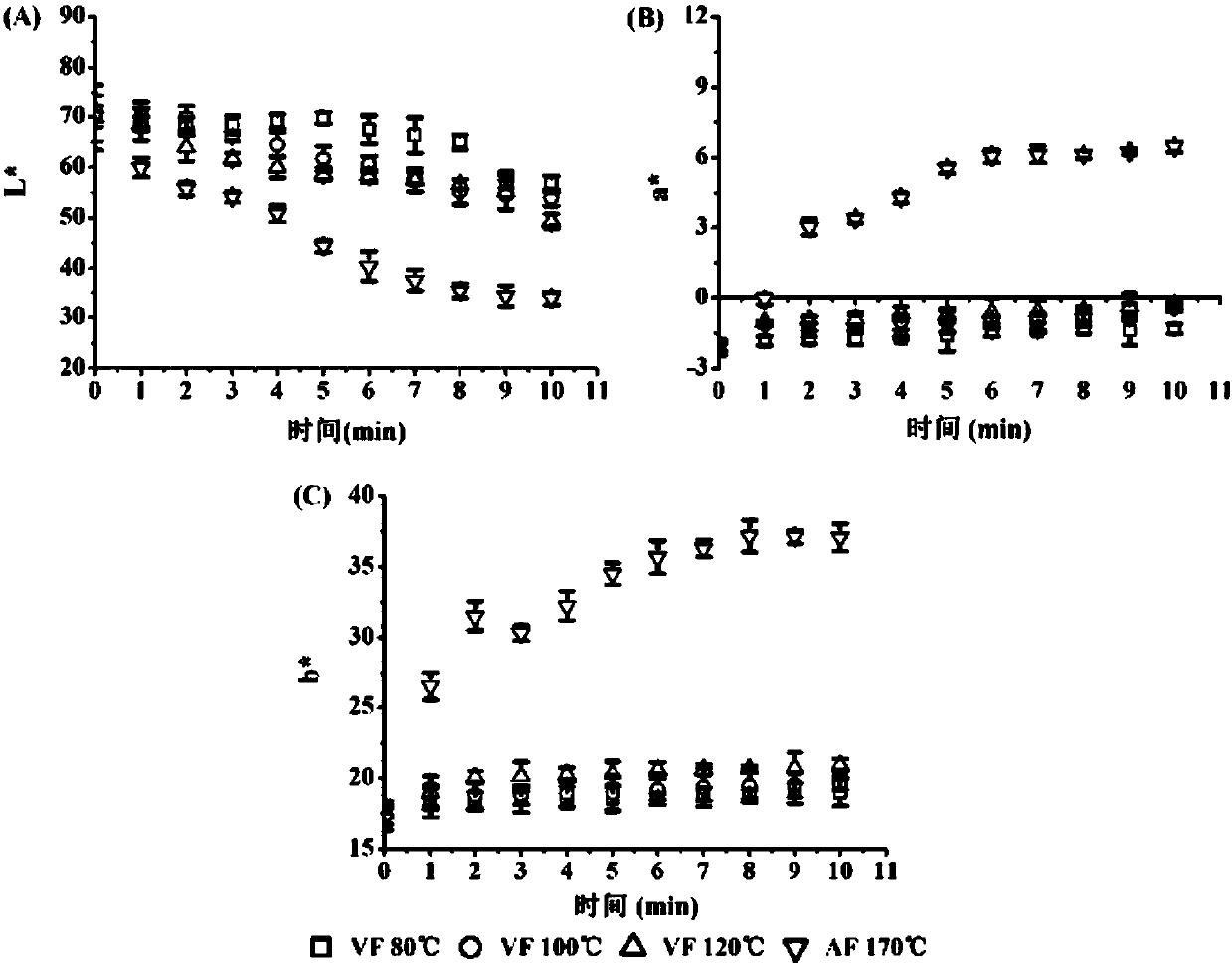

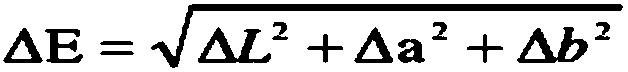

Making method of aroma strengthening longan wine

InactiveCN107267342AIncrease the content of aroma substancesFruit wine with strong aromaMicroorganismsMicroorganism based processesFruit wineFlavor

The invention discloses a making method of aroma strengthening longan wine. The making method includes the steps of 1), juicing; 2), enzymolysis; 3), blending; 4), fermentation; 5), clarification and ageing. Strains of Lalvin EC1118 saccharomycetes, Lalvin 71B saccharomycetes and Lalvin KD saccharomycetes are adopted for mixed fermentation, and ononin is added in longan fruit pulp; the longan wine is high in content of aroma-producing substances, low in content of tannin, high in nutritive value, good in healthcare value, rich in fruit wine aroma, tasty in flavor and bright and transparent in color.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

A bagged radix puerariae health-care tea

The present invention discloses a bagged radix puerariae health-care tea which comprises the following components in parts by weight: 20-30 parts of radix puerariae, 5-10 parts of salvia miltiorrhiza and 5-10 parts of green tea. Firstly, the radix puerariae is cut into slices and protected by a composite color-protecting solution, and then mixed with the sliced salvia miltiorrhiza and green tea to obtain the finished products. The radix puerariae and the salvia miltiorrhiza are mixed to improve the health-care value of the tea, and at the same time the green tea is added into the mixture to make the finished products have a better color, a more fragrant taste and a mellow mouthfeel; and a composite solution is used to soak the radix puerariae to prevent the occurrence of browning during the operation and ensure that the radix puerariae displays a white color, and thus the color of the radix puerariae would not affect the overall color of the tea after being mixed with the salvia miltiorrhiza and the green tea, and the composite solution soaking also ensures the presence of flavonoids as main nutrients in radix puerariae.

