Patents

Literature

144 results about "Acoric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetic acid, also known as ethanoic acid, is an organic chemical compound best recognized for giving vinegar its sour taste and pungent smell. It is one of the simplest carboxylic acids (the second-simplest, after formic acid) and has the chemical formula CH3COOH.

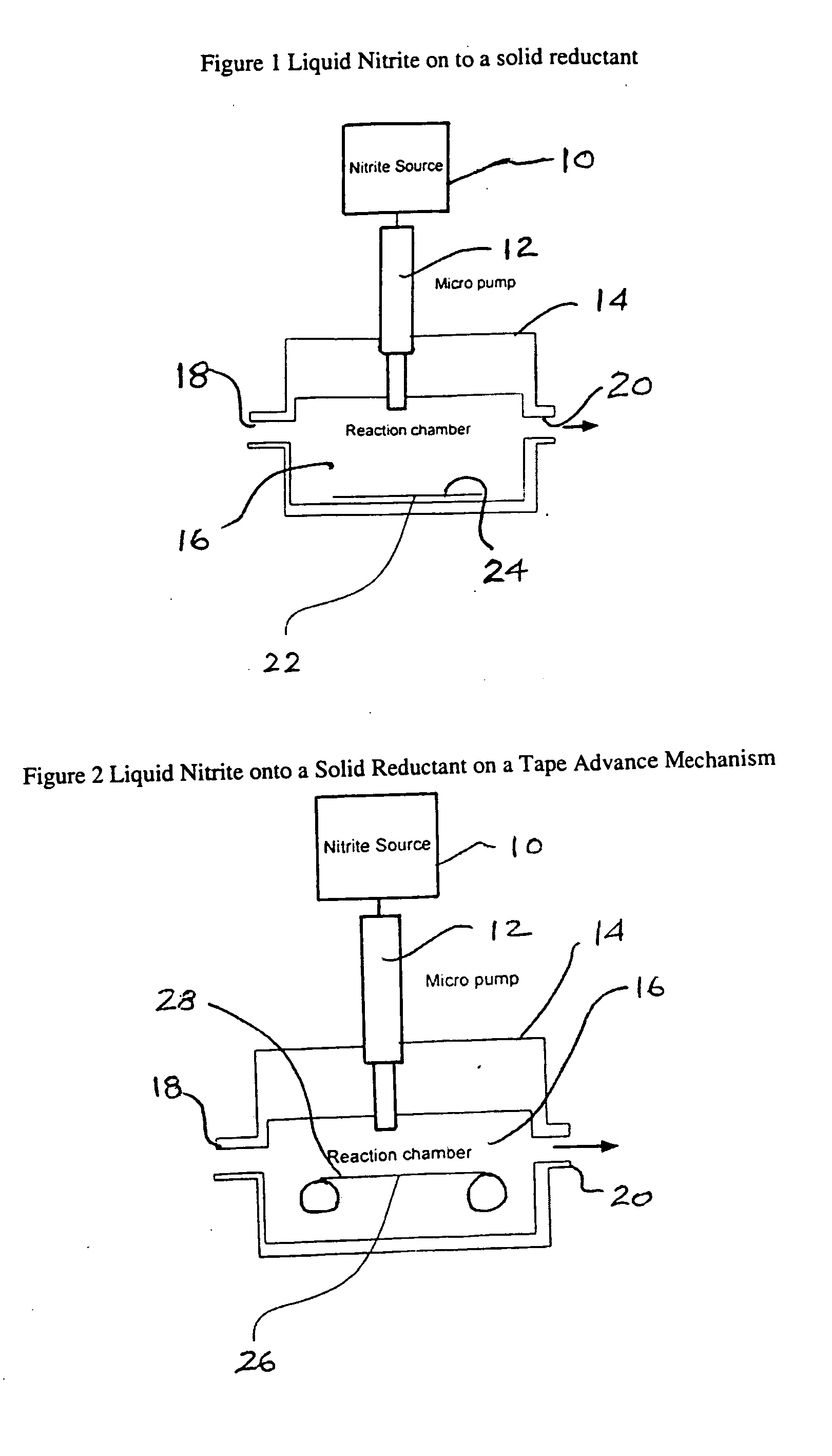

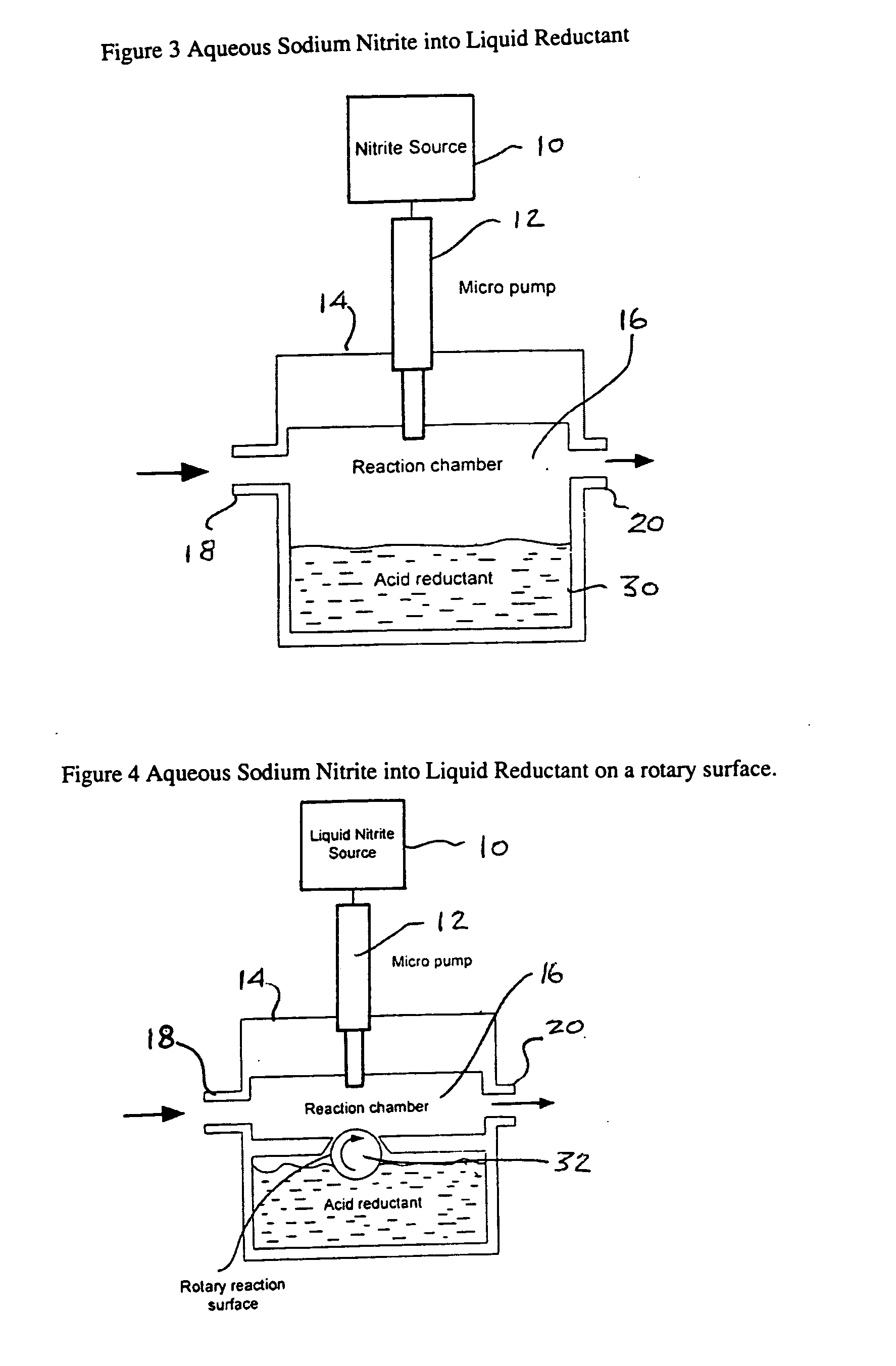

Method and apparatus for generating nitric oxide for medical use

ActiveUS20070190184A1Reduce weightReduce electric powerRespiratorsBiocideNitric oxide formationAcoric acid

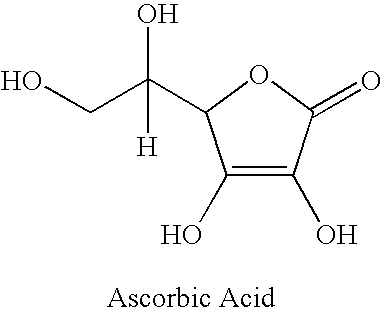

A method and system for generating and delivering nitric oxide directly to a patient. A reaction chamber is provided that is located at or in close proximity to the patient and reactants within the reaction chamber react together to produce a predetermined amount of nitric oxide. The reaction is controlled by metering at least one of the reactants into the reaction chamber to generate a predetermined quantity of nitric oxide as required by the patient. The reactants can include a nitrite salt, such as sodium nitrite, and a reductant such as ascorbic acid, maleic acid or a mixture thereof. By generating and delivering the nitric oxide directly to the patient in close proximity thereto, the formation of NO2 is minimized. One or both of the reactants may be in liquid form.

