Method for preventing excessive browning reaction due to improper tobacco leaf curing

A browning reaction, tobacco leaf technology, applied in the direction of tobacco, application, treatment of tobacco, etc., to achieve the effect of inhibiting the browning reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

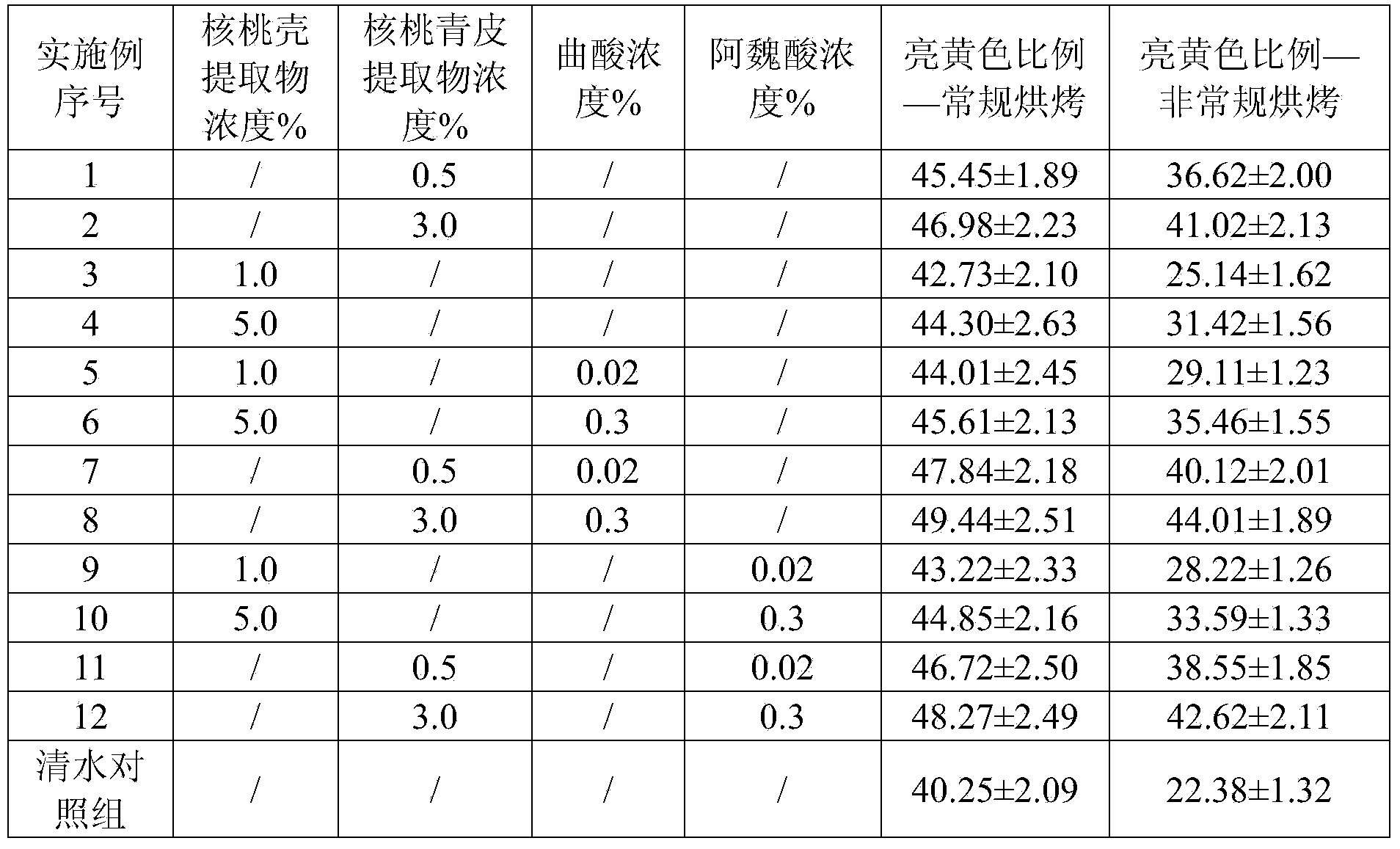

Examples

Embodiment 1

[0020] Preparation of walnut green husk extract: after cleaning fresh walnut green husk, extract according to the ratio of the weight of walnut green husk to the volume of ethanol or food-grade acetone as 1:200, and use ultrasonic-assisted extraction for 2 hours. Afterwards, filter, collect the filtrate, carry out rotary evaporation, concentrate, and then put it into a vacuum freeze dryer, and obtain a solid powder extract after 8 hours. The extract is dissolved in water to a concentration of 0.5% by mass before use.

[0021] Tobacco leaf treatment method: put the solution in a rectangular water tank, immerse the harvested fresh tobacco leaves in the water tank for 3-5 minutes, take it out, drain the open water, let it dry for 0.5-1 hour, then transfer it to the barn for conventional baking and extraordinary Regular baking. The control was soaked in clean water, and the follow-up treatment was consistent with that of the treatment group. Conventional baking is carried out in...

Embodiment 2

[0023] Preparation of walnut green husk extract: after cleaning fresh walnut green husk, extract according to the ratio of walnut green husk weight to ethanol or food-grade acetone volume of 1:30, and use ultrasonic-assisted extraction for 0.5 h. Afterwards, filter, collect the filtrate, carry out rotary evaporation, concentrate, and then put it into a vacuum freeze dryer, and obtain a solid powder extract after 8 hours. The extract was dissolved in water to a concentration of 3.0% by mass before use.

[0024] Tobacco leaf processing method is the same as embodiment 1.

Embodiment 3

[0026] Preparation of walnut shell extract: extract according to the ratio of walnut shell weight to ethanol or food-grade acetone volume of 1:100, and use ultrasonic-assisted extraction for 3 hours. Afterwards, filter, collect the filtrate, carry out rotary evaporation, concentrate, and then put it into a vacuum freeze dryer, and obtain a solid powder extract after 8 hours. The extract is dissolved in water to a concentration of 1.0% by mass before use.

[0027] Tobacco leaf processing method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com