Owner:DONGZHI MAKENG XINFU TEA IND

Processing method of crangon affinis meat

InactiveCN107836665AImprove nutritional structureGood nutritionLipidic food ingredientsNatural extract food ingredientsCelluloseAdditive ingredient

The invention belongs to the field of processing of aquatic products, and relates to a processing method of crangon affinis meat. The processing method comprises the following steps of performing vacuum deep-frying on pretreated crangon affinis meat, wherein the vacuum deep-frying temperature is 80-120 DEG C, the deep-frying time is 6-10min, the negative pressure of vacuum degree is 0.098-0.08MPa,and the pretreatment of the crangon affinis meat comprises the following steps of sequentially performing low-temperature rinsing on crangon affinis, removing heads, shells and intestinal glands, cutting apart backs, keeping tails, performing low-temperature rinsing, performing soaking in salt water, performing pre-cooking, performing powder pre-wrapping, performing pulp wrapping, performing bread crumb wrapping and performing cold storage. In the pulp pre-wrapping process of the crangon affinis meat, ingredients are in reasonable compatibility, so that pre-wrapped pulp is rich in high cellulose, multivitamins and trace elements, the pre-wrapped pulp is better matched with the crangon affinis meat to obtain more nutrition, and the nutritive structure of deep-fried foods can be improved; and then through pre-cooking, powder pre-wrapping, pulp wrapping, cold storage and deep-frying, the running off of nutrient substances can be greatly reduced, detrimental effects of microorganisms andenzymes can also be restrained, and the original fragrance, the original nutrition and the original meat quality are sufficiently maintained.

Owner:舟山达康科技有限公司

Anti-fatigue blueberry concentrated beverage

InactiveCN107691928AReduce total glycoside contentImprove functional healthFood ingredient functionsPectinaseAdditive ingredient

The invention discloses an anti-fatigue blueberry concentrated beverage. The anti-fatigue blueberry concentrated beverage is processed from components such as blueberries, ginseng leaves, blueberry leaves and grapes. A processing method of the anti-fatigue blueberry concentrated beverage comprises the following steps: (1) preparation of a nutrient : firstly airtightly soaking the ginseng leaves, the blueberry leaves, boxthorn leaves and black nightshade leaves in absolute ethanol and stir-frying, and then carrying out fermentation and cooking treatment; (2) pretreatment: immersing the blueberries and the grapes in saline water for washing, then soaking the blueberries and the grapes by using a sodium selenite liquid, and heating and preserving heat; (3) preparation of concentrated juice: beating and grinding the pretreated blueberries and grapes, and carrying out enzymatic hydrolysis and high-pressure cooking; (4) clarification treatment: mixing the concentrated juice and the nutrientliquid for low-temperature freezing, then heating up, and adding pectinase for ultrasonic oscillation; (5) high-pressure homogenization: pouring primarily prepared juice into a homogenizing barrel andadding calcium gluconate and honey for high-pressure stirring and homogenization; and (6) sterilization and packaging: subjecting the homogenized juice ultraviolet sterilization and then filling to prepare an anti-fatigue cranberry beverage.

Owner:BENGBU KUNPENG FOOD & BEVERAGE

Kudzu tea and method for preparing same

The invention discloses kudzu tea. The kudzu tea is flake-shaped, and the total flavonoid content of kudzu is 0.21 to 0.29 percent. The method for preparing the kudzu tea comprises the steps of cleaning fresh kudzu, removing leaves, slicing, performing color protection, drying, stir-frying, baking, performing flavor distilling and the like. The waste kudzu is used as a raw material, and the fresh kudzu is soaked in a proper compound color-protecting solution for color protection treatment in the preparation process, so that resources are fully utilized, the pollution of wastes to natural environment is avoided, the browning reaction of kudzu is effectively inhibited, the kudzu tea keeps original color of the kudzu, the visual effect is quite good, the flavonoid content of the kudzu tea is high, the nutritional value is also quite high, more added values are given to the product, and the market competitiveness of the kudzu tea is higher. The preparation method has the advantages of simple process, short flow and convenience in operation and control.

Owner:达州市山参葛业有限责任公司

Method for producing fresh-eating jujube crisp slices

The invention discloses a method for producing fresh-eating jujube crisp slices and belongs to the technical field of fruit and vegetable food processing. According to the method, fresh-eating jujubes serve as a raw material; after being chosen and cleaned, the fresh-eating jujubes are peeled, enucleated and pulped in one time, protective color liquid is added in the pulping process for color protection; the fresh-eating jujube pulp is laid in a die at a thickness of 0.5-1 cm; after being pre-freezed, the fresh-eating jujube pulp undergoes microwave vacuum freezing drying to be dried and dehydrated, moisture is controlled to be 20-40%, microwave vacuum puffing is performed, and the water content of the finished products is below 10%. According to the method, dehydration and drying time is remarkably shortened, energy consumption is low, efficiency is high, original flavor and nutrient in the fresh-eating jujubes are reserved to be largest extent, and the products are yellow green in color, uniform in texture, crisp in taste and pleasant to the palate and are a natural oil-free fruit and vegetable leisure food conforming to the modern consumption requirements.