Owner:MALLINCKRODT HOSPITAL PRODUCTS IP LTD

Oral hygiene products containing ascorbic acid and method of using the same

InactiveUS20080057007A1Efficient removalEffectively and efficiently protectCosmetic preparationsOrganic active ingredientsDiseaseAdditive ingredient

The present invention is directed to dental compositions, including dentifrices, containing ascorbic acid for removing and inhibiting dental biofilms which form plaque and tartar, and also for treating and preventing gingivitis and periodontitis. The ascorbic acid composition can contain may additional ingredients, including an enamel-strengthening component, and be used in many different forms, including breath spray, chewing gum, dental floss, dental powder, gargle, lozenge, mouth spray, mouth wash, tooth gel, tooth liquid, tooth paste and tooth strips. Also described in a method of using a dental composition containing ascorbic acid in order to treat plaque and tartar as well as gum disorders.

Owner:DENTECH

Process for the Manufacture of a Tea Product and Products Obtained Thereby

A process is provided for the manufacture of a tea product which is readily infusible and has improved red colour. The process comprises contacting black tea with ascorbic acid and / or its salts, an oxidizing agent and water for a period of at least 5 minutes followed by drying to prepare a tea product that is infusible in water at 5 to 100° C.

Owner:CONOPCO INC D B A UNILEVER

Combined energy and topical composition application for regulating the condition of mammalian skin

InactiveUS20080031833A1Improve the situationEasy to superviseCosmetic preparationsBiocidePersonal careSalicylic acid

Method for regulating the condition of mammalian skin comprising the steps of applying a first personal care composition to an area of skin where regulation is desired, wherein the first personal care composition comprises at least one skin care active selected from the group consisting of niacinamide, salicylic acid, peptides, N-acetyl glucosamine, panthenol, butylated hydroxytoluene, N-acyl amino acid compounds, hexamidine, green tea, ascorbyl glucoside, hexanediol, pentanediol, a skin lightening agent, a heat shock protein potentiator, and mixtures thereof, and delivering energy to the area of skin by contacting the skin with an energy delivery device for a treatment period of at least 2½ minutes, wherein the energy delivery device comprises a skin-contacting surface that is controllably heatable to a temperature of from 37° C. to 50° C.

Owner:THE PROCTER & GAMBLE COMPANY

Methods for preserving fresh produce

Methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce, and preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce, are provided. The method comprises: providing a solution of produce preservative comprising: water; a preservative cation which is selected from the group consisting of a strontium ion, lithium ion, barium ion, aluminum ion, copper ion, ammonium ion, iron ion, manganese ion, potassium ion, or mixtures thereof; and ascorbate ions, or erythorbate ions; wherein the ascorbate ions or erythorbate ions and the preservative cation are present in an ion ratio of preferably from 0.2:1 to 8:1, more preferably 0.75:1 to 8:1, even more preferably from 1:1 to 4:1, yet more preferably 1.5:1 to 3:1; most preferably 1.1:1 to 2.5:1; and, applying said produce preservative to the produce. The invention also relates to fresh produce preserved with the produce preservatives.

Owner:MANTROSE HAEUSER

Brown fruit and vegetable preserving agent and preparation thereof

InactiveCN1509615AGood anti-browning effectFruit and vegetables preservationAdditive ingredientPhytic acid

A brown-resistant antistaling agent for fruit and vegetable is prepared through dissolving the modified chitosan in the aqueous solution of citric acid, stirring, adding aqueous solutions of ascorbic acid and phytic acid, and stirring. It is applied by coating it on the surface of fruit or vegetables. Its advantage is high effect.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Cosmetic and/or dermatological use of a composition containing at least one oxidation-sensitive hydrophilic active principle and at least one N-vinylimidazole polymer or copolymer

InactiveUS20030124161A1Good cosmetic effectIncrease differentiationCosmetic preparationsBiocideWater activityAcoric acid

The invention relates to the use of a composition containing, preferably in a physiologically acceptable medium comprising an aqueous phase, at least one oxidation-sensitive hydrophilic active principle selected from the group consisting of ascorbic acid and its derivatives and at least one non-crosslinked N-vinylimidazole polymer or copolymer, the active principle and the polymer or copolymer both being present in the aqueous phase, for promoting the synthesis of epidermal ceramides and / or for improving the barrier function of the skin, among other uses.

Owner:LOREAL SA

Sheet for whitening cosmetics and method for using the same

InactiveUS6458379B1Easy to storeEfficient use ofCosmetic preparationsBiocideVitamin CMagnesium phosphate

A sheet for whitening cosmetics comprises a sheet-like substrate and an adhesive layer which comprises a wet pressure-sensitive adhesive composition formed on the substrate. The whitening component includes vitamin C or its derivatives such as magnesium L-ascorbyl-2-phosphate, vitamin E nicotinate, kojic acid, hydroquinone, ellagic acid, albumin, galenical extracts, and rice bran extracts. Kojic acid and magnesium L-ascorbyl-2-phosphate are preferred. By contacting the adhesive layer with water and / or a hydrophilic medium such as alcohols, e.g., methanol, ethanol, etc., the wet pressure-sensitive adhesive composition exhibits excellent stickiness and excellent applicability to skin as well as excellent whitening effect with alleviating or eliminating stains, freckles, non-transparency, etc. on the skin.

