Annular protecting liquid for oil and gas well

An annulus protection fluid and well annulus technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of inability to maintain long-term stability and poor high temperature stability, and achieve high temperature resistance and thermal stability Good, low formation damage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the present invention comprises density regulator, corrosion inhibitor, antibacterial agent, oxygen scavenger, desulfurizer, water, wherein: density regulator is KCOOH, consumption is 20.0%; Corrosion inhibitor is CT2-12, The dosage is 5.0%; the antibacterial agent is dodecyltrimethylammonium chloride, the dosage is 1.5%; the oxygen scavenger is sodium erythorbate, the dosage is 4.1%; the balance is water.

Embodiment 2

[0020] Embodiment 2: Density regulator is NaCOOH, and consumption is 20.0%; Corrosion inhibitor is CT2-12, and consumption is 5.0%; Antibacterial agent is dodecyl dimethyl tertiary amine, and consumption is 1.5%; Oxygen scavenger It is sodium ascorbate, the dosage is 4.1%; the desulfurizer is basic zinc carbonate, the dosage is 1.0%; the balance is water.

Embodiment 3

[0021] Example 3: The density regulator is a compound of KCOOH and NaCOOH, the dosage of KCOOH is 20.0%, and the dosage of NaCOOH is 13.0%; the corrosion inhibitor is CT2-12, and the dosage is 4.0%; the antibacterial agent is dodecyl trimethyl Ammonium chloride, the dosage is 1.5%; the oxygen scavenger is sodium erythorbate, the dosage is 2.0%; the sulfur removal agent is the iron complex compound, the dosage is 1.5%; the balance is water.

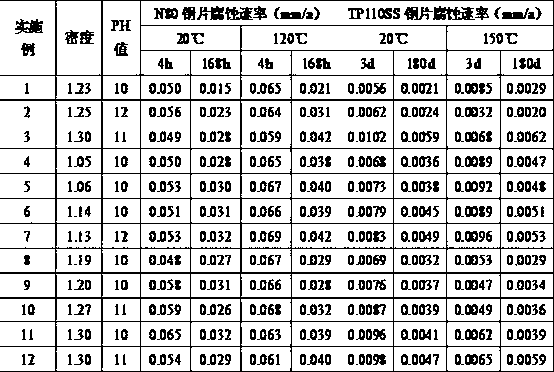

[0022] Other embodiments are identical with above-mentioned embodiment preparation method, and concrete formula is as shown in table 1:

[0023] Table 1 is the embodiment of the present invention

[0024] components Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 Example 8 Example 9 Example 10 Example 11 Example 12 KCOOH 20.0 0 20.0 0 0 10.0 0 20.0 20.0 20.0 33.0 33.0 NaCOOH 0 20.0 13.0 0 0 0 10.0 0 0 0 0 0 CT2-12 5.0 5.0 4.0 3.0 3.0 3.0 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com