Owner:NORTHWEST A & F UNIV

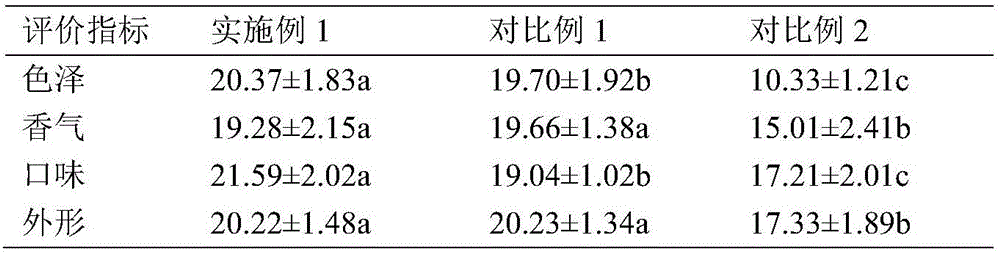

Treatment method for improving fresh-keeping effect of fresh-cut yellow peaches

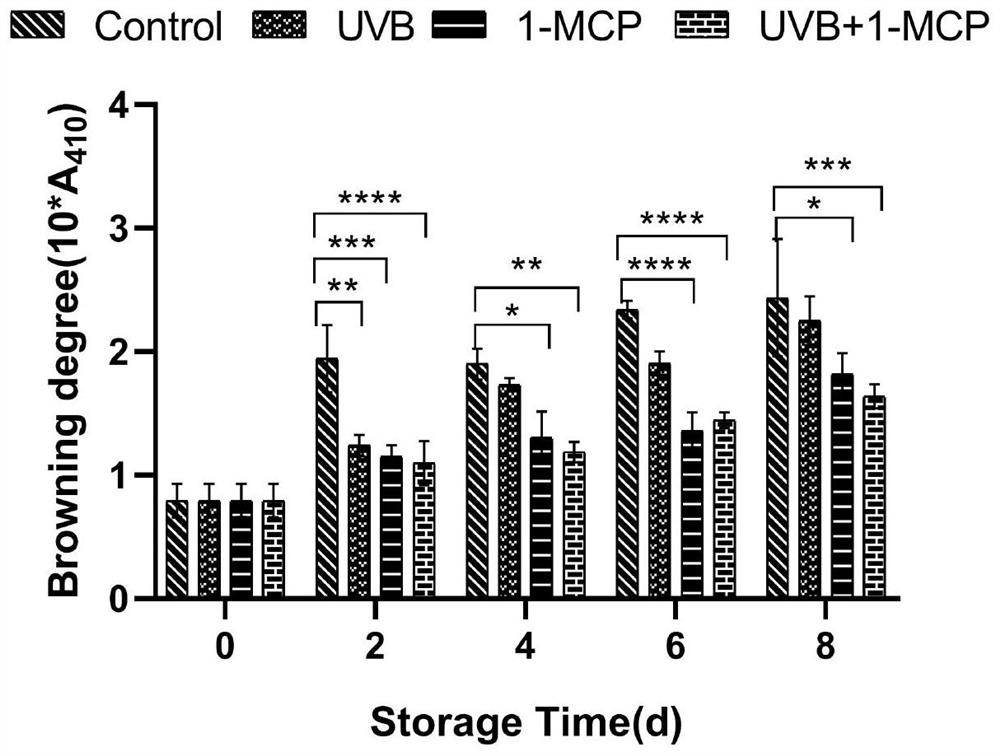

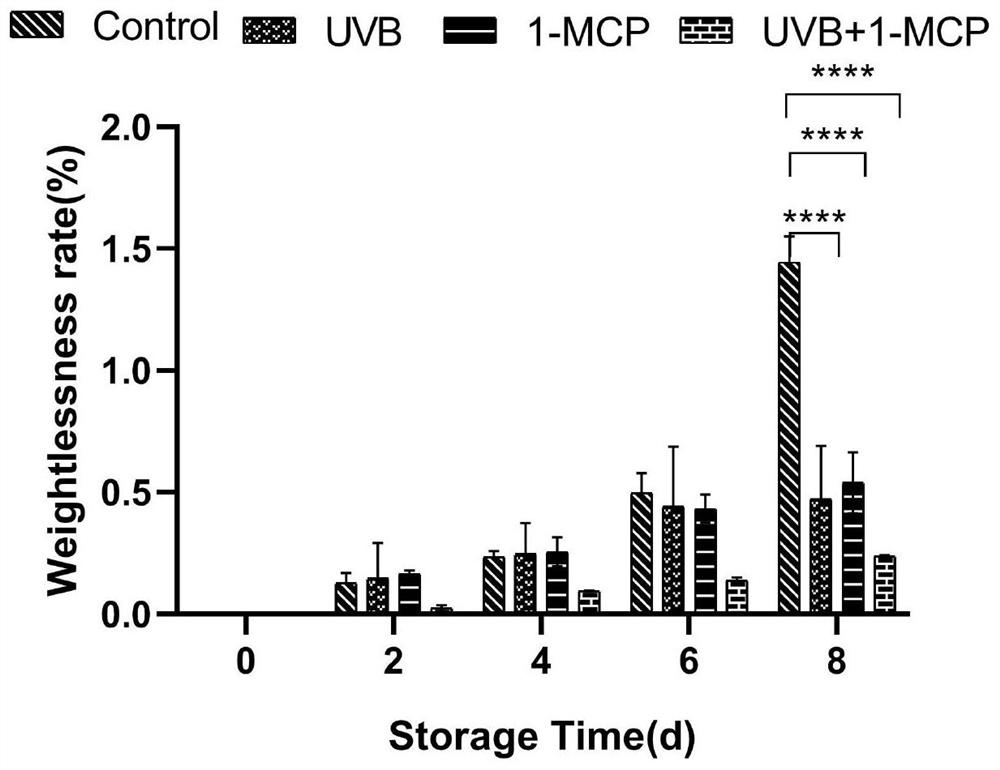

ActiveCN112400980AReduce browningDelay quality deteriorationFruits/vegetable preservation by irradiation/electric treatmentFood ingredient for microbe protectionBrowningInsect pest

