Patents

Literature

43results about How to "Dark green color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizer special for rice

InactiveCN106220391ADark green colorEnhanced tillering abilityBiocideCalcareous fertilisersRare-earth elementChemistry

A fertilizer special for rice comprises a base fertilizer and a foliage fertilizer. The base fertilizer is prepared from, by mass, 80-100 parts of a nitrogen, phosphorus and potassium compound fertilizer, 4-8 parts of medium and trace elements, 0.05-0.1 part of rare earth elements, 5-10 parts of quick lime, 60-100 parts of an organic fertilizer, 10-15 parts of fluorspar powder and 12-20 parts of vermiculite; the foliage fertilizer is prepared from, by mass, 10-15 parts of urea, 6-8 parts of potassium sulphate, 1-1.6 parts of magnesium sulfate, 1.2-1.8 parts of zinc sulfate, 0.8-1 part of borax, 0.5-0.8 part of sodium selenite, 1.2-1.6 parts of ferrous sulfate, 30-40 parts of amino acid, 20-25 parts of humic acid, 0.5-1 part of glycerol, 1.2-1.8 parts of Chinese herb extracts and 0.1-0.5 part of a plant regulator. According to the fertilizer special for the rice, multiple elements are compounded, the organic elements and the inorganic elements are combined, various nutritional ingredients achieve the synergistic effect, the nutrition is complete, slow-release growth is achieved, the utilization rate is high, the water retaining capacity and the fertilizer retaining capacity are good, the physical characteristics of soil are improved, the Chinese herbs achieve pest killing and fungus resisting, the safety is high, the rice quality is improved, and the rice yield is increased.

Owner:左邦庆

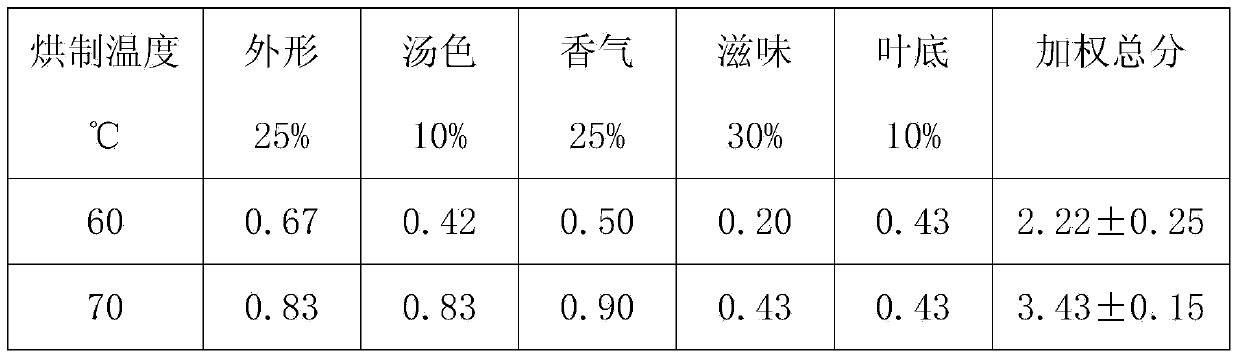

Making process of oolong black tea

ActiveCN102783532ADark green colorThe soup is bright red and transparentPre-extraction tea treatmentChemistryEpigallo-catechin gallate

Making process of oolong black tea includes the steps of harvesting tea, sunning, cooling green leaves, rocking the green leaves, allowing the green leaves to stand, baking, rolling, fermenting, and drying to obtain a fished product. The oolong black tea is made out of fresh leaves of oolong tea, green leaf making process of oolong tea and fermenting process of black tea are combined to make the novel tea with unique flavor, the novel tea integrates sweetness of the black tea and flower and fruit aroma of the oolong tea and is blackish green, soup of the novel tea is red and clear, flower aroma is apparent, and the novel tea is sweet and smooth, has long aftertaste and is durable in brewing. The problems of waste of summer tea resources, low profit in summer tea processing and the like are solved directly. The biochemical characters of the raw green tea leaves is taken to full consideration, baking is performed first so that flower-type aromatic matters can be converted richly and sufficiently, completeness of tea strips is also maintained, and the tea leaves are more attractive. Fermenting later promotes conversion of contents of the green leaves into thearubigins and theaflavinsand the like better, the ratio of polyphenols to amino acids is proper, and the quality characteristics of sweetness and mellowness of the black tea are fully expressed.

Owner:CHOTEA WEIS TEA IND

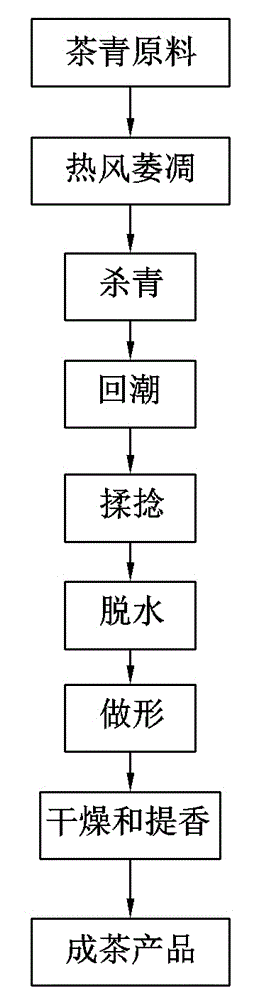

Green tea processing process

The invention discloses a green tea processing process, belonging to the technical field of tea processing. The green tea processing process comprises the following steps: putting picked fresh leaves into a room to naturally wither, and then withering the leaves in hot air; repeatedly operating until moisture of the withered leaves is 45-55%; cooling by utilizing cold air until temperature of the withered leaves is 15-20 DEG C; transferring the cooled withered leaves into a roller water-removing machine for primary water-removing; taking out and spreading the leaves in a dustpan, and quickly transferring the leaves into a microwave water-removing machine for secondary water-removing 5-10 minutes latter; taking out and putting the water-removed tea leaves into a pan to stir-fry, and taking out the tea leaves after stir-frying for 3-5 minutes, wherein the temperature of the pan is 60-70 DEG C; rolling; drying; and putting the dried tea leaves into an aroma raising machine, and preparing a finished product 3-5 minutes later, wherein the temperature of the aroma raising machine is 90-100 DEG C. The green tea processing process is uniform and complete in water-removing, and the prepared green tea is strong in aroma.

Owner:务川自治县鑫隆缘茶业有限责任公司

Soil fertilizer composition

InactiveCN102617248ASimple production processReduce manufacturing costFertilizer mixturesMonopotassium phosphateFertility preservation

The invention discloses a soil fertilizer composition, which is composed of the following raw materials by weight: 10 to 20 parts of bean pulp, 20 to 30 parts of thoroughly decomposed crop straw, 30 to 40 parts of thoroughly decomposed cattle fertilizer or pig fertilizer, 0.06 to 0.15 part of saccharomycetes, 1 part to 10 parts of quick lime, 10 parts to 15 parts of ferrisulphas, 0.6 part to 3 parts of copper sulfate, 0.8 part to 3 parts of monopotassium phosphate, 3 to 4 parts of chlorothalonil, 10 to 13 parts of Chinese cabbage dreg and 15 to 20 parts of decoction dreg. The soil fertilizer composition can improve quality, increase production substantially, remarkably improve physical characteristics of soil, improve water permeability of the soil and improve moisture and fertility preservation capability of the soil.

Owner:常熟市南洋化肥有限公司

Method for preparing Maofeng tea by using non-whitened-stage fresh tea leaves

ActiveCN104585370ADark green colorIntegrity guaranteedPre-extraction tea treatmentEconomic benefitsProcessing cost

The invention belongs to the technical field of tea processing, and particularly relates to a method for preparing Maofen tea by using non-whitened-stage fresh tea leaves. The finished tea is prepared according to the steps of selecting materials, withering, inactivating enzyme, regaining moisture, twisting, dewatering, shaping, drying, scenting, and winnowing. According to the method, high quality of the finished product is ensured at all the stages due to the adoption of refine processing technology, so that the processing time and processing cost of Zhen'an white tea are greatly reduced, the production efficiency is improved, simultaneously the finished product processed according to the method has the unique characteristics of tight, thin curled and uniform shape, green color, durable clean aroma and fresh taste, and the economic benefit of the finished product is improved; and meanwhile, the problem of waste of non-whitened-stage Zhen'an fresh tea leaves is solved, and the economic benefit is improved.

Owner:ZHENGAN JINLIN TEA IND +1

Special composite organic fertilizer for mangnolia officinalis and preparation method of special composite organic fertilizer

The invention discloses a special composite organic fertilizer for mangnolia officinalis and a preparation method of the special composite organic fertilizer, wherein the special composite organic fertilizer for mangnolia officinalis consists of the following ingredients in parts by weight: 10 to 20 parts of soybean meal, 30 to 40 parts of plant straws, 10 to 13 parts of cabbage slag, 0.5 to 2 parts of composite strains, 15 to 20 parts of potassium sulfate, 0.3 to 0.8 part of manganese sulfate, 0.4 to 0.9 part of ferrous sulfate, 10 to 25 parts of ammonium sulfate, 2 to 5 parts of borax, 10 to 15 parts of diammonium phosphate, 2 to 5 parts of fulvic acid, 1 to 4 parts of soluble chitosan, 2 to 5 parts of trace boron ore, 0.04 to 0.08 part of dipterex, 0.03 to 0.05 parts of chlorothalonil and 25 to 32 parts of filling materials. According to the growth rule of the mangnolia officinalis, the fertilizer provided by the invention adopts a great number of biological organic nitrogenous fertilizers, the physical properties of the soil can be obviously improved after a great number of fertilizers are utilized, the effective void content of the soil is increased, and the survival rate of the young seedlings of the mangnolia officinalis is improved.

