Day lily anoxic drying method and baking device

A drying method and technology for day lily, applied in the direction of preservation of fruits and vegetables, preservation of fruits/vegetables by dehydration, food preservation, etc., can solve the problems of short drying time, inability to effectively remove the green color on the surface of vegetable strips, unsightly black and green, etc. Beautiful color, improved market value, high nutritional quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

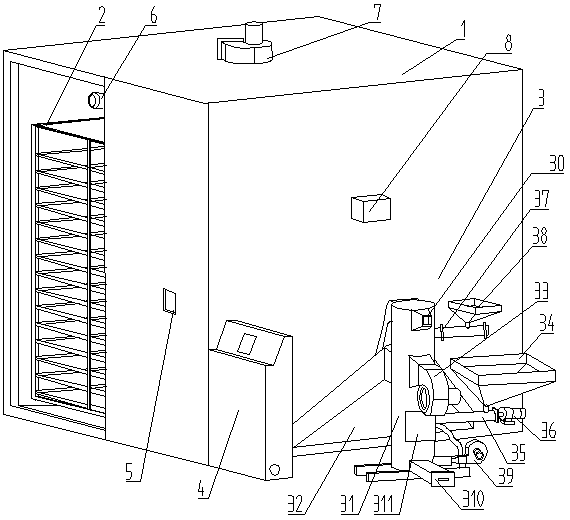

Image

Examples

Embodiment 1

[0032] Add 20 mL of peroxidase with an enzyme activity of 400,000 U / mL and 15 g of catalase with an enzyme activity of 500,000 U / mL to 1,000 mL of purified water to prepare a compound enzyme solution, soak 1 Kg of fresh day lily in the above compound enzyme solution , treated at room temperature for 70 minutes, removed and drained. Wrap 2.0g Maoyanberry powder with a particle size of 100 mesh and put it into the bottom of a PVC plastic bag, then put the above-mentioned day lily into the plastic bag, seal it immediately, and then store it in an incubator at 45°C for 4 hours to make the day lily The dish turns yellow, and then the day lily is added into the ozone water pool for immersion in ozone water with a concentration of 0.4 mg / L. Then remove and drain; then dry the day lily with hot air at 55°C for 120 minutes until the moisture content is 45-50% (wet basis), and then stack it on a 10-mesh stainless steel drying net with a stacking thickness of 25-30cm. The surface of the ...

Embodiment 2

[0061] Add 400mL of peroxidase with an enzyme activity of 400,000U / mL and 300g of catalase with an enzyme activity of 500,000U / mL to 20,000 mL of purified water to prepare a compound enzyme solution, soak 20Kg of fresh day lily in the above compound enzyme solution , treat at room temperature for 60 minutes, remove and drain. Wrap 40.0g Maoyanberry powder with a particle size of 120 mesh and put it into the bottom of a PVC plastic bag, then put the above-mentioned day lily into the plastic bag, seal it immediately, and then store it in an incubator at 40°C for about 5 hours. The day lily turns yellow, and then the day lily is added to the color protection equipment and soaked in ozone water with a concentration of 0.5mg / L. Then remove and drain, then dry the day lily with hot air at 55°C for 120 minutes until the water content is 45-50% (wet basis), and then stack it on a 10-mesh stainless steel drying net with a stacking thickness of 25-30cm. The surface of the day lily shoul...

Embodiment 3

[0063] Add 400mL of peroxidase with an enzyme activity of 400,000U / mL and 300g of catalase with an enzyme activity of 500,000U / mL to 20,000 mL of purified water to prepare a compound enzyme solution, soak 20Kg of fresh day lily in the above compound enzyme solution , treated at room temperature for 90 minutes, removed and drained. Wrap 20.0g Maoyanberry powder with a particle size of 80 mesh and put it into the bottom of a PVC plastic bag, then put the above-mentioned day lily into the plastic bag, seal it immediately, and then store it in an incubator at 45°C for about 5 hours. The day lily turns yellow, and then the day lily is added to the color protection equipment and soaked in ozone water with a concentration of 0.45mg / L. Then remove and drain; then dry the day lily with hot air at 55°C for 120 minutes until the moisture content is 45-50% (wet basis), and then stack it on a 10-mesh stainless steel drying net with a stacking thickness of 25-30cm. The surface of the day li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com