The invention discloses a treatment method for improving the fresh-keeping effect of fresh-cut yellow peaches, and belongs to the technical field of storage and fresh keeping of fruits and vegetables.The preparation method comprises the following steps: firstly, soaking yellow peach fruits which are uniform in size, consistent in maturity and free from mechanical injury and plant diseases and insect pests by using NaClO or 75% ethanol solution, performing washing by using deionized water, performing draining, and cutting the peaches into yellow peach slices with the thickness of 1-2cm; then performing UV-B irradiation treatment on the yellow peach slices, wherein the irradiation dose of the UVB treatment is 1.056 kJ / m <2> to 1.464 kJ / m<2>; thirdly, performing 1-MCP fumigation treatment onthe yellow peach slices t, wherein the concentration of 1-MCP fumigation treatment is 1[mu]l L<-1> to 10 [mu]l L<-1>; and finally, performing sealing storage on the treated yellow peach slices, wherein the storage humidity ranges from 80-92%, and the storage temperature ranges from 2 DEG C to 8 DEG C. By means of the treatment method, the preservation time of the fresh-cut yellow peaches is prolonged to 8 days, browning of the fresh-cut yellow peaches can be effectively slowed down, weight loss is reduced, and good economic value is achieved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Fragrant and crisp Chinese yam slice and processing method thereof

InactiveCN108813471ASilky meatReduce pile upFood coatingFood ingredient for microbe protectionBiologyRhizome

The present invention discloses a fragrant and crisp Chinese yam slice and a processing method thereof, and relates to the field of food processing. The fragrant and crisp Chinese yam slice comprisesChinese yams, fingerleaf rodgersflower rhizome and citric acid. A layer of fingerleaf rodgersflower rhizome micro-powder is evenly spread on the surfaces of the Chinese yam slice to prevent the browning of the Chinese yam slice. Secondly, the Chinese yams and fingerleaf rodgersflower rhizome are combined; and the fragrant and crisp Chinese yam slice removes greasiness, relieves toxins by frying and roasting, improves digestion, and reduces or even eliminates dyspepsia symptoms possibly happening after eating the oil-fried Chinese yam slice.

Owner:襄阳农博源农业有限公司

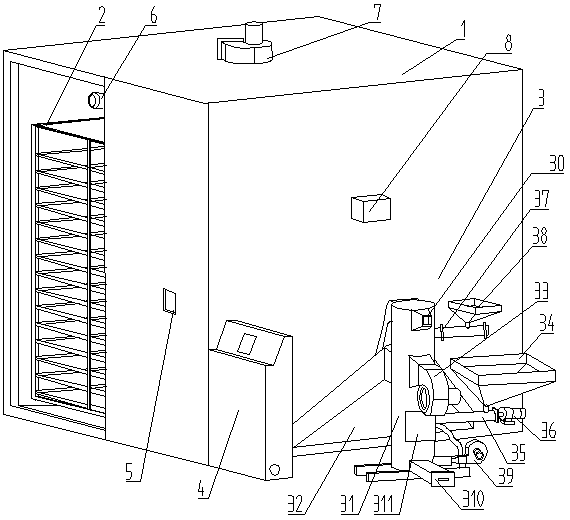

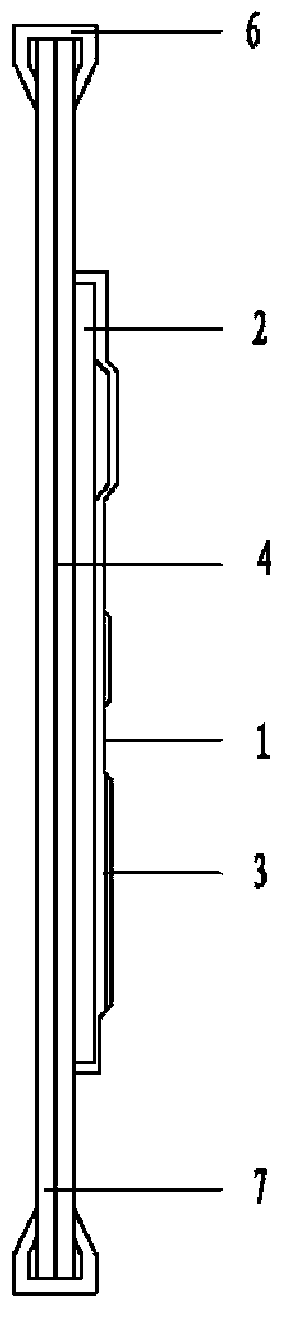

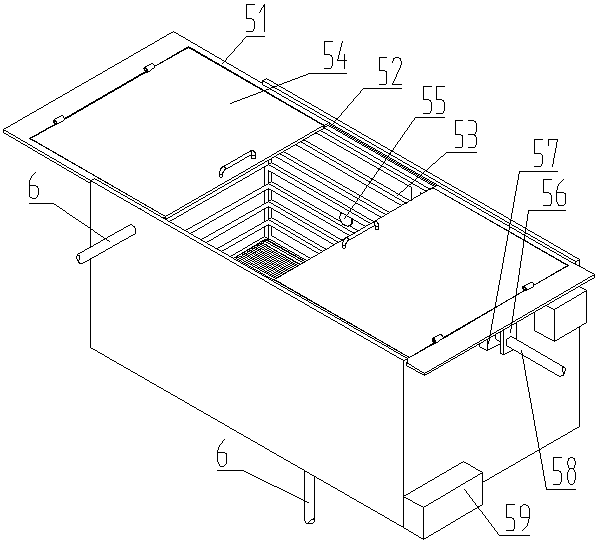

Day lily anoxic drying method and baking device

ActiveCN108783521AHigh market valueHelps adjust surface colorFood treatmentFruits/vegetable preservation by dehydrationNutritional qualityRiver sand

The present invention discloses a day lily anoxic drying method. The day lily anoxic drying method comprises the following steps: raw material selecting, compound enzyme solution preparing, mixed enzymatic hydrolyzing, sealing and storing, ozonated water soaking, river sand covering, anoxic drying, etc. The provided day lily anoxic drying method is beneficial to adjusting the color and luster of the surface of the day lily, can remove the green color on the surface of the day lily, obtains the day lily presenting yellow surface, and enables the day lily to be more beautiful in color and higherin nutritional quality.