Owner:HUBEI FUSOURCE BIOLOGY OF BIOLOGICAL TECH CO LTD

Multiple-effect edging body building tea

InactiveCN101238887AMellow tasteNice appearancePre-extraction tea treatmentFood preparationSteepingThirst

The invention belongs to tea technical field. The object of the invention is to a new type fringe tea series product with wider use using Chinese special species resource and new method. The fresh fringe leaf or initial open flower or radix cortex is subjected to spreading, destroying enzyme, rolling (cutting the large leaf and peel), primary drying, shaping and drying, bettering aroma and the like to produce fringe tea of peral-like shape, cord shape, skein shape, bag-steeping or instant powder and the total precious resource are comprehensively used. The new type fringe tea series product from remote mountains in north of China have features of beautiful look, different postures, bright, elegant odor, pure flavor, removing summer-heat and satisfying one's thirst, fat abstraction, reducing blood sugar, protecting liver, promoting the function of gallbladder, preventing angiosclerosis, increasing immunity, inhibiting tumor, anti-bacterium and diminishing inflammation, skin care and thinning.

Owner:付和玉

Method for cultivating new species of plant ginseng fruit child

InactiveCN101406153AFull of nutritionFruit high proteinHorticulture methodsPlant genotype modificationGibberellic acidDisease

The invention discloses a method for cultivating sapodilla dolls, which is a new plant variety. A panicled fameflower root which belongs to a portulacaceous fameflower annual or perennial herbaceous plant is taken as a male parent, and is hybridized with a sapodilla which belongs to a perennial solanaceae herbaceous plant and is taken as a female parent; a hybrid progeny seedling is taken as a scion, and is grafted on calabash which belongs to a cucurbitaceous plant and is taken as a rootstock; and a fruit borne on a grafted branch after grafting is stippled by use of gibberellin and mepiquat chloride solution, so as to generate a fruit exactly like a doll, namely a sapodilla doll. The new plant variety cultivated by the method has the advantages of developed root system, thick leaves, deep green color, vigorous growth, strong disease resistance, high yield, rich fruit nutrition, beautiful appearance and processing convenience.

Owner:石林镇园人参果科技有限公司

Method for making zinc-rich preserved eggs

A method for making zinc-rich preserved eggs comprises four major steps of egg selection, soaking, mud covering and sealing for storage. The method for making zinc-rich preserved eggs has the following advantage that the made preserved eggs are complete in gel, green black in color, soft in taste, aromatic in flavor, stable in preparation process and high in quality; in particular, zinc oxide is added to a soaking liquid and covering mud so that the preserved eggs are rich in zinc element; in the processing process, the eggs are firstly soaked in the soaking liquid and then covered with the covering mud, so that the zinc element can permeate into the eggs, and then the content of the zinc element in the preserved eggs is increased. Besides, if people eat the preserved eggs, the zinc element in the bodies can be effectively supplemented.

Owner:滕代琼

Processing method of bar-shaped high-fragrance black tea

The invention relates to the field of tea making, and discloses a processing method of bar-shaped high-fragrance black tea. The processing method comprises the following steps of (1) selecting fresh leaves; (2) performing dynamic withering; (3) performing rolling; (4) performing fermentation; (5) performing stir-frying; (6) performing continuous strip tidying; and (7) performing continuous drying.According to the processing method, the processing technology of conventional black tea is innovated, so that the problem of conventional bar-shaped black tea is solved, and the entire quality of theblack tea is improved. Particularly, the fragrance of the black tea is improved, the bar-shaped high-fragrance black tea is tight in outer strips, and the soup is bright in color, mellow in taste, rich in fragrance, and notable in flower fragrance. The processing method is suitable for processing of the black tea in spring, summer and autumn, and the quality of the black tea is stabilized.

Owner:HANGZHOU TEA RES INST CHINA COOP

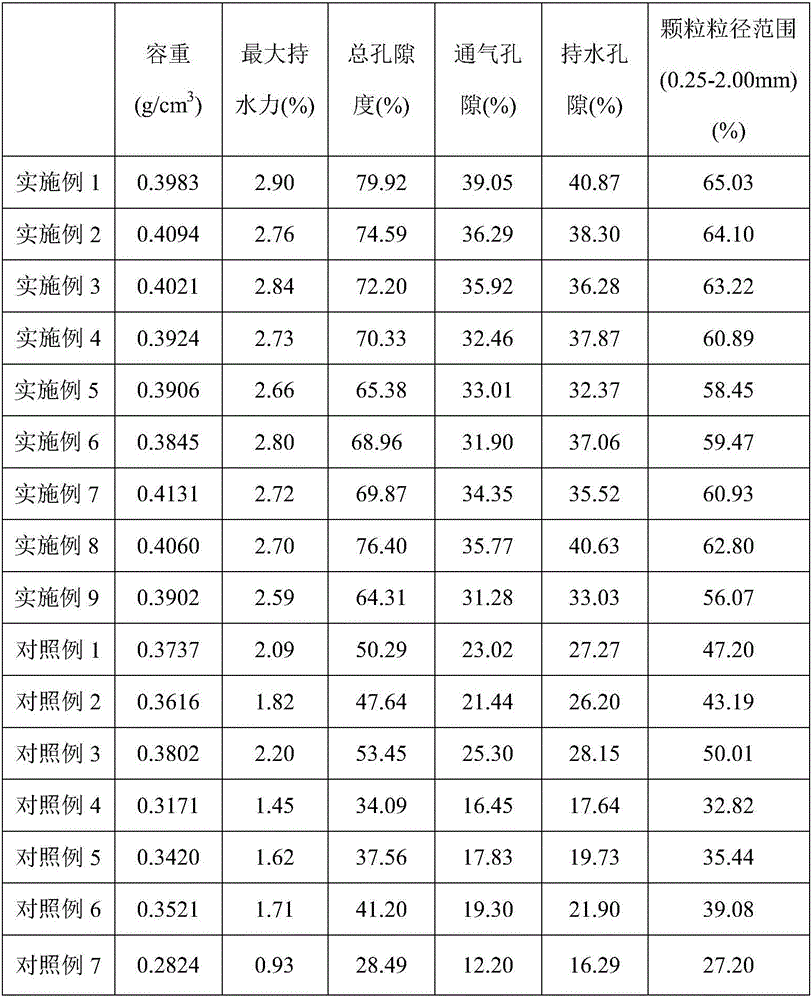

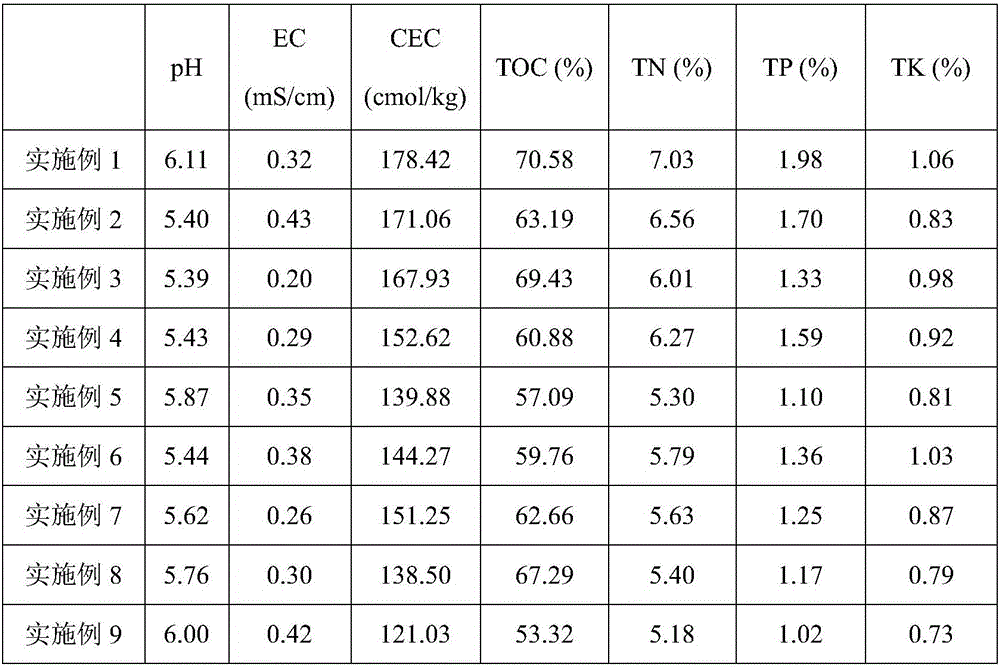

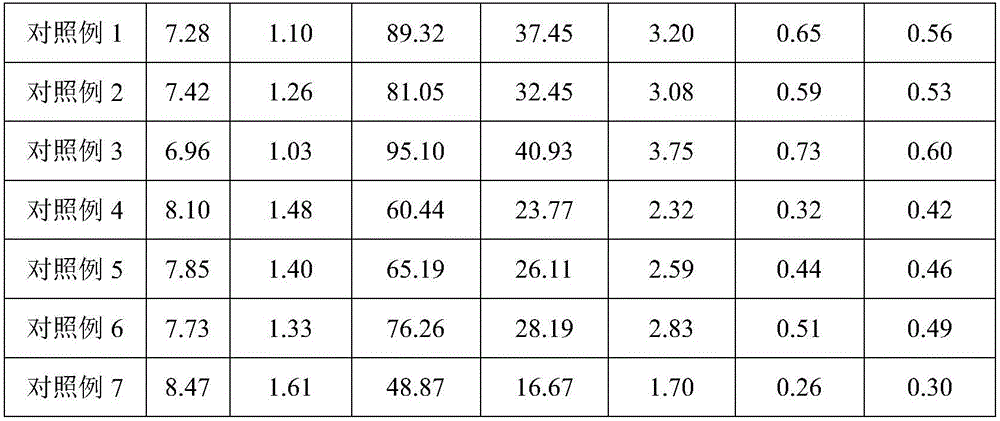

Plant culture substrate conditioner, method for using conditioner for preparing composite culture substrate and prepared culture substrate

