Method for producing fresh-eating jujube crisp slices

A technology of fresh jujube and crisp chips, which is applied in the field of fruit and vegetable food processing, can solve problems such as hindering the continuous production of fresh jujube chips, unfavorable health of consumers, and poor product color and quality, so as to maintain product color and shorten drying time. Time, color retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

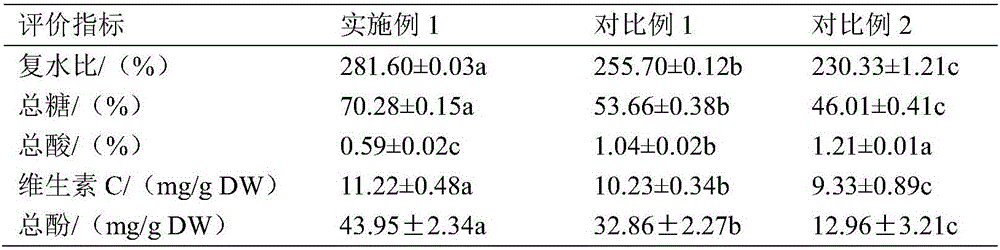

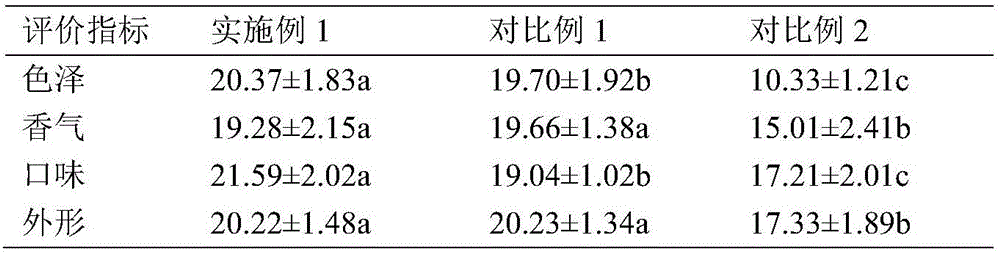

Examples

Embodiment 1

[0031] Embodiment 1: the processing method of microwave vacuum freezing and microwave vacuum puffing joint process production winter jujube chips (square):

[0032] (1) Raw material pretreatment: Select winter jujube from northern Shaanxi that has no pests, no rot and deterioration, and smooth skin, rinses with running tap water and drains, puts the rinsed winter jujube into a jujube peeling, pitting and beating machine for peeling, The pitting and beating are completed at one time, and 0.1% citric acid is added to protect the color before beating.

[0033] (2) Molding: Pour the winter jujube pulp into a square mold with a uniform thickness of 0.5 cm.

[0034] (3) Pre-freezing: put the winter jujube pulp into the mold in a -20°C refrigerator, and pre-freeze for 80 minutes.

[0035] (4) Microwave vacuum freezing: place the formed winter jujube slices in a microwave vacuum freeze dryer for preliminary drying and dehydration, the vacuum degree is 0.065KPa, the microwave power is...

Embodiment 2

[0038] Embodiment 2: the processing method of pear jujube chips (bar shape) produced by microwave vacuum freezing and microwave vacuum puffing joint process

[0039] (1) Raw material pretreatment: select pear jujubes with no pests, no rot and deterioration, and smooth skin, rinse with running tap water and drain, put the rinsed pear dates into the jujube peeling, pitting and beating machine for peeling, The pitting and beating are completed at one time, and 0.1% citric acid is added to protect the color before beating.

[0040] (2) Mould-filling: Pour the pear jujube pulp into a strip mold with a uniform thickness of 0.7 cm.

[0041] (3) Pre-freezing: put the winter jujube pulp into the mold in a -25°C refrigerator, and pre-freeze for 90 minutes.

[0042](4) Microwave vacuum freezing: put the formed pear jujube strips in a vacuum freeze dryer for preliminary drying and dehydration. The vacuum degree is 0.07KPa, the microwave power is 700W, the cold trap temperature is -40°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com