Method for preparing L-ascorbic acid-2-phosphate

A technology of ascorbic acid and phosphate ester, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, animal feed, etc., can solve problems such as VC loss and incomplete reaction, and achieve high material specificity and water solubility small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

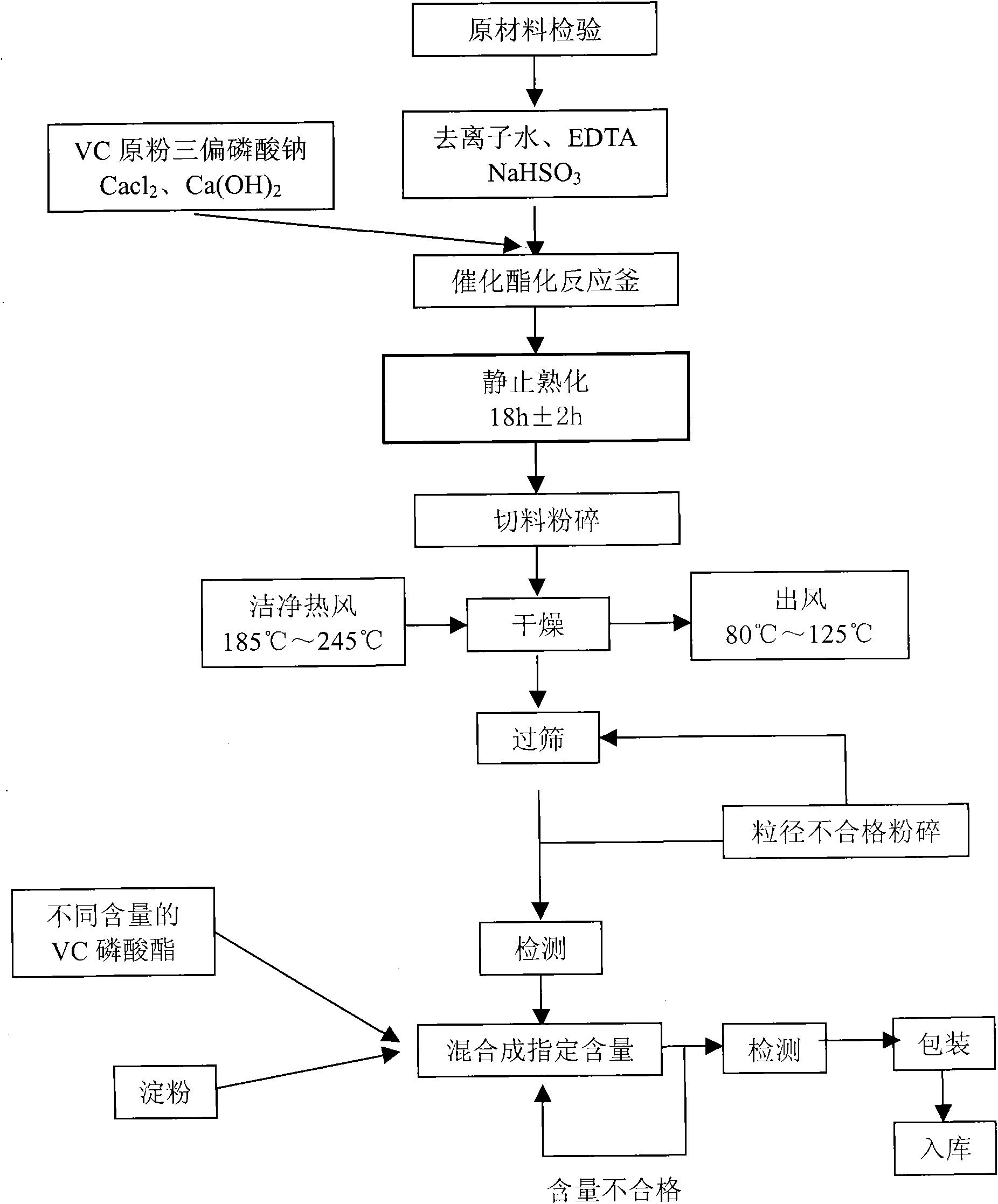

Image

Examples

Embodiment 1

[0018] (1) Acceptance of raw materials: after the raw materials are put into storage, the quality department will take samples and test them, and pass the inspection and put them into the warehouse;

[0019] (2) VC raw powder, sodium trimetaphosphate, calcium chloride, calcium hydroxide: the raw materials are transported to the synthesis station for review, and the outer packaging is removed for use;

[0020] (3) Deionized water, disodium ethylenediamine tetraacetate, sodium bisulfite: the water should be clean and transparent, meeting drinking water standards, the catalysts should be weighed separately, and kept clean for use;

[0021] (4) Catalytic esterification reactor

[0022] Preparation of calcium hydroxide solution: add 240kg of water to 120kg of calcium hydroxide and stir evenly. Add 350kg of deionized water to the reaction kettle, start stirring after adding water, slowly add 100g of disodium ethylenediaminetetraacetic acid (EDTA-2Na), keep the temperature below 20°...

Embodiment 2

[0042] In the (4) step catalytic esterification reactor, the amount of material added is different from Example 1, specifically as follows:

[0043] Preparation of calcium hydroxide solution: add 230kg of water to 115kg of calcium hydroxide and stir evenly. Add 340kg of deionized water to the reaction kettle, start stirring immediately after adding water, slowly add 100g of disodium ethylenediaminetetraacetic acid (EDTA-2Na), keep the temperature below 20°C and stir; put in 250kg of VC, and add 10kg of calcium chloride at the same time , stir and dissolve for 20 minutes; start to add calcium hydroxide solution dropwise, when the pH value reaches (4.5-5), add 400 g of sodium bisulfite, continue to adjust the pH value to (6.4-7.0), turn off the dropwise addition, and add three Sodium metaphosphate 170kg (1 ~ 2) minutes to complete, the above control temperature is the best state below 20 ℃; open the calcium hydroxide solution and continue to drop, control the temperature below 2...

Embodiment 3

[0046] In the (4) step catalytic esterification reactor, the amount of material added is different from Example 1, specifically as follows:

[0047] Preparation of calcium hydroxide solution: add 250kg of water to 125kg of calcium hydroxide and stir evenly. Add 360kg of deionized water to the reaction kettle, start stirring immediately after adding water, slowly add 100g of disodium ethylenediaminetetraacetic acid (EDTA-2Na), keep the temperature below 20°C and stir; put in 250kg of VC, and add 16kg of calcium chloride at the same time , stir and dissolve for 20 minutes; start to add calcium hydroxide solution dropwise, when the pH value reaches (4.5-5), add 400 g of sodium bisulfite, continue to adjust the pH value to (6.4-7.0), turn off the dropwise addition, and add three Sodium metaphosphate 190kg (1 ~ 2) minutes to complete, the above control temperature is the best state below 20 ℃; open the calcium hydroxide solution and continue to drop, control the temperature below 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com