InactiveCN106083354AEasy to prepareEasy to operateBioloigcal waste fertilisersOrganic fertiliser preparationFiberGrowth plant

The invention discloses a plant culture substrate conditioner and a preparation method thereof and a method for using the conditioner for preparing a composite culture substrate. The substrate conditioner comprises alga residues, coconut fibers and phosphorite. The composite culture substrate prepared through the substrate conditioner is balanced in nutrition, high in nutrient content, stable in physical property and reasonable in nutritional structure. The prepared composite culture substrate has good cation exchangeability and adsorbability, can adsorb a large amount of salt with a buffer effect, has a buffer effect and can obstruct rapid changes of pH values and EC values, the acid-base environment of the substrate is regulated, the effect that nutrients are slowly released is achieved, breathing and growth of plant root systems are promoted, absorption of the nutrients by the root systems is promoted, plant growth requirements are met, the survival rate of plant culture is raised, and the appreciation effect is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Horseradish soil fertilizer composition for preventing and curing soil-borne disease

ActiveCN102603406ASimple production processReduce manufacturing costFertilizer mixturesPlant diseaseMoisture

The invention discloses a horseradish soil fertilizer composition for preventing and curing soil-borne disease, which consists of the following raw materials: horseradish, bean pulps, fully-matured crop straws and herb residues. With the adoption of the horseradish soil fertilizer composition, the quality can be improved, the substantial increase production can be increased, the physical characteristics of soils can be obviously improved, the water penetration and the water permeability of the soils can be enhanced, and the moisture and fertility preservation capability of the soils can be improved.

Owner:常熟市润丰农业有限公司

Manufacturing technique and method for refining petroleum aqueous emulsion

InactiveCN101283682AStrong emulsificationStrong decontaminationBiocidePlant growth regulatorsInsect pestSolvent

The invention relates to a production process of refined petroleum emulsion in water and belongs to the field of pesticide manufacturing process. The refined petroleum emulsion in water is made from refined petroleum, film-forming agent, emulsifiers, plant nutrients, defoaming agent, stabilizers, antifreezing agent and deionized water, by uniform dispersion using a high-speed shear mixing emulsifier. The refined petroleum emulsion is innoxious and non-irritant or low-toxic or low-irritant to animals and human beings, is harmless to crops, has environmental affinity, enhances the resistance of crops, and can promote the growth of crops. The refined petroleum emulsion can kill main insect pests, regulate the growth of crops, enhance resistance to cold and diseases and increase the yield of crops. The invention has the advantages of use of water as solvent, reduced waste of resources, no discharge of three wastes, environmental friendliness, scientific formulation, advanced process, low cost and good effect.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