Owner:HUNAN AGRICULTURAL UNIV

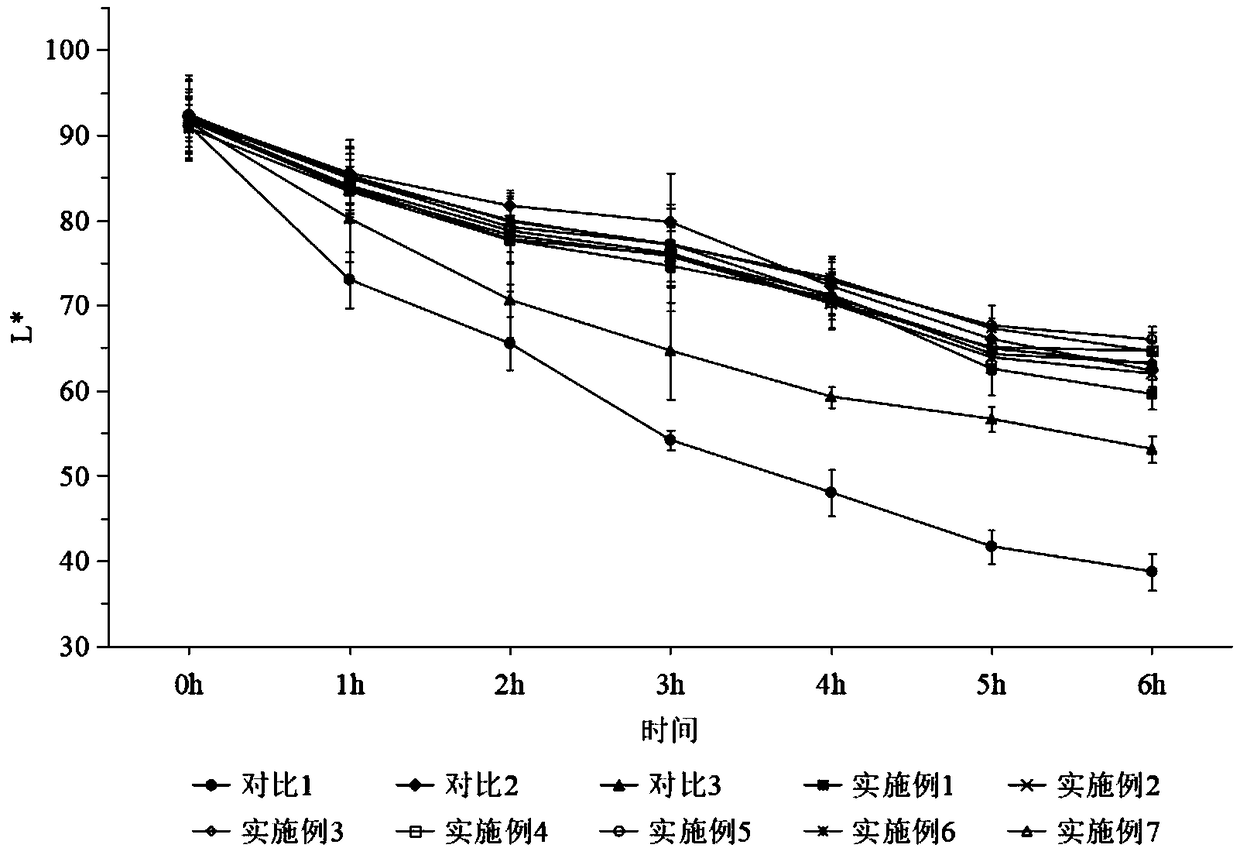

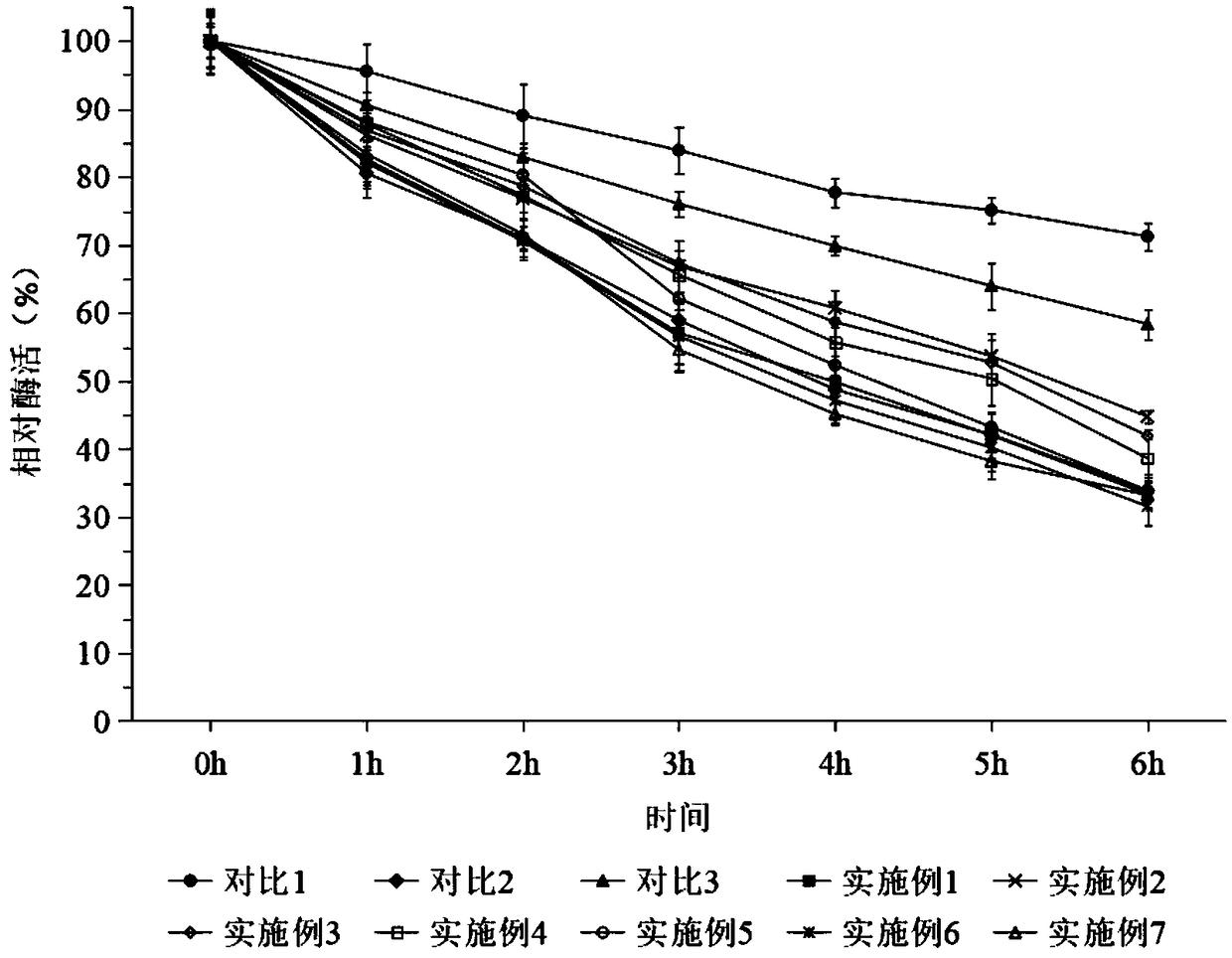

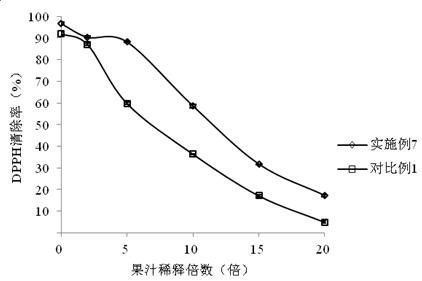

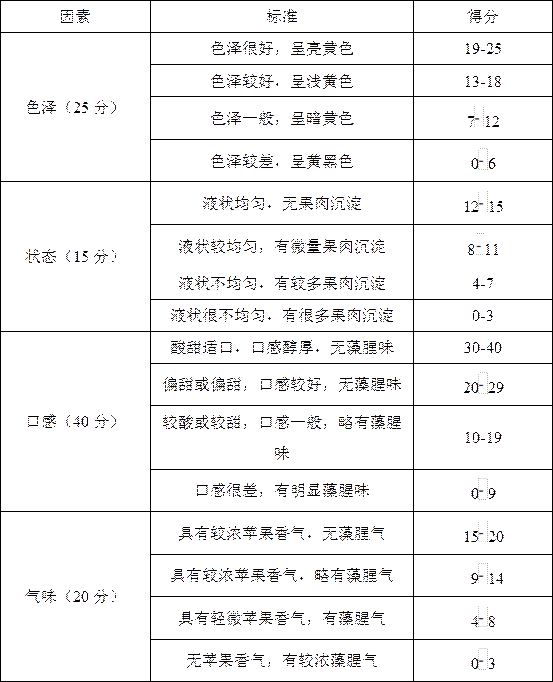

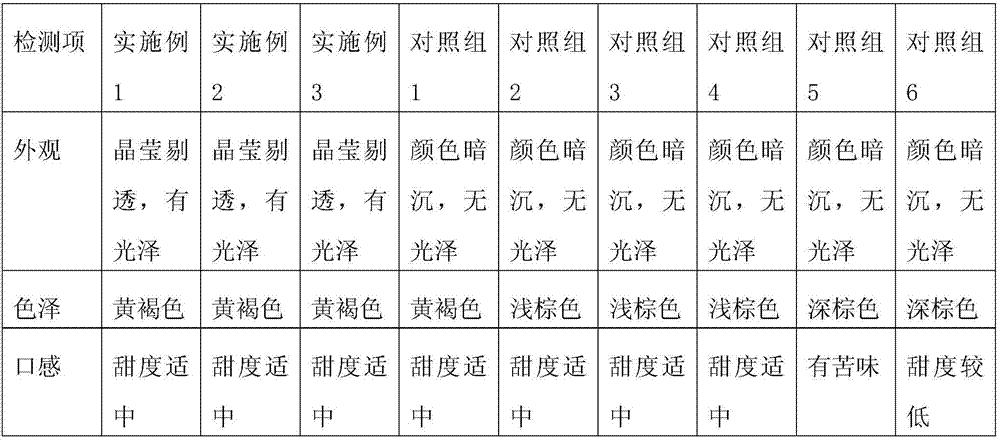

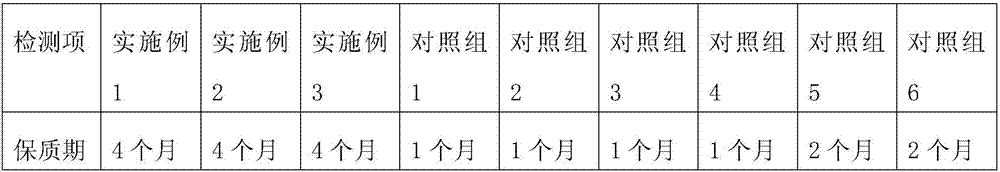

Composition for preventing browning of beverage and application of compositon

ActiveCN113243477APrevent browningInhibit browning reactionFermentationFood ingredient functionsBiotechnologyVitamin C

