Withering machine

A technology of withering machine and fan, applied in the field of withering machine, can solve the problems of large area, long withering time, slow withering speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

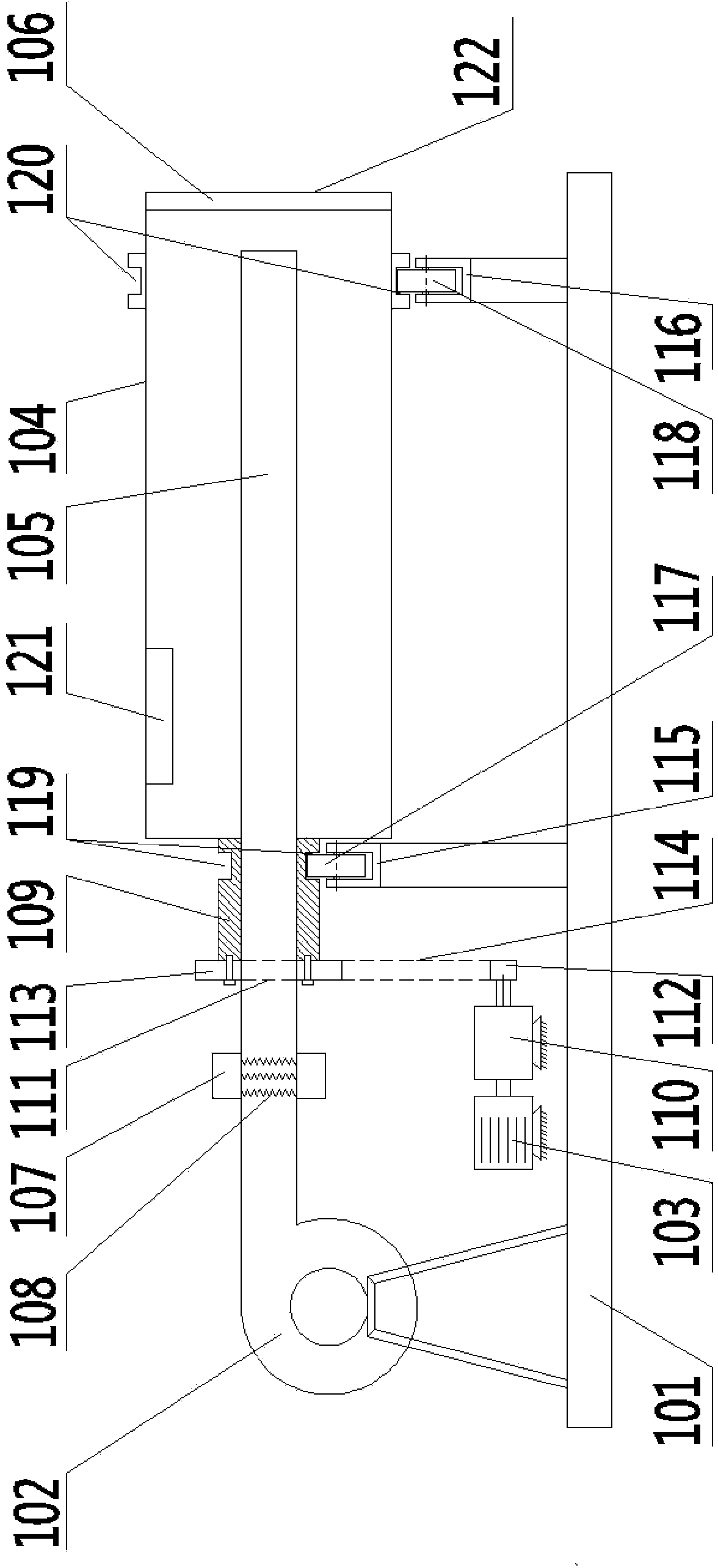

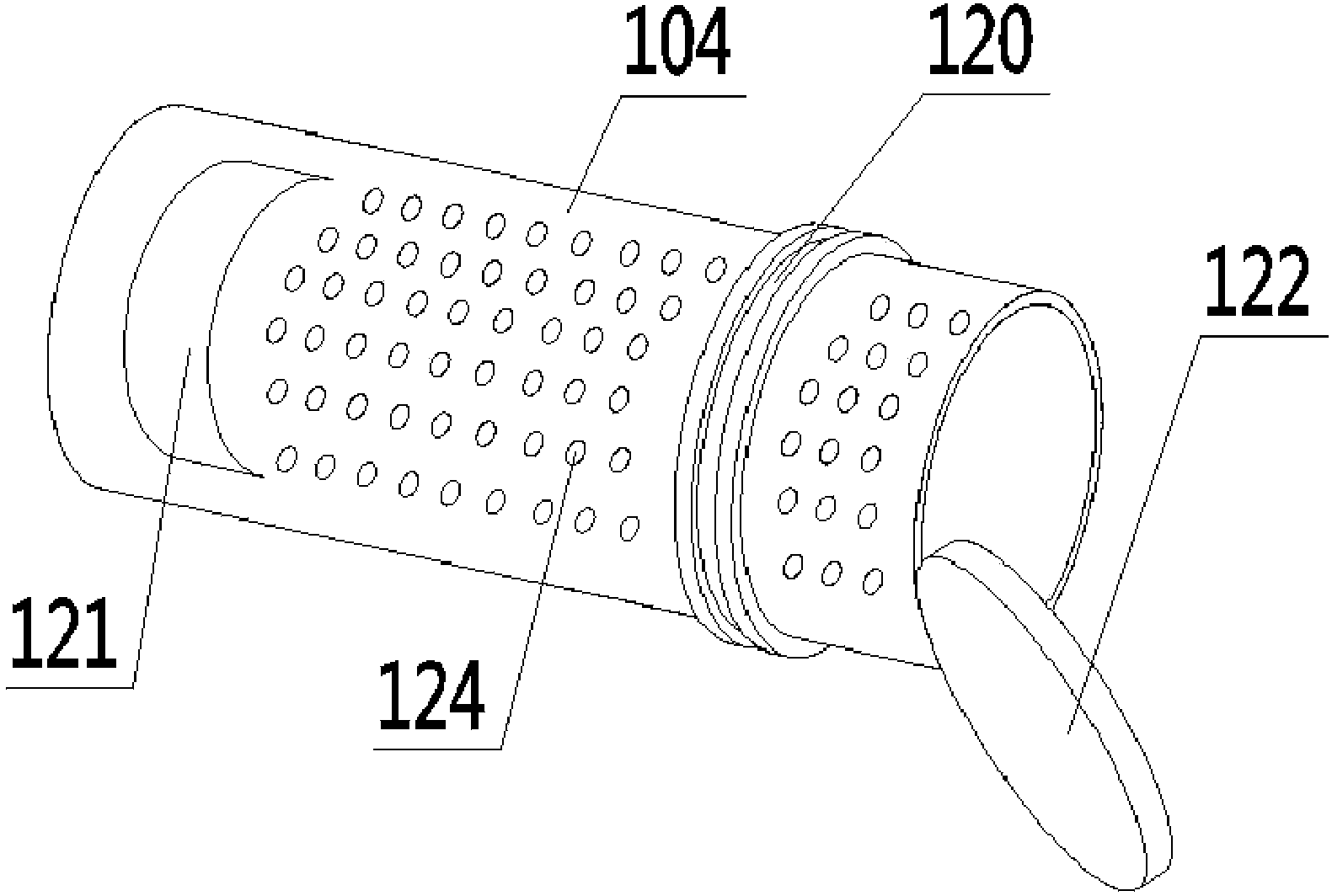

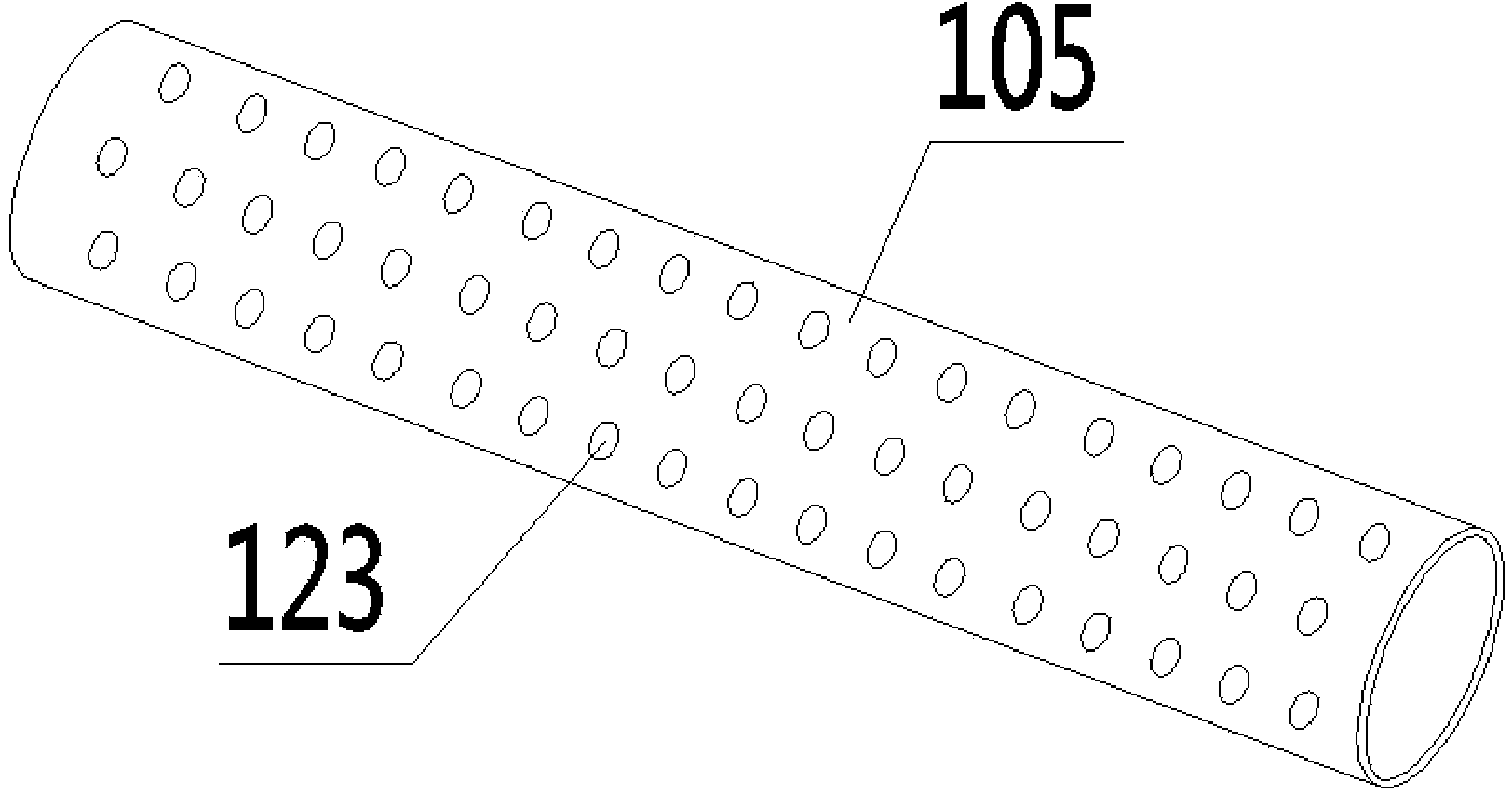

[0026] figure 1 The structural representation of the withering machine that the embodiment of the present invention provides; Please refer to figure 1 , the present invention provides a withering machine, which includes a frame 101, a fan 102, a motor 103, an air duct 105, and a rotatable rotating drum 104, the fan 102 is arranged at one end of the frame 101, and the rotating drum 104 is arranged at The other end of frame 101, the air outlet of fan 102 communicates with the air inlet of air duct 105, and one end of rotating drum 104 is provided with opening, and air duct 105 stretches in the rotating drum 104 through the opening of rotating drum 104, and motor 103 and The rotating drum 104 is connected by transmission, and the rotating drum 104 is provided with an organic door 106 .

[0027] Fan 102 is arranged on the frame 101, and frame 101 plays a supporting role to fan 102; The rotating sleeve part of the rotary drum 104 enables the rotary drum 104 to rotate on the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com