Owner:NITTO DENKO CORP

Annular protecting liquid for oil and gas well

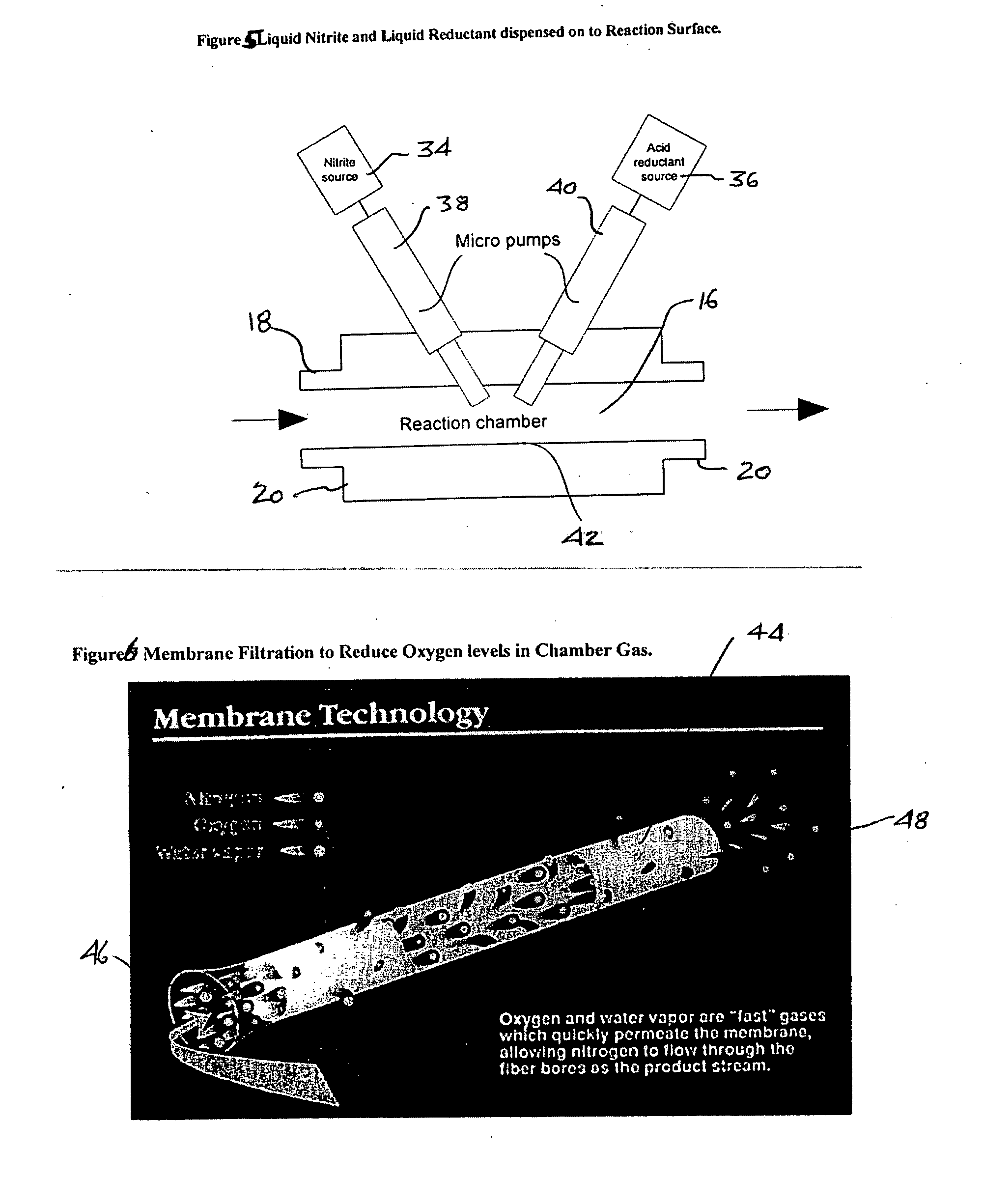

ActiveCN102719233AExtended service lifeImprove thermal stabilityBorehole/well accessoriesActive agentCarbonate

The invention relates to an annular protecting liquid for oil and gas wells and belongs to the chemical technology field. In the liquid, a solution of organic acid salts is used as a density modifier, an imidazoline quaternary ammonium salt is used as a corrosion inhibitor, a quaternary ammonium salt cationic surfactant is used as a bacteriostatic agent and an isoascorbic acid alkali metal salt or an optical isomer thereof is used as a deoxidant. And an iron-centric coordination compound with two-valence ion or basic zinc carbonate can be added as a Desulphurizing Reagent, according to the sulfur-containing situation of a casing annulus. With a corrosion rate to N80 steel discs of 0.070mm / a and a corrosion rate to TP110SS steel discs of 0.0105mm / a, the annular protecting liquid, which is capable of prolonging the service life of an annular tubular column of a shaft by over 50% and decreasing the safety accidents resulted from corrosion perforation by over 30%, satisfies the requirements of annular protecting liquid for wells with different depths, has the characteristics of low stratum damage rate and no pollution and is applicable to the annular protection of oil and gas wells with high content of sulfur or other oil and gas wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

Depigmenting cosmetic skin-care composition and use thereof

A cosmetic skin-care composition containing as the active principle a depigmentationally active combination of (a) an acidic mixture including (i) at least one alpha-hydroxylated acid or a derivative thereof, with the exception of ascorbic acid, and (ii) at least one compound selected from the group which consists of kojic acid, caffeic acid, azelaic acid, aminobutyric acid, fusaric acid, 5-hydroxy 2-hydroxymethyl-gamma-pyridone, and derivatives thereof, and (b) at least one active component of a plant extract from at least one plant selected from white mulberry, liquorice, skull cap, grapefruit, birch, heather, strawberry tree, bearberry, lemon, lettuce, oarweed, cucumber, ginseng, hop, sweet corn, feverfew, sage, soya, elder, spirulina, lime, ferocious aloe, yukinoshita, bloodwort, hoelen, wood rose, alpha-orizanol, burnet, ginkgo biloba, tanlex VB and Eclipsa alba, with the proviso that when the composition contains kojic acid and a liquorice extract, it contains at least one other plant extract component. The use of said composition for preparing a drug or in a cosmetic method is also disclosed.

