Plant culture substrate conditioner, method for using conditioner for preparing composite culture substrate and prepared culture substrate

A technology for cultivation substrates and conditioners, which is applied in the field of conditioners for plant cultivation nutrient substrates. It can solve the problems of reduced organic matter and nutrient content, destruction of soil ecological cycle, acidic or alkaline soil, etc., and achieves moderate pH and physical and chemical properties. Effect of stabilization and loosening of cultivation mixed substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1. Preparation of matrix conditioner

[0083] 1-1) Prepare the raw materials according to the following weight parts (Kg)

[0084] Seaweed residue 30

[0085] Coir 40

[0086] Phosphocalcite 15

[0087] 1-2) The seaweed residue, coconut shell fiber, and calcium phosphate soil are respectively pulverized into seaweed residue powder, coconut shell fiber powder, and calcium phosphate soil powder. The particle size of the seaweed residue powder is 2~5mm; the particles of coconut shell fiber powder The diameter is 3.0~5.0cm; the particle diameter of phosphocalcite powder is 2.5~5.0mm, spare;

[0088] 1-3) Mixing seaweed residue powder, coconut shell fiber powder and phosphocalcite powder evenly to obtain a cultivation substrate conditioner.

[0089] The cultivation substrate conditioner of the present invention is mainly aimed at the phenomenon that the pH value of the cultivation substrate is too high or too low, and the EC value is too high. It can effectively adjust the pH value of ...