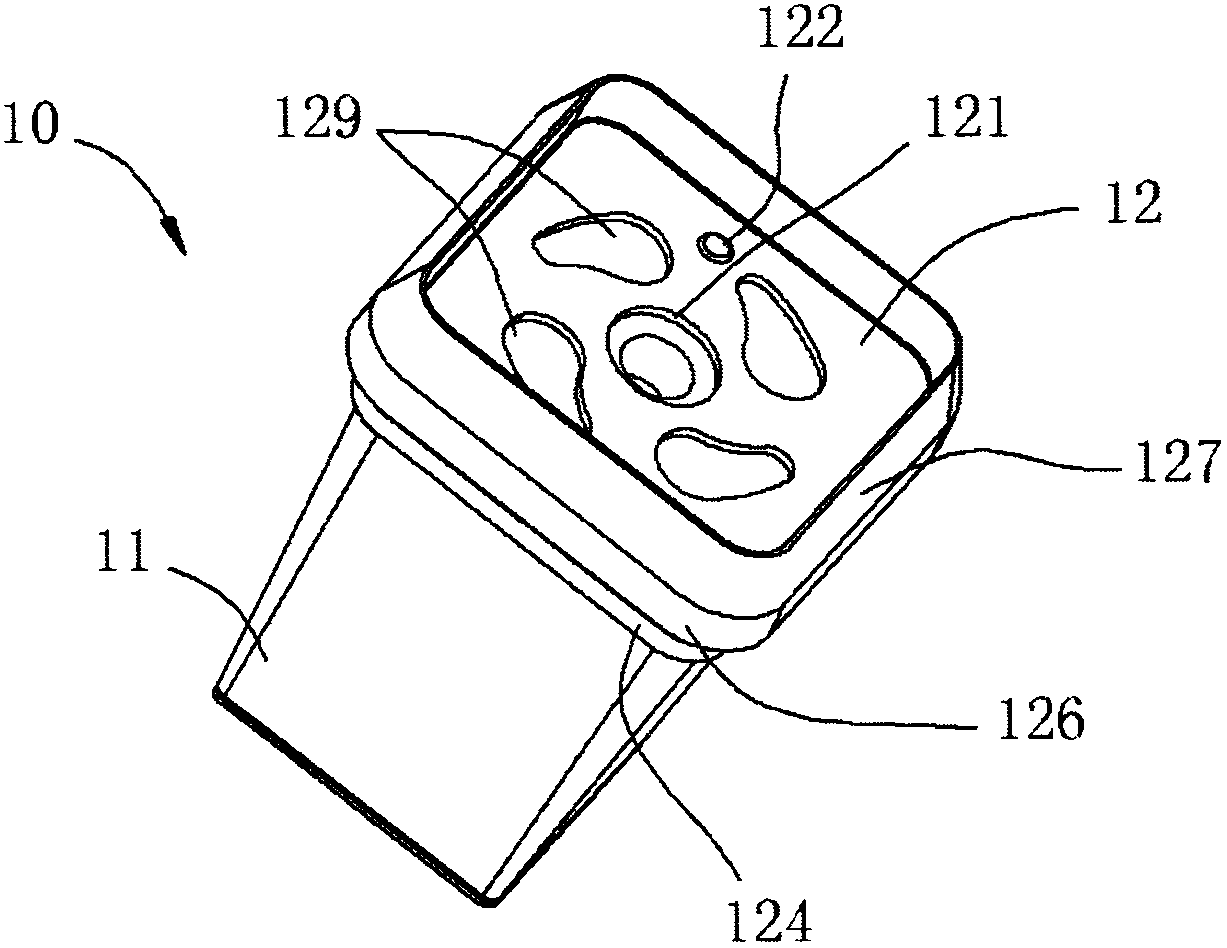

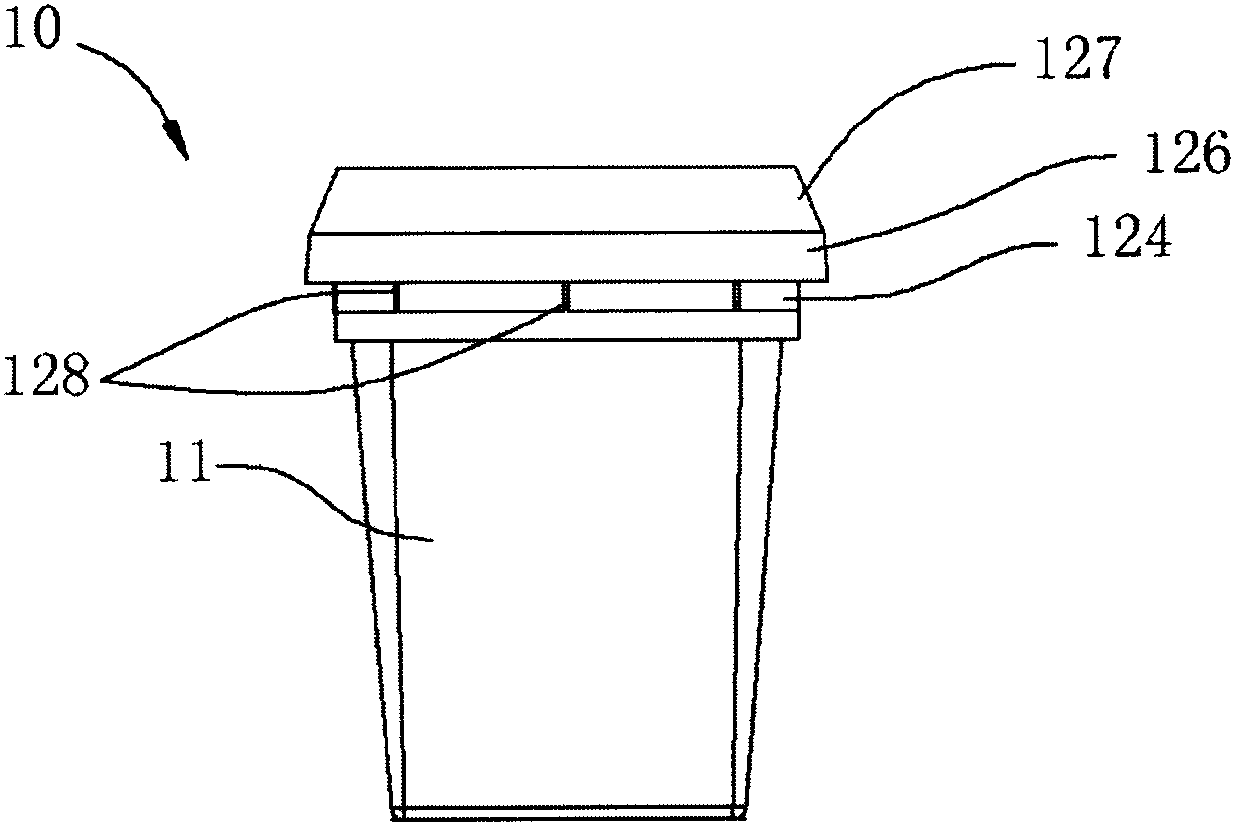

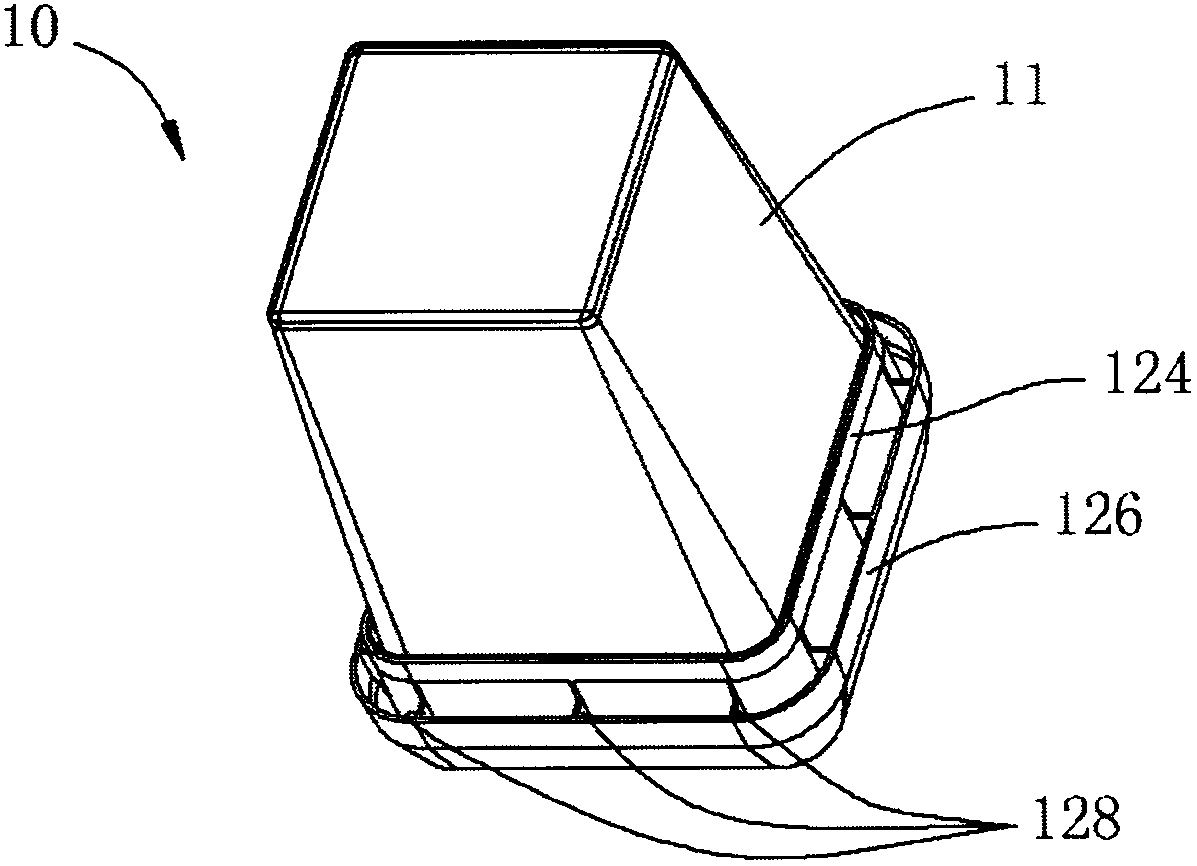

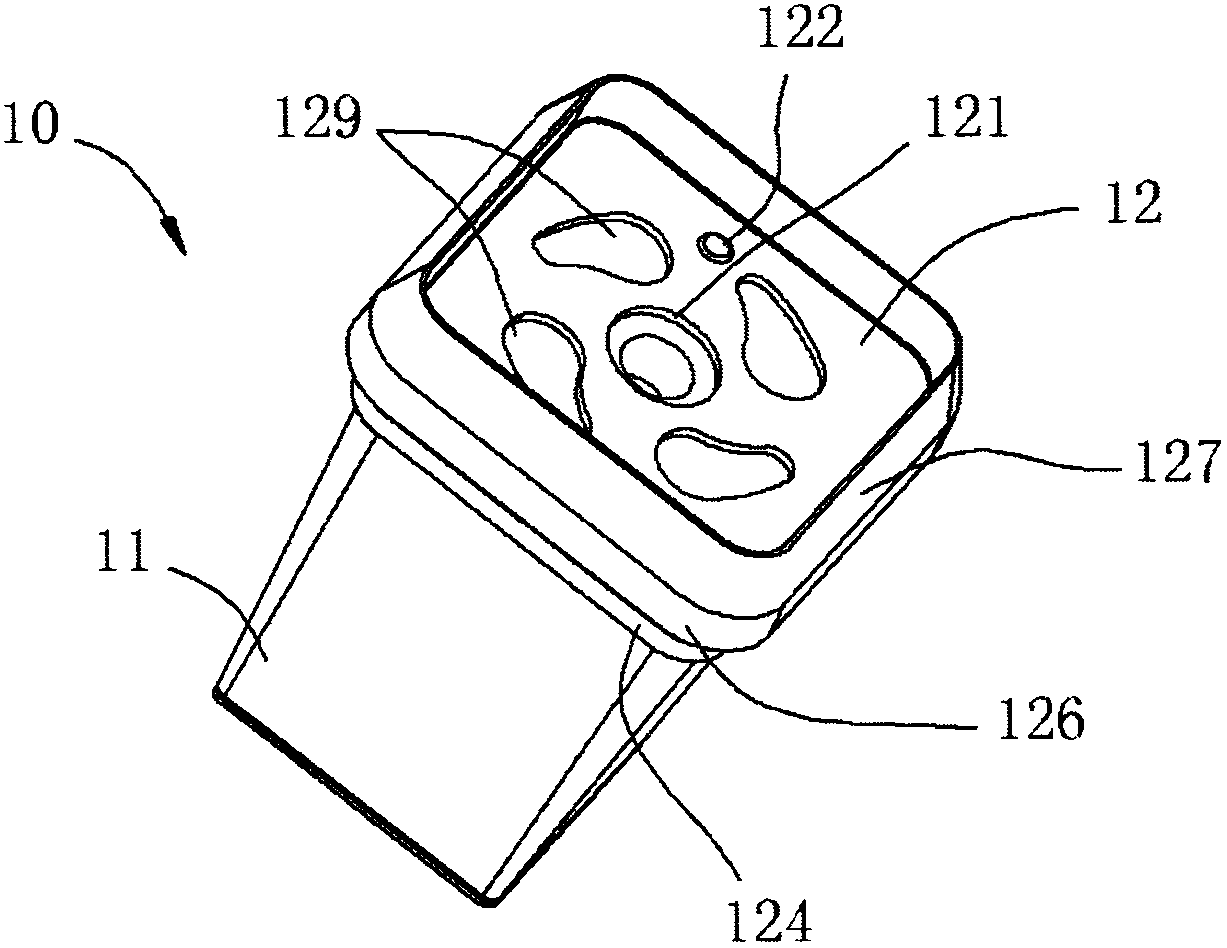

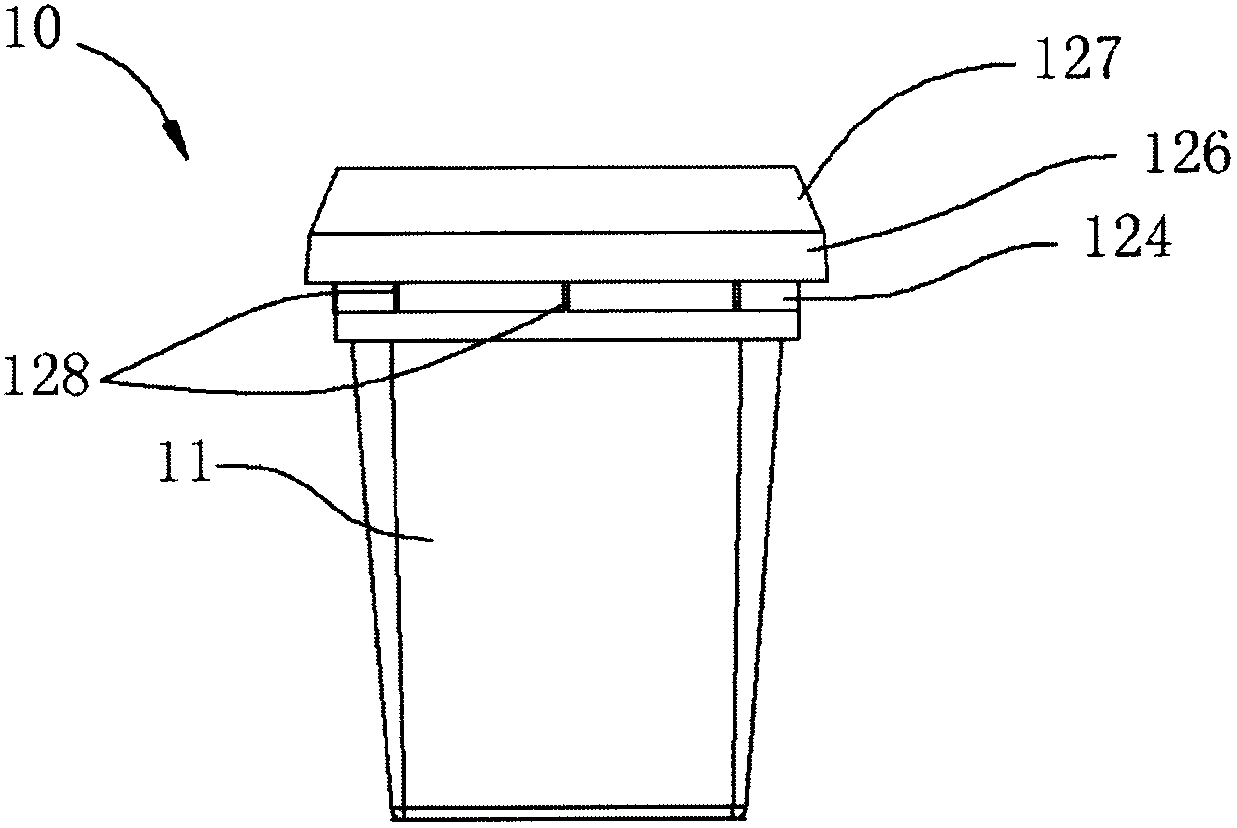

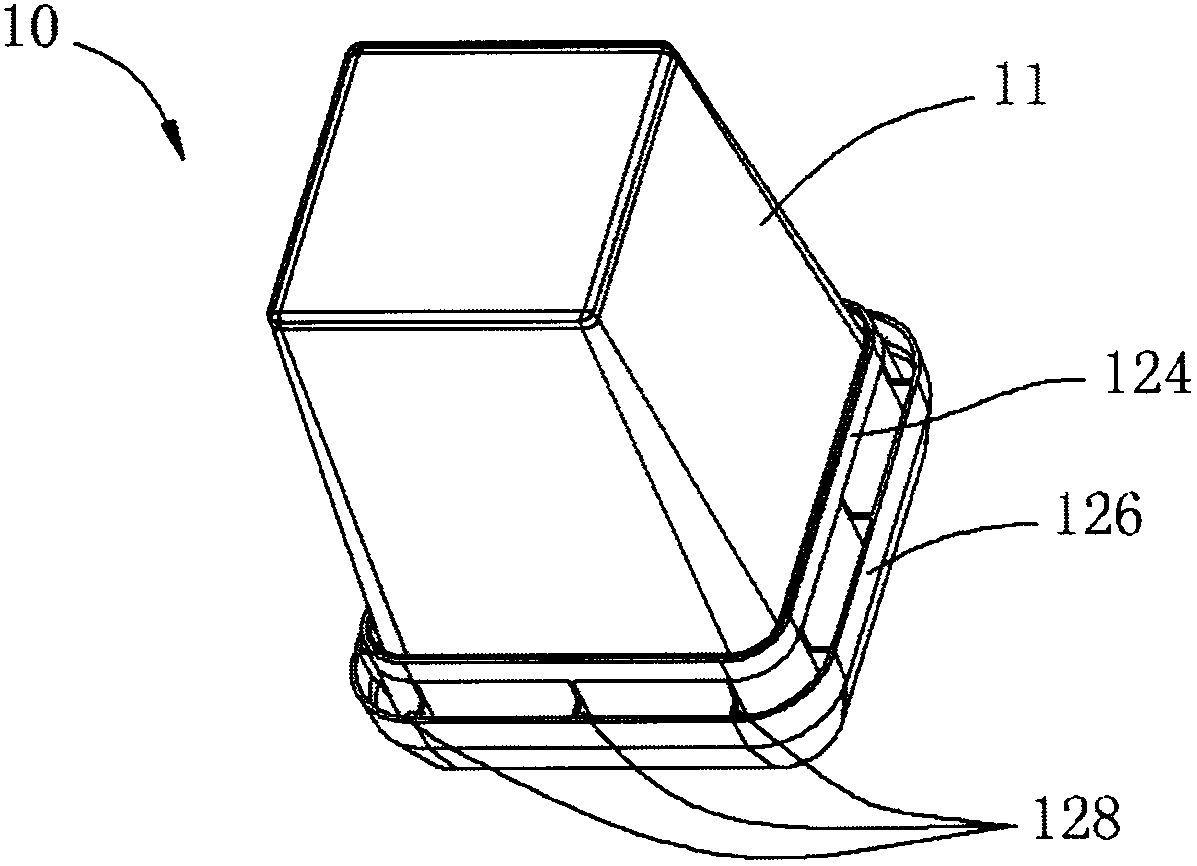

Sealed hydroponic device and method

InactiveCN102640696AIncrease productionImprove qualityAgriculture gas emission reductionCultivating equipmentsEngineeringCompressibility

The invention is applied to the technical field of plant hydroponics and provides a sealed hydroponic device and method. The device comprises a container with an open mouth, a cover body covered on the open mouth of the container, and a sealing plate which is arranged on the cover body and is used for sealing the open mouth of the container, wherein the cover body and the sealing plate are correspondingly provided with insertion holes for insertion of the hydroponic plants, and the sealing plate is made of an elastic material or a compressibility material. Since the sealing plate has elasticity or compressibility, when the plants grow thicker, the sealing plate and the plants can be always in close fit, so that moisture and nutrient in the container can be well separated from the outside and be maintained for a long term, and the water can be prevented from being polluted by the environment. The sealed heat preservation effect can protect the cultured roots of the plants for winter to some extent. The device has the advantages of high yield, good quality, no pollution, no weed harm, water and fertilizer conservation and the like, and the method creates the development direction of new technology in the hydroponic field and makes up for various deficiencies of the traditional hydroponic cultivation.