Owner:COHEN MARCEL GEOR MR

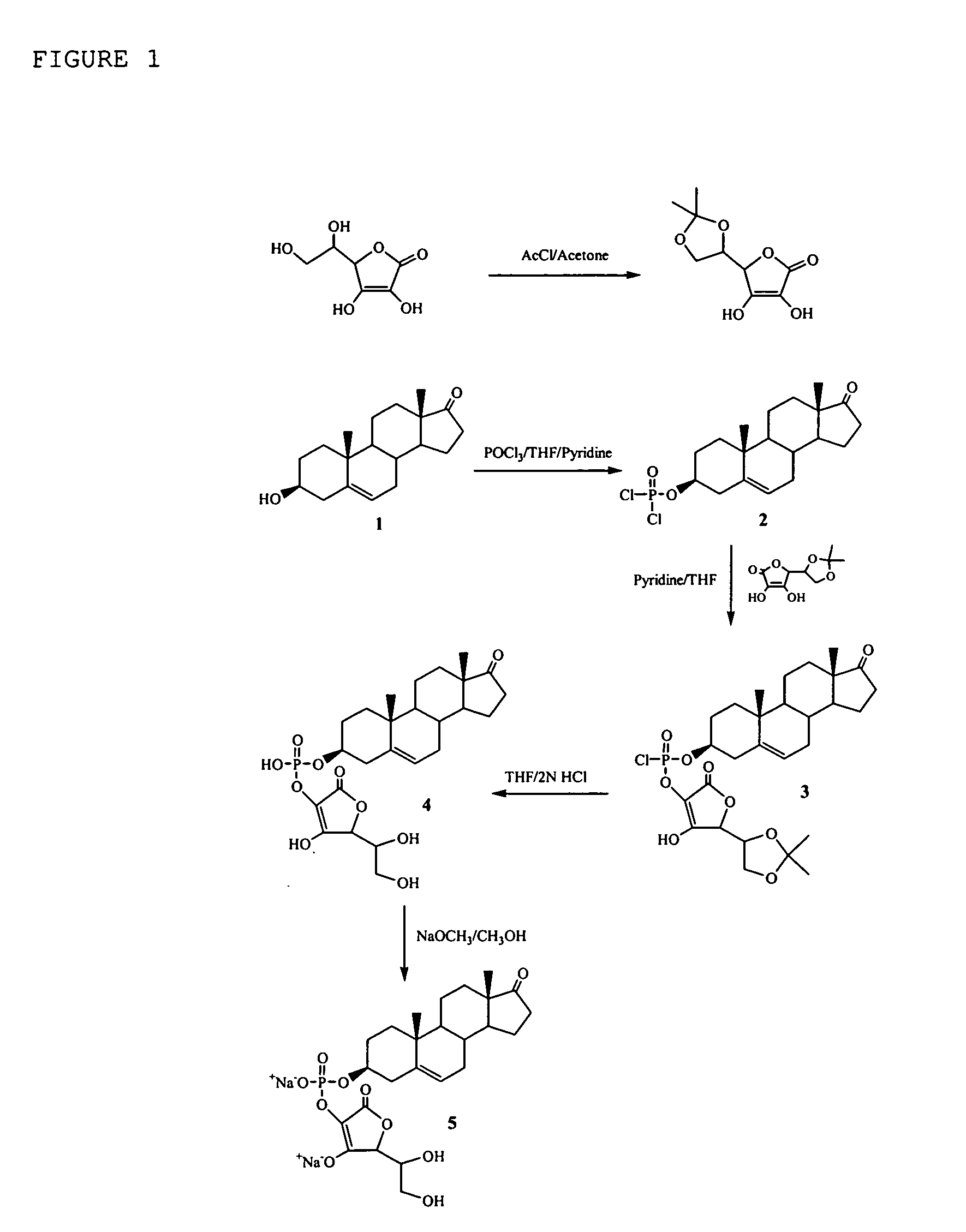

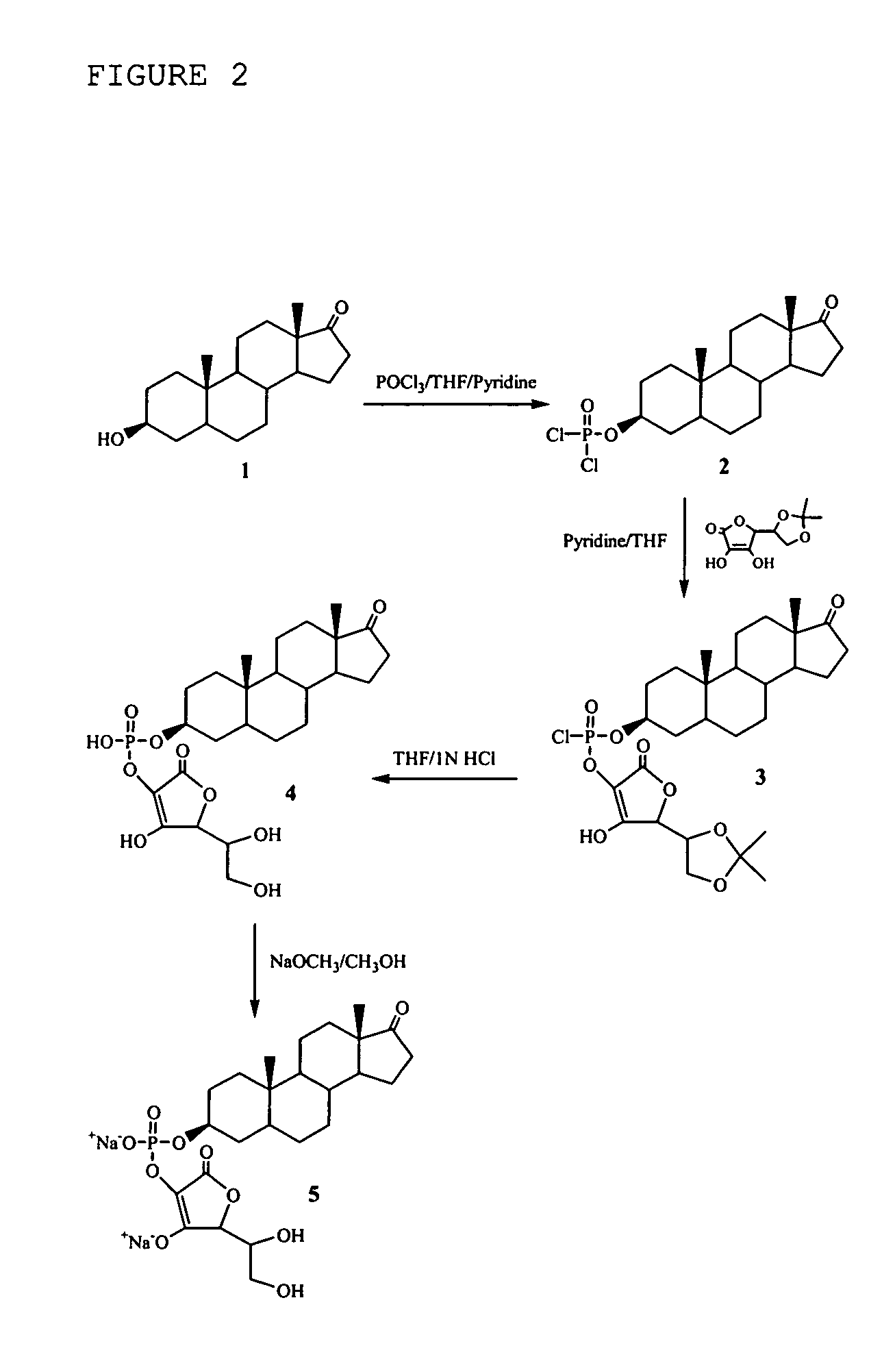

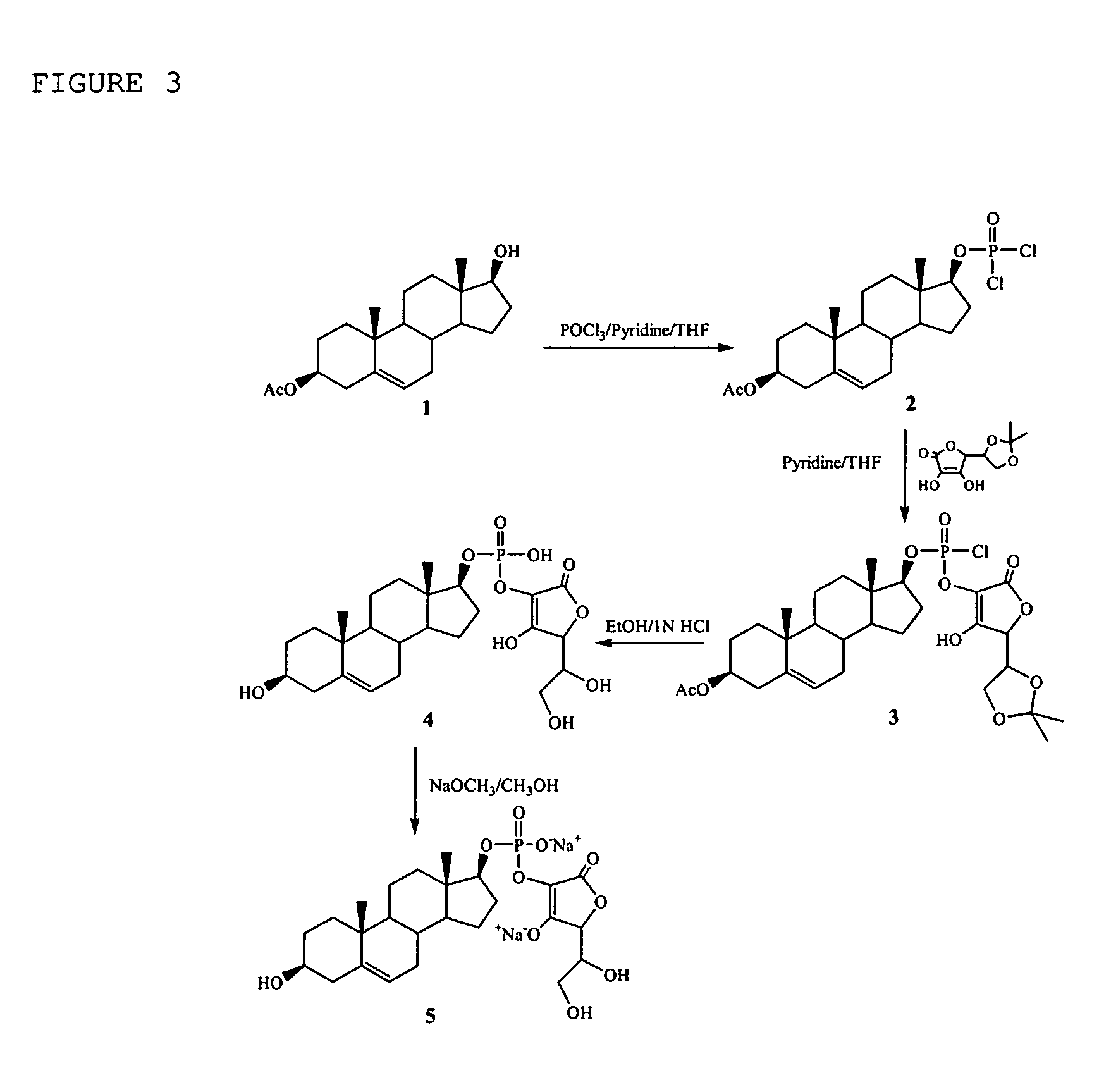

Compositions comprising one or more policosanols and/or policosanoic acids combined with sterol and/or steroid based ascorbic acid derivatives, and uses thereof

InactiveUS20050234025A1Lowering LDL-cholesterolReadily solubleBiocideHydroxy compound active ingredientsAlcoholSterol

A composition comprises one or more long chain alcohols (policosanols) and / or their respective acids (policosanoic acids) and one or more ascorbic acid derivatives, including all biologically acceptable salts or solvates or prodrugs of at least one such derivative or of the salts or of the solvates thereof and is used for the treatment and prevention of a variety of conditions and disorders.

