Low-viscidity drag-reduction slick water acid liquid for carbonate reservoir bed

A carbonate reservoir and resistance reduction technology, applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problem of difficult extension of fracture corrosion distance, failure of fracture seepage channels, and influence of fracture permeability, etc. problems, to achieve good corrosion inhibition effect, well-developed crack system, and good resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

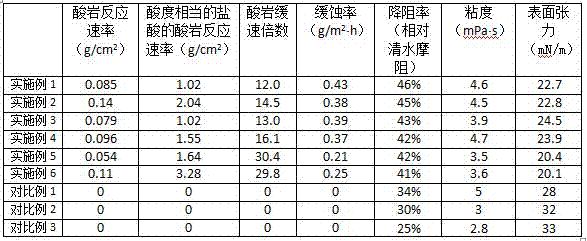

Examples

Embodiment 1

[0022] 1. A low-viscosity drop-resistance slick water acid solution for carbonate reservoirs, consisting of the following raw material components in weight percent (total amount 100%): hydrochloric acid 5%, dodecyl trimethyl chloride Ammonium 1%, sodium ascorbate 0.5%, polyacrylic alcohol emulsion 0.5%, citric acid 1%, BSA-401 drainage aid 3%, and the balance is water.

[0023] 2. The preparation method of the low-viscosity slick water acid solution used in carbonate reservoirs: take 805g of water and place it in a Wuyin mixer with a volume of 2000ml, add 135g of 37% hydrochloric acid solution, stir and dissolve, and then Add 10g of dodecyltrimethylammonium bromide, 5g of sodium ascorbate, 5g of polypropylene alcohol emulsion, 10g of citric acid, and 30g of BSA-401 drainage aid, and stir for 2 minutes to obtain 1000g of low-viscosity slippery water acid solution.

Embodiment 2

[0025] 1. A low-viscosity drop-resistance slick water acid solution for carbonate reservoirs, consisting of the following raw material components in weight percent (total 100%): 12% hydrochloric acid, cetyl trimethyl chloride Ammonium 3%, sodium ascorbate 2%, polyvinylpyrrolidone emulsion 0.1%, citric acid 0.5%, BSA-401 drainage aid 1%, and the balance is water.

[0026] 2. The preparation method of the low-viscosity slick water acid solution used in carbonate reservoirs: take 610g of water and place it in a Wuyin mixer with a volume of 2000ml, add 324g of 37% hydrochloric acid solution, and stir to dissolve it successively Add 30g of cetyltrimethylammonium chloride, 20g of sodium ascorbate, 1g of polyvinylpyrrolidone emulsion, 5g of citric acid, and 10g of BSA-401 drainage aid, and stir for 5 minutes to obtain 1000g of low-viscosity slippery water acid solution.

Embodiment 3

[0028] 1. A low-viscosity drop-resistance slick water acid solution for carbonate reservoirs, consisting of the following raw material components in weight percent (total amount 100%): 8% formic acid, dodecyl trimethyl bromide Ammonium 2.7%, sodium ascorbate 1%, acrylamide and 2-acrylic acid-2 methylpropanesulfonic acid copolymer emulsion 0.2%, citric acid 0.6%, BSA-401 drainage aid 1.5%, and the balance is water.

[0029] 2. The preparation method of the low-viscosity slick water acid solution used in carbonate reservoirs: take 833g of water and place it in a 2000ml volume Wuyin mixer, add 107g of 75% formic acid solution, stir and dissolve, then Add 27g of dodecyltrimethylammonium bromide, 10g of sodium ascorbate, 2g of acrylamide and 2-acrylic acid-2 methylpropanesulfonic acid copolymer emulsion, 6g of citric acid, 15g of BSA-401 drainage aid, and stir for 4 minutes to obtain 1000g low-viscosity and drag-reducing slippery water acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com