Owner:周冬祥

Eucommia male flower tea and processing method thereof

The invention discloses eucommia male flower tea and a processing method thereof. The processing method comprises the following steps: thinly spreading fresh eucommia male flowers; uniformly spraying a water solution containing 0.03% of Zn<2+>, burning in a boiling water boiler, rapidly cooling, and carrying out centrifugal dewatering; drying in a boiling drying machine, and carrying out fragrance extraction and frying in a tea stir-frying machine; and finally, pouring out, spreading for airing, bagging and sealing, and storing in a refrigeration house. The eucommia male flower tea has the beneficial effects that the processing method is very simple, the operation is easy, and the effect is remarkable; by uniformly spraying the water solution containing 0.03% of Zn<2+> on the petals of the eucommia male flowers, the disadvantages that the eucommia male flower tea browns and deteriorates in the processing process are effectively overcome, and functional ingredients and nutritional ingredients of the eucommia male flowers are preserved; as the boiling drying machine is selected for drying and the tea stir-frying machine is selected for fragrance extraction, the drying speed is rapid, the drying time is short, the drying is easily controlled, the colors and shapes of the eucommia male flowers are greatly maintained, a fragrance increase effect is good, and the eucommia male flower tea is attractive in appearance, has a deep blackish green color, a strong eucommia flower flavor and a complete shape and is relatively low in cost.

