Technique for melting honey with hot air

A technology of hot air and technology, applied in the fields of application, food preparation, food science, etc., to achieve the effect of reducing labor intensity, shortening time, and homogeneous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

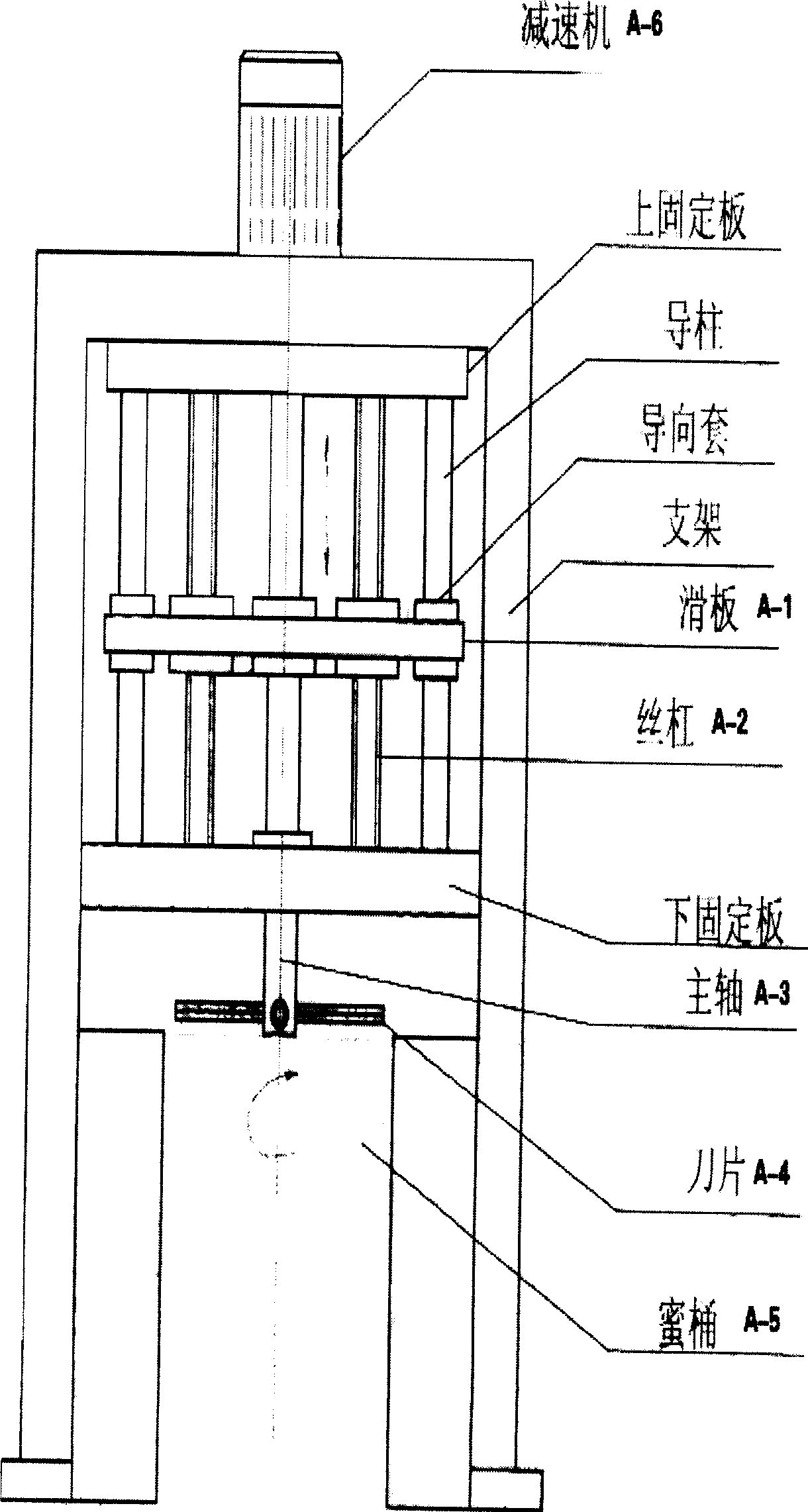

[0012] Step 1 (see Figure 1 for the schematic diagram of the crystal breaker)

[0013] The steel barrel truck puts the crystallized honey barrel at A-5, turns on the power, the geared motor A-6 drives the screw A-2 to rotate, the main shaft A-3 and the slide plate A-1 move downward, and the blade A-4 enters The barrel rotates to break the crystallized honey and stir evenly. When the blade is close to the bottom of the steel barrel, press the reverse switch, and the blade returns to the original position to complete the crystal breaking process.