Owner:FORBES MEDI TECH

External Preparation for Skin Containing a Phosphorlated Saccharide

InactiveUS20080274068A1Preventing wrinkle formationMoisturize the skinOrganic active ingredientsCosmetic preparationsAntioxidantPhosphorylation

Provided is an external preparation for skin, comprising a phosphorylated saccharide. The phosphorylated saccharide may be an inorganic salt of a phosphorylated saccharide. The phosphorylated saccharide may be a calcium, magnesium, potassium, zinc, iron or sodium salt. Also provided is an external preparation for skin, comprising a phosphorylated saccharide and a second component, wherein the second component is selected from the group consisting of moisturizing agents, whitening components, ultraviolet absorbents, anti-inflammatory agents, cell-activating agents and antioxidants. The moisturizing agent may be ascorbic acid or an ascorbic acid derivative.

Owner:EZAKI GLICO CO LTD

Composition for the oxidative treatment of hair or skin fixative compostion and method for permanent deformation of hair

InactiveUS20070092471A1Without damaging structureCosmetic preparationsHair cosmeticsAcid derivativeAcoric acid

Cosmetic composition for the oxidative treatment of hair or skin, prepared by mixing of at least two components, in which dehydroascorbic acid or a dehydroascorbic acid salt or a dehydroascorbic acid derivative is generated from ascorbic acid, ascorbic acid derivative and ascorbic acid salt prior to application by an enzyme that catalyzes the enzymatical oxidation of said of ascorbic acid as well as a process for carrying out the oxidative treatment of keratin, particularly for the oxidative post-treatment of reduced hair in the process of permanent deformation of hair using said composition.

Owner:WELLA AG

Color-protecting antistaling agent for compound pickled vegetables and production method thereof

InactiveCN102578221AImprove the preservation effectExtended shelf lifeFruit and vegetables preservationDehydroacetic acidSodium acetate

The invention discloses a color-protecting antistaling agent for compound pickled vegetables and a production method thereof. The color-protecting antistaling agent is composed of dehydroacetic acid, sodium acetate, ascorbic acid, sodium erythorbate, sodium phytate, sodium citrate, citric acid, sodium metabisulfite and sodium chloride. The color-protecting antistaling agent is reasonable in components and convenient to manufacture, can effectively improve preserving performance of the pickled vegetables, prolongs guarantee period, is safe, and enables the preserving performance of the pickledvegetables to be improved by over one time compared with the preserving performance of an ordinary marketing product.

Owner:唐洪权

Composite antistaling agent for restraining lignification of bamboo shoot, and method of use

InactiveCN1726789AInhibition of the lignification processImprove food qualityFruit and vegetables preservationSalicylic acidAcoric acid

A composite antistaling agent for suppressing the lignification of bamboo shoot is proportionally prepared from salicylic acid, citric acid and ascorbic acid through dissolving in water. Its application method includes such steps as immersing the fresh bamboo shoots in said antistaling liquid, drying in air, vertically loading them in paper board case, and storage at 1-3 deg.C for 55-65 days.

Owner:ZHEJIANG UNIV

Composition containing leukocyte extract for the whitening or lightening of skin

InactiveUS7226583B2Inhibits the formation of melaninIncrease ratingsCosmetic preparationsBiocideKojic acidMagnesium phosphate

Cosmetic compositions intended for topical application to the skin for lightening and / or brightening the skin are provided. The subject compositions are characterized by the presence of leukocyte extract in combination with one or more secondary skin whitening or brightening agents. A preferred group of such agents includes bearberry, arbutin, rutin, ascorbyl glucoside, ascorbyl magnesium phosphate, hydroquinone, kojic acid or combinations thereof. Another group of preferred agents includes extracts of mulberry, lemon, orange, licorice, cucumber, cinnamon, cherry (fermentate), rosemary and / or derivatives thereof. It has been found that the combination of leukocyte extract with such agents possesses enhanced efficacy over similar preparations that do not contain leukocyte extract.

Owner:HAIR SYST

Making method for plums preserving agent

InactiveCN101053340ALow priceCause harmFruit and vegetables preservationManufacturing technologyAdditive ingredient

A manufacturing method for plums preserving agent, the present invention relates to a fruit preserving agent, specific manufacturing method for plums preserving agent. For preserving plums at present, one is putting preserving agent into package box or bag, the other is adopting low temperature storage. Because the current preserving agent contains noxious components, and low temperature storage affects the fruit shelf quality. The present invention includes the proportion of raw materials and manufacturing technology for preserving agent. The raw materials includes potassium permanganate, calcium hydroxide, ferrous sulfate, calcium oxide, sodium hypochlorite, anhydrous calcium chloride, zinc oxide, ascorbic acid, and sodium polyacrylate etc., zeolite as the carrier, in proportion mixed, crushed, stirring uniform and then sieving. Adding little water makes granule. The preserving agent made by this invention can adjust oxygen and carbon dioxide concentration around the fruits, decrease ethylene content, thus inhibiting fruits respiratory, delaying ripening, and reaching preservation purposes. The present invention method is simple, easy to implement, having obvious active effects compared with current products.

Owner:辽宁省果树科学研究所

Methods for preserving fresh produce

InactiveUS20050084602A1Extended shelf lifePreserve textureMilk preservationDough treatmentAluminum IonFood flavor

Methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce, and preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce, are provided. The method comprises: providing a solution of produce preservative comprising: water; a preservative cation which is selected from the group consisting of a strontium ion, lithium ion, barium ion, aluminum ion, copper ion, ammonium ion, iron ion, manganese ion, potassium ion, or mixtures thereof; and ascorbate ions, or erythorbate ions; wherein the ascorbate ions or erythorbate ions and the preservative cation are present in an ion ratio of preferably from 0.2:1 to 8:1, more preferably 0.75:1 to 8:1, even more preferably from 1:1 to 4:1, yet more preferably 1.5:1 to 3:1; most preferably 1.1:1 to 2.5:1; and, applying said produce preservative to the produce. The invention also relates to fresh produce preserved with the produce preservatives.

Owner:MANTROSE HAEUSER

Stable vitamin c compositions

ActiveUS20070196310A1Increase stratum corneum turnover rateIncrease collagen synthesisBiocideCosmetic preparationsVitamin CRoom temperature

Disclosed is a composition comprising ascorbic acid or a derivative thereof, a silicone containing compound, and an essential oil, wherein at least 50% of the initial amount of the ascorbic acid in the composition remains stable when the composition is stored for at least 1 month at room temperature. The composition can be non-aqueous.

Owner:MARY KAY INC

Method for preventing browning reaction caused by improper tobacco leaf curing

InactiveCN103478895AInhibit browning reactionInhibitory activityTobacco treatmentOrganic acidKojic acid

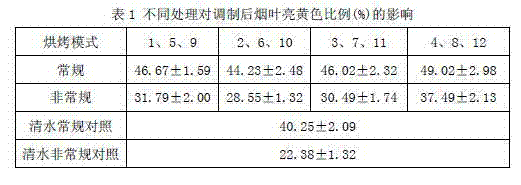

The invention discloses a method for preventing a browning reaction caused by improper tobacco leaf curing, and belongs to the technical field of cigarette making. The method comprises the following steps: picking tobacco leaves, soaking and curing, wherein the soaking step comprises the following sub-steps: flatly laying the tobacco leaves in a rectangular water tank filled up with a polyphenol oxidase inhibitor solution, and soaking for 5-8 minutes, so that the activity of the polyphenol oxidase (PPO) can be inhibited, the browning reaction can be reduced, and a tobacco leaf curing effect can be improved. A polyphenol oxidase inhibitor is one or more of kojic acid, ferulic acid and ascorbate, and also can contain other organic acids. By applying kojic acid, ferulic acid, ascorbate and other organic acid combinations, the browning reaction of the tobacco leaves can be effectively inhibited and the proportion of bright yellow tobacco leaves can be increased to 6%-15%.

Owner:SHANDONG LINYI TOBACCO

Cold water soluble tea

InactiveUS20010033880A1High yieldSuperior tea colourPre-extraction tea treatmentTea extractionKetoneWater soluble

A process for manufacturing a black leaf tea that is infusible in hot or cold water. The process involves macerating freshly plucked tea leaves, allowing them to ferment, firing the leaves to arrest fermentation and then drying them to yield black leaf tea, wherein the tea leaves are treated with a solubilising compound selected ascorbic acid, dehydroascorbic acid, 1-scorbamic acid, 5-phenyl-3,4-diketo-gamma-butyrolactone (4-phenyl-2,3-diketo-gamma-butyrolactone) or their salts and mixtures thereof in an amount that is sufficient for the black leaf tea to be soluble in water at 5 to 100° C.