Owner:SHAANXI BAISHENG BIOLOGICAL ENG

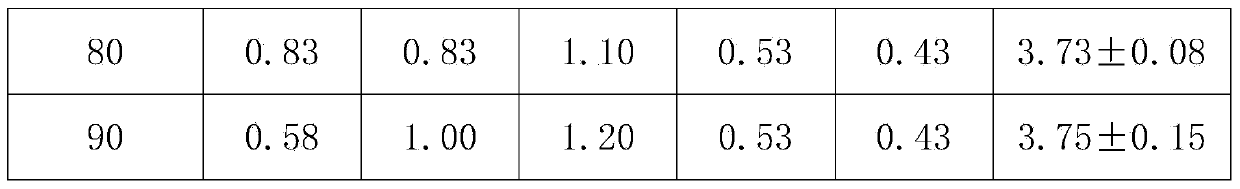

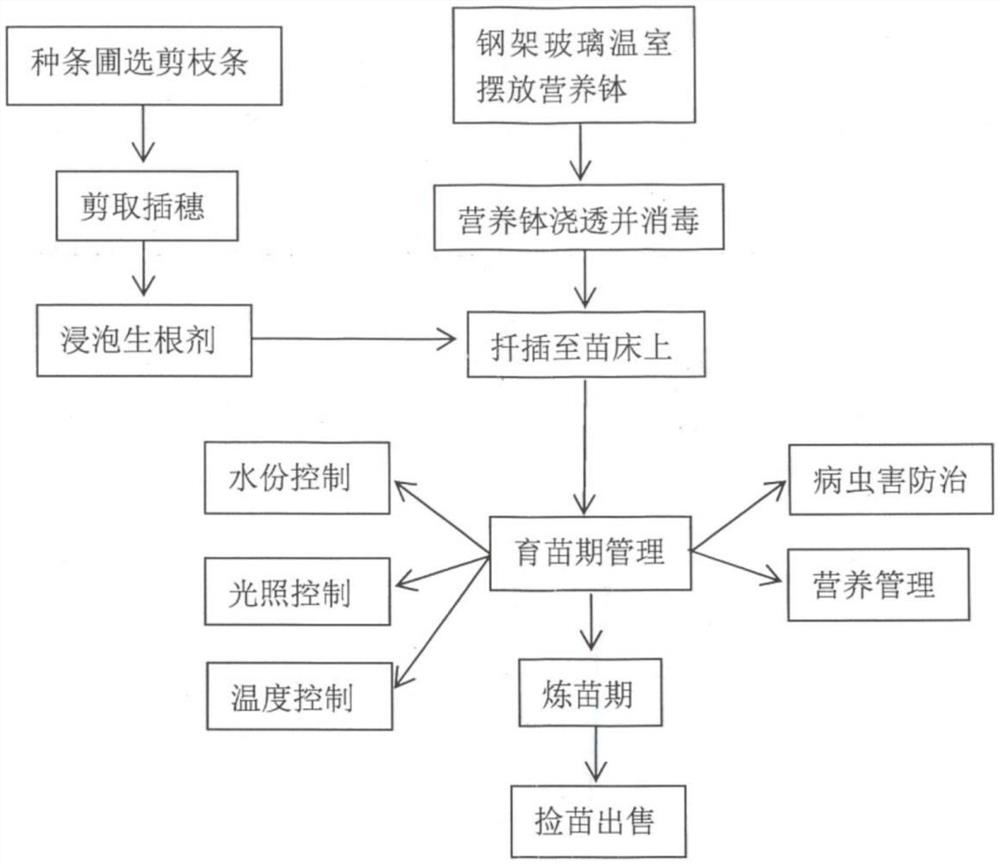

Seedling raising by cutting method of taxodium 'Zhongshansha' in green house containers, and substrates

InactiveCN111758529APromote warmingQuality improvementGrowth substratesCulture mediaForest industryTaxodium

The invention discloses a seedling raising by cutting method of taxodium 'Zhongshansha' in green house containers. The seedling raising by cutting method comprises the steps of preparing seedbeds, performing cutting and performing management after cutting. The invention also discloses substrates for seedling raising by cutting of taxodium 'Zhongshansha' in green house containers. The substrates consist of the following components of 76-84% of turf, 7-9% of perlite, 5-7% of carbonized rice chaff, 3-5% of vermiculite and 1-3% of controlled-release fertilizers. A high bed cultivation mode is combined with adjustment of components of the substrates, control of temperature and humidity during the seedling raising period is guaranteed, and the substrates consisting of the turf, the perlite, thecarbonized rice chaff, the vermiculite and the controlled-release fertilizers are combined for use, so that the survival rate can be greatly increased, cutting seedlings of the same year can be sold in the same year to generate economic benefits and can be completely sold before plum rain season the next year, production of next batch of cutting seedlings of the taxodium 'Zhongshansha' in glass green houses is not influenced, transformation and upgrading of a conventional seedling raising manner of forestry seedlings to high-quality development are realized, and a high-efficient development mode of being short, stable and fast, of the forest seedling industry can be realized.

Owner:江苏省弶港农场有限公司

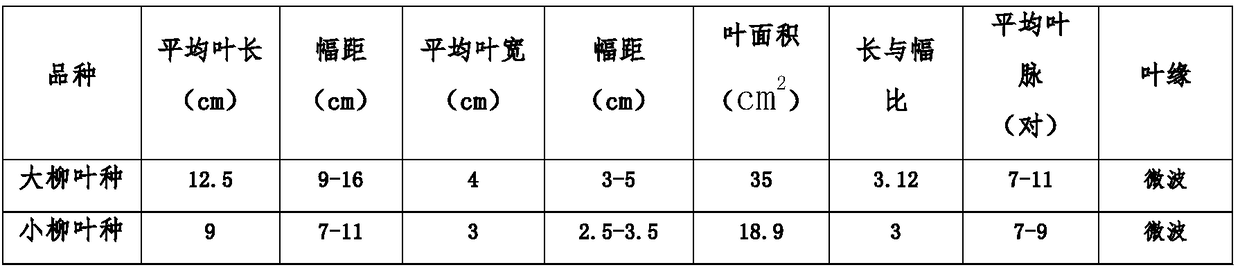

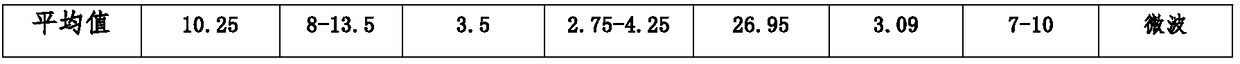

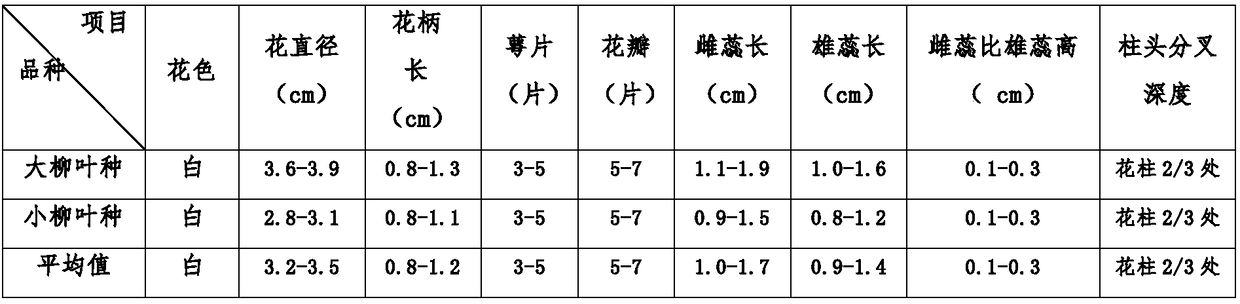

Manual making method of willow leaf species Yongxi houqing tea

InactiveCN108812971ADark green colorBright colorPre-extraction tea treatmentCell buddingAgroforestry

The invention belongs to the field of tea making technologies and specifically relates to a manual making method of willow leaf species Yongxi houqing tea. The method comprises the following steps: tea picking, fresh leaf pretreatment, de-enzyme, shaking-rolling-spreading, stir-frying of tea base, pan frying, screening and storage. The picking standard of two true leaves and one terminal bud is adopted, and tea leaves are picked eight centimeters from the tip of tea; the stir-frying of tea base comprises stir-frying of first tea base and stir-frying of second tea base; the preparatory work before pan frying is pan washing, tea juice and tea ash on the inner wall of the pan are removed to keep the pan wall smooth and bright and the tea soup pure and clear; and pan frying is a process of shaping and drying, the frying method is changed in the process, and smokeless charcoal fire is adopted for long-time low-temperature drying. By manual manufacture of Yongxi houqing tea, the original natural features of Yongxi houqing tea are maintained, and color of the obtained tea is blackish green and apparent and gloss is obvious; fragrance is rich and long-lasting. As the formed tea is dried atlow temperature, fragrance of the tea is more refreshing, fresh and lasting, and the taste is mellow and thick.

Owner:吴建华

Method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time

ActiveCN107027461APromotes and accelerates rootingEnsure Physiological ConsistencyPlant cultivationCultivating equipmentsBudRapid prototyping

The invention discloses a method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time. The method comprises the steps of direct cutting in flowerpots and directional seedling growing for one time and pinching and trimming for one time in the seedling stage. Compared with a traditional multi-step potted flower cultivation method that seedlings are first cultivated and then potted, the production steps of seedling potting and transplanting, and combining and molding are reduced, damage and investment which are caused by seedling potting and transplanting are prevented, survival rates of the seedlings are increased, rooting and sprouting are ordered and consistent, and production cost is reduced. The number of flower branches and extension directions of foliage leaves can be directionally cultivated by the technologies of directional cutting and pinching and trimming for one time, the sprouting time of plant buds and consistency of flower branch growth are ensured, the potted flowers are promoted to the molded rapidly and fully, ornamental characteristics are largely improved, insect diseases are prevented, the ratio of high-quality potted flowers is significantly improved, the production cycle is as short as 60-85 days.