Embodiment 2

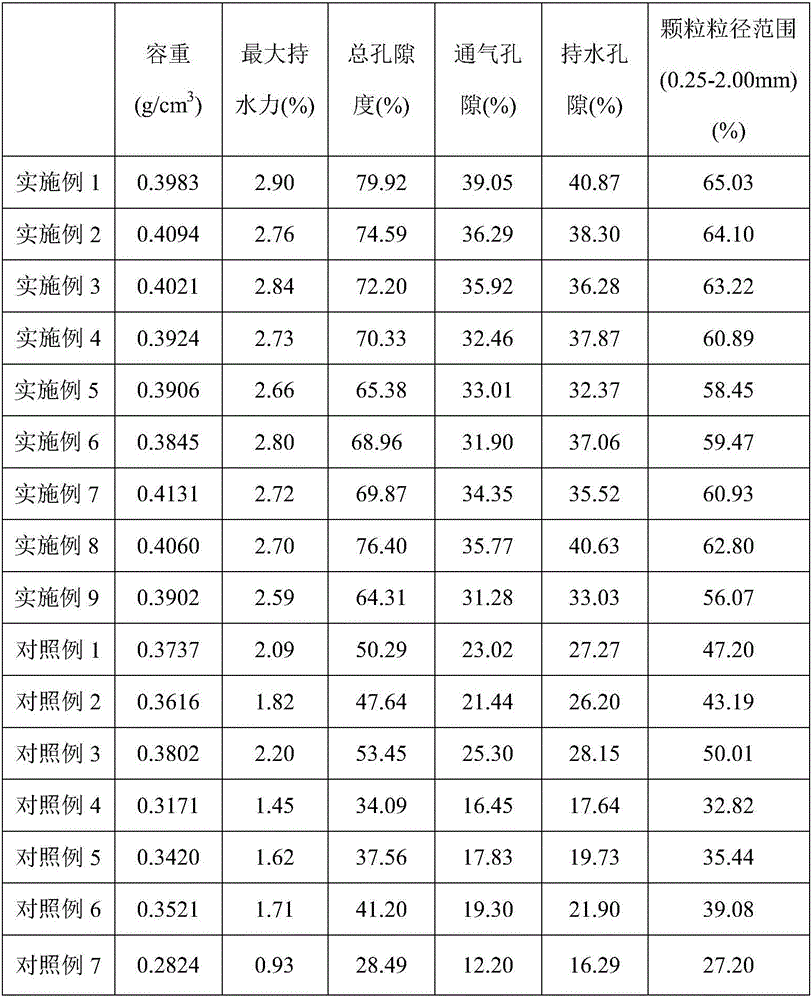

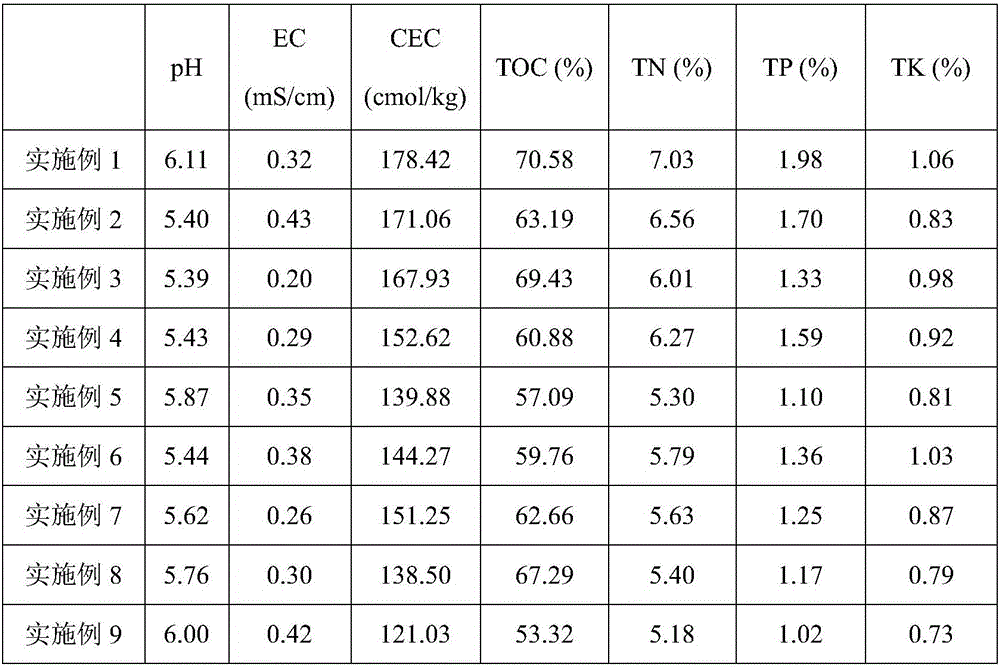

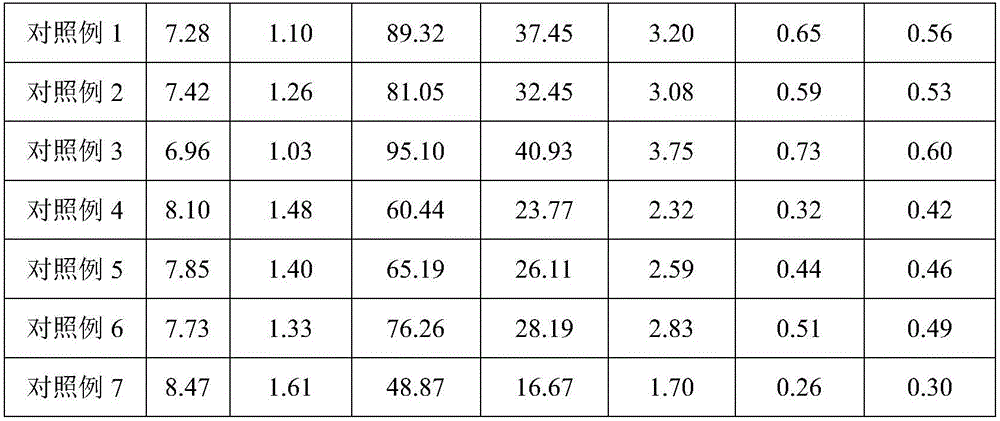

[0112] Except for the selection of soil for plant cultivation substrate in step 2-1), the weight ratio of soil to plant cultivation substrate conditioner is 100:30, and the weight ratio of soil to fungicide is 10000:0.35; step 2-2) adds water mixture The water content is 62%, and the rest is the same as in Example 1. The performance measurement results of the prepared composite plant cultivation substrate are shown in Tables 1 and 2.

Embodiment 3

[0114] Except for the selection of waste compost substrate for plant cultivation substrate in step 2-1), the weight ratio of waste compost substrate and plant cultivation substrate conditioner is 100:35, and the weight ratio of compost substrate and fungicide is 10000:1.35; step 2-2) Except that the water content of the water-added mixture is 65%, the rest is the same as in Example 1. Among them, the waste compost substrate is prepared as follows:

[0115] 2-1-1) Use a pulverizer (Beijing Zhongyi Shenlong Machinery Co., Ltd.) to pulverize the branches and trunks of garden waste (pruned branches and trunks of willow, locust, poplar, etc.) into particles with a particle size of ≤ 1 cm. For waste particles, Kjeldahl method is used to determine the nitrogen content of agricultural and forestry waste particles; potassium dichromate volumetric method-external heating method is used to determine the organic carbon content in agricultural and forestry waste particles;

[0116] 2-1-2) Add u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com