Method and equipment for quickly treating high-COD-value sewage by Fenton reaction

A sewage treatment equipment, sewage technology, applied in filtration treatment, water/sewage treatment, water treatment parameter control and other directions, can solve the problems of large consumption of chemicals, low COD removal rate, large site occupation area, etc., to save consumption, High processing efficiency and guaranteed full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

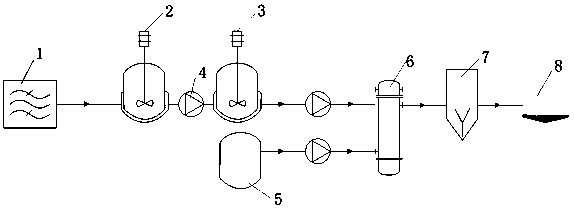

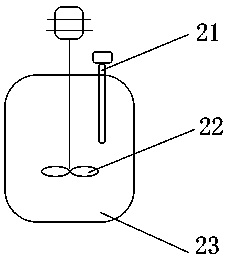

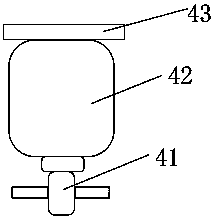

[0036] As shown in the figure, the method and equipment for quickly treating high COD values by Fenton reaction are characterized in that: the reaction equipment for rapid treatment of high COD values by Fenton reaction includes sewage filtration system 1, PH control system 2, mixing and stirring system 3 , high-precision flow control system 4, ultrasonic enhanced reaction system 6, material storage container 5, aging mixing system 7 and sludge treatment system 8; sewage first enters the sewage filtration system 1, and the sewage filtration system 1 is connected to all The PH control system 2, the PH control system 2 is connected to the mixing system 3, the mixing system 3 and the storage container 5 are connected by the high-precision flow control system 4 and the ultrasonic enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com