Method for jointly drying cucumbers by vacuum pulse and negative-pressure pulse-spouted microwave

A technology of vacuum pulsation and pulse spraying, which is applied in food drying, food ultrasonic treatment, and the function of food ingredients, etc. It can solve the problems of unfavorable nutritional quality of crisp chips and industrialized rapid production, unfavorable preservation of nutrients, low retention rate of nutritional ingredients, etc. problems, to achieve the effect of shortening the production cycle, reducing loss, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

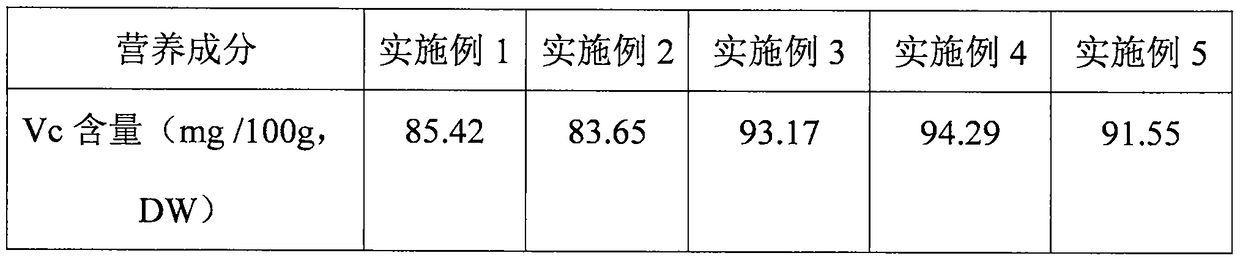

Examples

Embodiment 1

[0053] 1. A method of vacuum pulsation and negative pressure pulse ejection microwave combined drying cucumber is as follows:

[0054] ①Choose fresh cucumbers that have no rot and deterioration, no mechanical damage, thick flesh, and pesticide residues that do not exceed the standard; ②Wash the cucumbers with clean water, remove the stalks, and cut them into 7mm slices with a slicer; ③Use the sliced cucumbers with ultrasonic waves Auxiliary color protection solution for color protection: ultrasonic frequency is 20KHz, power is 200W, and color protection time is 1min; ④The cucumbers after color protection are blanched with ultrasonic-assisted high-temperature, high-humidity superheated steam to kill enzymes and bacteria: ultrasonic frequency is 40KHz, power 400W, superheated steam blanching temperature 120°C, relative humidity 60%, gas flow rate 24m / s, blanching time 90s; : the drying temperature in the drying chamber is 45°C, and the vacuum is pulsated between 0MPa and 0.08M...

Embodiment 2

[0056] A method for drying cucumbers combined with vacuum pulsation and negative pressure pulse ejection microwave is as follows:

[0057] ①Choose fresh cucumbers that have no rot and deterioration, no mechanical damage, thick flesh, and pesticide residues that do not exceed the standard; ②Wash the cucumbers with clean water, remove the stalks, and cut them into 8mm slices with a slicer; ③Use the cut cucumbers with ultrasonic waves Auxiliary color protection liquid for color protection: ultrasonic frequency is 20KHz, power is 200W, and color protection time is 3min; ④The cucumbers after color protection are blanched with ultrasonic-assisted high-temperature, high-humidity superheated steam to kill enzymes and bacteria: ultrasonic frequency is 50KHz, power 500W, superheated steam blanching temperature 100°C, relative humidity 30%, gas flow rate 12m / s, blanching time 60s; : the drying temperature in the drying chamber is 55 ℃, and the vacuum is pulsated between 0MPa and 0.09MPa ...

Embodiment 3

[0059] A method for drying cucumbers combined with vacuum pulsation and negative pressure pulse ejection microwave is as follows:

[0060] ①Choose fresh cucumbers that have no rot and deterioration, no mechanical damage, thick flesh, and pesticide residues that do not exceed the standard; ②Wash the cucumbers with clean water, remove the stalks, and cut them into 9mm slices with a slicer; ③Use the cut cucumbers with ultrasonic waves. Auxiliary color protection liquid for color protection: ultrasonic frequency is 20KHz, power is 200W, and color protection time is 2min; ④The cucumbers after color protection are blanched with ultrasonic-assisted high-temperature, high-humidity superheated steam to kill enzymes and bacteria: ultrasonic frequency is 45KHz, power 400W, superheated steam blanching temperature 110°C, relative humidity 45%, gas flow rate 20m / s, blanching time 80s; : the drying temperature in the drying chamber is 50°C, the vacuum is pulsated between 0MPa and 0.08MPa wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com