Owner:THOMAS J LIPTON DIV OF CONOPCO

Sulfur-dioxide-free full juice fermented kiwifruit wine and production process thereof

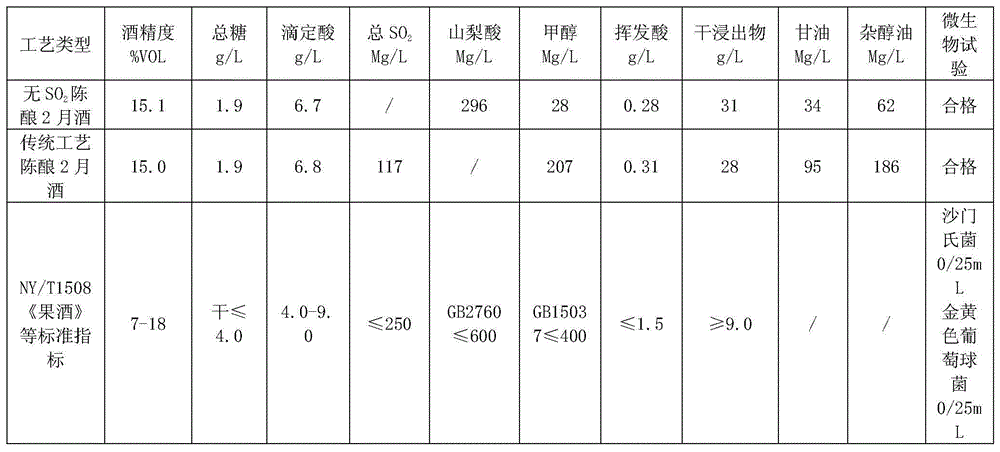

ActiveCN104130904AGuaranteed normal fermentationInhibit G+ bacteriaAlcoholic beverage preparationVitamin CFruit juice

The invention provides a sulfur-dioxide-free full juice fermented kiwifruit wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of crushing and juicing, adjusting the acidity of the juice, removing turbidity, resisting bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base and transiting and storing. The kiwifruit wine has the beneficial effects that an innovative process of replacing SO2 with a composite of six non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan, vitamin C and ethanol materials (refined alcohols and the like) is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the kiwifruit wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:万源市大面山酒业有限公司

Process for preparing ascorbic acid ester

The invention provides a process for preparing an ascorbic acid ester. Ascorbic acid and fatty acid are used as raw materials. The process comprises the following steps of: cooling the reacted mixture after sulfuric acid catalytic synthesis, adding water into the mixture, extracting the mixture by using mixed solution of aliphatic monoaldehyde and halogenated hydrocarbon, washing the extract by using water, evaporating the extract to obtain a coarse product, re-crystallizing the coarse product by using the halogenated hydrocarbon, and filtering, washing and drying the re-crystallized product to obtain high-purity ascorbic acid-6-fatty acid ester. The process is operated in the same reaction kettle, and the extracting process is in a liquid-liquid form so as to avoid the defects of difficult filtering and drying and difficult moisture removal in the prior art; the extracting solution well dissolves the esterification product and is easily separated from the water, the byproduct is little, and particularly the disadvantages that the purity of a target product is reduced and the quality becomes poor due to emulsification during acid washing in the prior art are avoided; and the coarse product is re-crystallized by using the halogenated hydrocarbon so as to effectively remove a little amount of residual fatty acid which is not totally extracted. The yield of the fatty acid ester product of the ascorbic acid ester produced by the process is over 70 percent, and the purity is over 98 percent.

Owner:HONGFENG CHEM GUAN COUNTY HEBEI PROV

Complex color protection preservative and production method thereof

InactiveCN104757105ABright colorExtended shelf lifeFruit and vegetables preservationEthylene diamineCITRATE ESTER

The present invention discloses a complex color protection preservative which includes distannous citrate, disodium sulfite, ascorbic acid or sodium isoascorbate, ethylene diamine tetraacetic acid, sodium phytate, sodium citrate and silicon dioxide. The present invention can maintain the bright color and prolong the shelf life of products.

Owner:唐洪权

Polishing composition

The polishing composition contains an abrasive, a microwaviness reducing agent, an oxidizing agent, a polishing accelerator, and water. The microwaviness reducing agent is a reducing agent and contains at least one kind selected from phosphonic acid, phosphinic acid, ammonium hypophosphite, ammonium sulfite, sodium sulfite, hydroquinone, pyrogallol, erysorbic acid, sodium erysorbate acid, L-ascorbic acid, formic acid, sodium formate, amumonium formate, oxalic acid, ammonium oxalate, ammonium iodide, and gallic acid. The abrasive can contain silicon dioxide, and the oxidizing agent can contain hydrogen peroxide. The accelerator can contain e.g. phosphoric acid, glycolic acid, maleic acid or succinic acid as well as diammonium hydrogen phosphate or ammonium dilhydrogen phosphate. The polishing composition can be used in polishing a substrate for a magnetic disk.