Owner:云南云秀花卉有限公司

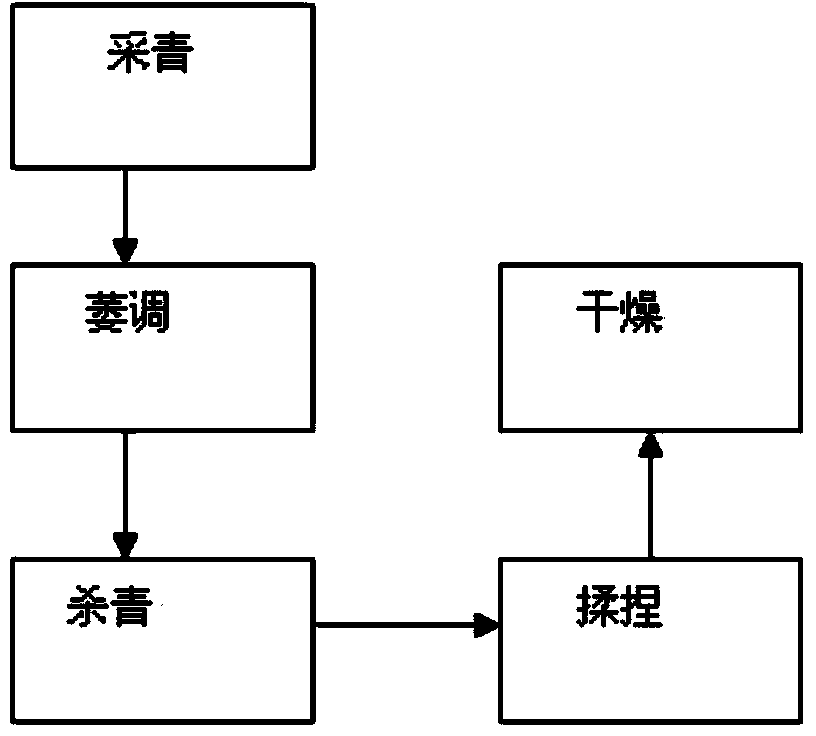

Tea primary processing method

The invention provides a tea primary processing method. The method comprises the processes of plucking, withering, fixing, rolling and drying. The method has the beneficial effects that through withering, the activities of enzymes in fresh leaves are moderately promoted, the inclusions undergo moderate physical and chemical changes, and part of the moisture is diffused, so that the stems and the leaves are withered, the color is dark green and the green grass smell scatters and disappears; fixation is firstly carried out at high temperature and then carried out at low temperature, so that tea stir-frying to brown due to high leaf temperature, impacts on transformation of the inclusions and reduction of the tea quality can be avoided and the defects of tea sticking, browning, heaping for yellowing and the like in the traditional processes are eliminated; the produced finished tea has beautiful shape, sweet and mellow taste, pure aroma and bright green color and achieves a higher quality grade.

Owner:ANHUI HUOSHAN COUNTY SHENGMING TEA

Mechanized continuous making method of Yongxi huoqing

ActiveCN107996745AUniform qualityDark green colorPre-extraction tea treatmentStandardizationCooking & baking

The invention relates to a mechanized continuous making method of Yongxi huoqing. The mechanized continuous making method comprises specific operation steps and working procedures of performing mechanized tedding, performing fixation, performing spreading for cooling, performing light kneading, performing deblocking, performing spreading for cooling, performing re-roasting, performing spreading for cooling, performing primary shaping, performing spreading for cooling, performing secondary shaping, performing sieving, performing color selection, performing baking and the like. The processed Yongxi huoqing is dark green in color, oily, moistening and glossy black, and peculiar properties of being clear, green and bright in soup color, clear and rich in fragrance, long in aftertaste and the like are formed; the Yongxi huoqing is round, tight and coiled like coiled buns and homogeneous in quality; the method is suitable for mechanized processing and continuous clean production of the Yongxi huoqing, the standardized production degree of the Yongxi huoqing is increased, the added value of products is increased, the market competitiveness is strengthened, and the method conforms to the industrialized development trend of the Yongxi huoqing.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Yin-nourishing and yang-tonifying preserved egg

ActiveCN102742866AHas the function of nourishing yin and tonifying yangDark green colorFood preparationFlavorSyzygium

The invention relates to a yin-nourishing and yang-tonifying preserved egg which is prepared by soaking material liquid and sealing and wrapping material mud. The preserved egg prepared by adopting the method has complete gel, dark green color, good taste and aromatic flavor. The preparation process is table, the merit factor is high. The yin-nourishing and yang-tonifying preserved egg is characterized in that wolfberry fruit, cortex lycii radicis, chamomile, achyranthes, rhizoma acori graminei, polygala tenuifolia, dried rhizome of rehmannia, eucommia bark, dodder, semen astragali complanati, achyranthes root, blueberry, rhizoma curculiginis, herba epimedii, syzygium aromaticum and zinc oxide are added to the material liquid and the material mud so that the preserved egg can have the functions of nourishing yin and tonifying yang, and the preserved egg is contribute to improving the level of physical health of people eating the eggs.

Owner:母素玉

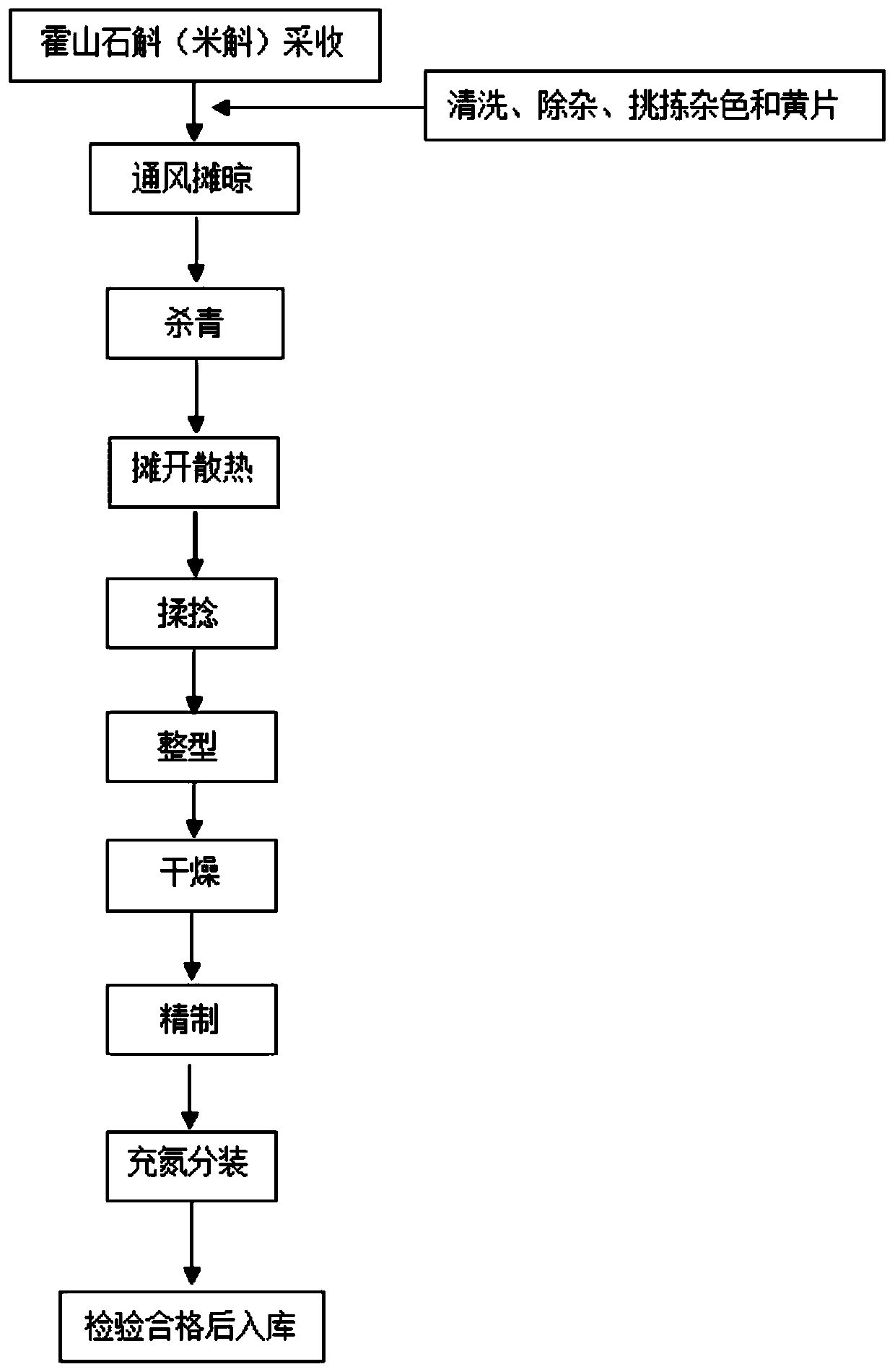

Processing technology of dendrobium huoshanense leaf tea and dendrobium huoshanense leaf tea prepared through processing technology

InactiveCN109845859AImprove utilizationImprove dissolution efficiencyTea substituesSalivation StimulationAgroforestry

The invention discloses a processing technology of dendrobium huoshanense leaf tea, and relates to the field of processing of substitute tea. The processing technology is suggested for solving the problems that dendrobium huoshanense leaves are not fully utilized to cause that the utilization rate of dendrobium huoshanense is low. The leaf tea is a product which is greenish black in color and uniform tabular or slightly curly tabular in shape, and is prepared through the steps of cleaning dendrobium huoshanense fresh leaves, performing picking and choosing, performing spreading for airing, performing fixation, performing rolling, performing trimming, performing drying and performing refining. The processing technology disclosed by the invention has the beneficial effects that the dendrobium huoshanense fresh leaves are processed into substitute leaf tea products which can be brewed for drinking, so that the utilization degree of rare valuable traditional Chinese medicine materials suchas the dendrobium huoshanense can be increased, the dendrobium huoshanense leaf tea is convenient to carry and convenient to brew, the dissolving out efficiency of effective components in the dendrobium huoshanense leaves can also be improved, the health efficacy of the dendrobium huoshanense leaves can be better exerted, and the utilization rate of the dendrobium huoshanense can be increased. The dendrobium huoshanense leaf tea disclosed by the invention is even and orderly in appearance, greenish black in color, delicately fragrant in scent, yellowish green in soup color, mellow, refreshingand smooth in mouth feel, capable of promoting salivation and sweet in aftertaste.

