Processing technology of dendrobium huoshanense leaf tea and dendrobium huoshanense leaf tea prepared through processing technology

A processing technology and technology of dendrobium leaf tea, applied in the field of substitute tea processing, can solve the problems of low utilization rate of Dendrobium huoshanense, underutilization of Dendrobium huoshanense leaves, etc., and achieve the advantages of improving dissolution efficiency, mellow and smooth taste, and improving utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

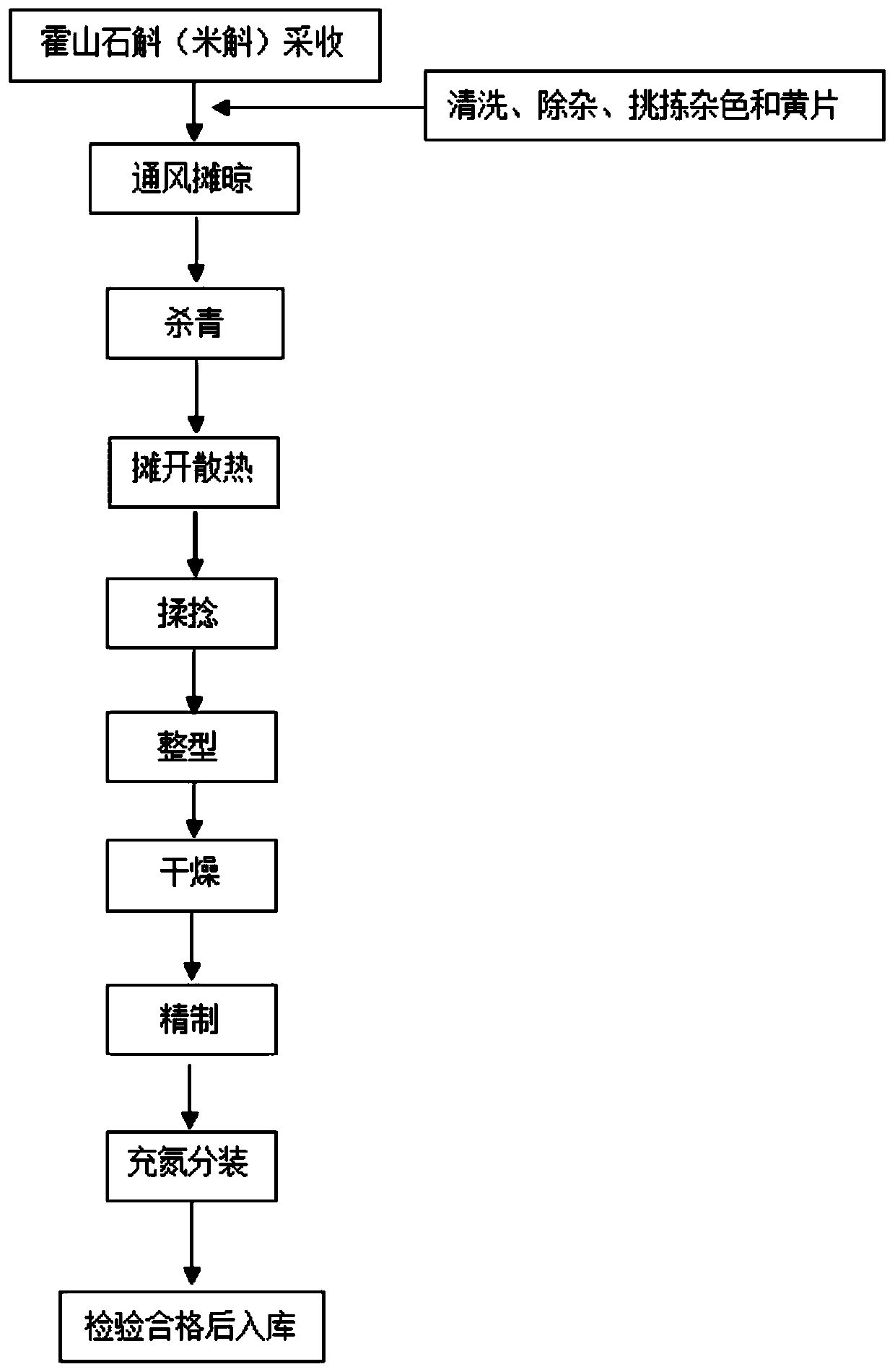

[0030] A processing technology of Huoshan Dendrobium leaf tea includes the following steps:

[0031] (1) Harvest the complete and green fresh leaves of Dendrobium huoshanense, clean and remove impurities and pick out the variegated leaves and yellow leaves to obtain 4kg of fresh leaves;

[0032] (2) Under ventilated conditions, the moisture content of the fresh leaves will be lost to 75% after drying for 2 hours at 25℃;

[0033] (3) The dried leaves of Dendrobium huoshanense are cured at 200°C for 2 minutes. After the curing is completed, they are quickly spread out, dissipates heat and emits water vapor;

[0034] (4) Put the finished Dendrobium leaves into a twisting machine at a room temperature of 25°C and use a light-heavy-light method to twist for 30 minutes. After twisting, the cell breakage rate of the leaves of Dendrobium huoshanense is 86%; the twisting machine is a 30-type barrel plate. Twisting machine, the pressure range is 0-1.2Mpa, light-heavy-light is adjusted by the li...

Embodiment 2

[0043] A processing technology of Huoshan Dendrobium leaf tea includes the following steps:

[0044] (1) Harvest the complete and green fresh leaves of Dendrobium huoshanense, clean and remove impurities and pick out the variegated leaves and yellow leaves, to obtain 5kg of fresh leaves;

[0045] (2) Under ventilated conditions, the moisture content of fresh leaves will be lost to 78% after drying at 20℃ for 3 hours;

[0046] (3) The dried leaves of Dendrobium huoshanense are cured at 190°C for 3 minutes. After the curing is completed, they will be quickly spread, heat dissipation and water vapor;

[0047] (4) The dried leaves of Dendrobium huoshanense were put into a kneading machine at a normal temperature of 25°C and kneaded in a light-heavy-light method for 35 minutes. The cell crushing rate of the kneading leaf was 82%; the kneading machine was a 30-type drum-disc kneading machine. The pressure range is 0-1.2Mpa, light-heavy-light is adjusted by the lid on the drum-twisting machi...

Embodiment 3

[0056] A processing technology of Huoshan Dendrobium leaf tea includes the following steps:

[0057] (1) Harvest complete and green fresh leaves of Dendrobium huoshanense, clean and remove impurities, and pick out variegated leaves and yellow leaves to obtain 1kg of fresh leaves;

[0058] (2) Under ventilated conditions, the moisture content of the fresh leaves will be lost to 70% after drying at 20°C for 1 hour; the dried Dendrobium huoshanense leaves are cured at 180°C for 1 minute, and after the curing is completed quickly spread, heat dissipation and water vapor;

[0059] (3) Put the finished Dendrobium leaves into a twisting machine at room temperature 20°C and use a light-heavy-light method to twist for 20 minutes. The cell breakage rate of the twisted leaves is 90%; the twisting machine is a 30-type barrel-disc twisting machine. The pressure range is 0-1.2Mpa, light-heavy-light is adjusted by the lid on the drum-twisting machine, light pressure is 0.1-0.2Mpa, heavy pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com