Owner:FUJIMI INCORPORATED

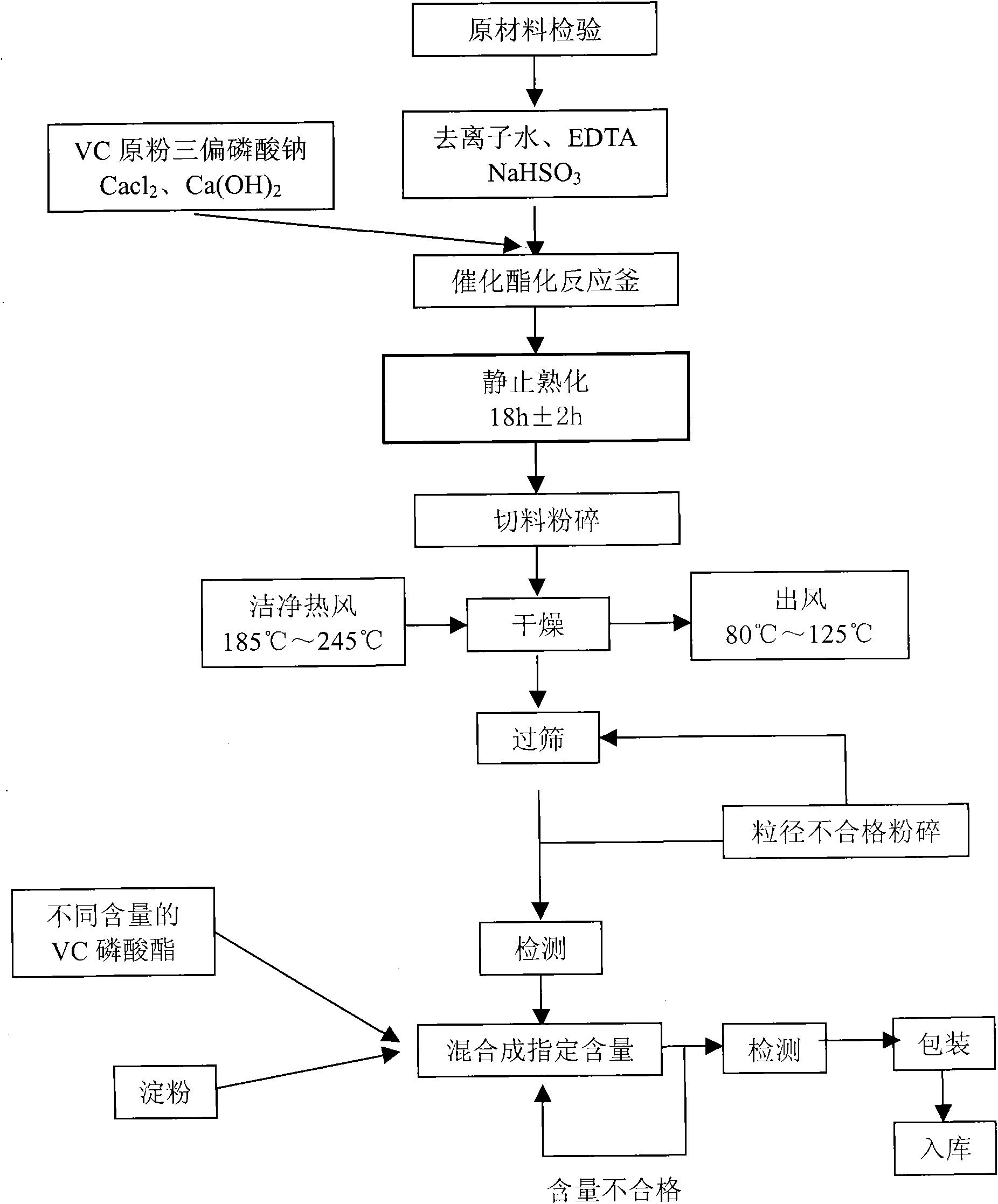

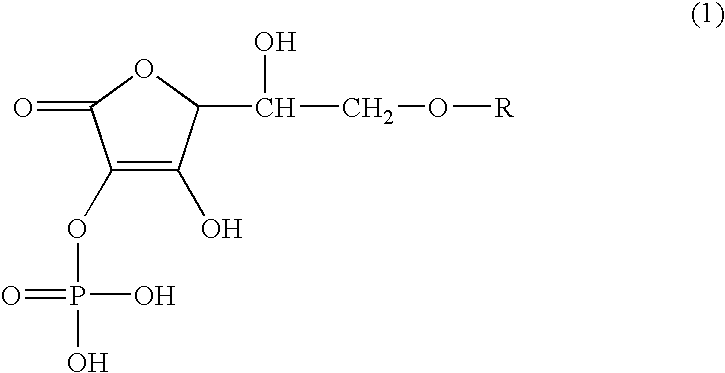

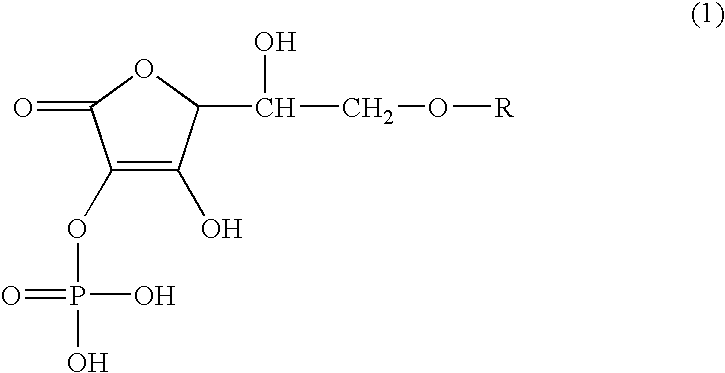

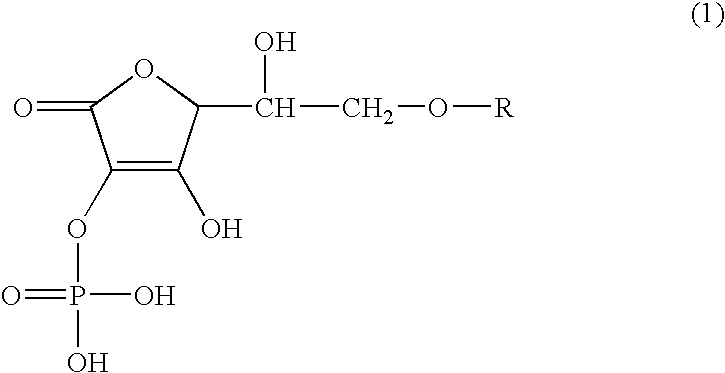

Method for preparing L-ascorbic acid-2-phosphate

ActiveCN101665517AProportionally largeLow water solubilityGroup 5/15 element organic compoundsAnimal feeding stuffSolubilityPhotochemistry

The invention discloses a method for preparing L-ascorbic acid-2-phosphate. The preparation method comprises the following steps: taking VC raw powder, sodium trimetaphosphate, calcium chloride and calcium hydroxide as raw materials to perform catalytic esterification reaction; and standing and curing a catalytic esterification product for 18+ / 2 hours, and drying the product to obtain the L-ascorbic acid-2-phosphate. The L-ascorbic acid-2-phosphate has the characteristics of large specific gravity of materials, small water solubility and the like, and is particularly suitable for compound feed of aquatic animals.

Owner:宜兴市江山生物科技有限公司

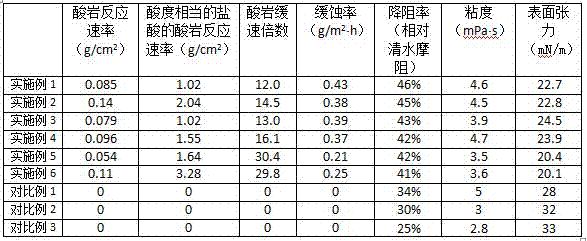

Low-viscidity drag-reduction slick water acid liquid for carbonate reservoir bed

InactiveCN107216867ASlow reaction rateAvoid the danger of deformationFluid removalDrilling compositionSodium ascorbateReaction rate

The invention provides a low-viscidity drag-reduction slick water acid liquid for a carbonate reservoir bed, which contains the following raw materials in percentage by weight: 5-20% of an acid, 1-3% of an alkyl quaternary ammonium salt, 0.5-2% of sodium ascorbate, 0.1-0.5% of an emulsion corrosion retarder, 0.5-1% of citric acid, 1-3% of a discharge aiding agent, and the balance of water, wherein the emulsion corrosion retarder is any one of polypropylene emulsion, polyvinylpyrrolidone emulsion and 2-acrylamido-2-methylpropanesulfonic acid-acrylic acid copolymer emulsion; the acid is any one of hydrochloric acid, formic acid, acetic acid or a bionic acid. The low-viscidity drag-reduction slick water acid liquid provided by the invention has low acid-rock reaction rate and good drag-reduction effect, and can reduce fracture acidizing construction wellhead pressure, so that the slot volume crack wall surface suffers from uniform acid corrosion all along, and the crack system around a well casing is more developed, which is helpful for yield increase. The low-viscidity drag-reduction slick water acid liquid has good corrosion inhibition effect, and can realize on-site large displacement construction.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