Owner:JIUXIANZUN HUOSHAN DENDROBIUM CO LTD

Processing technology of broadleaf holly leaves

InactiveCN108812953AImprove tea aromaEnhance fragrance concentrationPre-extraction tea treatmentTea flavoringVegetable oilToughness

The scheme discloses a processing technology of broadleaf holly leaves in the technical field of tea processing. The technology is as follows: carrying out enzyme deactivation on tea leaves after withering, preparing a hot stir-frying pan during the enzyme deactivation, smearing vegetable oil on the wall of the pan, then pouring clear water, boiling the clear water, putting the obtained withered tea leaves into the pan with stirring, heating the tea leaves in boiling water for 30-60s, and filtering out the tea leaves; putting the tea leaves into cold water for cooling immediately after the filtering, and conducting primary rolling at 58-68 DEG C for 15-20min after dehydration; and conducting standing for 15-20min, conducting re-rolling, and then carrying out drying. The scheme of the invention is combined with a special enzyme deactivation mode, the tea leaves are flexible in texture and not easy to tear up after the enzyme deactivation; then the rapid cooling avoids the internal texture of tea leaves from destructive changes due to persistent high temperature; and under the early-stage preparation conditions, with the primary rolling and re-rolling process and the drying mode, theobtained broadleaf holly leaves have distinct particles, are granular, are high in toughness, and are not easy to break by external force.

Owner:余庆县玉笏春茶业有限责任公司

A method of quickly cultivating miniature roses in potted plants

ActiveCN107027461BPromotes and accelerates rootingEnsure Physiological ConsistencyFlowers cultivationCultivating equipmentsInsect diseaseRapid prototyping

The invention discloses a method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time. The method comprises the steps of direct cutting in flowerpots and directional seedling growing for one time and pinching and trimming for one time in the seedling stage. Compared with a traditional multi-step potted flower cultivation method that seedlings are first cultivated and then potted, the production steps of seedling potting and transplanting, and combining and molding are reduced, damage and investment which are caused by seedling potting and transplanting are prevented, survival rates of the seedlings are increased, rooting and sprouting are ordered and consistent, and production cost is reduced. The number of flower branches and extension directions of foliage leaves can be directionally cultivated by the technologies of directional cutting and pinching and trimming for one time, the sprouting time of plant buds and consistency of flower branch growth are ensured, the potted flowers are promoted to the molded rapidly and fully, ornamental characteristics are largely improved, insect diseases are prevented, the ratio of high-quality potted flowers is significantly improved, the production cycle is as short as 60-85 days.

Owner:云南云秀花卉有限公司

Special composite organic fertilizer for mangnolia officinalis and preparation method of special composite organic fertilizer

InactiveCN102617246BIncrease concentrationIncrease profitOrganic fertilisersFertilizer mixturesCompound organicSlag

The invention discloses a special composite organic fertilizer for mangnolia officinalis and a preparation method of the special composite organic fertilizer, wherein the special composite organic fertilizer for mangnolia officinalis consists of the following ingredients in parts by weight: 10 to 20 parts of soybean meal, 30 to 40 parts of plant straws, 10 to 13 parts of cabbage slag, 0.5 to 2 parts of composite strains, 15 to 20 parts of potassium sulfate, 0.3 to 0.8 part of manganese sulfate, 0.4 to 0.9 part of ferrous sulfate, 10 to 25 parts of ammonium sulfate, 2 to 5 parts of borax, 10 to 15 parts of diammonium phosphate, 2 to 5 parts of fulvic acid, 1 to 4 parts of soluble chitosan, 2 to 5 parts of trace boron ore, 0.04 to 0.08 part of dipterex, 0.03 to 0.05 parts of chlorothalonil and 25 to 32 parts of filling materials. According to the growth rule of the mangnolia officinalis, the fertilizer provided by the invention adopts a great number of biological organic nitrogenous fertilizers, the physical properties of the soil can be obviously improved after a great number of fertilizers are utilized, the effective void content of the soil is increased, and the survival rate of the young seedlings of the mangnolia officinalis is improved.

Owner:HUBEI FUSOURCE BIOLOGY OF BIOLOGICAL TECH CO LTD

Horseradish soil fertilizer composition for preventing and curing soil-borne disease

The invention discloses a horseradish soil fertilizer composition for preventing and curing soil-borne disease, which consists of the following raw materials: horseradish, bean pulps, fully-matured crop straws and herb residues. With the adoption of the horseradish soil fertilizer composition, the quality can be improved, the substantial increase production can be increased, the physical characteristics of soils can be obviously improved, the water penetration and the water permeability of the soils can be enhanced, and the moisture and fertility preservation capability of the soils can be improved.

Owner:常熟市润丰农业有限公司

Processing method of seasoned laver

The invention provides a processing method of seasoned laver. The method comprises the steps of selecting material, wherein the material is dry laver made from laver picked at the middle period and the later period of the laver picking period; cutting into blocks, namely, soaking the dried laver into clear water for 5 minutes at the room temperature, then cleaning, draining off and cutting into blocks; seasoning, namely, blending table salt, monosodium glutamate and edible oil, and spraying the mixture onto the laver, wherein weight ratio of table salt to monosodium glutamate to edible oil to laver is (5-15): (5-15): (40-50): 1000; packaging, namely, packaging in a vacuum way; sterilizing, namely, sterilizing at the temperature of 95-100 DGE C; cooling, namely, naturally cooling. The processing method of the seasoned laver has the beneficial effects that 1, the seasoned laver is convenient to eat and unique in flavor; 2, the laver picked at the middle period and the later period of the laver picking period is fully utilized.

Owner:DONGTOU AQUATIC SCI TECH INST

Processing technology of bead-shaped broadleaf holly leaves

InactiveCN108576331AImprove tea aromaEnhance fragrance concentrationTea substituesVegetable oilBead shape

The scheme of the invention discloses a processing technology of bead-shaped broadleaf holly leaves in the technical field of processing of tea leaves. The processing technology comprises the following steps of performing fixation on withered tea leaves, during fixation, preparing a frying pan which is heated to be hot, applying vegetable oil onto pan walls, then pouring clean water in the fryingpan, boiling over the clean water, then putting green tea leaves obtained through withering, performing stirring while putting the green tea leaves, and after the green tea leaves are heated in boiling water for 30-60s, filtering off the heated green tea leaves; after the heated green tea leaves are filtered off, immediately putting the filtered-off green tea leaves in cold water for cooling, andafter dehydration, performing first-step twisting under 58-68 DEG C for 15-20min; and after the green tea leaves after the first-step twisting are subjected to standing for 15-20min, performing second-step twisting, adopting a handmade shaping manner, placing tea leaves in the centre of the palm, mutually kneading the tea leaves with two hands, performing kneading for 6-8 times, wherein the kneading lasts for 6-10s each time, and the kneading direction each time is kept consistent, after kneading each time, mutually pressing the tea leaves in the centre of the palm with two hands, and finallyperforming roasting. The broadleaf holly leaves made by the method disclosed by the invention are in the shape of beads, curled tea leaves are not liable to open in the course of roasting and storage,when being brewed, the curled tea leaves gradually spread apart when being in contact with water, the spread-apart leaves are complete, sundries do not exist, and tea soup is clear.

Owner:余庆县玉笏春茶业有限责任公司

Sealed hydroponic device and method

InactiveCN102640696BIncrease productionImprove qualityAgriculture gas emission reductionCultivating equipmentsEngineeringCompressibility

The invention is applied to the technical field of plant hydroponics and provides a sealed hydroponic device and method. The device comprises a container with an open mouth, a cover body covered on the open mouth of the container, and a sealing plate which is arranged on the cover body and is used for sealing the open mouth of the container, wherein the cover body and the sealing plate are correspondingly provided with insertion holes for insertion of the hydroponic plants, and the sealing plate is made of an elastic material or a compressibility material. Since the sealing plate has elasticity or compressibility, when the plants grow thicker, the sealing plate and the plants can be always in close fit, so that moisture and nutrient in the container can be well separated from the outside and be maintained for a long term, and the water can be prevented from being polluted by the environment. The sealed heat preservation effect can protect the cultured roots of the plants for winter to some extent. The device has the advantages of high yield, good quality, no pollution, no weed harm, water and fertilizer conservation and the like, and the method creates the development direction of new technology in the hydroponic field and makes up for various deficiencies of the traditional hydroponic cultivation.

Owner:周冬祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com