Ultrathin copper clad laminate and production method thereof

A manufacturing method and technology of copper clad laminates, applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of poor dimensional stability of glass fiber cloth, skewed weft of glass fiber cloth, uneven tension, etc. The effect of smooth view, ensuring product quality and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

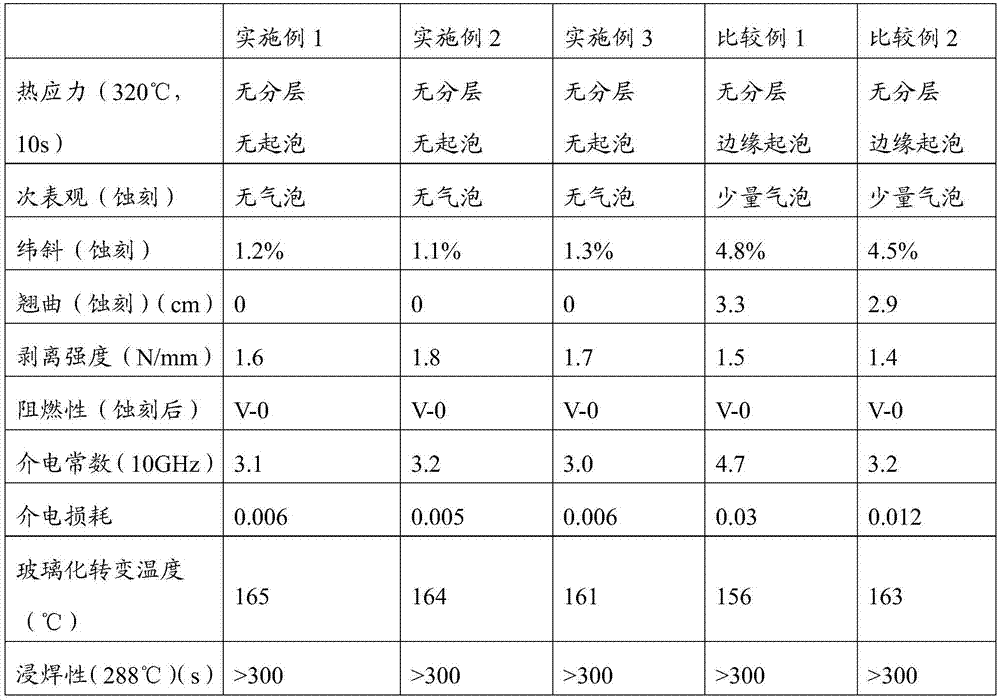

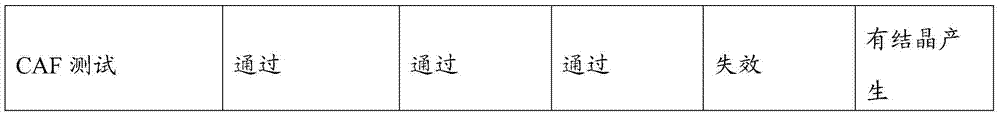

Examples

Embodiment 1

[0047] An ultra-thin copper-clad laminate suitable for high-frequency and high-speed propagation, the manufacturing method of which comprises the following steps:

[0048] First prepare resin glue and copper foil, wherein the resin glue includes: 100 parts of dicyclopentadiene phenol epoxy resin, 10 parts of dicyandiamide, 2 parts of crosslinking curing accelerator, 5 parts of silicon micropowder and Appropriate amount of solvent; the copper foil is 9μm electrolytic copper foil;

[0049] Then make the shaped cloth and resin-coated copper foil: the shaped cloth is made by the first method of making the shaped cloth; the resin glue is coated on the rough surface of the copper foil, dried and semi-cured to obtain a copper-coated Foil resin, wherein the thickness of the resin layer is controlled within the range of 10-70 μm;

[0050] Pressing and curing: the copper foil coating resin and the sizing cloth are pressed together at a temperature of 80-160°C by lamination, and cured. ...

Embodiment 2

[0052] An ultra-thin copper-clad laminate suitable for high-frequency and high-speed transmission, the manufacturing method of which comprises the following steps:

[0053] First prepare resin glue and copper foil, wherein the resin glue includes: 80 parts of mixtures of dicyclopentadiene phenol epoxy resin and biphenyl type epoxy resin, 10 parts of bisphenol A type epoxy resin, 15 parts of imidazole, 20 parts of silicon micropowder and an appropriate amount of solvent; the copper foil is a rolled copper foil of 12 μm;

[0054] Then make the shaped cloth and resin-coated copper foil: the shaped cloth is made by the second method of making the shaped cloth; the resin glue is coated on the rough surface of the copper foil, dried and semi-cured to obtain a copper-coated Foil resin, wherein the thickness of the resin layer is controlled within the range of 10-68 μm;

[0055] Pressing and curing: the copper foil coated resin and the sizing cloth are rolled together at a temperatur...

Embodiment 3

[0057] An ultra-thin copper-clad laminate suitable for high-frequency and high-speed transmission, the manufacturing method of which comprises the following steps:

[0058] First prepare the resin glue and copper foil, wherein the resin glue is calculated in parts by weight, including: 60 parts of dicyclopentadiene phenol epoxy resin, 20 parts of AF type epoxy resin, 15 parts of imidazole, and 30 parts of hollow silica microspheres. part and appropriate amount of solvent; the copper foil is a rolled copper foil of 12 μm;

[0059] Then make the shaped cloth and resin-coated copper foil: the shaped cloth is made by the second method of making the shaped cloth. The resin glue is coated on the rough surface of the copper foil, dried and semi-cured to obtain a copper-coated copper foil. Foil resin, wherein the thickness of the resin layer is controlled within the range of 10-68 μm;

[0060] Pressing and curing: the copper foil coated resin and the sizing cloth are laminated togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com