Method for preventing browning reaction caused by improper tobacco leaf curing

A browning reaction, tobacco leaf technology, applied in the direction of tobacco, application, treatment of tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

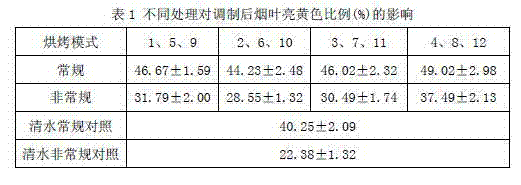

Image

Examples

Embodiment 1

[0017] Polyphenol oxidase inhibitor solution: use tap water or distilled water as a solvent to prepare a solution containing 0.5% (mass ratio) of kojic acid and 2.0% (mass ratio) of ascorbate.

[0018] Tobacco leaf treatment method: put the solution in a rectangular water tank, immerse the harvested fresh tobacco leaves in the water tank for 5-8 minutes, take it out, drain the open water, let it dry for 2-3 hours, then transfer it to the barn for conventional baking and extraordinary Regular baking. The control was soaked in clean water, and the follow-up treatment was consistent with that of the treatment group. Conventional baking is carried out in the farmhouse, using a standardized 5-stage baking mode. The unconventional baking was carried out in the laboratory with the YHSJ-1 baking test machine produced by Kunming Jiaye Technology Co., Ltd. Compared with conventional baking conditions, the late yellowing period is extended for 24 hours, and other process conditions rem...

Embodiment 2

[0020] Polyphenol oxidase inhibitor solution: use tap water or distilled water as a solvent to prepare a solution containing 0.2% (mass ratio) of ferulic acid and 2.0% (mass ratio) of ascorbate.

[0021] Tobacco leaf processing method is the same as embodiment 1.

Embodiment 3

[0023] Polyphenol oxidase inhibitor solution: use tap water or distilled water as a solvent to prepare a solution containing kojic acid at a concentration of 0.05% (mass ratio) and ascorbate at a concentration of 2.0% (mass ratio).

[0024] Tobacco leaf processing method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com