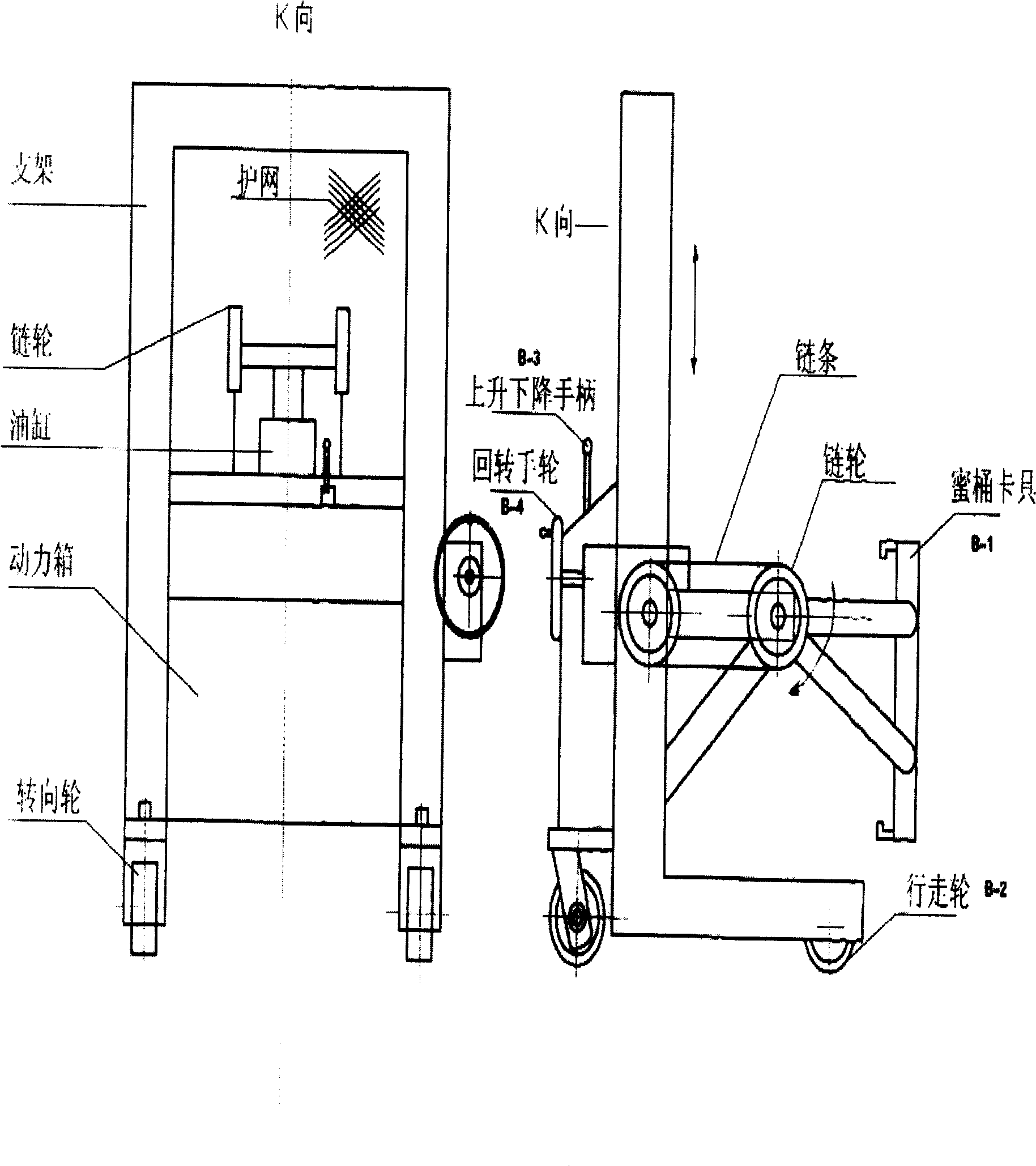

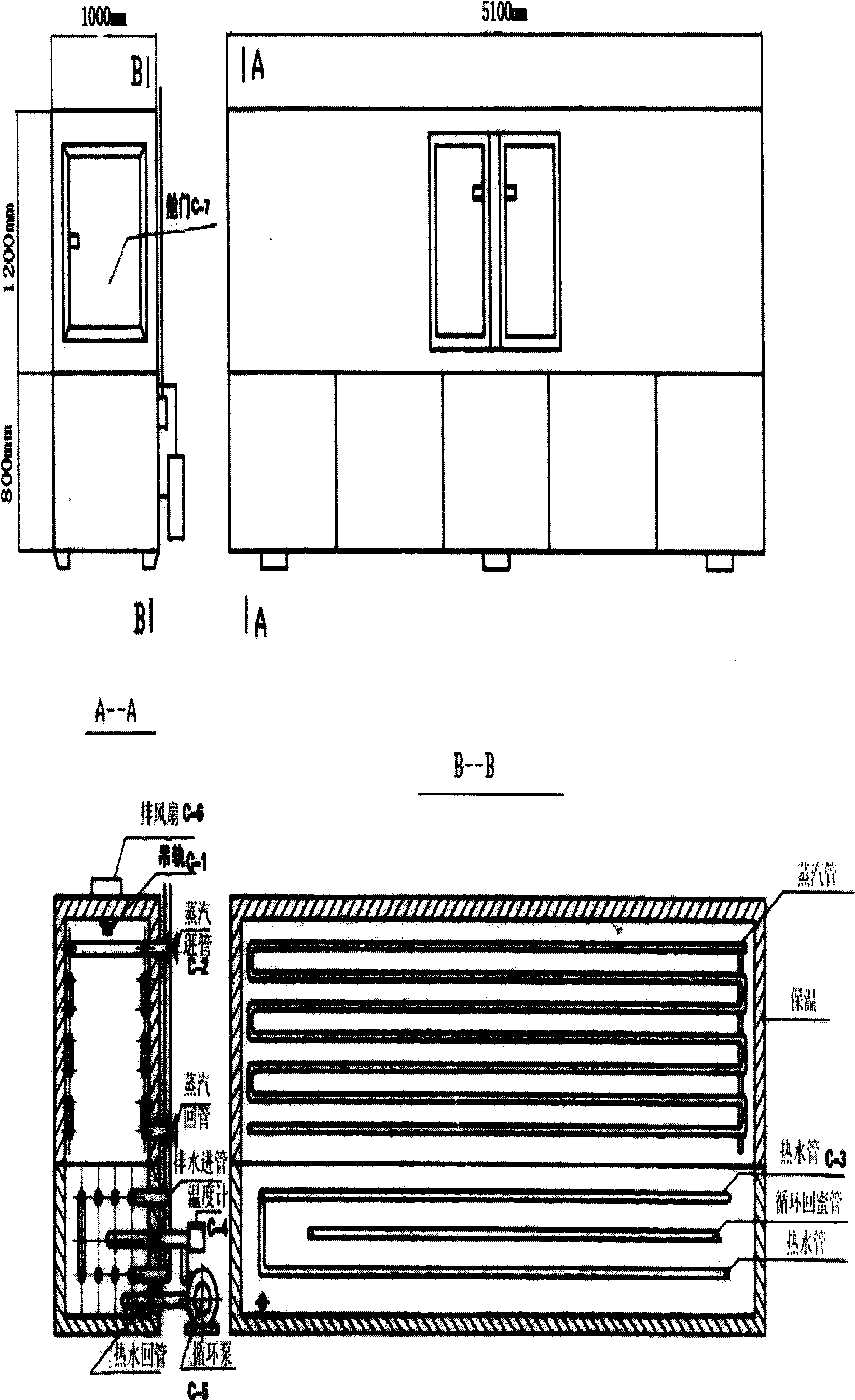

[0014] Step 2 (see Figure 2 for transfer and overturning vehicle)

[0015] Send the broken crystal honey to the feed inlet of the hot air melting honey tank (Figure 3) with a transfer car, move the lifting handle B-3, raise the honey bucket to the same height as the feed inlet, and turn the rotary handwheel B -4, and push the honey bucket into the hot air melting honey box with a transfer overturning car to turn it over 180°, hang th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com