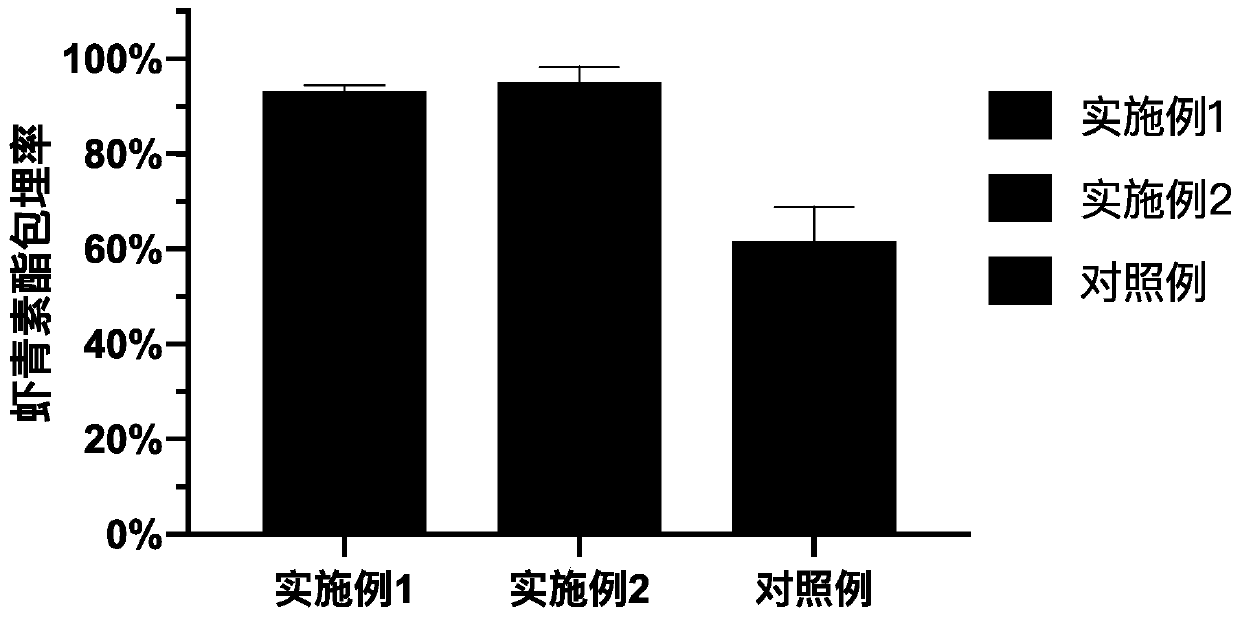

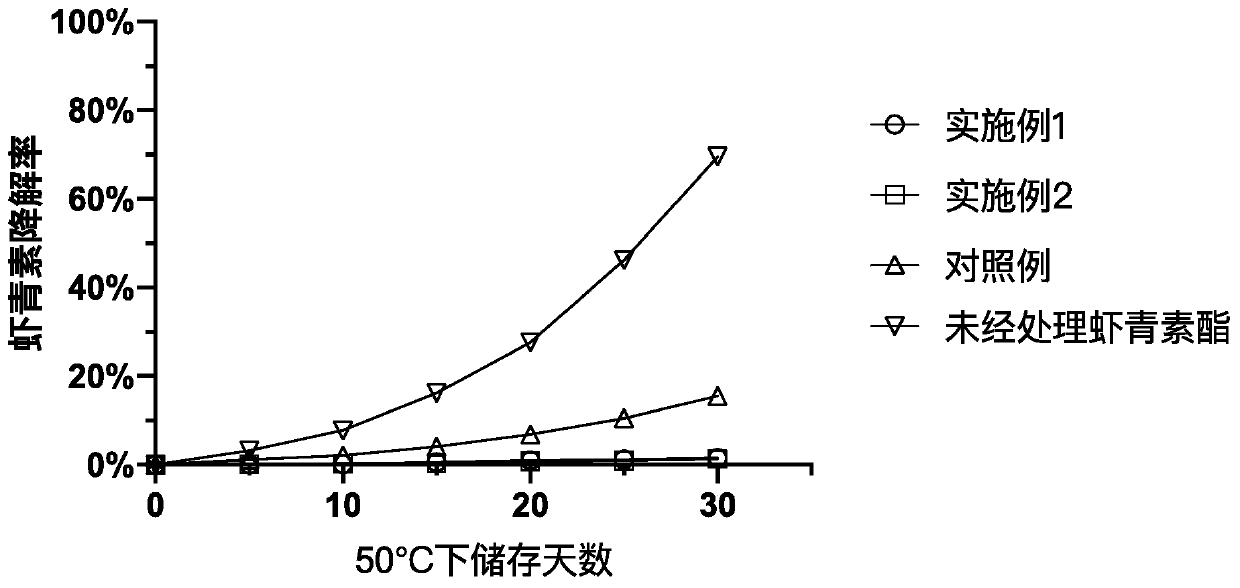

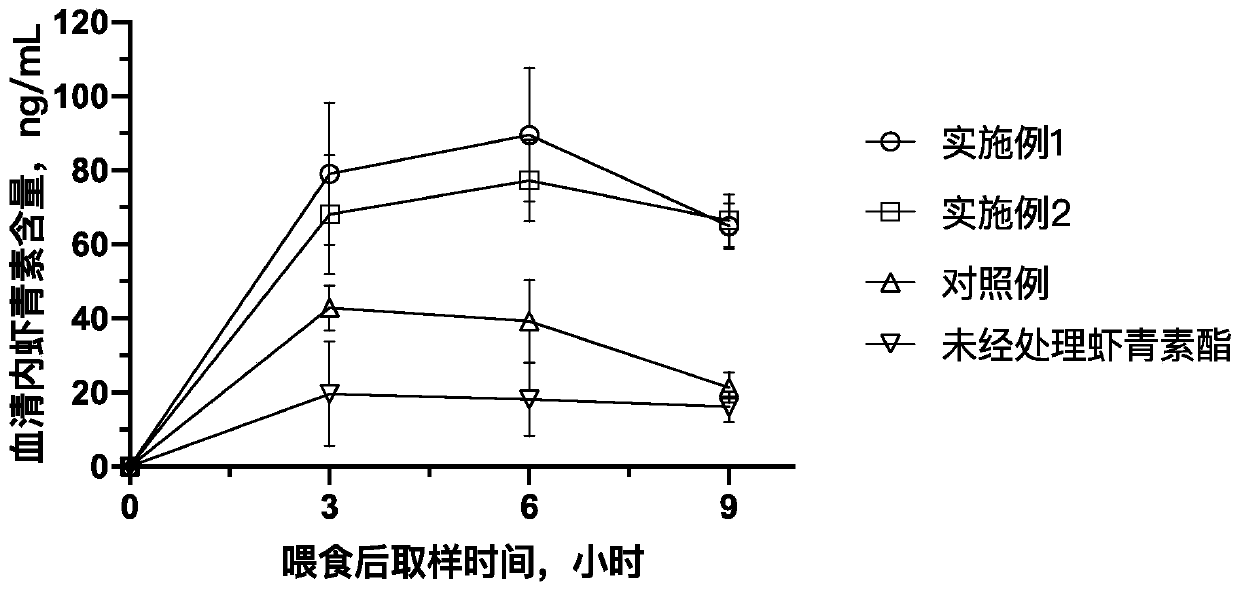

Microcapsule containing natural astaxanthin ester and preparation method thereof

InactiveCN109820837AAdjust the rupture conditionGood water dispersibilityOrganic active ingredientsCosmetic preparationsSucroseAdditive ingredient

The invention discloses a microcapsule containing natural astaxanthin ester and a preparation method thereof. The microcapsule comprises a capsule wall material and an oil phase which is wrapped by the capsule wall material and contains natural astaxanthin ester. The capsule wall material includes a main ingredient and an auxiliary ingredient, the main ingredient is one or more of glue, polysaccharide, glycan, protein and peptide, and the auxiliary ingredient is one or more of sucrose ester, polyalcohol aliphatic ester, ascorbic acid and salts thereof, erythorbic acid and salts thereof, ethylenediamine tetraacetic acid and natural polyphenol. The oil phase includes natural astaxanthin ester, fat, oil, phospholipid, polyalcohols and a stabilizer. The preparation method is high in embeddingrate, can remarkably improve the storage stability of natural astaxanthin ester, has the good flowability, and can remarkably improve the living body absorption rate of natural astaxanthin ester. Themicrocapsule can be applied to products of food, beverages, cosmetics, skincare products, medicines and the like.

Owner:睿藻生物科技(苏州)有限公司

Emulsion composition

ActiveUS20090252773A1Good moisturizing effectBeautiful appearanceCosmetic preparationsBiocidePhosphoric Acid EstersEmulsion

An emulsion composition of the present invention includes (A) a salt of a higher fatty acid ester of ascorbic acid-2-phosphoric acid ester, (B) a polyglycerin fatty acid monoester including polyglycerin having a mean polymerization degree of 8 to 12 and an unsaturated fatty acid residual group of 14 to 22 carbon atoms, (C) a polyglycerin fatty acid monoester comprising polyglycerin having a mean polymerization degree of 2 to 6 and an unsaturated fatty acid residual group of 14 to 22 carbon atoms, and (D) a hydrocarbon oil, wherein the blending ratio by mass between the component (B) and the component (C) is in the range of 1:1 to 3:1, and the blending ratio by mass between the total of the components (B) and (C) and the component (D) is in the range of 10:1 to 1:4. By the use of the emulsion composition of the present invention, a skin external preparation can be provided which is prevented from decrease of a salt of a higher fatty acid ester of ascorbic acid-2-phosphoric acid ester attributable to decomposition of the salt, is excellent in retention of moisture, and has a beautiful appearance.

Owner:RESONAC CORP

Colon cleansing compositions and methods

InactiveUS20070098764A1Great tasteLower the volumePowder deliveryBiocideSodium bicarbonateTolerability

A composition comprising, per litre of aqueous solution, from 30 to 350 g polyethylene glycol, from 3 to 20 g of an ascorbic acid component selected form the group consisting of ascorbic acid, a salt of ascorbic acid, or a mixture thereof, an alkali metal or alkaline earth metal sulphate, preferably from 1 to 15 g thereof, and optionally one or more electrolytes selected from sodium chloride, potassium chloride, and sodium hydrogen carbonate, and preferably also comprising flavourings, is effective in cleansing the gut in preparation for a endoscopy, especially colonoscopy. It is safer than conventional sodium phosphate-based gut cleansing compositions, and hence can be used for patients who would be at risk with sodium phosphate-based compositions, and is better tolerated than conventional PEG-based compositions, leading to better patient compliance and enabling effective out-patient use.

Owner:NORGINE BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com