Method for preventing banana pulp from browning

A banana and pulp browning technology, which is applied in application, food preparation, food science, etc., can solve the problems of large equipment investment and uncontinuous production, and achieve the effects of simple equipment, no browning reaction, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

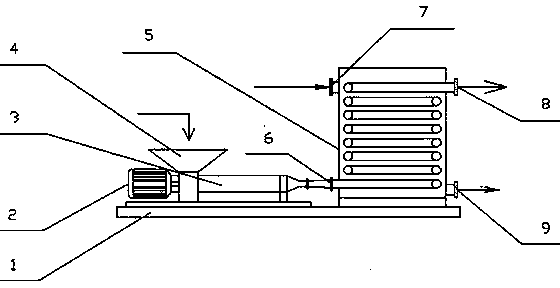

[0020] Such as figure 1 As shown, a motor 2, a screw pump 3 and a coil heat exchanger 5 are installed and fixed on the base 1 respectively. This is how the invention works:

[0021] (1) Feeding: quickly add peeled bananas to 12°BX sugar water. At this time, the weight ratio of sugar water to bananas is 6:4. At this time, start the motor 2 to drive the screw pump 3 to work, and then dip the Bananas in sugar water and sugar water are put into the screw pump 3 in the feeding hopper 4 at the same time, and the rotation of the screw pump 3 pushes the input bananas forward, and crushes the bananas into a pulp while pushing;

[0022] (2) Enzyme elimination: Steam enters the coil heat exchanger 5 from the steam inlet 7, so that the temperature in the coil heat exchanger 5 is constant at 100-120°C. At this time, driven by the screw pump 3, the The banana pulp is sent into the coil heat exchanger 5, and the banana pulp is pushed to the material outlet 8 under the action of the screw p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com