Energy-saving and environment-friendly device for preparing lithium iron phosphate and preparation method

A lithium iron phosphate, energy-saving and environmentally friendly technology, applied in chemical instruments and methods, phosphorus compounds, sustainable manufacturing/processing, etc., can solve the problems of environmental pollution, large amounts of waste water and waste gas, etc. Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

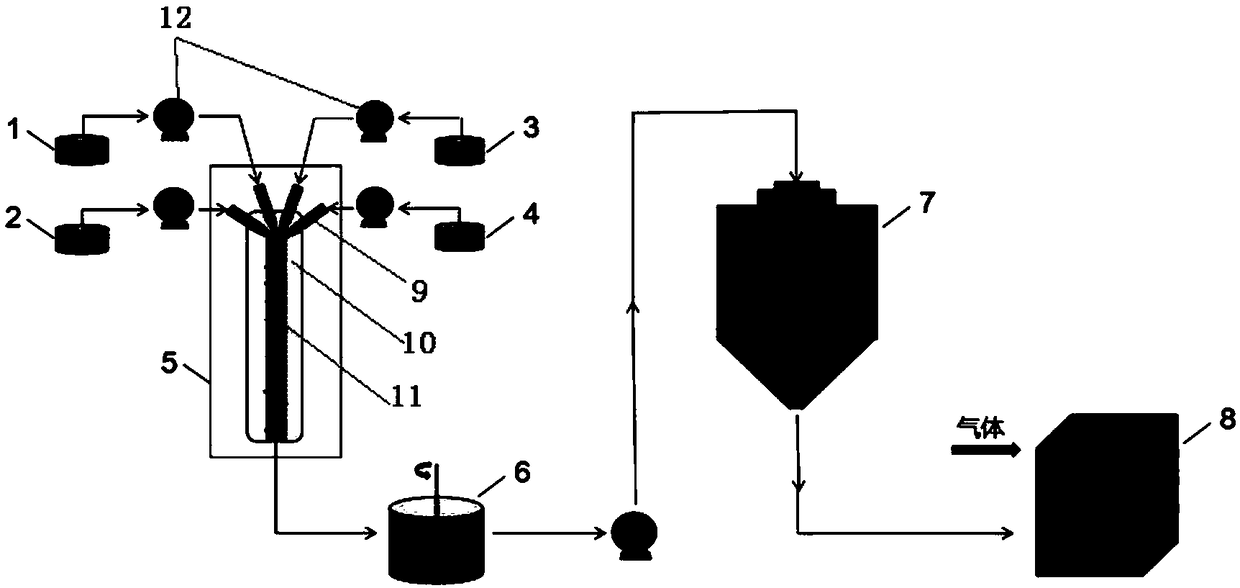

[0055] Embodiment one: a kind of method for preparing lithium iron phosphate, is characterized in that, comprises the following steps:

[0056] S1) Weighing lithium source, iron source, carbon source and phosphoric acid in a certain proportion, wherein the molar ratio of elements Li:Fe:P in the raw material is 0.95:1:1.1, and the carbon source accounts for 6% of the total mass of the raw material;

[0057] S2) take by weighing 100g lithium hydroxide and dissolve in the No. 1 storage container by the solid content of 20wt%, take by weighing 300.5g ferrous oxalate and dissolve in the second storage container by the solid content of 20wt%, weigh 80g starch by weighing The solid content of 10wt% is dissolved in the No. 3 storage container, and 409g of phosphoric acid is weighed to be prepared in the No. 4 storage container by a concentration of 20wt%, all using water as a solvent;

[0058] S3) The slurry in the No. 1 storage container, the No. 2 storage container, the No. 3 storag...

Embodiment 2

[0061] Embodiment two: a kind of method for preparing lithium iron phosphate, is characterized in that, comprises the following steps:

[0062] S1) Weigh lithium source, iron source, carbon source and phosphoric acid in a certain proportion, wherein the molar ratio of elements Li:Fe:P in the raw material is 1.05:1:1.1, and the carbon source accounts for 8% of the total mass of the raw material;

[0063] S2) Take by weighing 100g lithium acetate and dissolve in No. 1 storage container by 20wt% solid content, take by weighing 300.5g ferrous oxalate by weighing 20wt% solid content and dissolve in No. 2 storage container, weigh 80g starch by 10wt% The solid content of % is dissolved in the No. 3 storage container, takes by weighing 409g phosphoric acid and is formulated in the No. 4 storage container by the concentration of 20wt%, all uses water as solvent;

[0064] S3) The slurry in the No. 1 storage container, the No. 2 storage container, the No. 3 storage container and the No. ...

Embodiment 3

[0067] Embodiment three: a kind of method for preparing lithium iron phosphate, is characterized in that, comprises the following steps:

[0068] S1) Weighing lithium source, iron source, carbon source and phosphoric acid in a certain proportion, wherein the molar ratio of elements Li:Fe:P in the raw material is 1.1:1:0.9, and the carbon source accounts for 12% of the total mass of the raw material;

[0069] S2) take by weighing 100g lithium hydroxide and dissolve in the No. 1 storage container by the solid content of 20wt%, take by weighing 300.5g ferric citrate and dissolve in the No. two storage container by the solid content of 20wt%, weigh 80g citric acid Dissolve in No. 3 storage container by the solid content of 10wt%, take by weighing 409g phosphoric acid and prepare in No. 4 storage container by the concentration of 20wt%, all use water as solvent;

[0070] S3) The slurry in the No. 1 storage container, the No. 2 storage container, the No. 3 storage container and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com