The invention discloses a composition for preventing browning of a beverage and application of the composition. The composition for preventing browning of the beverage provided by the invention comprises chlorella enzymatic hydrolysate and vitamin C. The composition can effectively prevent browning reaction of the fruit juice beverage, although research shows that vitamin C can inhibit browning, the inhibition effect is not obvious, and by adding the chlorella enzymatic hydrolysate, the browning prevention effect is remarkably improved. Besides, the chlorella enzymatic hydrolysate contains a large amount of active polypeptide components, and compared with common protein beverages in the market, the active polypeptide components are easier to absorb and play an active role.

Owner:OCEAN UNIV OF CHINA

True peony and herbaceous peony flower art picture and preparing method thereof

InactiveCN103847423AOrnamentalKeep colorfastDecorative surface effectsSpecial ornamental structuresFiberEmulsion

The invention relates to a true peony and herbaceous peony flower art picture and a preparing method of the art picture. The true peony and herbaceous peony flower art picture comprises an uvioresistant polymeric membrane, and Chinese art paper, paper jam, tough paper made from bast fiber of paper mulberry and the like, wallpaper or cloth; the true peony and herbaceous peony flower art picture also comprises flower material (including plant flower materials such as peony and herbaceous peony) which is subjected to press drying and color protecting, and edges made of damask silk, tough silk or paper; the peony and herbaceous peony flower materials which are subjected to the press drying and the color protecting is stuck on the outer surface of the Chinese art paper, the paper jam, the tough paper made from the bast fiber of the paper mulberry and the like, the wallpaper or the cloth; the uvioresistant polymeric membrane is covered with the outer surface of peony and herbaceous peony flower materials which are subjected to the press drying and the color protecting; the edges made of the damask silk, the tough silk or the paper are embedded at the periphery of the Chinese art paper, the paperboard, the tough paper made from the bast fiber of the paper mulberry and the like, the wallpaper or the cloth. According to the true peony and herbaceous peony flower art picture, plants such as the peony and herbaceous peony coming from the nature are subjected to the press drying and the color protecting, the flower materials which are subjected to the press drying are stuck and molded on patterns which are drawn on the paper jam or the cloth in advance by white emulsion adhesive, and inscription, signature and the like are carried out on the paper jam or the cloth.

Owner:洛阳甲天下牡丹园艺有限公司

Preparation method of dried figs prepared through sugaring

InactiveCN107996808AGood colorReduce heatSugar food ingredientsConfectioneryUltrasonic assistedMicrowave

The invention discloses a preparation method of dried figs prepared through sugaring. The method comprises the steps as follows: (1) fig pretreatment: figs are cleaned, peeling and slicing are performed, and fig peels are dried for later use; (2) color protecting treatment: fig slices are impregnated in a color protecting solution for 1-2 min, and the color protecting solution contains a fig peelextract; (3) sugaring: the figs obtained after the color protecting treatment are impregnated in a sugar solution to be subjected to ultrasonic-assisted impregnation for 3-5 h; and (4) drying: the figs treated with the sugar solution are subjected to microwave drying until the moisture percentage content is 8%-12%. The prepared dried figs have good color, low calories and good healthcare effects,are not prone to mildewing and have a long expiration date.

Owner:柳州飞升鹏科技有限公司

A lychee sports drink

InactiveCN103622114BFruityInhibit browning reactionFood ingredient functionsBiotechnologyFruit juice

The invention relates to a lychee sports drink, which belongs to the technical field of fruit juice processing, wherein the parts by weight of each component are 5 to 10 parts of lychee juice, 1 to 5 parts of lemon juice, 1 to 5 parts of kiwi fruit juice, and 1 to 10 parts of fructooligosaccharide 0.001-0.005 parts of sucralose, 0.01-0.05 parts of taurine, 0.02-0.05 parts of sodium chloride, 0.01-0.03 parts of potassium dihydrogen phosphate, 0.01-0.05 parts of potassium chloride, 60-90 parts of water; The sports drink has the typical aroma of lychee, with a strong fruity aroma and moderate sweetness and sourness. It can effectively relieve fatigue after exercise and quickly restore physical strength after drinking.

Owner:李海珍

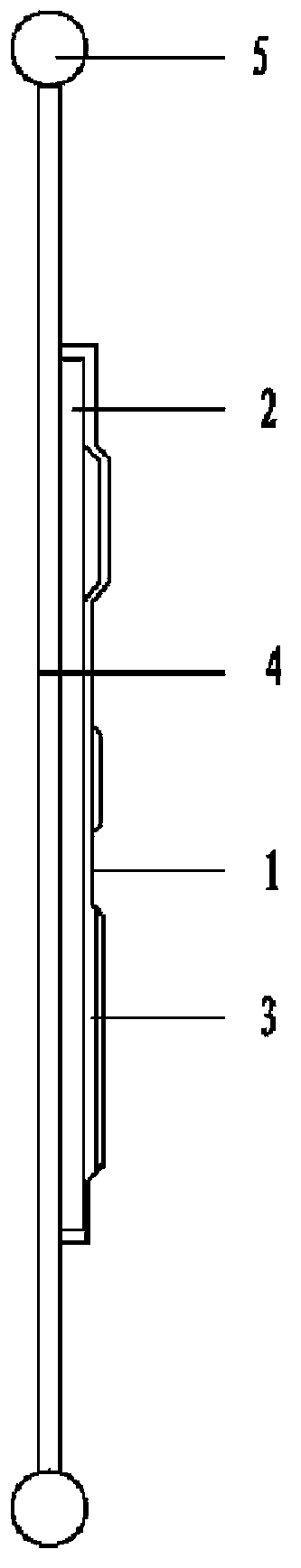

Hemerocallis fulvs drying pretreatment method and color protecting equipment

ActiveCN108618028AHigh market valueLow costFood ingredient functionsPretreatment methodPre treatment

The invention discloses a hemerocallis fulvs drying pretreatment method, and the method comprises the steps of choosing the raw materials, preparing a compound enzyme liquid, mixing, implementing enzymolysis, sealing, storing, and soaking in ozone water and the like. The invention provides the hemerocallis fulvs drying pretreatment method, the green color on the surface of hemerocallis fulvs fadesand the yellow color is shown before the hemerocallis fulvs is dried, and a foundation is laid for a dry product of the hemerocallis fulvs. In addition, the invention provides color protecting equipment, the color protecting equipment is specially used for soaking the hemerocallis fulvs in the ozone to protect the color, the cost is low, the practicality is strong, the concentration is convenientto regulate, and the production efficiency is improved.

Owner:HUNAN AGRICULTURAL UNIV

Tangerine pith essential oil preparation method

InactiveCN105219533AAvoid SaponificationInhibit browning reactionEssential-oils/perfumesAlcoholismsThirst

The invention discloses a tangerine pith essential oil preparation method. The method includes the steps of firstly, adding tangerine pith and water into a screw extrusion press to be extruded according to the mass ratio of 10 to 1.8-2.2, and filtering liquid obtained through extrusion through a sieve of 80-120 meshes to obtain filtrate; secondly, adding salt accounting for 5-7% of the mass of the filtrate to the filtrate in the first step to be evenly mixed, standing for 20-28 h, pouring out tangerine pith oil on the upper layer to be placed in a refrigerating chamber at a temperature of 5 DEG C to 7 DEG C for 7-9 days, and then separating out the upper layer to obtain a tangerine pith essential oil crude product; thirdly, conducting decompression distilling and purifying on the tangerine pith essential oil crude product, collecting distillate till no distillate is evaporated, and obtaining tangerine pith essential oil, wherein the tangerine pith essential oil is obtained after decompression distilling is conducted at a temperature of 70-90 DEG C and at a vacuum degree of 40-60 Pa. The tangerine pith essential oil has effects on dredging collaterals, regulating vital energy, reducing phlegm and treating meridian qi depression, chronic coughs and chest pain, blood-stained sputum and alcoholism thirst and is quite safe to human bodies.

Owner:ANHUI TANGREN PHARMA

Quick drying processing method of raisin

InactiveCN102669255BExtended processing timeIncrease productivityFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationHigh humidityRoom temperature

The invention belonging to the technical field of fruit and vegetable processing, and relates to a quick drying processing method of raisin, which comprises the following steps of (1) selecting fresh grapes without rot or deterioration; (2) washing surface with clean water to remove dust, impurities and the like; (3) blanching cleaned grape in a high-temperature high-humidity gas jet impulse blancher, wherein the blanching temperature is 90-130 DEG C, the relative humidity of the high-humidity gas is 20-70%, the gas flow rate is 6-30 m / s, and the blanching time is 30-240 s; (4) drying the blanched grape in a gas jet impulse drying box, wherein the drying temperature is 50-80 DEG C, the air speed is 6-30 m / s, and drying is stopped when the wet basis water content of the grape is below 20%; and (5) packaging after the raisin is cooled to room temperature. The quick drying processing method has the advantages of high drying efficiency, simplicity and convenience in operation, cleanliness and hygiene, capability of effectively inhibiting browning during drying and the like.

Owner:CHINA AGRI UNIV

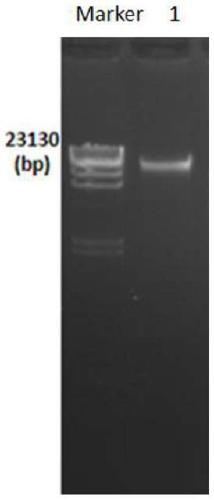

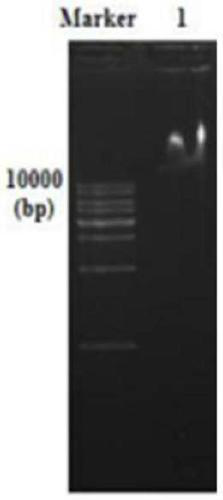

Efficient extraction method of dendrobium officinale genome DNA

InactiveCN111440788AInhibit browning reactionInhibition of spontaneous oxidationDNA preparationBiotechnologyPectinase

The invention relates to the technical field of molecular biology, in particular to an efficient extraction method of dendrobium officinale genome DNA. According to the method, the formula of an extraction buffer solution in a classical CTAB method is optimized, one-step pectinase cracking is added, and the extraction process is optimized. Compared with a classical CTAB method, the DNA extractionmethod has the advantages that spontaneous oxidation of phenol can be well inhibited and DNA browning reaction caused by polyphenol oxide can be prevented in the extraction buffer solution treatment process, polysaccharide is promoted to be combined with high-concentration CTAB under the high-salt condition, and therefore extraction and removal are facilitated; insoluble substances in dendrobium officinale are further dissolved in the pectinase treatment process, so that the extracted DNA is not viscous any more, and the subsequent DNA sample library building and sequencing processes are remarkably simplified. According to the extraction method disclosed by the invention, the DNA extraction efficiency and the DNA purity are obviously improved.

Owner:WUHAN FRASERGEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com